APF Issue 09

-

Upload

mdm-publishing-ltd -

Category

Documents

-

view

237 -

download

6

description

Transcript of APF Issue 09

APF ON-LINE

www.apfmag.com

An MDM PUBLICATIONIssue 9 – March 2004

ASIA PACIFIC FIRE MAGAZINE

REPORTING TO THE ASIA PACIFIC FIRE PROTECTION AND FIRE SERVICE INDUSTRY

OFC 9/11/06 11:10 am Page ofc1

2X Digital Zoom:Zoom in on distant objects when getting closer is unsafeor impractical.

Digital Image Capture:Capture time and date stamped thermal images and printthem for reporting and investigative matters.

UNLEASH THE POWER OF

THE MOST ADVANCED

FIREFIGHTING THERMAL

IMAGER AVAILABLE.

1898 Safety Way, Cynthiana, KY 41031 • 877-BULLARD • www.thermalimager.com

Whether it’s fire, hazmat, search and rescue,or any job requiring emergency response, theTI Commander puts you in charge.

TM

• 2X Digital Zoom• Digital Image Capture• Relative Heat Indicator™• Custom Startup Graphics• Large 5 Inch Display• Thermal Throttle

• Built ™

™

Advert/ifc 9/11/06 11:15 am Page 1

3 NFPA Foreword

5-9 The Basic Uses of a ThermalImager

11-15 Very Early Warning SmokeDetection: Why and How it’s Applied toMission Critical Facilities

16-18 What Personal ProtectiveEquipment?

21 Companies Join Forces toExpedite ANSULITE® Foamafter Japan EarthquakeProduct Profile

22 Emergency Preparedness –Fact or Fiction?

25-26 High Rise RescueOperations

28-29 China Fire 2004 Preview

31-35 Rescue Cutters Showcase

37-40 Sour Gas: The DeadlyOilfield Threat

43-45 Environmental Issues forDecontamination

46 Hale Product Profile

49-50 Flexible Solutions toEmergency Water Supplies

52-53 Master Steam NozzlesMarket Guide

54-55 Product Update

56 Advertisers’ Index

ASIA PACIFIC FIREwww.apfmag.com

1

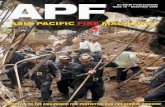

Front cover picture: A firefighter removeshis helmet as he faces fires on the outskirtsof northern Sydney.Copyright © Jason Reed/Reuters

PublishersMark Seton & David Staddon

Editorial ContributorsJonathan Bastian, Eddie Tieppo, Nick Lacey, Mike Sorensen, John Ng, Robert Henderson, John Jones, Mike Willson

APF is published quarterly by:MDM Publishing Ltd 18a, St James Street, South Petherton, Somerset TA13 5BWUnited KingdomTel: +44 (0) 1460 249199Fax: +44 (0) 1460 249292 e-mail: [email protected]: www.apfmag.com

©All rights reserved

Periodical Postage paid at Charnplain NewYork and additional officesPOSTMASTER: Send address changes toIMS of New York, P 0 Box 1518 Champlain NY 12919-1518USAUSPS No. (To be confirmed)

Subscription RatesSterling – £35.00 AUS Dollars – $100.00US Dollars – $55.00 (Prices include Postage and Packing)ISSN – 1476-1386

DISCLAIMER:The views and opinions expressed in ASIA PACIFIC FIREMAGAZINE are not necessarily those of MDM PublishingLtd. The magazine and publishers are in no way responsibleor legally liable for any errors or anomalies made within theeditorial by our authors. All articles are protected bycopyright and written permission must be sought from thepublishers for reprinting or any form of duplication of anyof the magazines content. Any queries should be addressedin writing to the publishers.Reprints of articles are available on request. Prices onapplication to the Publishers.

Page design by Dorchester Typesetting Group LtdPrinted by The Friary Press Ltd

APF ON-LINE

www.apfmag.com

An MDM PUBLICATION

Issue 9 – March 2004

ASIA PACIFIC FIRE MAGAZINE

REPORTING TO THE ASIA PACIFIC FIRE PROTECTION AND FIRE SERVICE INDUSTRY

March 2004 Issue 9

Contents

APF p. 1-15 17/11/06 11:39 am Page 1

Advert/p2 9/11/06 11:19 am Page 1

Compliance with CodesSome recent events have focused my mind on the issue of Code compliance. Unfortu-nately there have been two recent events which involved the deaths of Firefighters andothers which have implications regarding Code compliance. The events were the suddenstructural collapse of buildings involved in fire. One occurred in China and killed twentyFirefighters and the other was in Egypt and killed at least twelve Firefighters andPolice. Whilst I am not in a position to make any comment on the specific events, as Iam not privy to the circumstances: it does raise the issue of Code compliance.

For those not directly involved in the creation and use of Codes and Standards itmay seem an uninteresting and complex issue but for developing countries it is a cru-cial issue as infrastructure and new construction increases dramatically. The legacy thatwill be left for future generations to deal with in emergencies will depend on the Codeschosen and whether there are assurances regarding compliance and maintenance.

The first issue is which Codes to use. The Codes chosen must be current, allow use ofnew technology and be updated on a regular basis. They should also be created in anenvironment which does not allow dominance by any special interest group. Not sur-prisingly I would recommend NFPA Codes for this purpose.

The next issue is for those providing approvals to understand the Codes fully.There is a need to ensure compliance at time of construction. Compliance cannot be

achieved on the basis of total trust of the builder but should include inspections atleast on a random basis.

Finally there is the need for Inspection and Maintenance on the intervals called for inCodes.

Without Code compliance we will see the number of tragedies involving loss of lifeof the public and Emergency Services increase dramatically.

I wish I was wrong, but I know I am not.

Jeff GodfredsonNFPA’s Asia-Pacific Operations Director

ASIA PACIFIC FIREwww.apfmag.com

3

FOREWORDby Jeff GodfredsonNFPA’s Asia-Pacific Operations Director

APF p. 1-15 9/11/06 11:20 am Page 3

SIZEDOES

MATTER

•5” Display

•Superior Image Quality

•Color Pallets

•Infotherm™

•Digital Temperature Measurement

•Design Accommodates Crawling

877-322-7282www.flir.com/iff0204

BIGGEST DISPLAY FORMULTIPLE-PERSON VIEWING

WORLD’S LARGESTTHERMAL IMAGING COMPANY

CALL TODAY AND DISCOVER COLOSSAL PERFORMANCE.

Advert/p4 9/11/06 11:20 am Page 1

THE TECHNOLOGY

Current fire service TIs use old militarytechnology. This technology detectsinfrared energy and converts it into avisible image on a display. Modern mili-taries use infrared (IR) detectors to per-mit their forces to see and targetopposing forces, regardless of the bat-tlefield’s light and smoke conditions.The properties that made IR detectionvaluable to the military also make itvaluable to fire services.

IR is a portion of the electromagneticspectrum, which ranges from gammarays and x-rays, through visible light,past infrared and microwaves to radiowaves. The energy’s wavelength deter-mines placement within the spectrum.As the wavelengths vary, so do theproperties of the different types of

energy. IR is a portion of the electro-magnetic spectrum that humans nor-mally perceive as heat.

Visible light has a relatively smallwavelength. This wavelength is suscep-tible to interference from small air-

borne particles, such as the carbon insmoke or the water in fog. IR has alonger wavelength than visible light.The longer wavelength is not easilyreflected by small particles; therefore IR essentially “weaves” through theparticles to reach the detector (the IRreceiver, also called a focal plane arrayor FPA).

Another way to understand the dif-ference between infrared energy andvisible light is to compare the TI andthe human eye. The FPA and the eyeare both receivers. They receive energy(IR or visible light) and convert it intoan image our brains can interpret. The

ASIA PACIFIC FIREwww.apfmag.com

5

TI Comm type 3 fire

The BasicUses of a

ThermalImager

Visible light has a relatively smallwavelength. This wavelength issusceptible to interference fromsmall airborne particles, such as thecarbon in smoke or the water infog. IR has a longer wavelengththan visible light.

THERMAL IMAGING is one of the newest technologies to enter the fire service.The rapid acceptance of thermal imagers by the fire service alludes to theimportance of these new tools. The Federal Emergency Management Agency (agovernment agency in the USA) recently estimated that only one-fourth of allUS fire departments have a thermal imager (TI). Anecdotal evidence indicatesthe ratio may be even lower internationally. This article is written for those whoare relatively unfamiliar with thermal imaging, and briefly explains how thetechnology works, as well as how it can be used effectively at emergencies.

The BasicUses of a

ThermalImagerBy Jonathan Bastian, Bullard Thermal

Imaging Training Manager

APF p. 1-15 9/11/06 11:21 am Page 5

FPA receives wavelengths of heat energycalled “infrared” while the eye receiveswavelengths of energy called “visiblelight.”

FIRE!

Structure fires are the most commonand most understood application forthermal imaging. A firefighter can usethe TI during incident size up. Whilesizing up the building, Engine 5 evalu-ates the image from Photo 1. Thisimage clearly shows that high heat hastaken the entire right portion of thebuilding. Very high heat near the roofis evident as well, and because this typeof building uses steel truss supports,the roof is a safety concern. Engine 5now knows that the fire is well involvedand already attacking the roof sup-ports. If there are no victims inside, thefirefighters can choose to operate moresafely from the outside.

Firefighters can also use TIs duringfire attack. By using a TI while advanc-ing its line, a hose team can find it’sthe seat of the fire quickly and safely.Because the team can see walls andfurniture with the TI, it can movequicker and safer through complicatedbuildings. In heavy smoke conditions,the TI might even help identify whichroom or apartment is actually on fire.Firefighters will locate stairs and lad-ders faster as well.

Ventilation is another aspect of thestructure fire where TIs can assist fire-fighters in doing their jobs more effec-tively. With the TI on the roof,firefighters can look for the highestheat source to ensure they place anyventilation holes as close as possible.Perhaps more importantly, the TI mayhelp identify compromised roofingbefore a company is committed to theroof. Holes or gaps hidden by smoke ordarkness could be evident on thedisplay.

The most common thermal imaginguse is search and rescue. Several studieshave shown that TIs improve searchspeeds by up to seventy-five percentand can more than double search suc-cess rates. For thermal imagers to beeffective in search and rescue effortsthe TIs must arrive early in the incidentand they must come off the apparatuswith the firefighters.

Many departments successfully use

ASIA PACIFIC FIREwww.apfmag.com

6

The Basic Uses of a ThermalImager

The Basic Uses of a ThermalImager

In case of firebetter safe than sorry!

We offer to the fire professional the completerange of high performance foaming agents,e.g.

MOUSSOL-APSAlcohol resistant universal AFFF foam liquids

STHAMEX-AFFFAqueous film forming foam liquids

STHAMEXSynthetic foam liquids

STHAMEX-class-AFoam liquids for class A and B

FLUOR-FOAMOUSSEFluoroprotein foam liquids

FOAMOUSSE-FFFPFilm forming fluoroprotein foam liquids

FOAMOUSSEProtein foam liquids

Ask for more information!

fights

Dr.STHAMER HAMBURGLiebigstrasse 5 · D-22113 Hamburg · GermanyTelefon +49 40 73 61 68-0 · Telefax +49 40 73 61 68-60

E-Mail: [email protected] · http://sthamer.com

APF p. 1-15 9/11/06 11:21 am Page 6

their TIs in overhaul. By using the TI to identify hot spots,firefighters can focus their overhaul efforts and limit collater-al damage. Focused efforts reduce firefighter fatigue as wellas reduce on-scene time. For firefighters to gain the most useout of their TIs, they must know how to use them in areasthat exhibit “thermal saturation,” which occurs when every-thing in the viewed area is very warm (such as a room afterthe fire is extinguished). The TI will then display everything invarying shades of light gray and white because everything inthe scene is warm or hot. In this situation, firefighters needto properly use the other features of their TIs (such as ther-mal throttles, EI modes or pyrometers) to identify the hottestspots.

SAFETY!

A key aspect of thermal imaging use is firefighter safety. A TImay confirm that a building has truss-roof construction or itmay show damaged or missing trusses. Holes in floors andpartial collapse, normally hidden by smoke or fire, may be

ASIA PACIFIC FIREwww.apfmag.com

7

bst after thermal layer falls

The most common thermalimaging use is search andrescue. Several studies haveshown that TIs improvesearch speeds by up toseventy-five percent and canmore than double searchsuccess rates.

Capture the imagewith the Argus®3

thermal imager

• 26 image capture and download

• choice of two sensor cores(BST and ASi microbolometer)

• x2 zoom function

• 8 screen colour settings—from monochrome to full colour

• customisable on-screen graphics

• spot and ambient temperature measurement

• integrated wireless video output

Argus®—Trademark licensed from Argus Industries Inc.

Security Systems (FE) Limited3/F 657 King’s Road, Quarry Bay, Hong Kong

Tel: 852 2880 0622

Fax: 852 2856 1684

Email: [email protected]

Representing:

APF p. 1-15 9/11/06 11:22 am Page 7

visible to a firefighter with a TI. Withproper training, firefighters can evenidentify the thermal layer and possiblyrecognize pre-flashover conditions. Dif-ferent IR detectors will “see” the super-heated gasses of the thermal layerdifferently, but firefighters can train torecognize them. Photos 2a and 2bdemonstrate how TIs can show super-heated gasses, as well as how quicklyconditions can change even if firefight-ers are equipped and experienced withTIs.

These images also demonstrate howfirefighters can get overconfident withTIs. By standing, these firefighters areviolating a basic rule of firefighting.The intense heat from a diesel-fueledfire not only forces them to the floor,but it drives the firefighters from thearea in less than one minute. Firefight-ers must always remember that TIs donot eliminate the need to follow basicfirefighting safety practices.

CREATIVITY!

Many fires are outdoors, and many firedepartments have successfully used TIsfor wildland (bush) firefighting. The TIcan help officers’ track personnel andvehicles, guiding them through smokeor helping them avoid unseen hazards.Used in a helicopter, a TI can helpdetermine the exact fire line and moni-tor any hot spots. Because IR does notpenetrate glass, firefighters using ahandheld TI from a vehicle or aircraftmust operate it safely through anopening.

Thermal imagers have also assistedduring hazardous materials incidents.The imager can help track productleaks, identify leaking containers andeven determine product levels in sealedcontainers. Any hazardous material sit-uation that involves temperaturechanges and product separation can bean excellent opportunity to use a TI.Firefighters should be cautious inexplosive environments, however, sincethere is no thermal imager that isintrinsically safe. Photo 3 demonstrateshow a TI can indicate product levels

under the correct conditions.Thermal imagers can also assist with

emergency medical incidents. One easyapplication is looking for amputatedfingers. Fingers amputated in a factoryshould have a different temperaturethan the factory floor, and thereforeshould be visible on the TI. At motorvehicle accidents, the TI can help findpassengers who were thrown from thevehicle by the collision. Creative fire-fighters have even used thermalimagers to look for heat signatures incar seats to see if they were recentlyoccupied. Just as the technology canhelp departments locate patients at anaccident, it can also help them find alost child in a forest or an elderly per-son who wandered away from anursing home.

Training is another use for thermalimaging. TIs help firefighters monitorinterior conditions and participantsafety during live-fire evolutions. Safetyofficers can identify firefighters at riskof high-heat exposure before theirturnout gear is damaged or before theyare injured by heat or steam. Sincemost TIs are available with a wirelesstransmitter, training officers can con-nect the receiver to a television andvideo recorder and remotely monitorand record the thermal images. Theycan review the recording later for addi-

ASIA PACIFIC FIREwww.apfmag.com

8

t3 5 gallon pails half full

The Basic Uses of a ThermalImager

The Basic Uses of a ThermalImager

APF p. 1-15 9/11/06 11:22 am Page 8

tional learning opportunities.

CONCLUSION

Thermal imagers restore the ability tosee in thick smoke or at night, withcapabilities limited only by the creativ-ity of the firefighter. TIs regularlydemonstrate their value as critical fire-

fighting tools for fire departmentsaround the world. When properly used,

TIs offer tremendous advantages tofirefighters at a variety of emergencies,including fires, searches for victims andoutside operations. Once firefightersunderstand the value of thermal imag-ing, they can request these essential

ASIA PACIFIC FIREwww.apfmag.com

9

bst before thermal layer falls

Jonathan Bastian is the ThermalImaging Training Manager atBullard. He leads the training team,whose primary focus is to educatethe fire service on the safe andproper use of thermal imagers.Bastian is certified as a thermalimaging instructor by the LawEnforcement Thermographers’Association (LETA), the inter-national public safety organizationspecializing in thermal imager cer-tification and training. He is also amember of the NFPA TechnicalCommittee on Fire Service Training.Educated at Brown University andlicensed as a high school teacher inIllinois, Bastian served 12 years onthe North Park Fire Department (IL),including the last three as a captain.As Health and Safety Officer, he ledthe development and implementa-tion of the Department’s RapidIntervention Team SOG. Bastian is a certified Fire Instructor I andFirefighter III, and he spent 12 yearsas an EMT-I/D. He has taughtclasses on thermal imaging, rapidintervention teams and search andrescue operations.

The SOLOvision is a fully operational thermal imaging camera with Virtual Reality Viewing Optics. The light weight and unique ergonomic design enables “hands free” operation.

The image is picked up through a centrally mounted camera. Even in the thickest smoke and with the face visor entirely covered, the image seen by the wearer remains undiminished in quality.

GET IN, GET ON, GET OUT WITH...

SOLOvision FIRE and SOLOvision HAND HELDTHERMAL IMAGING SENSORS

THE LIGHTEST ONTHE MARKET

WEIGHS APPROX 850g•

WIRELESS TRANSMISSION•

CAN WITHSTAND FLASHOVER OF1000oC FOR 10 SECONDS

•RAYTHEON MICRO

BOLOMETER SENSOR•

4 HOURS OPERATING TIME WITHFULLY CHARGED BATTERY PACK

•RAPID CHARGE FACILITY

•AVAILABLE IN A RANGE OF COLOURS

Agencies worldwide. For full details or to arrange a demonstration with a GB Solo representative contact - GB Solo Ltd. Tel: 01609 881855

• Fax: 01609 881103 • email: [email protected] • www.gbsolo.co.uk

APF p. 1-15 9/11/06 11:22 am Page 9

IR FLAME DETECTORRIV-601/F

WATERTIGHTIP 65 ENCLOSURE

For industrial applications indoorsor outdoors where fire can spread out rapidly due to the presence of

highly inflammable materials,and where vast premises need an optical

detector with a great sensitivityand large field of view.

CONTROL LOGICIR FLAME DETECTOR

the fastest and most effective fire alarm devicefor industrial applications

BETTER TO KNOW IT BEFOREEye is faster than nose.

In the event of live fire the IR FLAME DETECTOR

responds immediately

Also forRS485 two-wire serial line

Sparks flyat high speed.

They travel at a hundred kilometresper hour along the ducts of the dustcollection system and reach the silo

in less than three seconds

The CONTROL LOGICSPARK DETECTOR

is faster thanthe sparks themselves.

It detects them with its highlysensitive infrared sensor,

intercepts and extinguishesthem in a flash.

It needs no periodic inspection.

The CONTROL LOGIC system is designed for “total supervision”.

It verifies that sparks have been extinguished, gives prompt warning of

any malfunction and, if needed, cuts off the duct and stops the fan.

CONTROL LOGICSparkdetector

designed fordust collectionsystemsto protectstorage silosfrom the riskof fire.

20137 Milano - Via Ennio, 25 - ItalyTel.: + 39 02 5410 0818 - Fax + 39 02 5410 0764E-mail: [email protected] - Web: www.controllogic.it CONTROL LOGIC s.r.l.

ISO 9001

20137 Milano - Via Ennio, 25 - ItalyTel.: + 39 02 5410 0818 - Fax + 39 02 5410 0764E-mail: [email protected] - Web: www.controllogic.it CONTROL LOGIC s.r.l.

ISO 9001

IR FLAME DETECTORRIV-601/FAEXPLOSIONPROOFENCLOSURE

For industrial applications indoorsor outdoors where is a risk of explosionand where the explosionproof protection is required.One detector can monitor a vast areaand responds immediately to the fire, yet of small size.

Advert/p10 9/11/06 11:23 am Page 1

● 72% of mission-critical applicationsexperience nine hours of downtime peryear2

● 90% of businesses go bankrupt withintwo years of a significant failure1

● The average cost per hour of downtimefor a financial brokerage house is esti-mated at US$6.5M3

Of the companies that experience a dis-aster but have no tested business recoveryplans in place, only one in ten are still inbusiness two years later.

Mission Continuity is assured for facil-ities through the use of redundant powersupplies, redundant mechanical systemsand state of the art Fire Protection sys-tems. This paper discusses the SmokeDetection system and its role in fire pre-vention and smoke contamination withina Mission Critical Facility.

THE FIRE RISK WITHIN TODAY’S DATA CENTERToday’s computing technology is becom-ing smaller and therefore requires lessspace, but the heat being dissipated by thedigital hardware is also increasing. The

result is that the heat density on the chipand in the cabinet is growing at anunprecedented rate. By illustration:

● The average Intel 486 CPU consumesabout 10W, the latest Pentium 4 con-sumes 100W.

● With the processing density and powerconsumption of blade servers it is notuncommon for standard 47U cabinetsto consume in excess of 21kWhr . . .that’s a lot of heat!!

The result of this high heat loadrequires significant cooling via the Com-puter Room Air Conditioning (CRAC) sys-tem to remove the heat generated withinequipment cabinets. Failure to cool thisequipment will result in equipment overheating and provide the potential for afire.

Mechanical cooling and airflow move-ment is an essential parameter within theFire Detection design and is discussedfurther in this paper.

THE DETECTION STRATEGYWithin a Data Center the type of smokegenerated and the dynamics of the air-flowcreates a challenge for the Fire Engineer

to design an effective Fire DetectionSystem. It is the detection of smoke that isthe most critical part of the FireProtection System. Detection Systemsserve the basic function of alerting occu-pants within the building of a fire and isused to activate other systems such asmechanical exhaust and Fire SuppressionSystems.

The traditional smoke detectors knownas Early Warning Smoke Detectors (EWSD)or conventional spot type detectors are of ionisation or photoelectric type. Ionisa-tion type detectors were designed todetect very small particles such as the type produced by flammable liquids.Photoelectrical detectors detect largerparticles such as those produced by non-natural materials like PVC. Given thisfact photoelectrical detectors are moresuitable to detect the fire type we expectwithin a computer facility, however thereare other factors contributing to photo-electric detector’s deficiency within theseenvironments.

Within the Fire Industry detectors arecategorised as Early Warning SmokeDetection (EWSD) and Very Early WarningSmoke Detection (VEWSD). In fact somepeople use these terms very loosely and donot differentiate the two correctly. AnEWSD system provides detection of a FireCondition prior to the time that itbecomes threatening to the occupants ofa building. Generally this is the time thatsmoke is visible. Lets use the example of apaper basket fire within a standard office.Seconds after the paper has ignited,smoke will generate and rise to the ceiling.This visible and hot smoke will eventuallyenter the smoke detection chamber andtrigger the alarm to alert the occupantsthat a fire has commenced. In contrast if acomputer terminal within the same roomhad a fault within the electronics resultingin a thermal event, it may smoulder forhours before a flame ignites. We refer tothe smouldering stage as the incipientstage to a fire. During this incipient stage

ASIA PACIFIC FIREwww.apfmag.com

11

By Eddie Tieppo, B.Eng, Dip MgtVision Fire & SecurityBusiness Development Manager – Asia Pacific

Very Early WarningSmoke Detection

Why and How it’s Applied toMission Critical Facilities

Mission-critical refers to the operations that are critical to an organisation’sability to carry out its mission. In other words, mission-critical operations arethose operations that are essential to an organisations ability to perform itsintended function. A mission-critical facility is one that guarantees it willcontinue to operate, regardless of external conditions. A critical bankingfacility is an example of such a facility that must maintain operation 24 hoursa day 7 days a week. In fact, a minor interruption in service, or loss of datacould seriously impact the operational continuity resulting in economic lossespecially during high transaction periods.

APF p. 1-15 9/11/06 11:23 am Page 11

the human eye will not see the particlesbut may smell them. EWSD are notsensitive enough to detect smoke at theincipient stage of an electrical type fire.Only a VEWSD will detect an incipient fireand thus the term “VERY EARLY WARN-ING”. This stage of a fire could last forhours or even days.

Spot type smoke detectors are ‘passive’detectors in that they wait for smoke andrely on the airflow to transport the smoketo the detector. Therefore their perfor-mance is affected by high airflow. Sincethe rate of smoke generation in a smoul-dering fire is relatively small, and the air-flow velocity in the room is quite high, themovement of smoke is dominated by theairflow of the mechanical systems. Fur-thermore the smoke generated during theincipient stage is not hot therefore there isvery little thermal lift. This often restrictssmoke movement directly to the ceiling,where spot type detectors are located,causing the smoke to dissipate morewidely. The aspirated smoke detectionsystem is ‘active’, constantly sampling the air from multiple points throughoutthe environment and therefore is nottotally dependant on thermal energy to transport to and enter the smokedetector.

SMOKE CONTAMINATIONSo why is the detection of smoke at theearliest possible stage important? Becausethe biggest risk to the continuous opera-tion within a computer room facility is thesmoke damage to electrical equipment,not the fire. In fact according to the USAFederal Commission of Communications,95% of all damage within these facilitiesis non-thermal.

The by-products of smoke from PVCand digital circuit boards are gases such asHCL and these gases will cause corrosionof IT equipment. The graph bellow depictsthe damage that can be caused by theincrease of particulates within the com-puter room. Even at 16 micro grams thereis moderate corrosion with long-termeffects on Electronics, at 30 micro gramsthe corrosion is active and the effects areshort term. Above this the damage toequipment is detrimental to ongoingperformance.

ASPIRATED DETECTIONAspirated smoke detectionsystems are quite differentfrom conventional spot typesmoke detectors. Aspiratedsystems typically comprise anumber of small-bore pipeslaid out above or below aceiling in parallel runs,some metres apart. Smallholes, also some metresapart, are drilled into eachpipe to form a matrix ofholes (sampling points),providing an even distribu-tion across the ceiling. Airor smoke is drawn into thepipework through the holes and onwardto a very sensitive smoke detector mount-ed nearby, using the negative pressure ofan aspirator (air pump).

HOW MUCH SMOKE SHOULD WE DETECT?Obscuration as a unit of measurement hasbecome the standard definition of smokedetector sensitivity used in the industrytoday. Obscuration is the effect that smokehas on reducing visibility. Higher concen-trations of smoke, result in higher obscura-tion levels, lowering visibility.Typical Smoke Detection Ratings forsmoke detectors:● Photoelectric: 3.0–12% obscuration

metre● Beam: 3.0–7.0% obscuration per metre● VESDA: 0.005–20% obscuration per

metre

Test performed by Vision Fire & Secur-ity have shown that by burning a measuredlength of wire within a controlled roomwe can determine the resulting Obscura-tion/m. In a 1,000 square metre room witha ceiling height of 4.5m, the insulationfrom approximately a 480m length of 18AWG wire would have to bum to produce13%/m obscuration throughout the room.

Whereas burning of only a 0.3m lengthof the same insulation would produceapproximately a 0.0156 obscuration permetre level of smoke throughout this room.

The amount and colour of smoke creat-ed in a room during a fire is dependent onthe type and amount of material burned.Smouldering combustion of a printed cir-cuit board may produce a heat release rateof one or two Kilowatts and the heatrelease rate of a single resister is as low as10W. By comparison the heat releasedfrom a paper basket fire may be between2 to 4 Kilowatts (UL standard paper burn(3 sheets) is 4kW. The fire size to bedetected must clearly be less than or equalto 1.0kW within a Data Center if we are tomeasure the performance of a VEWSD.

Current testing practice within telecom-munications and computer rooms todayuse a practical on site test to determinethe effectiveness of a Fire Detection Sys-tem. In the past system testing was con-ducted with a can of smoke that wassprayed into the end of pipe network orinto the point detector to determine if thesystem was working. But this test does notcheck the system’s performance to a realsmall fire scenario, which is the benchmarkfor VEWSD.

ASIA PACIFIC FIREwww.apfmag.com

12

Contamination and failure probability4

Air Sampled through a capillary and sample point

Smoke Obscuration measured based on a Burning wire within a 1000m2 room

Smoke Damage ProbabilityDevice Failure Probability after Smoke Exposure

Contamination Exposure µg/cm2

Failu

re P

rob

ab

ilit

y

0 50 100 150

1

.8

.6

.4

.2

0

APF p. 1-15 9/11/06 11:24 am Page 12

A common test used today is theBS6266 “Code of Practice for Fire Protec-tion for Electronic Data Processing Instal-lations”. This test involves electricallyoverloading a short length (1 or 2 metre)of PVC-coated wire which produces asmall amount of light grey smoke barelyvisible and simulates a smouldering fire ofapproximately 100W.

Typically, the test is performed withinthe room during the commissioningprocess and the VEWSD should give analarm indication within 60–120 secondsor what ever the objective for the design.

Computational Fluid Dynamic Model-ling (CFDM) used by Fire Engineers todetermine the effects of such fires withinHigh-Airflow environments can calculatethe theoretical growth of incipient firessmoke development and the contamina-tion that results from such smoke. Suchmodels can be used to determine the levelof contamination (mass of particulate permetre3) for any size of fire. This is usefulin estimating the amount of contamina-tion to which IT equipment is exposedduring various fire conditions. As shown inGraph 1 the contamination exposurecaused by fires will increase the probabilityof IT equipment failure.

Use of a VEWSD detector to detect suchcontaminants can reduce the risk of suchdamage occurring. In many cases the cont-aminants are present at very low levels,often as a result of high backgroundsmog/smoke levels, often introduced frompoor quality air during the use of ‘economycycle’ HVAC. Without the use of VEWSDthe low levels of these contaminants cango unnoticed for long periods of timecausing insidious but permanent damage.

In addition, the use of the event log ofa sophisticated VEWSD can be used tosupport a warranty or product replacementclaim on an equipment vendor whereequipment fails within its warranted termsof use. This is especially important wherethe vendor’s warranted terms of use refer-ence the quality of the environment ratherthan the deposition of contaminants onthe equipment, as is often the case.

BEYOND THE CONVENTIONAL DESIGN TECHNIQUESAlthough the design of fire protectionsystems has primarily been based ontraditional prescriptive fire codes, there isan increasing emphasis on performance-based codes that address individual envi-ronment requirements. Performance-baseddesign determines the best fire protectionsystem by assessing the function, riskfactors, and internal configuration andconditions of a specific environment.

When designing a Fire Detection Sys-tem for VERY EARLY WARNING thedesigner must consider the following:

1 The airflow characteristics and the airchange rate within the room

2 The coverage area per detector orsample point

3 The sensitivity required per samplingpoint

4 The room size and characteristics –raised floor, tall ceilings etc

ASIA PACIFIC FIREwww.apfmag.com

13

The Advantage…VESDA – the world’s leading aspirating smoke detectionsystem – provides the optimum protection against fire byreliably detecting the presence of smoke at the earliest possible stage.

Supports Innovative Performance Based DesignWith the trend towards performance based fire safetysystems, designers are able to show an increasing level ofinnovation when designing new buildings or remodellingexisting ones. VESDA’s modularity and flexibility supportsdesigners in their quest to provide ideal fire detectionsolutions without compromising fire safety.

Call your nearest VESDA office today.www.vesda.com

Vision Fire & SecurityAsia/Pacific Head Office495 Blackburn Road,Mount WaverleyVIC 3149, AustraliaTel: +613 9211 7200Fax: +613 9211 7202

BeijingTel: +8610 6539 1027Fax: +8610 6539 1283

ShanghaiTel: +8621 2890 3046Fax: +8621 2890 3047

Hong KongTel: +8610 8225 0695Fax: +8610 8225 0716

TaiwanTel: +886 227 841 669Fax: +886 227 841 679

SingaporeTel: +65 6428 8202Fax: +65 6428 8387

APF p. 1-15 9/11/06 11:24 am Page 13

5 The annunciation of emergencyresponse systems

6 The activation of mechanical controlsystems such as air extraction andsuppression systems

The detection system must be designedfor conditions when the Air Handling Sys-tem is either operational or out of service.

The following example describes thedetection method on the CRAC return airpath, relevant in circumstances where theCRAC is operational. This method ofVEWSD is suitable for rooms that useEWSD spot type detectors as the detectionscheme in circumstances where the CRACis out of service.

The following example shows the ASDpipe network configured for both circum-stances; where the CRAC is operationaland out of service. The sampling pipes onthe ceiling and within the floor void areused for detection where the CRAC is outof service. The pipe used to detect smokeacross the return air path is used fordetection where the CRAC is operational.This design method is suitable for roomswhere the ceiling height is not tall androom is small in area.

For large rooms with High Airflows it isrecommended to use a combination ofboth on ceiling detection, underfloordetection and return air.

COVERAGE AREAThe area coverage of the detector is a veryimportant criterion of the design. This istrue from both a performance and cost-effectiveness perspective.

Below is an illustration of a grid layoutfor an ASD detector for a 2000 m2 area(this is the maximum area coverage per-missible within the codes, BS, AS, NFPA).The sample points of an ASD detector istreated the same as a spot type detectorwithin most prescriptive codes. You cansee below that the area coverage for asample point is effectively the circle orclose to the square around it, which is10m x 10m = 100m2 (this illustrationbelow is designed as per AS1670 andwould be suitable for a low airflow envi-ronment). For ASD applications in HighAirflow environments, we can decrease thearea coverage for the sample point byadding more holes and making the dis-tance between each pipe less.

The prescriptive Codes and Standardstoday describe detection techniques for onceiling detection. But new codes such asDraft NFPA 76 “Standard for the Protec-tion of Telecommunication Facilities” isthe first code that uses a prescriptive andperformance based approach for the FireProtection of Telecommunication facilities.Within this code it specifies both the areacoverage as well as the sensitivity of thedetector. Presently the Draft of the NFPA76 Standard for the Protection ofTelecommunications Facilities documentrequires that “Every type of sensor andport installed in a space shall be limited toa maximum coverage area of 200 sq. ft.(reference page 51, section 6-5.3.1.2*)Exception: When (2) levels (high and low)of ports or sensors are provided, each level

shall be limited to a coverage of 400 sq.ft. or less per port or sensor.

NFPA 72 “National Fire Code for theUSA” recommends the area coverage forspot type detectors to be reduced withinhigh airflow environments to as low as11.5 m2 per detector for rooms that have60 air changes per hour.

British Standard – BS 6266 (1992), Sec-tion 5.2.5.1 Detector Spacing – General – “From the point of view of automatic firedetection, EDP areas present fire risksquite different from those in many otherpremises. The concentration of high valueequipment, sensitive to damage by even asmall fire or smoke, and particularly thehigh potential consequential losses, makeit important to use close spacing of detec-tors. Detector density should be highenough to enable the smallest fire to bedetected quickly without unduly increasingthe false alarm risk. A reason for a higherthan normal density of detectors is theinfluence of the air-conditioned system,which dilutes the smoke being producedby fire.” Section 5.2.5.2 Point Detectors –“Recommended area coverage per detectorfor the different location zones are givenin table 1. As follows: EDP equipmentroom (ceiling height above 3 metres),require a maximum spacing of 15-25square metres (150–250 square feet).

As well as codes there are insurancecompanies such as Factory Mutual whospecify in their Property Loss PreventionData Sheet (5-48) for Automatic FireDetectors page 7 “A maximum coverage of200 sq. ft. (20 m2) per detector may benecessary where room air is changing at arate of 20 air changes per hour or 100ft/min (0.5m/sec).

So the message is that more detectorsshould be used in high airflow environ-ments to increase the chance of seeing afire however, this requirement can be off-set by the use of a VEWSD which can sup-port a large number of sampling points ina single pipe network.

SENSITIVITY OF ASPIRATED SMOKE DETECTION

Although this reduced spacing willincrease the probability of smoke beingdetected, it does not determine if thesmoke generated has an obscuration den-sity high enough to trigger an alarm.Therefore the sensitivity of the system isalso fundamental to the design of theVEWSD system. The sensitivity of theAspirated Detection System’s samplingpoint is extremely important to ensureconsistent and sensitive detection withinthe zoned area is achieved. But whatcodes and standards do not take intoaccount for Aspirated Smoke DetectionSystems is their ability to use Cumulativeair sampling within an environment.

Cumulative Air Sampling refers to theway the Aspirated Smoke Detector samplessmoke over the network of samplingpoints allowing each to contribute to thesmoke being sampled at the detector.Within a high airflow environment thisphenomena becomes very useful sinceparticles of smoke are spread through theroom allowing the Cumulative samplingeffect to take place.

Take the example of a 200 square metreroom with 10 sample points on the ceil-ing. If the detector sensitivity is set to0.1% Obscuration/m this effectively makeseach sample point’s sensitivity 0.1 x 10 =1.0% Obscuration/m. That is, if only onesample point was exposed to smoke itwould require 1.0% Obscuration/m totrigger an alarm. This is because the fluidmechanics of the model takes intoaccount dilution caused by the otherholes.

Using the same example if smoke entersthree holes the effective sensitivityrequired to trigger an alarm is 0.1 x 10divided by 3 = 0.33% Obscuration/m.Clearly, cumulative sampling allows muchlower levels of smoke, and therefore very

ASIA PACIFIC FIREwww.apfmag.com

14

Areacoverage

ASDDetect

Sampling Sampling

APF p. 1-15 9/11/06 11:25 am Page 14

early warning to be detected. If the sameroom was designed with EWSD and eachdetector was rated at 5% obscuration/mthe alarm would only trigger once thesmoke density has reached this pointthroughout the room or at one detector.

IN-CABINET AND INTEGRATED-EQUIPMENT DETECTIONInterest is developing regarding the appli-cation of ASD within data racks & enclosedequipment cabinets and integrated in spe-cific equipment or assets. It is desirable tofit ASD within these cabinets because insome circumstances it would not beacceptable for smoke from a fire within thecabinet to ‘breech’ the cabinet, enter themission critical facility, contaminate othersystems or processes and possibly activatemain alarms and suppression systems.

In-cabinet smoke detection and actionenables an excellent very early warningsolution because:

1 The sampling is performed closest tothe source of the fire, before dilution,which allows earliest detection

2 Sampling within the enclosure allowsclear identification of the source of theproblem. This “addressability” reducestime, effort and error in identifying andremedying the problem.

3 The detection occurs before any spreadof the risk; loss can be minimised:

● Smoke is not allowed to contami-nate or otherwise affect other sys-tems in the data centre

● Compartmentation ensures that inworst cases the Estimated and Pos-sible Maximum Loss and BusinessInterruption estimates are min-imised (for insurance assessment)

4 The background dust and smoke levelswithin sealed enclosures is relativelyconsistent. Also, the airflow dynamicswithin a sealed enclosure can be pre-dicted with relative confidence by com-putational fluid dynamic models. Thisensures that detection systems can bedesigned, built and commissioned withconfidence of their efficiency andperformance.

5 Fire responses can be more automated,and cost and downtime from fireresponses, such as use of suppression,is reduced.

6 Better control of the issue managementand escalation processes is possible – analarm can be routed to the data centremanager as an “environmental alarm”,rather than reporting via the main firealarm system. This staged response to afire threat allows IT staff investigationand possible intervention, an ability tomove processes or data from problemequipment, action such as power-downof problem equipment and, if necessary,suppression of an escalated fire. Such astaged response will often negate theneed for suppression to be fitted or, iffitted, will negate the need for expen-sive suppressant to be released.

7 Cause & effect is localised, ie. fire con-trols used are specific to the cabinet

rather than the room. Common are aprotection systems means that thecommon area is unprotected after sup-pression has been affected until thesystem is re-charged.

8 Integration with existing communica-tions systems is possible – remote andcentralized monitoring and mainte-nance (especially for unmanned orautomated facilities), eg over LAN,MAN, WAN becomes cost effective.Also, coupling advanced smoke detec-tion with a full suite of environmentalmonitoring systems (power loss, access-control, security, temperature, waterloss, humidity etc) offers a number ofsynergies.

CONCLUSIONDue to the huge financial loss and poten-tial business risk, a Mission Critical Facilitycannot risk downtime especially of the size

and duration potentially caused by fire andsmoke contamination. The most importantsystem that contributes to the preventionof Fire and Smoke Damage is a Very EarlyWarning Smoke Detection system, whichmeets the performance objective to detectsmoke at the very early stages of a fire.

REFERENCES1. (Source: Steven R. Christensen andLawrence L. Schkade, “Financial and Func-tional Impact of Computer Outages on Busi-ness,” University of Texas at Arlington)2. (Source: Standish Group Research, 1998)3. (Source: Computerworld, August 4, 1997)4. 2nd International Fire Protection SeminarBuenos Aires 1999 – TelecommunicationFacilities.5. BS62666. NFPA 72, NFPA 767. AS16708. Factory Mutual

ASIA PACIFIC FIREwww.apfmag.com

15

APF p. 1-15 9/11/06 11:25 am Page 15

The date was the 20th August1998, and I was about to get myfirst taste of the Vietnamese ‘Safety

culture’! I had to travel the two and a half

hour journey by road from Ho Chi MinhCity to the southern most point of Viet-nam, a place called Vung Tau, whichwas to be the departure point to mynew home for the next six weeks off-shore. This was a Floating ProductionStorage and Offload facility, betterknown to those in the business as aFPSO (Pronounced Fipso). I was to findmyself forty minutes by Helicopter off-shore of South Vietnam. I still had myjourney by road to overcome first, andboy what an eye opener!

Teams of local roadwork ‘Specialists,’were busy repairing some of the manypotholes to be found en route. Some ofthese were over eighteen inches indepth! These workers were dressed in all

their best Personal Protective Equipment(PPE). This consisted of vest, shorts andwell worn “safety boots”. Better knownto Expats as flip-flops. One worker wasoperating a pneumatic drill, breaking uphuge heavy chunks of tarmac whilst hiscolleagues were removing them, alsoattired in their ‘flip-flop safety boots.’What PPE? Was this the standard ofsafety I was to expect? Surely theseworkers were a one off; these guys can-not be for real; could they?

I was then treated to a spectacularshow of balancing skills, which theMoscow traveling circus would be proudto possess and all whilst riding on amoped, as along with bicycles, this isthe favored form of transport in Viet-nam and much of South East Asia. Ofcourse the whole operation is carriedout, minus any head protection, leathersor protective clothing we are accus-tomed to, and of course wearing the

standard ‘safety flip-flops.’ I watchedamazed as two men carried a plate glasswindow, lodged between them on aclapped out rusty moped. Then a manwith an arm chair, part of a three piecesuite, which was strapped to his backwith the sheer weight forcing his bonychin onto the handlebars of the ricketyrusty bike. Then to cap it all, a smilingfamily of six, complete with babe inarms and of course well-worn, designer‘Safety Flops’. I never did get to see aparty of seven! Just what have I letmyself in for? Surely the locallyemployed work force offshore would bemore safety conscious than this? Surelythose guys offshore will be totallydifferent?

Looking back over the last 30 years, Ihave learned an awful lot about Safetyin general, and the various types of PPEavailable.

Safety cultures differ dramaticallythroughout the countries of the world.Having worked in many areas of theglobe and currently in West Africa, it isclearly apparent that International stan-dards and stringent regulations for thewearing and use of PPE are not onlytotally disregarded, but also completelyunheard of!

SO WHAT EXACTLY IS P.P.E.?It’s a last line of protection, the very lastresort. The book definition of PPE is;‘Any device or appliance designed to be

ASIA PACIFIC FIREwww.apfmag.com

16

By Nick Lacey

IT SEEMS A LIFETIME AGO since I struggled through the teeming mass ofeagerly expectant taxi drivers, which were forming the running gauntlet fromTat Son Nhat International Airport, Vietnam.

I had finally arrived after my epic journey, jet lagged, bleary eyed anddishelved, only to be met by a torrential downpour. “Good Morning Vietnam”!But where’s the sun? I had imagined to be met with the warm embracingtropical breeze of this far-flung country, not raindrops the size of golf ballsleaping two feet into the air off the steaming tarmac. The whole scenario couldnot have been further from my imagination.

What Personal ProtWhat Personal ProtAPF p. 16-35 17/11/06 11:40 am Page 16

worn or held by an individual at workfor protection against one or morehealth and safety hazards’.

PPE really is the last line of defense.The majority of employers know thatPPE, if worn correctly, can protectemployees from the risk of injury bycreating a barrier against workplacehazards. It is not a substitute for soundengineering controls and documentedworkplace procedures. It should be wornand used in conjunction with these con-trols, if there is no other way to protectthe worker. We cannot protect theworkforce purely by providing them withvarious items of PPE.

Which item should they choose? Howshould it be worn? Does it afford suit-able protection for the task in hand? Fartoo many employers still believe “it issomeone else’s problem” and “It is notmy fault if the employees do not wearit, at least we provide it.”

I recently attended a safety seminarin Singapore, whilst assigned to a newFPSO conversion. During the course ofthe seminar, it came to light that afatality had occurred in the offshoreindustry to an employee who wasactually in the process of putting onan item of PPE. Inconceivable; yetnevertheless true. The protective itemhappened to be a safety harness, andthe unfortunate individual was in theprocess of donning the harness whilstwalking between rotating equipment.The harness became entangled in theequipment and pulled the unsuspectingindividual into the rotating component,resulting in fatality.

Many smaller incidents involving PPEspring to mind. For instance a youngVietnamese welder sustaining a super-ficial burn on the back of his wrist, thesize of a watch face, as a result of a hot piece of welding slag droppinginside his gloves. Was it incorrect PPEfor the job? Was he even aware that he had the wrong gloves on for the task he was undertaking? He shouldhave been wearing correct weldinggauntlets, but who should provide thisequipment? Who was responsible fortraining him? Who was his direct lineSupervisor?

SO WHAT ARE THE GUIDELINES? It’s not enough to merely provide PPEand expect employees to know how it isworn correctly. Management are

accountable and directly responsible forensuring a duty of care to their employ-ees. The bad old days of “But we’vedone it like this for years!” are nowthankfully gone. The PPE at work regu-lations 1992 often referred to as part ofthe “Six pack” clearly place a duty ofcare on employers and the self-employed to provide serviceable andsuitable PPE, at no cost to theiremployees. One only has to pick up thedaily papers to see that today com-panies are heavily fined if a breach ofthese regulations take place and this canalso rise to civil claims against theemployer.

The Personnel Protective Equipmentat Work Regulations 1992, clearly out-line these requirements. A new regula-tion has recently been included to placea duty on all suppliers to supply safe

PPE. Contravention of this requirementis now an offence under the consoli-dated regulations and extends to theretailers and the suppliers of PPE. Thedesign of equipment and clothing mustbe of a safe design and construction forthe work to be performed and easilymaintainable. Various regulations con-cerning PPE maybe country specific tothe region you are working in, so it isworth ensuring that the regulations youare following are applicable to thecountry in which you are working.

So what exactly are the responsibil-ities towards PPE?

RESPONSIBILITIESEmployers – They have primary respon-sibility for the implementation of thePPE Program in their work place. Thisincludes:

ASIA PACIFIC FIREwww.apfmag.com

17

otective Equipment?otective Equipment?

A new regulation has recently beenincluded to place a duty on allsuppliers to supply safe PPE.Contravention of this requirement is now an offence under theconsolidated regulations andextends to the retailers and thesuppliers of PPE.

APF p. 16-35 17/11/06 11:41 am Page 17

■ Conducting workplace Risk Assess-ments or Job Safety Analysis (JSA’s)to determine the presence of hazards,which necessitate the use of PPE.

■ Conducting periodic workplaceinspections and reassessments ofhazards.

■ Maintaining documented records onall hazard assessments.

■ Providing training and technicalassistance to Supervisors on theproper use, care and cleaning ofapproved PPE.

■ Providing guidance to the purchaseror Supervisor for the correct selectionand purchase of approved PPE.

■ Periodically reevaluating the suitabil-ity of previously selected PPE.

■ Reviewing, updating and evaluatingthe overall effectiveness of the com-pany PPE program.

Supervisors – Have the responsibilityfor the implementation of the PPE Pro-gram in their designated work areas.This includes:

■ Providing appropriate PPE and mak-ing it available to their employees.

■ Ensuring employees are trained onthe proper use, care, and cleaning ofPPE.

■ Maintaining records on PPE instruc-tion and training.

■ Supervising their staff to ensure thatthe elements of the PPE program arefollowed and that employees properlyuse and care for their PPE.

■ Notifying the authorities when newhazards are introduced or whenprocesses are changed or added.

■ Ensuring defective or damagedequipment is immediately replaced.

Employees – They also have responsi-bility for:

■ Following the requirements of thecompany PPE program.

■ Always wearing PPE as required.■ Attending required training sessions.■ Caring for, cleaning and maintaining

PPE.■ Informing the Direct line Supervisor

of the need to repair or replace dam-aged or defective items of PPE.

TRAININGCareful consideration should be given tothe comfort and correct fit of PPE inorder to ensure that it will be used. Pro-tective devices are usually available in avariety of sizes, so care should be takento ensure that the right size is readilyavailable and selected for use. Anyemployee required to wear PPE shallreceive training in the proper use andcare of PPE. This also includes the directline Supervisors. Training should include,

but not necessarily be limited to:

■ When PPE should be worn.■ What PPE is necessary for the partic-

ular hazards in the workplace.■ How to correctly don, adjust and

wear the PPE.■ The limitations of the PPE.■ The proper care, maintenance and

useful life expectancy.

After training the employees shalldemonstrate that they understand, thecomponents of the company PPE pro-gram and that they know how to usethe PPE properly. Written records areessential and should include the type oftraining provided, names of all personstrained and the dates the trainingoccurred. These records should be keptfor at least 3 years.

PEER PRESSURE VERSUS OPEN SHOP?A problem still exists in many compa-nies, especially in third world locationsusing National staff, when individualsrequire PPE replacement or even initialissue. Employees are often reluctant toapproach their Supervisors or managersto replace defective items of clothing orequipment. In order to prevent highconsumption, and the associatedexpense to maintain stocks of replace-ment PPE, a fine line needs to be drawnbetween an “open shop” policy and the‘third degree’ in-depth scrutiny as towhy the individual wants the PPEreplaced, without deterring them fromasking for replacement.

It is common in these situations formany companies to operate an open, noquestions asked, “hand in” replacementprogram after initial issue. This allowsbetter controls to be kept on the con-sumption/cost of the PPE, the defectiveor old PPE can be disposed of correctly,and additionally as the used or worn outequipment is collected it can help withthe analysis of how certain types/modelsof PPE are actually withstanding theapplication duties in the workplace.

RIGHT KIT FOR THE RIGHT JOB?So how do we know that we have theright PPE for the task in hand?

Although PPE may be provided, it isessential that the Supervisor or personresponsible for issuing the equipment isaware of its limitations. As an examplethere are numerous types of glovesavailable in today’s market, but are theright type chosen for the correct task inhand? One type of glove will not workin all situations. Gloves that can protectagainst chemicals may afford littleprotection against abrasions, cuts,lacerations or punctures or harmfultemperature extremes. Fire suit glovesthat are used in a domestic capacity

might not afford suitable protection forcrash rescue purposes?

Many years ago in the mid seventies,during a training exercise, a colleague ofmine was burnt quite severely on bothhands during a drill. The gloves he waswearing gave very little protection forthe situation he was faced with. He wascaught in a flash back resulting in burnsto both hands.

So careful consideration is essential inensuring the right PPE is selected forthe task in hand. Consideration shouldalso be given to the comfort and fit ofPPE in order to ensure that it will beused. Protective devices are generallyavailable in a variety of sizes, so careshould be taken to ensure that the rightsize is selected.

If a Fireman is employed in a domes-tic role and is then switched to airportduties, does he need to also switch to aclose proximity suit? The answer ofcourse comes back to sound manage-ment, documented procedures and goodsupervision backed up by methodicaltraining methods.

ASIA PACIFIC FIREwww.apfmag.com

18

Nick Lacey has over 30 yearsexperience in fire fighting, fire pre-vention and aircraft crash rescueprocedures, having served in theRoyal Navy’s Fleet Air Arm for 23years as an Aircraft Handler. Duringthis time Nick was employed on Air-craft Carrier flight decks and shoreside in the Naval Air Command FireService, where he finished hiscareer as Fire Chief. On leaving theservice, Nick moved into a Healthand Safety role having studied theNEBOSH general Certificate inHealth and Safety and attendednumerous courses for the offshoreindustry.

Nick is currently employed as SafetyOfficer onboard a FPSO producingover 110,000 barrels of oil per day.He is responsible for all aspects ofsafety and training onboard and isalso the Helicopter Landing Officer(HLO).

APF p. 16-35 17/11/06 11:41 am Page 18

Advert/p19 14/11/06 3:46 pm Page 1

ANSUL and WILLIAMS FIRE & HAZARDCONTROL have teamed up to introduce theultimate firefighting foam for flammableliquids. THUNDERSTORM™ 1x3Alcohol-Resistant AFFF can be applied at a3% ratio for polar solvent fuels like acetoneand methanol – or at a very efficient 1% ratiofor hydrocarbons like gasoline and jet fuel.ANSUL is the global quality leader in"special hazard" fire protection technology.RED LINE® fire extinguishers, ANSULITE®

AFFFs, the original "twin-agent" system, andnow THUNDERSTORM 1x3 foam are amongthe many "firsts" developed at the AnsulFire Technology Center.WILLIAMS FIRE & HAZARD CONTROL isknown worldwide for its technologicaladvances in firefighting equipment andextinguishment methodology. WILLIAMS’strike force stands ready for virtually anychallenge with the flexibility offered byTHUNDERSTORM 1x3 foam.

24-Hour Emergency Numbers:409-727-2347 or 281-999-0276Non-Emergency Inquiries: 800-231-4613

www.williamsfire.com

www.ansul.com

The two most trusted namesin petroleum-chemical fireprotection are striking back.

The two most trusted namesin petroleum-chemical fireprotection are striking back.ANSUL and WILLIAMS FIRE & HAZARDCONTROL have teamed up to introduce theultimate firefighting foam for flammableliquids. THUNDERSTORM™ 1x3Alcohol-Resistant AFFF can be applied at a3% ratio for polar solvent fuels like acetoneand methanol – or at a very efficient 1% ratiofor hydrocarbons like gasoline and jet fuel.ANSUL is the global quality leader in"special hazard" fire protection technology.RED LINE® fire extinguishers, ANSULITE®

AFFFs, the original "twin-agent" system, andnow THUNDERSTORM 1x3 foam are amongthe many "firsts" developed at the AnsulFire Technology Center.WILLIAMS FIRE & HAZARD CONTROL isknown worldwide for its technologicaladvances in firefighting equipment andextinguishment methodology. WILLIAMS’strike force stands ready for virtually anychallenge with the flexibility offered byTHUNDERSTORM 1x3 foam.

ISO 9001 Registered

Advert/p20 14/11/06 3:47 pm Page 1

ASIA PACIFIC FIREwww.apfmag.com

21

Having consumed its stock of proteinand fluoro-protein foam agent tobattle earthquake-initiated fires

involving flammable liquid storage tanks,Idemitsu Kosan Co., Ltd. – HokkaidoRefinery, located near Tomakomai, Japan,called on the marketplace for emergencyreplenishment of foam stocks. Tyco Fire &Security,’s Fire Suppression Business andALERT Disaster Control of Singapore metthe challenge to begin shippingANSULITE® firefighting foam agent withina 24-hour deadline.

A powerful earthquake, which registered8.0+ on the Richter scale, rocked Japan on26 September 2003 and with subsequentaftershocks was responsible for major stor-age tank damage and fires at the refinery,located approximately 750 km (460 miles)north of Tokyo. Idemitsu Kosan imme-diately initiated its Emergency ResponsePlan and together with the assistance ofNational Authorities and regionalmutual aid contingencies, was success-ful in containing and controlling theevent. The operations included a tankcontaining crude oil, which experiencedan initial full rim seal fire and subse-quent structural loss due to manifoldseparation, resulting in a fully involvedbund fire. A second tank containingNaphtha experienced a total product,roof and eventual structural loss due toa fully involved surface fire. In addition,the facility experienced an estimated

forty-three roof failures within open topand coned roof storage tanks exposing con-siderable volumes of product to atmosphereand potential ignition sources. The magni-tude of the operation set a previouslyunrecorded precedence for such an occur-rence within the region. In a gallantattempt to extinguish the fires and maintainvapour suppression during product transferoperations, emergency stock and mutual aidreserves of available foam inventory wereexpended.

In order to ensure delivery of proven firesuppression resources and products,Idemitsu Kosan placed an emergency orderwith ALERT Disaster Control for 500,000litres (132,000 gal) of 3% AFFF (aqueousfilm-forming foam). The order was splitwith an initial order totalling 200,000 litres

(52,835 gal) of AFFF. On 03 October 2003,ALERT Disaster Control awarded approxi-mately 100,000 litres (26,350 gal) of theinitial order to Tyco Fire & Security withthe stipulation that the order would beginshipping within 24 hours. Working aroundthe clock, Tyco’s Fire Suppression manu-facturing operation in Marinette, Wiscon-sin, USA shipped 27,000 litres (7,133 gal)of ANSULITE 3% AFFF the same day andcompleted the entire order by 06 October2003. The product was transported toChicago for airfreight to Japan by NipponCargo Airlines (NCA).

After successfully delivering the initialorder, Tyco’s Kevin White, Director of Asia-Pacific Sales commented: “I had no doubtwe were up to the challenge... and it paidoff. As a result of our fast performance, wehave been awarded the balance of the con-tract. That’s another 300,000 litres (79,250gal) of foam, three times the initial Order!”Through ALERT’s extended contract for thesupply of additional foam stocks, Tycoreceived the second order on 10 October2003 with a required lead-time of sevendays. The last shipment was delivered toNCA on 16 October 2003, one day early.

Our partners in this unique project,ALERT Disaster Control, continue to assistIdemitsu Kosan through the provision ofon-site technical consultation, training inleading firefighting technologies andapplication methodologies, and additionalservices and product sales encompassingtransportable firefighting pumps, supportequipment and systems.

Shortly after returning from Japan tothe ALERT (Asia) base of operations in Sin-gapore, Mike Allcorn, Managing Director,

stated proudly, “During our Customersmoment of crisis, we were grateful forthe opportunity to work together withtheir Management and plant opera-tions personnel and fulfil their fire pro-tection requirements in a professional,expedient and cost effective manner.ALERT’s global emergency responseand integrated risk management ser-vice capabilities, combined with thevast resources of the Tyco Fire & Secu-rity network and systems support fromour associates at Williams Fire & Haz-ard Control, clearly provided the opti-mum fire suppression solution for ourCustomer.”

P R O D U C T P R O F I L E

Steve Hansen, Foam Marketing Manager, Tyco Fire SuppressionBusiness (second from right) discusses the packaging andloading of foam tote containers with Nippon Cargo Airlinespersonnel at Chicago’s O’Hare International Airport.

ALERT Integrated Firefighting Pumps positioned alongside Idemitsu Kosan loading terminal delivering10,000 – 12,000 gpm water/foam solution through large diameter hose for supply of trailermounted firefighting monitors

COMPANIES JOIN FORCES TOEXPEDITE ANSULITE® FOAM

AFTER JAPAN EARTHQUAKE

APF p. 16-35 9/11/06 11:30 am Page 21

ASIA PACIFIC FIREwww.apfmag.com

22

EMERGENCY Protocol mustalways remain committed to pre-vention. In fact, as responsible

members of the business community,this is the only acceptable method ofprotecting our personnel, the environ-ment, assets and our reputation. Yet, itremains an often-tragic revelation thatfar more monies are expended in termsof actual emergency response activitiesand litigation than for preventativemeasures (training, drills, audits, etc.).It has become a sad realization thatmany companies today have lost focuswith the basics of emergency pre-paredness. Applied logic offers noother excuse for what we witness on adaily basis, and while it would be niceto limit this to one particular industry,it is endemic. Remember, everyone is apotential casualty, not everyone is apotential survivor.

No company today is immune to man-made or natural disasters. Therefore, awell-organized and tested emergencyresponse plan is vital. It is imperative thatwe prepare ourselves to deal with any andall potential problems. As such, it becomescritical that all hazards have been identi-fied and subsequent risks assessed andcontrolled. World events continuouslyremind us that even though the probabil-ity of occurrence may be extremely low, itwill not be impossible. We also note thatthe degree and speed of escalation of anincident is inversely proportional to thelevel of preparedness. Hence the question,are we really prepared to respond? Arewe simply competent on paper, or arewe truly proven competent?

Our primary response to an event mustdeal with safeguarding personnel and theenvironment. Secondary response providesfor protection of assets in addition todirecting our efforts to promote postevent recovery and ultimately the preser-

vation of our reputation. To accomplishthis, each and every operational unit mustbe responsible for maintaining their rele-vant level of emergency response infra-structure. Likewise, Management, atdefined levels throughout the organiza-tion’s hierarchy, must also possess theability to provide the requisite support(Emergency and Crisis Management). Thedefined infrastructure must clearly detailthe roles, responsibility, accountability andauthority that shall be adhered to in anemergency situation. Subsequently, eachoperational unit must be provided withthe resources to deal effectively with anyevent that arises. Resources must includecommunication links, equipment, trainedpersonnel and support services.

To gain an accurate picture of an orga-nization’s level of emergency prepared-ness, specific areas must be assessed usinga well-defined and systematic approach.These include, as a minimum:

• Pre-incident Planning• Resource Allocation• Emergency Response Teams• Essential Services• Transportation• Emergency Center and Communication• Interaction with Mutual Aid Partners

and Cooperating Agencies• Salvage and Restoration Operations

(Business Continuity)

The philosophy to be used whendesigning and ultimately conducting theassessment dictates that for every actioninitiated during an emergency situationthere will be a reaction.

For example, if we delay calling theappropriate technical specialist, controlof the fire may be lost. Likewise, if weact without forethought and planningwe may inadvertently cause the situa-tion to escalate.

Emergency Preparedness assessmentsmust combine the attributes of bothtest and learning experience. The expe-rience should always strive to provide arealistic atmosphere for the participantswithout placing them in a “no–win” sit-uation. If participants become frustrateddue to unrealistic or unfair escalationthen the environment loses the aspectsconducive to learning. However, if par-ticipants are unable to respond properlydue to inherent faults in the system itmust be made known. Irrespective ofthe outcome, we are provided with atrue assessment of our competence.

In the end we either conduct ourselvesresponsibly or we do not, we verify our levelof preparedness or simply tell ourselves thatwe are competent. One thing we can neverdo is to blame the system if the failure liesin our failure to prepare. Through adequatepreparation, we remove the propensity forkey personnel to simply act as a result oftheir emotions and limited knowledge ofthe event. A well-trained team will makeinformed judgments based on known factsand react in a positive manner.

ALERT DISASTER CONTROL is a globalprovider of Emergency Response Servicesand Integrated Risk Management Solu-tions. ALERT offers fully integrated Inci-dent Management Systems encompassingEmergency Response and ContingencyPlans, interactive emergency preparednessexercises, associated training, audits andcompetence assessments for every facet ofthe business community.”

For more information, please contact:

ALERT DISASTER CONTROL(ASIA) PTE. LTD.

Box 5008, Block B, #01-00Loyang Offshore Supply Base

Loyang Cresent, 508988 Singapore

Tel: +65 6 545 5088Fax: +65 6 545 3033

E-mail: [email protected]: www.alertdisastercontrol.com

EMERGENCY PREPAREDNESS– Fact or Fiction?

What have YOU done lately to assess your competence?

APF p. 16-35 9/11/06 11:30 am Page 22

EMERGENCY RESPONSE SERVICES:• Oilfield Firefighting and Blowout Control • Well Control Engineering and Management• Marine and Industrial Firefighting • Hazardous Material Control (Level I - II - III)

INTEGRATED RISK MANAGEMENT SOLUTIONS• QHSE Management Systems Development • Risk Assessments • QHSE Audits• Safety and Survival Training (IWCF, OPITO, STCW 95) • Onsite HSE Representatives• Toxic Environment Protection • Fire and Safety OEM and Product Sales

“Global Emergency Response andIntegrated Risk Management Solutions”

ALERT maintain an Integrated QHSE Management System to ISO 9001:2000, ISO 14001 and OHSAS 18001 standards as Certified by Det Norske Veritas

ALERT DISASTER CONTROL(ASIA) PTE. LTD.

Box 5008, Blk B, #01-00Loyang Offshore Supply Base,

Loyang Crescent, Singapore 508988Tel: (65) 6545 5088 (24 Hrs)

Fax: (65) 6545 3033Email: [email protected]

ALERT DISASTER CONTROL(MIDDLE EAST) LTD.

Building #34,Oil Field Supply Center, Jebel Ali,

Dubai, United Arab EmiratesTel: (971) 4 883 2343 (24 Hrs)

Fax: (971) 4 883 2395Email: [email protected]

ALERT DISASTER CONTROL(US) INC.

1730 Preston Road,Suite A, Pasadena,

Texas 77503, U.S.A.Tel: 1(713) 964 4084 (24 Hrs)

Fax: 1(713) 963 2903Email: [email protected]

ALERT DISASTER CONTROL(OCEANIA) PTY. LTD.

937 Oxenford Tambourine Rd,Wongawallan, Queensland 4210,

AustraliaTel: (61) 07 5573 2221 (24 Hrs)

Fax: (61) 07 5573 2774Email: [email protected]

www.alertdisastercontrol.com

THE ALERT GROUP OF COMPANIES

ALERT DISASTER CONTROL(CANADA) INC.

Atrium II, 300, 840-6th Avenue S.W.Calgary, Alberta T2P 3E5

CanadaTel: 1 (403) 233 8080Fax: 1 (403) 265 3785

Email: [email protected]

Advert/p23 9/11/06 11:31 am Page 1

www.ifcaa2004.com.twIFCAA NFA

IFCAA 2004 Secretariat National Fire Agency, MOI

Tel +886-2-2388-2119 ext. 8233, 8239 Fax +886-2-2504-4362 / E-mail [email protected] / Web www.ifcaa2004.com.tw

23rd International Fire Chiefs' Association of Asia

General Conference, 2004November 17~19, 2004 Taipei International Convention Center

2004 International Fire and Safety ExhibitionNovember 18~21, 2004 Taipei World Trade Center Exhibition Hall I, Area B

Disaster Response and Management Administration

Displays of the achievements of National Fire Agency, MOI and IFCAA member nations

and regions in the field of disaster prevention and response.

Fire Prevention and Safety Equipment

Fire prevention and fire safety equipment

Emergency rescue equipment

Electronic communications equipment

Fire prevention and emergency rescue vehicles, aerospace equipment, etc.

Disaster Prevention and Daily Life

Displays of emergency response measures operational procedures and achievements of

Government Agencies Enterprises and Civic Organizations in the field disaster prevention

and response.

The he Global lobal Vision on ision on Disasterisaster

Preparedness and reparedness and Responseesponse

The Global Vision on Disaster

Preparedness and Response

Advert/p24 9/11/06 11:31 am Page 1

HEIGHT RESCUE EQUIPMENT

Traditionally, the rescuers from the Fireand Emergency Services Departmentare highly trained men to accomplishdifficult and complicated height rescueoperations in rope access techniquesfor high angle rescue. However, highangle rescue techniques and super-highaerial ladders employed yesterday cansoon become obsolete or irrelevant intoday’s built-up environment as highrises progressively penetrating furtherinto the skyline.

Today’s firefighter is faced with notonly a bewildering array of difficult andcomplicated high rise rescue operationsbut also choosing the most efficientheight rescue equipment for firefightersafety. The most important factors are

the efficiency of the equipment andthe speed with which personnel andequipment designated for rescue pur-poses can be efficiently put into use.

TECHNOLOGY AND INNOVATION

The industry in fire and rescue equip-ment has a fine tradition of being inno-vative and creative. The mobile/portablerescue chute mounted on the bucket ofhydraulic platform or aerial ladder offire truck is an excellent example of theindustry’s innovative and creative out-look – of how to think and do beyondthe conventional. It is one of the mostvital pieces of height rescue equipmentin the market that provides dual func-tions in one unit portable rescue chute.This equipment allow the rescue per-sonnel to quickly deploy and put to useunder adverse conditions when space,speed and mobility are essential formass rapid height rescue operations:

● The quick deployment of mobilerescue unit and its flexibility ofextending or shortening the chutelength to the desired height for the

ASIA PACIFIC FIREwww.apfmag.com

25

Picture courtesy of Escape Consult Mobiltex (S) PTE. Ltd

By John NgEscape Consult

Mobiltex (S) PTE. Ltd

NO FIRE AND EMERGENCYServices Department likes to contemplate the possibility of ahigh-rise fire. While most buildingmanagement have a procedure forevacuation which is not dependenton the fire brigade, however, if thesystem fails then the fire brigadewill have to come to the rescue.When incidents involving high-riserescue operations, it can become adangerous affair of protecting andsaving the property and lives. Forthis reason the provision of meansof dealing with such incidents mustassume at all times the possibilityof, and need for, height rescue andextinguishing a fire at any timeduring rescue operations.

High RiseRescueOperations

Picture courtesy of Escape Consult Mobiltex(S) PTE. Ltd

High RiseRescueOperations

APF p. 16-35 9/11/06 11:32 am Page 25

rescue allow the rescuers the speedto quickly provide victims a safermeans of rapid vertical escape frombucket to ground. It eliminates thetime involved in lowering and raisingthe aerial platform, and reduces thespeed of mass rescuing victims fromtall building by almost ten times incomparison to using the conventionalmethod. Thus improves the evacua-tion capacity of any aerial ladder/hydraulic platform of fire enginefrom 10 to 100 times. In addition, it is able to evacuate over 100people in 10 minutes, including thehandicapped.

● Should the surrounding of thebuilding site could not accommodatethe fire aerial truck, the portabilityand versatility of the rescue chuteallows the rescue personnel to carrythe rescue unit to the desired floor.The universal platform has a pair ofbolts that serve as hangars that canhang on the handrail of the balconywithin minutes for ready use. In situa-tion where there is no handrail on thebalcony, with the additional equip-ment (horizontal arms and verticallegs), it allows the rescue chute to bepositioned at the parapet of balconyand window for quick rescue use.