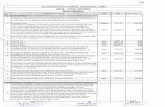

Package II Part I.3 Civil BOQ for Security Building

description

Transcript of Package II Part I.3 Civil BOQ for Security Building

Package-II Part-I Civil Works

Construction of Security Office Building

SL. NO.

QUANTITY DESCRIPTION OF ITEM UNIT RATE (In Figure & In Words) AMOUNT

I.3. Security Office BuildingEARTH WORK

1 450 Clearing Jungle including uprooting of rankvegetation, grass, brush wood, trees andsapplings of girth upto 30 cm measured at a heightof 1m above ground level and removal of rubbishupto a distance of 50m outside the periphery of thearea cleared. (Note: If however, only grass is metwith, the area will be measured and paid for, underas a separate item.)

Sq.M

2 Felling trees of the following girth (measured at aheight of 1M above ground level) including cuttingof trunks and branches removing the roots, fillingthe pit and depression, stacking of the serviceablematerials and disposal of unserviceable materialetc., as directed for:

a) 1 Felling Trees-beyond 30 cm upto including 60cmgirth

No

b) 1 Felling Trees-beyond 60 cm upto including 120cmgirth

No

c) 1 Felling Trees-beyond 120 cm upto including240cm girth

No

3 346.6 Providing and injecting Chemical emulsion for PRE-CONSTRUCTIONAL Anti-termite treatment andcreating a chemical barrier on top surface of plinthfilling, junction of inside wall and floor, on top ofdamp proof course (DPC) or on masonry at thelevel of plinth filling as per IS 6313 (Part-II) - 1981using chemicals like chloropyripos emulsifiable(IS: 8944-1978) 20EC, mixed with water in 1:19ratio (i.e. 1 litre of chemical to 19 litres of water).The emulsion is spread at 5 lit/sqm on top surfaceof plinth filling, top of Damp proof course and at 1lit / linear meter along the junction of wall and floor,all as per specifications and directions. (Plintharea of the building at ground floor only shall bemeasured).

Sq.M

Page 1 of 20

Package-II Part-I Civil Works

Construction of Security Office Building

SL. NO.

QUANTITY DESCRIPTION OF ITEM UNIT RATE (In Figure & In Words) AMOUNT

4 Earthwork in excavation for FOUNDATIONTRENCHES in ALL KINDS OF SOILS includingdressing of sides, ramming of bottom anddisposing the surplus excavated materials within adistance of 50m and lift upto 1.50m complete asper specifications. (Disposed soil to be leveled bybreaking clods if any and neatly dressed).

a) 258 Depth upto 1.5m Cu.M

5 73 Earthwork in excavation for FOUNDATIONTRENCHES in ROCKS, OTHER THAN HARDROCKS (ORDINARY ROCKS) either by manuallabour or by muffled blasting upto a depth notexceeding 1.5m including stacking or disposingthe excavated materials, lead upto 50m and liftupto 1.50m etc., complete all as per specificationsand directions of Engineer-in-Charge.

Cu.M

6 20 Earthwork in excavation for FOUNDATIONTRENCHES in HARD ROCK by muffled blastingupto an initial depth not exceeding 1.5m including

Cu.M

p p g gstacking or disposing the excavated materials,lead upto 50m and lift upto 1.50m etc., completeall as per specifications and directions of Engineer-in-Charge.

7 20 Earthwork in excavation for FOUNDATIONTRENCHES in HARD ROCK by chiselling upto adepth not exceeding 1.5m including stacking ordisposing the excavated materials, lead upto 50mand lift upto 1.50m etc., complete all as perspecifications and directions of Engineer-in-Charge.

Cu.M

8 346 Filling available excavated approved earth(excluding rock) in trenches, sides of foundations,plinth, etc, in layers not exceeding 15cms depthbreaking clods, consolidating each deposited layerby ramming, watering and dressing, etc., completefor lead upto 50m and all lifts etc., complete as perspecifications.

Cu.M

Page 2 of 20

Package-II Part-I Civil Works

Construction of Security Office Building

SL. NO.

QUANTITY DESCRIPTION OF ITEM UNIT RATE (In Figure & In Words) AMOUNT

MASONRY9 Providing and constructing Solid Cement Concrete

Block masonry in cement mortar 1:6 (1 Cement : 6Coarse sand) using factory made, load bearing,approved quality Cement Concrete blocks ofspecified size, Grade D (4.0), Density of blocksnot less than 1800 kg/cum. Minimum averageCompressive strength of units - 4.0 N/sqmm andMinimum strength of individual units 3.2 N/sqmm,setting in position, curing, raking out jointswherever required etc., complete with all leads andall as per specifications and directions of theEngineer-in-charge. IN FOUNDATION ANDPLINTH

34 For 200mm thick walls using (400 x 200 x 200)mm size blocks.

Cu.M

10 Providing and constructing Solid Cement ConcreteBlock masonry in cement mortar 1:6 (1 Cement : 6Coarse sand) using factory made, load bearing,approved quality, Grade D (4.0), Density of blocksnot less than 1800 kg/cum. Minimum averageCompressive strength of units 4 0 N/sqmm andCompressive strength of units - 4.0 N/sqmm andMinimum strength of individual units 3.2 N/sqmm,set to level plumb including setting in position,providing scaffolding, curing, raking out jointswherever required etc., complete with all leads andall as per specifications and directions of theEngineer-in-charge. IN SUPER STRUCTUREUPTO ALL HEIGHTS.

81 For 200mm thick walls using (400 x 200 x 200)mm size blocks.

Cu.M

11 Providing and constructing Solid Cement ConcreteBlock masonry in cement mortar 1:4 (1 Cement : 4Coarse sand) using factory made, load bearingapproved Cement concrete blocks of specifiedsize, Grade D (4.0), Density of blocks less than1800 kg/cum, Minimum average Compressivestrength of units - 4.0 N/sqmm and Minimumstrength of individual units 3.2 N/sqmm, set tolevel, plumb, setting in position, providingscaffolding, curing, raking out joints whereverrequired etc., complete with all leads and all as perspecifications and directions of the Engineer-in-charge. IN SUPER STRUCTURE UPTO ALLHEIGHTS.

Page 3 of 20

Package-II Part-I Civil Works

Construction of Security Office Building

SL. NO.

QUANTITY DESCRIPTION OF ITEM UNIT RATE (In Figure & In Words) AMOUNT

102 For 100mm thick partition walls without RCCstiffener using (400 x 100 x 200) mm size blocks.

Sq.M

PLAIN CEMENT CONCRETE12 Providing and laying cement concrete using 40mm

nominal size graded hard granite stone aggregateobtained from approved quarry includingcompaction, finishing top surface to level, curingbut excluding cost of formwork, etc., complete asper specifications. Mix ratio specified is for(cement: coarse sand: graded stone aggregate).

a) 32 In foundations with PCC 1:5:10 Cu.M

b) 39 In sub-base to floors & Hardstand with PCC 1:5:10 Cu.M

13 Providing and laying cement concrete usinggraded hard granite stone aggregate of 20mmnominal size obtained from approved quarryincluding formwork, compaction, finishing, curing,etc., IN BED BLOCKS, SILL BLOCKS COPINGupto all heights complete all as per specifications.Mix ratio specified is for (cement: coarse sand:graded stone aggregate). The work includesproviding throating/ drip mould wherever requiredas per standard engineering practice of size not beless than 40mm x 15mm. The rate is inclusive formaking drip mould and no extra cost shall be paidfor.

a) 1 In coping with P.C.C (1:3:6) Cu.M

b) 0.5 In window cills with P.C.C (1:3:6) Cu.M

c) 3 In blocks for Gate with P.C.C (1:2:4) Cu.M

Page 4 of 20

Package-II Part-I Civil Works

Construction of Security Office Building

SL. NO.

QUANTITY DESCRIPTION OF ITEM UNIT RATE (In Figure & In Words) AMOUNT

REINFORCED CEMENT CONCRETE14 Providing & laying in position machine batched,

machine mixed and machine vibrated design mixcement concrete / RMC of specified grade forreinforced cement concrete structural elements,using graded hard granite stone aggregates ofmaximum 20mm nominal (down graded) sizeobtained from approved quarry including fineaggregates conforming to latest IS 383 andcement all as per approved design mix proportionsconforming to latest IS 10262 with minimumcement content for durability including supplyingand providing concrete cover blocks etc., whichshall be followed as per latest IS 456-2000including mixing, transporting, placing vibrating,compaction, finishing to required levels, curingetc., complete all as per specifications butexcluding cost of formwork and steelreinforcement.Rate to include labour for keeping embedments ifany wherever required while casting. Rate also toinclude lift charges and scaffolding for heights,depths and levels from FFL/GL. (The design mixproportions shall clearly indicate cement: fineaggregate: coarse aggregate: water cement ratio

d l h ll b bt i d f E i iand approval shall be obtained from Engineer-in-charge for initial and subsequent mixes as andwhen there will be change in quarry/materials forM-25 grade reinforced cement concrete, etc., allwork upto plinth level.

a) 136 Footings Cu.M

b) 7 Pedestals Cu.M

c) 28 Plinth beams Cu.M

d) 3.5 Columns Cu.M

Page 5 of 20

Package-II Part-I Civil Works

Construction of Security Office Building

SL. NO.

QUANTITY DESCRIPTION OF ITEM UNIT RATE (In Figure & In Words) AMOUNT

15 Providing & laying in position machine batched,machine mixed and machine vibrated design mixcement concrete / RMC of specified grade forreinforced cement concrete structural elements,using graded hard granite stone aggregates ofmaximum 20mm nominal (down graded) sizeobtained from approved quarry including fineaggregates conforming to latest IS 383 andcement all as per approved design mix proportionsconforming to latest IS 10262 with minimumcement content for durability including supplyingand providing concrete cover blocks etc., whichshall be followed as per latest IS 456-2000including mixing, transportation, placing, vibrating,compaction, finishing to required levels, curingetc., complete all as per specifications butexcluding cost of formwork and steelreinforcement.Rate to include labour for keeping embedments ifany wherever required while casting. Rate also toinclude lift charges and scaffolding for heights,depths and levels from FFL/GL. (The design mixproportions shall clearly indicate cement: fineaggregate: coarse aggregate: water cement rationand approval shall be obtained from Engineer-in-h f i iti l d b t i dcharge for initial and subsequent mixes as and

when there will be change in quarry/materials forM-25 grade reinforced cement concrete, etc., allwork above plinth level upto all heights.

a) 30 Walls (any thickness) including attached pilasters,buttresses, plinth and string courses, fillets,columns, pillars, piers, abutments, posts andstruts, etc.,

Cu.M

b) 90 Beams, suspended floors, roofs having slope upto18 degree, landings, balconies, shelves, chajja,lintels, bands, plain windows sills, staircases andspiral staircases etc.,

Cu.M

16 Same as item no. 15 above but using M20 gradeof concrete.

2 Lintels & Staircases Cu.M

Page 6 of 20

Package-II Part-I Civil Works

Construction of Security Office Building

SL. NO.

QUANTITY DESCRIPTION OF ITEM UNIT RATE (In Figure & In Words) AMOUNT

FORM WORK17 Providing rigid and water tight centering and

shuttering using best quality wood/ plywood /steelforms and centering with steel props, acro tubesetc., including strutting, propping, bracing, stagingetc., complete for all RCC items fixed in positionas required including labour for careful removal ofform work etc., complete all as per specificationsat all heights. In Horizatal / Vertical / slantingsurfaces.

a) 253 Foundations, footings, bases of columns, massconcreting, floorings, etc

Sq.M

b) 317 Lintels, beams, plinth beams, girders, bressumersand cantilevers

Sq.M

c) 417 Suspended floors, roofs, landings, shelves andtheir supports, balconies and chajjas.

Sq.M

d) 117 Walls (any thickness) including attached pilasters,buttresses plinth and string courses etc.

Sq.M

e) 212 Columns pillars abutments posts and struts Sq Me) 212 Columns, pillars, abutments, posts and struts. Sq.M

STEEL WORK18 Steel reinforcement for all RCC items including

decoiling, cutting, hooking, bending, cranking,fabricating to required shape, placing in positionand tying the system with soft drawn annealedbinding wire of diameter not less than 1.00mm with2 strands etc., complete all as per specifications atall heights (binding wire will not be measured for

20 With TMT 415 bars. M.T

19 Supplying, fabricating, assembling, hoisting /erecting and fixing in position at all heights andwith all leads, structural steel works of welded built-up sections, all as per structural drawings and asper detailed specifications (for materials andworkmanship) in the situations describedhereinafter includinga) Cutting of components to required lengths/widths and shapes/ profilesb) Smooth machining of edges/ faces

Page 7 of 20

Package-II Part-I Civil Works

Construction of Security Office Building

SL. NO.

QUANTITY DESCRIPTION OF ITEM UNIT RATE (In Figure & In Words) AMOUNT

c) Welding (electric arc welding) at joints of built-up sections/ single sections for required weldlengths and sizes and d) Painting all over with two coats of syntheticenamel paint of approved quality, make and colour/ shade over one coat of red oxide zinc chromateprimer with surfaces duly pressed to receivepainting etc., complete all as directed by theEngineer-in-Charge.NOTE: The Contractor shall submit fabricationshop drawings for work involved based onconstruction drawings (that may be issued duringconstruction period) for approval by Engineer-in-charge. The fabrication work shall start only after approvalto the fabrication drawings. Any change requiredin the fabrication drawings shall be carried out atno extra cost over the quoted rates. Fabricationshall be in a perfectly workmanship like mannerand as provided in Section V and VI of IS 800 andIS 7215. Welding shall be carried out by qualifiedwelders.

Electrodes for welding, the procedure, selection,test and inspection shall conform to provisions inIS 816 IS 818 IS 822 d IS 833 E ti /IS 816. IS 818, IS 822 and IS 833. Erection /hoisting shall commence only after passing offabricated parts by the Engineer-in-charge.

a) 0.20 Structural steel works and welded builtup sectionswith MS plates of any thickness

M.T

b) 0.50 Structural steel works in welded built up sectionswith MS channels for fencing posts

M.T

c) 0.50 Structural steel works with MS angles, Tees andother sections

M.T

Page 8 of 20

Package-II Part-I Civil Works

Construction of Security Office Building

SL. NO.

QUANTITY DESCRIPTION OF ITEM UNIT RATE (In Figure & In Words) AMOUNT

FLOORINGS20 Providing and laying cement concrete in

pavements and ramps in panels not exceeding 10sqm per panel and plinth protection in panels notexceeding 3 sqm per panel using graded hardgranite stone aggregate including providingnecessary formwork, making 10mm wide groovesin panels for depth of 1/3rd of thickness ofpavement or 40mm whichever is more and fillingthe grooves with approved hot poured sealingcompound confirming to grade A or B of IS-1834,consolidation, curing and treatment for the top withbroom finish, etc., complete all as perspecifications, Mix ration specified is for (cement:coarse sand: graded stone aggregate).

5 Using 20mm nominal size aggregate In CC 1:3:6for Plinth protection

Cu.M

21 Providing plain cement mortar skirting 20mm thickin a mix of 1:3 including a base layer and finishedsmooth to required level and plumb at corners andat face in cement slurry mixed at the rate of 10Kgsper 10 Sqm inclusive of hand rubbing, curing, etc.,complete all as per specifications. ( Rate toinclude cost of chasing of walls whereverrequired).

15 In skirting 100mm high. Mtr.22 Providing and laying Indian patent stone flooring

with cement concrete 1:2:4 (1cement: 2 coarsesand: 4 graded stone aggregate) using gradedgranite stone aggregate obtained from approvedquarry laid to level or slope in bays not exceeding3sqm per panel including providing 3mm thickaluminium dividing strips to the full depth of theflooring and finished smooth, curing, etc.,complete all as per specifications.

16 40mm thick (Using 20mm nominal size stoneaggregate)

Sq.M

Page 9 of 20

Package-II Part-I Civil Works

Construction of Security Office Building

SL. NO.

QUANTITY DESCRIPTION OF ITEM UNIT RATE (In Figure & In Words) AMOUNT

23 Providing and laying 18mm to 20mm thick mirrorpolished granite stone slab flooring of approvedcolour and shade using mirror polished granitestone slabs of size 1800mm x 1200mm / 1800mmx 2400mm and smaller sizes as per site condition(cut from the bigger sizes of mirror polished waterjet cut stone slab of approximate size 6.5ft x10.5ft) approved colour / texture and pattern ofRANDOM GRANITE SLABS, water cut quality,machine cut to required size, laid over a bed of20mm thick cement: mortar 1:6 and cement slurryat the rate of 4.4kg/sqm for bedding and jointingincluding grouting the joints pigments to match theshade of the slabs, finishing to required level andslope, curing, cleaning, mopping, etc., complete allas per specifications at all heights in all floors.

a) 3 18 to 20mm thick Polished granite for platform Sq.M

b) 7 Polished jet black granite stone flooring in risers ofsteps.

Sq.Mp

c) 10 Polished ruby red granite stone flooring in treadsof steps, not exceeding 300mm in width.

Sq.M

d) 13 Extra for nosing in granite stone for treads andplatform

Sq.M

e) 4 Extra for providing opening of required size andshape for wash basins / kitchen sink in kitchenplatform, vanity counters and similar locations inmarble / stone work including necessary holes forpillar taps etc., including rubbing and polishing ofcut edges etc., complete per opening

Nos

Page 10 of 20

Package-II Part-I Civil Works

Construction of Security Office Building

SL. NO.

QUANTITY DESCRIPTION OF ITEM UNIT RATE (In Figure & In Words) AMOUNT

24 Providing and laying vitrified ceramic tile flooring /skirting using approved quality vitrified ceramictiles of approved size and thickness according tosize manufactured by M/s. Johnsons Ceramic /Somani / Khajaria or equivalent make laying thetiles over a bed of 20mm thick cement mortar 1:3with cement slurry @ 3.3 Kg/sqm, jointed andpointed with matching grey / white cement slurrymixed with matching pigment and finishing torequired level, curing etc., as per manufacturer'sspecifications, drawings etc., at all heights for

a) 313 Tile size of 600 x 600mm of marble series forflooring

Sq.M

b) 15 Tile size of 600 x 100mm of marble series forskirting

Sq.M

25 Providing and laying Ceramic tile flooring / dadoingof approve quality, size, colour and thicknessaccording to the dimensions of tiles and havingg gscratch hardness and other parameter conformingto IS 13630 ( Bell or Navin or spartek or Jhonsonor kajaria or somany or equivalent make) laid overa bed/backing as specified below, with cementslurry at 3.30 kg/sqm, close jointed and pointedwith matching white cement slurry mixed withapproved pigment and finishing to required level,curing etc., complete all as per specification andas directed by EIC at all floors.

a) 25 In flooring with approved colour Matt finish / Anti-Skid premium floor tiles of size 300mm x 300mmas per IS 13755-1993 over bed/backing of 20mmthick in CM 1:4.

Sq.M

b) 61 In dado with approved colour wall tiles (Regular /plain or dark colour / glossy or mat series ) size300mm x 200mm as per IS 13753-1993 over abed/backing of 12mm thick in CM 1:3.

Sq.M

Page 11 of 20

Package-II Part-I Civil Works

Construction of Security Office Building

SL. NO.

QUANTITY DESCRIPTION OF ITEM UNIT RATE (In Figure & In Words) AMOUNT

WOOD WORK & JOINERY26 Providing and fixing M.S. grills of required pattern

in wooden / steel frames of windows, ventilators,clerestory windows, etc; with M.S. flats, square orround bars with round headed bolts and nuts or byscrews, etc., complete all as per drawings anddirections of Engineer-in-charge.

165 Plain grill ( With vertical, horizontal members or acombination of both)

Kgs

27 Providing and fixing at all heights/ in all floors withall leads coloured anodized aluminium doors/windows/ partitions manufactured from bestextruded Aluminium sections confirming to ISI, cutto length, joints mitred and corners grinded withjoints water proof the outer frame and shutterframe stiffened with corner angle strips or providedfor in the frame for fixing the frame to RCCcolumns/ masonry on sides, RCC lintels on topand PCC cills or floor at bottom, the frame workfixed with standard approved fastenings allgenerally as per details shown in drawings andspecificationsspecifications with all the sections pretreated for removal of anyrust and prevention of further rust formation andcoated with greasy materials for non-adherence ofmortar or any other sticky materials and this coatto be removed after installations of the sub-dividing frames by tennoned and rivetted intoframes all aluminium surface be thoroughlycleaned free or rust scale or dirt and mill scale bypickling surface finished with anodized dull mattfinishing 15 MICRON thick including cost of pulland push plates andfixtures for hinged openings (arrangement withsteel bearings wherever necessary), cost of labourfor fixing of mortice lever locks, aluminiumhandles, door fittings like tower bolts etc., suppliedfree for fixing including screws/ bolts (or thesesmaterials measured separately elsewhere) whereshutters are involved etc., complete, cost ofproviding and fixing of glass of selected glazingquality of thickness and type of glass specifiedhereinafter or panel boards including nylon or PVCor rubber lining of approved quality woodengrounds, rubber gasketc, aluminium glazing clips,mastic etc.,

Page 12 of 20

Package-II Part-I Civil Works

Construction of Security Office Building

SL. NO.

QUANTITY DESCRIPTION OF ITEM UNIT RATE (In Figure & In Words) AMOUNT

and fixing with aluminium glazing clips and alsosnap-on type with holes as per drawing andspecifications provided for separately in the subitems following the main items of frame work forpartition and door shutters as below:NOTE: All fitting works shall be carried out as perIS specifications including necessary rivets,screws, lugs, scaffolding, etc., complete allgenerally as per drawings.The sizes of the components should confirm asper details in drawings.

a) 290 Providing and fixing of coloured Anodisedaluminium (Matt finish) frame work (Horizontal andVerticals) for partitions Doors/ Windows withrequired sections of JINDAL/INDAL make orequivalent including all items and contingenciesdescribed above complete (Aluminium beadingsand glazing clips measured under this item only)

Kgs

b) 230 Providing and fixing of frame work (Styles andrails) for Doors shutters/ window shutters withrequired sections of JINDAL/INDAL make orequivalent including providing all items and hinged/pivotes arrangements for operation of shutters andlabour cost for fixing of door fittings and locks(Whi h h ll b f i f fi i id

Kgs

(Which shall be free issues for fixing or paidseparately) etc., complete. (Aluminium beadingsand glazing clips measured under this item only).

c) 3 Providing and fixing Glass panes of selectedglazing quality and thickness as specified belowincluding providing and fixing Nylon/ rubber/ PVClining of approved quality and fixing with aluminiumglazing clips/ Aluminium beadings (Supply cost ofaluminium clips/ Aluminium beadings aremeasured in items above for DOORS/ WINDOWS/ PARTITIONS etc., Using 4mm thick plain glass

Sq.M

d) 34 Providing and fixing Glass panes of selectedglazing quality and thickness as specified belowincluding providing and fixing Nylon/ rubber/ PVClining of approved quality and fixing with aluminiumglazing clips/ Aluminium beadings (Supply cost ofaluminium clips/ Aluminium beadings aremeasured in items above for DOORS/ WINDOWS/ PARTITIONS etc., Using 5mm thick plain glass

Sq.M

Page 13 of 20

Package-II Part-I Civil Works

Construction of Security Office Building

SL. NO.

QUANTITY DESCRIPTION OF ITEM UNIT RATE (In Figure & In Words) AMOUNT

28 10 Providing and fixing boards / sheets as specifiedbelow including cutting to required size and shape,fixing with aluminium glazing clips or triangularbeading (measured and paid under item 13.1 and13.2 above) including screws and putty etc.,complete, Using 12mm thick three layered flatpressed both sides teak veneered Teak woodparticle board, bonded with Phenol formaldehyde

Sq.M

29 Supplying of factory made composite door shutterwith frame and single shutter manufactured byM/s. Fimen Fibre Products Pvt. Ltd. Or equivalentwith door frame of size 70x50mm. The doorshutter shall be of rigid G.R.P. sandwich compostestructure of 26mm thick (minimum) laminated onall sides with G.R.P. skin fabricated using U.V.stabilized Isopthalic gel coat and one layer of 450GSM E glass chopped strand mat (CSM)impregnated with polyster resin. The thickness ofskins shall not be less than 1.5mm

4 Expanded polysterene structural foam panel ofdensity 20kg/cum shall be used as core materialfor the whole areas of door except the woodenframe structure. The wooden reinforcements

d f d l d bl k f i i

Sq.M

made of seasoned salwood block of minimumcross section of 70x26 for lock side 40x26 allround forming the framework for shutter andminimum of 75mm wide intermediate strip for thewidth of the door for fixing locks and fixture andshall conform to IS-4020-1998. The finish of theshutter be without grains and of approved colouretc., complete all as per manufacturersspecifications at all heights.

30 Providing and fixing steel door system made out ofstandard rolled steel sections. The door frame,shutter frame and diagonal stiffeners for theshutters, styles and rails and for shutters shall beMS angles / Tees. The shutter frame shall becovered with MS sheet (single / double skin)electrically welded. The door frame shall havebase tie made out of 12mm square MS rodembedded in flooring and 3nos. of 15mm x3.15mm lugs of 100mm long on each sideembedded in cement concrete blocks of size 150 x100 x 100mm of 1:3:6 mix (1 cement : 3 coarsesand : 6 hard granite stone aggregate 20mmnominal size) or with anchor fasteners or withfixing clips with bolts and nuts as required.

Page 14 of 20

Package-II Part-I Civil Works

Construction of Security Office Building

SL. NO.

QUANTITY DESCRIPTION OF ITEM UNIT RATE (In Figure & In Words) AMOUNT

The work includes providing approved pivots asrequired and iron oxidized butt hinges 125mmlong, 3nos. for each shutter conforming to IS 1341-1970 etc., including cutting the steel sections torequired lengths, joints mitred and electricallywelded, ground and cleaning the surfacethoroughly free from rust scales and painted withtwo coats of synthetic enamel over a coat of redoxide zinc chromate primer, after pre treatment ofthe surface by pickling and phosphating etc.,conforming to IS specifications including providingand fixing MS aldrops, MS tower bolts and MShandles etc., complete all as per specifications,drawings and instructions of Engineer in charge atall heights.

190 a) Fully openable (single / double) shutter andUsing MS sheet covered on single or both sides

Kgs

31 17 Providing and fixing 1000mm high railing with25mm dia stainless steel pipe of grade 316 asballusters spaced at 600mm c/c alround thecorridor and providing 2 nos. 15mm dia. stainlesssteel rods, connecting to the side of ballusters withnecessary fixing arrangements and providing50mm dia stainless steel pipe of grade 316 asrailing fixed to the ballusters including stainlesst l i l f d k tti

RMT

steel specials of approved make, cutting,fabricating, welding, grinding , buffing , polishingall materials and labour at all levels in all floorsetc., complete as directed including powdercoating for connecting member of railing andballusters of approved colour and shade.

32 17 Providing and fixing SS mosquito proof and flyproof mesh to aluminium frame work includingcost of mesh, and labour for fixing buildersharware and locking arrangements etc., completeall as per specifications but excluding cost ofbuilders hardware and locking arrangement issuedby the Department free of cost. (Aluminium framework shall be measured under the relevant item)

Sq.M

ROOFING33 Providing and laying water proofing treatment over

RCC roof in 3 courses, as specified below, afterthoroughly cleaning surface of the roof slab withwire brush, cleaning of dust and foreign matters,raking and cleaning of construction joints if anyetc., complete to make the surface suitable forreceiving water proofing treatment.

Page 15 of 20

Package-II Part-I Civil Works

Construction of Security Office Building

SL. NO.

QUANTITY DESCRIPTION OF ITEM UNIT RATE (In Figure & In Words) AMOUNT

I Course: The existing covering on slab to beremoved and the surface of the RCC slabexposed. Construction joints if any are to be rakedand cleaned. A coat of cement slurry at the rate of4.4kg/sqm mixed with acrylic water proofingcompound (as per manufacturers specification) isspread uniformly over the RCC roof area andensuring that the slurry penetrates in to the RCCslab below and fills all micron cracks and all otherporous areas. Over this a layer of 15mm thickcement mortar 1:5, mixed with acrylic waterproofing compound as per manufacturersspecifications shall be laid to place the II course.

II Course: A single layer of brick on edge with15mm wide gaps filled with CM 1:5 mixed withacrylic water compound is laid (i.e. bricks placedvertically on its 75x115mm side or 75x230mm sideas the case may be, to suit the required thicknessof courses), when the bottom layer (I course) isstill green and laid to slope of 1 in 60 as per roofdrainage scheme using approved well burnt bricks(wear absorption not more than 20%) withminimum thickness of 65mm at outer edgeincluding the top and bottom plastering (I&III

) t t i d di t l i th b i kcourse) to get required gradient, laying the brickswith not less than 15mm gap alround, which shallbe properly filled completely and compacted withCM 1:5 mixed with acrylic water proofingcompound as per manufacturers specificationusing full bricks or bricks cut to required size to laythe course with single layer with gradient saidabove for adequate drainage.

III Course: 20mm thick cement mortar 1:4 mixedwith acrylic water proofing compound with a layerof Chicken mesh 12mmx26G and marked with300mmx300mm false squares including curingetc., for not less than 7 days, complete all as perspecifications and directions of Engineer-in-charge. The 20mm thick layer shall be carried outin two layers of 10mm thick with an inter layer ofchicken mesh of 12mmx26G laid in between thetwo layers of cement mortar.

NOTE:The acrylic water proofing compound to be usedshall be;

Page 16 of 20

Package-II Part-I Civil Works

Construction of Security Office Building

SL. NO.

QUANTITY DESCRIPTION OF ITEM UNIT RATE (In Figure & In Words) AMOUNT

a). CHEMSEAL - Manufactured by M/s. OverseasWater Proofing Corporation, Mumbai. Theproportion of CHEMSEAL shall be 2% by weight ofcement. OR CONPLAST X 421 IC - integral waterproofing compound manufactured by M/s.FOSROC Chemicals (India) Ltd., Bangalore. Theproportion of CONPLAST x 421 IC shall be 130mlper 50 kgs of manufactured by M/s. ROFFEConstruction Chemicals Pvt. Ltd., liquid integralwater proofing compound at 140ml per 50kg ofcement or Equivalent.b)The second course of the treatment shall be laidin single course using full bricks/cut bricks as maybe required for laying the course in 1 in 60 slope.

c) The rate to include all labour, material andcontingent coats for execution of work in aworkman like manner including curing, etc.,complete for respective courses.d) The plane horizontal measurements of roof slabonly shall be measured for payment.e) The theoretical cement consumption requiredfor the above work will be worked out based on co-efficient for each layer of work as per specification.

f) Th k h ll b t t d th hf) The work shall be got executed throughspecilised water proofing agency.

400 g) The contractor should finish a guarantee bondin the prescribed format for satisfactory waterproofing performance for 10 years.

Sq.M

34 Providing and fixing rigid PVC SWR (soil, wasteand rain water) drainage/ rain water pipeconforming to type-A of IS 13592-1992, includingaccessories like bends and fixing with pipe clips,adhesive at joints all as per manufacturer'sspecifications to required length etc., complete allas per specifications and directions of Engineer-in-charge.

31 110mm OD pipes with minimum wall thickness of2.20mm.

Mtr

Page 17 of 20

Package-II Part-I Civil Works

Construction of Security Office Building

SL. NO.

QUANTITY DESCRIPTION OF ITEM UNIT RATE (In Figure & In Words) AMOUNT

35 Providing and making khurras of size specifiedbelow with 12mm thick CM 1:3 plaster finish overPCC 1:2:4 using 10mm nominal size stoneaggregate (1 cement: 2 coarse sand: 4 stoneaggregate) of 600mmx600mm of varying thicknessof 40mm at WPC side to 30mm at pipe end, laid toslope, compacted over PVC sheet of1000x1000mm x 400 micron laid over top of slabafter cleaning the surface of concrete slab. Thetop surface of CM 1:3 plaster shall be finishedsmooth with cement punning, rounding of edgesetc., complete all as per specifications anddirections of Engineer-in-charge.[Note: The RWP shall be fixed during constructionof parapet to ensure filling the joints and aroundpipe properly].

8 600mmx600mm size Each

36 2 Providing and fixing 75mm dia (O.D) UnplasticisedPVC pipe water spouts conforming to IS 4985-1988 inclusive of specials (Tee) conforming to IS7834 (part IV) 1987 of working pressure 6kg/sqcm.The outlet end shall be provided with PVC Tee and

Mtr

the inlet end shall be flush with inner face offacias/ parapets, fixing in cement mortar 1:3 etc;complete all as per specifications.

37 20 Providing and laying angular fillet 7.5 x 7.5cmcement concrete 1:2:4 (1 cement : 2 coarse sand :4 graded stone aggregate) 20mm nominal size,including compaction, finishing, curing, etc;complete all as per specifications.

Mtr

FINISHING38 Plastering 12mm thick with cement mortar

specified below, finished rough includingscaffolding, curing, etc. complete for EXTERNALSURFACES inclusive of sills, jambs, soffits,ceilings, etc., complete all as per specificationsfor IN ALL FLOORS AND AT ALL HEIGHTS. Mixspecified is for cement : coarse sand.

NOTE : i) CM 1 : 3 OR CM 1:4 is generallyapplicable for ceilings and RCC surfaces unlessotherwise specified.

a) With CM (1:5) to brick walls275 Upto 10 m Level Sq.M

b) With CM (1:4) to RCC surfaces

Page 18 of 20

Package-II Part-I Civil Works

Construction of Security Office Building

SL. NO.

QUANTITY DESCRIPTION OF ITEM UNIT RATE (In Figure & In Words) AMOUNT

122 Upto 10 m Level Sq.M

39 Plastering 12mm thick with cement mortarspecified below, finished smooth with lime neeruincluding scaffolding, curing, etc., complete forINTERNAL SURFACES of walls, beam, ribs, sills,jambs, ceiling, etc., complete all as perspecifications at ALL HEIGHTS. Mix specified isfor cement: fine sand.

a) 447 With CM 1:5 to masonry walls Sq.M

b) 229 With CM 1:4 to RCC surfaces Sq.M

c) 63 With CM 1:4 to ceiling Sq.M

40 10 Providing and fixing GI hexagonal chicken wiremesh of size 12mm x 22g at the junction of

Sq.Mmesh of size 12mm x 22g at the junction ofdisimilar surfaces of brick masonry wall and RCCcolumn by beams and the like including necessarynails for fixing etc, complete all as per specificationand direction of Engineer - in - charge for all floorsat all heights.

41 678 Providing and applying two coats of M/s Birla Wallcare putty or approved equivalent of 1.5mmthickness over plastered surface to prepare thesurface even and smooth complete.

Sq.M

42 678 Painting internal plastered surfaces with two ormore coats of super acrylic emulsion paint ofapproved brand and colour (Berger or Asian orequivalent) to give an even shade with requiredfinish over a caoat of water thinnable cementprimer including cleaning the surfaces, filling thecrevices with approve dfiller, scaffolding, curing,etc., complete all as per specifications.

Sq.M

Page 19 of 20

Package-II Part-I Civil Works

Construction of Security Office Building

SL. NO.

QUANTITY DESCRIPTION OF ITEM UNIT RATE (In Figure & In Words) AMOUNT

43 397 Painting external plastered surfaces with two ormore coats of 100% acrylic exterior emulsion paintof approved make and colour (weather coat ofBerger or apcolite apex of Asian or equivalent)having protection against fungal, growth, flaking,fading, alkali and UV degradation and to give aneven shade with required finish including cleaningthe surfaces, filling the crevices with approvedfiller, scaffolding, curing, etc., complete all as perspecifications at all heights.

Sq.M

44 15 Painting steel work with TWO or more coats ofSYNTHETIC ENAMEL PAINT of Ist quality andapproved colour to give an even shade over a coatof red oxide zinc chromate primer includingcleaning the surfaces, applying a coat of approvedputty on whole surface and rubbing the surface toachive desired smooth surface, scaffolding, etc.,complete all as per specifications. (Rate to includecost of zinc chromate primer, putty also).

Sq.M

TOTAL

Page 20 of 20

![[XLS] · Web viewSummary LIFT Fire Fighting Summary-FIRE FIGHTING BOQ_PLUMBING SUMMARY PLUMBING BOQ PART E - SUBSTATION BOQ PART D- LV BOQ PART C- DG BOQ PART B-COMMON BOQ PART A-FLAT-108](https://static.fdocuments.us/doc/165x107/5b0da56a7f8b9a2f788e0961/xls-viewsummary-lift-fire-fighting-summary-fire-fighting-boqplumbing-summary.jpg)