Gna training report

-

Upload

pradeep-adhikari -

Category

Documents

-

view

719 -

download

21

Transcript of Gna training report

ACKNOWLEDGEMENT

It is may proud to have conducted in GURU NANAK AUTO UDHYOG LIMITED, BUNDALA (JALANDHAR). A moderate industry for the manufacturing of auto parts and spares. This training is as per fulfillment of the requirement for the award of DEGREE (MECHANICAL ENGINEERING) of PUNJAB TECHNICAL UNIVERSITY. It is the industry engaged in typical mechanical machinery used for the production which provides support of the other mechanical industrial units and to the automobile industry in particular.

I found no words to express my deep sense of gratitude to the manager of H.R. DEPARTMENT for allowing me to undergo training at G.N.A.U. I am thankful to all training officers for providing me the requisite guidance and expanding me the full facilities to have practical and performance knowledge in various mechanical fields. Last but not least I express my thanks to all the workers who directly or indirectly contribute in making training interesting.

PREFACE

A sincere attempt has been made in the report to present a simplified face of new tech. equipments used in the unit for various purposes, which were seen and practiced during the period of practical industrial training held at GNA Udyog Limited (GNA Auto parts), Bundala , Jalandhar.The pure emphasis throughout is of a practical nature. However, attempts have been made to enter into wider theoretical aspects. Scientific explanations and descriptions have, however, been included, wherever applicable.Attempts have been made to present the Introduction to the unit followed in GNA Udyog.

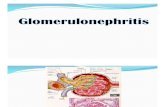

INTRODUCTION

GNA group is on a fast moving track towards growth and globalization. The company has a large customer base covering different sectors of the automotive industry with diversified product range. Along with this the company shows steady growth profile even during the time when there is demand fluctuations in the automotive sector.GNA is an Original Equipment manufacturer (OEM) of various Automobile Majors besides having a strong presence in the replacement market.GNA has been accredited with ISO 9002 and QS 9000 certifications for its quality systems, holds a reliable name in the world of automotive components. Quality Management at GNA is a timeless concept wherein, a change in customer expectations is a driving force to go beyond conformance to standards.It is situated at village BINDALA, DISTT.JALANDHAR. It was come into existence in 1946 by S.AMAR SINGH. It is spread in 27 acres. Its annual turnover is 60-70 crore. The production run in three shifts 8:00am to 4:00 pm (first shift), 4:00pm to 12:00 midnight (second shift), 12:00 midnight to 8:00 am (third shift).

GNA Udyog (propeller shaft) comes under GNA group. There are two more units also come in it i.e. GNA (axle ltd.), GNA (duraparts). It is one leading industry amongst them which involved in manufacturing of automobile component. The first component produced by them was axle. Growing from strength to strength the GNA brand image has today reached the zenith. High quality auto components, machining in international standard are produced using hi-tech state of art technology developed indigenously. GNA manufacture original equipment for supply to OEMS, spares and export market. The GNA ranges of products have a wide spectrum of application in heavy, medium and light commercial vehicles, passenger cars, jeeps, tractors and trailers. The GNA range of products can be categorized at the macro level as transmission system, hydraulic lift system, hand tool and steel forging.

COMPANY PROFILE

The existence of GNA came into being in 1946, in a small village called Bundala in District Jalandhar of Punjab. GNA has made its presence prominent not only in India but also across the world. Today, more than 6000 families are proud to be associated with this giant colossal tree that bloomed from a seedling sown 55 years ago. Founded with a modest beginning by Late Mr. Amar Singh Ji and nourished by his sons Mr. Rachhpal Singh and Mr. Gursaran Singh, with the artistic creativity that was gifted to the next generation by tradition, GNA is now boosted and taken care by the third generation Mr. Jasvinder Singh, Mr. Maninder Singh, Mr. Ranbir Singh and Mr. Gurdeep Singh. Today GNA group has created an important place for itself in Indian as well as Global Automotive Industry.

GNA group is on a fast moving track towards growth and globalization. The company has a large customer base covering different sectors of the automotive industry with a diversified product range. GNA manufactures quality automobile components which meet the highest international standards. The products include Rear Axle Shafts and U. J. Crosses, Propeller Shaft Assemblies, Hydraulic Lift Shafts, Steering components, Wheel Spanners, Brake S-cam Shafts, P. T. O. Shafts and Forgings for the automobile industry, for use in all types of light, medium and heavy vehicles.GNA sincerely believes in technology up-gradation for keeping a competitive edge. Indeed, this explains the continuous replacement of conventional manufacturing equipment with modernized transfer lines resulting in increased productivity and efficiency at low cost. GNA is core competency lies in its strong knowledge base of engineering and over 55 years of experience in manufacturing. GNA has come a long way yet journey toward excellence is never ending.Expanding the vision & keeping pace with the evolving technology GNA has successfully extended its product line to serve the rising needs of the auto component market.

AUTHORIZATION OF THE UNIT

GNA group is on a fast moving track towards growth and globalization. The company has a large customer base covering different sectors of the automotive industry with a diversified product range. GNA manufactures quality automobile components, which meet the highest international standards. The products include Rear Axle Shafts and U. J. Crosses, Propeller Shaft Assemblies, Hydraulic Lift Shafts, Steering components, Wheel Spanners, Brake S-cam Shafts, P. T. O. Shafts and Forgings for the automobile industry, for use in all types of light, medium and heavy vehicles.

Click here for a larger viewHEAD OFFICEMehtiana 146 001, Distt. Hoshiarpur Punjab (India)Phone : +91 (1882) 262273 (7 Lines)Fax : +91 (1882) 262302/262280Email : [email protected]

KENTUCKY EXPOSITION CENTRELOUISVILLE, KENTUCKY, USA.Friday, Saturday, SundaySeptember 24-25-26, 2004STAND NO:471160th IAA Show, Hanover, Germany23-30 September, 2004Hall No.H11 Stand No.F48at Fairgrounds of Deutsche Messe AG-Hanover, Germany

CUSTOMERS OF GNA UDYOG

Valued Customers Prop Shaft Assy & Components Ashok Leyland Nissan

Ashok Leyland Limited (Heavy Commercial Vehicles

Asia Motor Works

Case New Holland

Tata Motors Ltd ( Medium & Heavy Commercial Vehicles)

Swaraj Mazda Limited (Light Commercial Vehicles)

Maruti Udyog Limited ( Passenger Vans/MUVs)

Mahindra & Mahindra Limited

New Holland Fiat India Pvt. Ltd.

JCB

ITL (Tractors)

Caterpillar

Preet Tractors

Action Construction Equipments Limited (Tractor Division)

Piaggio Commercial Vehicles

Valued Customers off Highway Vehicles Mahindra & Mahindra Limited New Holland Tractors India Pvt.Limited Preet Tractors Limited Indo Farm Tractors Limited International Tractors LimitedGroup Customers John Deere

Renault

CLAAS

JCB

Graziano Transmissions

TMA, USA

Arvin Meritor

Case New Holland

Carraro

Automotive Axles Limited (Tier I Supplier)

TAFE (Tractors)

MANUFACTURING FACILITIES

Forging Heat Treatment and Induction Process Of Pivot Pins Machining Assembly Tool Room

PRODUCT RANGE

Propeller Shaft Assemblies Steering column Assemblies Intermediate Drive Shaft Assemblies Tie Rod Front Axle Assemblies & Components Pitman Arm Off Highway Products Rock Shaft P.T.O. Shaft Steering Column Assemblies JCB Pins

GROUP COMPANIES

GNA Udyog Limited

GNA Axles Limited

GNA-IMT

GNA Duraparts

WORKING OF G.N.A. UDYOG: -

1. Raw material

2. Weighed & Inspection

3. Material cutting

4. Chemistry lab

5. Forging

6. Heat treatment

7. Machining

8. Final inspection

9. Packaging

10. Dispatching

First of all the raw material is received at the security gate weighed and inspected by p.p.c. department. After that the raw material go to chemistry lab where different checks are made over material such as grain size, hardness test, chemical composition etc. after lab the raw material are cut according to specified length for proper forging of item. In the forging shop the different components are forge according to their size, shape and material. Heat treatment is done on the forged components so as to change their properties to withstand the requirement. To remove the excess material from the forged components Fettling & Shot blasting is done. The forged components go for machining and again heat treated after the final inspection is done. The components are then packed and dispatches to the customers.

DIE SHOP

Die is a cavity in which the hot piece is placed in forging & by the application of force the hot metal is given the required shape. So the die is the exact shape of the original component.Dies are of two types: -1. Rough blocker: - Blocker is the die which has the larger dimensions so that more metal flow is incorporated in first blows.2. Finisher: - Finisher is the die which has the exact dimensions including tolerances used to give the product during forging whole of metal not flows in the cavity. Some of it comes out to counter it a hollow portion is incorporated around die & this portion is called gutter.

Die is the most important tool for closed die forging. Making a die as per design specifications is most essential work in automobile industry. Die manufacturing is a completely sequential process, due to this there is a separate die manufacturing section is provided in the factory. Die shop plays an important role in the manufacturing of forging components. The parent of components i.e. dies (upper & lower) are manufactured here.

Composition of the die materials used is as under:-

(i) DIN 2713Carbon 0.55Silicon 0.30Manganese 0.66Phosphorus & sulphur 0.035Chromium 0.70Molybdenum 0.30Nickel 1.70Vanadium 0.10(ii) DIN 2714Carbon 0.56Silicon 0.30Phosphorus & sulphur 0.035Molybdenum 0.50Nickel 1.72Vanadium 0.10

Firstly the component drawing is issued by the engineering department to the die shop. The 3D model of the component is prepared by the CAD engineer in CAD software. Here I-DEAS (integrated design engineering & analysis software) software is used for 3D modeling. Then the die is developed in the CAD software after the completion of die design. The die is machined with the help of CNC machining centre (vertical). The CNC program is generated by the CAM engineer in CAM software is transferred to the machine using networks. Here unigraphics NX is used. The die is clamped in the CNC machine using fixtures. The CNC operator operates the machine after an initial parameter set up. The various programs i.e. roughing, semi finishing and finishing operations are run on die. After program completion the die is unloaded and plaster of Paris (p.o.p) is extracted from died for the inspection and given to forging inspection department. After the p.o.p inspection the die is delivered to forge shop for production.

Die making procedures:-

Block selection: - Here we have to select the size of the die block. For this we have to check the number of cavities. Approximately 20 mm of gutter is provided around a cavity of size 100 125 mm. next thing is to check the thickness of the block for general pieces 70 mm thickness & half the clearances. Block preparation: - - Automatic hand raw cutters are used to cut the blocks.- Both sides are given reference- Dove tail marking & machining is done.- No tool mark should be there.- Impression marking & marking of other location is done by choosing one machined surface as datum surface. Primary machining: - - Facing is done on lathe machine- Impression turning is done on milling machine- A hole is machined on both sides which are known as tong hole. Tong bars are put into these holes & die can be easily lifted.- Then marking is done. Marking means drawing up the marks where machining is done. It is done with the help of height gauge & surface plate.- The cavity can be made by either machining on a milling machine or by the help of an electrode on the EDM machine. Pressing & polishing: - By using a hand grinder the grinding is done. Also the tool marks are removed. Carbide cutter is used. Polishing is done with iron stone to have better surface finish & also easy withdrawal. Final inspection: - Dove-tail parallelity check Dove-tail alignment check Top surface level check Dove-tail reference check

FORGING SHOP Forging involves heating of a metal stock to a desired temperature; enable it to acquire sufficient plasticity followed by the operations like hammering, bending & piecering etc. to give it the desired shape. The forging process is very important and has indispensable position among the various manufacturing processes generally adopted in the workshops due to some reasons i.e. it refines the structures of metal, it renders the metal stronger by setting the direction of the grains & it effects considerable saving in time the labor and material as compared to the production of same by cutting from a solid stock and then shaping it.

FORGING SHOPForging department is one of the most important as every production is started from here itself. There are two types of forging sections. The categorization can be done on the base of the mechanism of the various machinery present i.e. in forging I we can say upsetting forging/closed die forging and similarly in forging II we can say it as drop forging/open die forging. These two sections consist of under mentioned machines: -

Forging I: - It consists of following machines:(i) Horizontal band saws having capacity of working upon maximum diameter jobs of 245mm, power3HP or 2.2 KW, efficiency of 82% & RPM of 1430. The diameter of job varies from 75 to 125mm.(ii) Forging furnace can be gas or oil fired and are widely used for heating the jobs for hammer forging. They prove quiet economical and facilitate better temperature and atmosphere control. Here in this shop oil fired is mostly used in which furnace oil is used as a fuel. There are brick arrangements provided in these furnaces Forging furnaces having working temperatures of 1123-1200 degree Celsius, mounted with 10hp powered motor & have capacity of work to be done of 1.25 ton/hr.(iii) Up set forging machine here are of two types and can be differentiated with the help of its working load capacity i.e. 500 ton and 800 ton. The diameters of the job that can be worked upon these machines are 115 and 150 mm respectively. The power used for running of these machines is pneumatic type i.e. air pressure.(iv) Compressors for producing air pressure for working the pneumatic machines. These are of reciprocating type. The oil used is of type AWS 100. The capacity of oil tank is of 10 liters. Working pressure is of 7kg/cm2g and hydraulic test pressure is 11.55 kg/cm2g.In forging I two types of products are being made. One is axle. The total production of the axle per day is 650 to 700. Similarly the product made is shaft & the total production per day is 200 to 300.

Forging II: -There are following machines in this shop: -(i) Forging furnaces are used to heat the raw material up to 1100 degree Celsius with the help of rough furnace oil, which is used as fuel. The feed of rough material are given in batch type feed and in continuous way. A pusher is provided to push the rectangular work pieces, which are brought, from the band saws. This pusher is operated by an electric motor. There is a pump to control the amount of oil to the furnace.(ii) Power hammers here are of two types are of two types i.e. capacity wise one is of 6.5 ton and 2.5 ton. These hammers are used to hit on to the die to form several shapes of products e.g. crown etc. These machine are working on the principle of pneumatic type i.e. power used is of air pressure. Pneumatic hammer is operated by a rotary air compressor of single stage type of two in quantity. Air is compressed to pressure of 7 bars and temperature of 120 degree F. the maximum pressure can be produced up to 20 bar. A foot operated lever controls the air supply and a required blow of the hammer is obtained. This hammer is used for forging of ring gear, drive gear, tail pinion, star gear and bevel gears etc.(iii) Power presses are kept in adjacent side of these power hammers so that they can be used for piercing and blanking operations just after hammering. These presses are of mechanical type and have capacity of 400 and 200 tones. These presses work on the crank mechanism.(iv) Normalizing furnace is used to normalize the product, which is to cover the cracks produced after hammering and other machines. The normalizing temperature is kept at the constant value of 880 to 920 degree Celsius with the help of setting of thermocouple. The type of structure obtained will depend upon thickness of the cross section and rate of cooling. Thin section will give much finer grain than that of thick section. Furnace oil is used as fuel in the normalizing furnace. There are 3 heat zones while this process. For example when material is 20MnCr5 zone I is of 880 degree C, zone II is of 900 degree C & zone III is of 920 degree C. time taken for all these is only 20 minutes. The purposes of normalizing are to produce a uniform structure, grain refinement, reduce internal stresses, improve mach inability & improve hardness, strength & other mechanical properties.(v) Short blasting machine is used for removing scaling produced due to past processes. This is done by throwing small size balls on the work material in batch way. This also produces somewhat good surface finish. The common material of metal shorts is malleable iron & cast steel.(vi) Brinell hardness tester is used to know the hardness in brinell scale before sending the product to next procedure.In forging II there are also two main products i.e. crown and bull gear. The total production per shift of these two products is 250 and 300 respectively. The total number of workers in both forging 1 and forging 2 are 100.

Forging Furnaces:-The furnaces used in the unit are oil-fired furnaces. In these furnaces, first of all from the main tank the supply of oil is provided to the furnace. A pumping unit is provided to all the furnaces used and this pumping unit consists of a heater which heats the oil to a temperature of 90-100 degrees and then the oil is supplied to the furnace. A blower is present which moves the air into the re-cubature. Its function is to heat the air to a temperature of about 250 degrees ant then move the air into the furnace. The furnace temperature which is used for forging is 1250-1300 degrees. A regulating valve is present and it is used to regulate the supply of oil and a butterfly valve is present to regulate the supply of air.Following are its two types:-1. Pusher-type furnace: - In the pusher-type a pushing system is provided which is used to push the work-pieces into the furnace. The pusher mechanism which is used is hydraulic and it is controlled by oil pressure. The temperature inside the furnace is 95-105 degrees and the pressure is 12-15 pound per square inch (psi).2. Batch-type furnace: - In the batch-type furnace, a batch of the work pieces is made & that batch of work pieces is heated at the required temperature & afterwards the work pieces are moved one by one to the forging machines.

Working procedure in forging shop: -1. Material cutting: - This is the first step which is involved in forging. After the material is received & inspected it is sent for the material cutting. In material cutting operation the material is cut in accordance with the required dimensions. The material cutting is done on band saw machines which are fully automatic in operation. After the material cutting is done the material is sent into the forging shop.2. Heating: - This is the second step which is involved. In this step the material is heated to the forging temperature in the furnace. The forging temperature is 1250-1300 degrees. The furnaces which are used are oil-fired furnaces & they can be either pusher type or batch type. After the material is heated it is sent to the forging machines. The process of heating the stock can be divided into two stages: - First stage (Preheating zone): - In this stage the temperature to which the stock is heated is 500-700 degrees.Second stage (Full heating zone): - In this stage the temperature is 1260-1300 degrees.3. Forging: - In this step the material is forged on either a drop hammer or a forging press or on the up-setter. The type of the machine which is to be used depends upon the shape & size of the component to be forged.4. Trimming: - In this operation the excess & unwanted material is removed from the forged component. After forging operation is done then the forged component is passed to the trimming press for the material removal.5. Heat treatment: - After the trimming operation is done then the forged component is ready for heat treatment. In this operation the forged components are placed in trays made of mild steel & are placed in the furnace for a suitable period of time. The heat treatment processes which are done at GNAU are normalizing, hardening & tempering. The type of the heat treatment process which is to be done depends upon the type of the steel. After heating, quenching of the heated components is done in a quenching bath for a suitable period of time. The heat treatment process is done to improve the mechanical properties of steel & to relieve the internal stresses which are set up due to forging.6. Shot-blasting: - This process is done to remove the scales & impurities which are caused during heat treatment. After the heat treatment the components are put in the shot-blasting machine & thus the scales are removed & the components are polished.7. Grinding: - This is the final step involved. In this step the unwanted material is removed from the components to provide them a smooth surface finish. The grinding process is done on the grinding machines which comprises of the grinding wheel.After the grinding process is completed the hardness checking of the components is done & afterwards these forged components are sent to the machine shop for further machining.

Measuring instruments used in forging shop: - The measuring instruments which are used in the forging shop are: -1. Vernier caliper2. Measuring scale3. Measuring tape4. External & internal calipersTemperature measurement instruments used in forging shop: -1. Thermocouple2. Optical pyrometerThe thermocouples are located at suitable heating zones inside the furnace & they measure the temperature of the heating zone & this temperature is represented on the digital temperature indicator to the operator.

HEAT-TREATMENT PROCESS

Heat treatment is defined as an operation involving heating and cooling of a metal or alloy in a solid state to obtain desirable conditions. There are many causes of the heat treatment to be done to the product to be done. It is done to cause relief of internal stresses developed during cold working processes. It is done to harden and strengthen materials, improve machine ability, change grain size, improve ductility and toughness, increase heat wear and corrosion resistance of materials & to homogenize the structure. As the name refers it is the shop in which heat treatment is given to the product to give it required hardness. This is done with the help of following mentioned processes & various machines:

(i) Carburizing: Carburizing is a method of introducing carbon into solid iron-base alloys in order to produce a hard case. Carburizing may be pack carburizing, gas carburizing and liquid carburizing. But here only gas carburizing is being done. In this process components are heated at 920 degree Celsius for four hours in an atmosphere of gases of [CO+H2+N2]. The main motive of this process is to diffuse into the outer surface of the components. It is the process by which the increasing of percentage of carbon is being done to gain good surface hardness. This can be only possible with the help of following apparatus:

1) EOT crane is used to carry the fixtures on which batches of items are carried. This crane has capacity to load 2 ton.

2) Washing bay is filled with caustic soda in which is the products which are covered with layer of oil & coolants are being washed. This process is being done for 10 to 15 minutes.

3) Carburizing furnace is the apparatus used for carburizing process. In this apparatus the temperature is maintained at 920 degree Celsius. In this after washing the crane lifts the fixture of the products and put into this apparatus. This process is carried for long period of 15 to 16 hours. The fluid used in this process is carburizing fluid 440.

4) Super quenching apparatus is the area where the fixture from the last process is put into. In this process the super quenching oil is the quenching medium. There is heat exchanger arrangement which does not allow the temperature of oil to raise more than 75 degree Celsius.

(ii) Tempering: Tempering involves heating hardening components below the lower critical temperature i.e. at 180 degree Celsius. In this process this temperature is being hold for about 2 to 2 hours and the cooling is being done open air. At this temperature a hexagonal lose packed carbide begin to form and with the rejection of carbon the crystal structure of martensite changes from tetragonal to body centered cubic characteristic of ferrite. This process is being carried with the help of following apparatus:

Tempering furnace is used for this process in which temperature is being maintained between 200 & 250 degree Celsius. In this furnace the walls inside are winded with the element which is being heated and there is a motor attached to fan to spread the hot air on the fixture on which the products are being arranged.

(iii) Scaling removing: It is being done with the help of short blasting machine. This process is used to clean the components after heat treatment. The metal slides are thrown on the surface e of the components. The material used as the short balls are malleable iron, cast iron or cast steel.

(iv) Hardness checking: It is being done with the help of Rockwell hardness testing machine. The harness is kept between 58 & 61 Rockwell hardness.

Purpose of Heat treatment: -

1) To relieve the internal stresses set-up in the material after hot or cold working in order to improve the machinability.2) To improve the mechanical properties like tensile strength, hardness, ductility, shock resistance etc.3) To modify the structure of steel.4) To increase the wear and tear resistance and to make it anticorrosive.

Furnace specifications: -

Type of furnace Oil fired Fuel used Residual Furnace Oil (RFO) Maximum loading capacity of trays - 150-200 kg at a time Capacity of hardening furnace 15 ton Maximum loading capacity of furnace 12 trays at a time Capacity of tempering furnace 15 ton Fuel consumption Approximately 100 liters per day

Measuring instruments used in heat treatment: -

(i) To check heat treatment furnace temperature, Temperature controller / Indicator thermocouple are used.(ii) To check hardness, BHN Testing Machine / Micro-measure are used.(iii) To quench oil temperature checking, temperature indicator is used.

Heat treatment of machined components: -

The first stage of the heat treatment was concerned with the heat treatment of the components after forging. Now in the second stage comes the heat treatment of the components after machining. These heat treatment processes mainly comprises of the case hardening techniques of heat treatment. The case hardening processes which are used in GNAU are: -

(i) Induction hardening: - The Induction hardening is a surface hardening process in which the surface layers of the metal are hardened but a relatively soft core is maintained. The induction hardening is achieved by passing a high frequency alternating current through the work-piece which is placed in an inductor coil. The alternating current generates a magnetic field of equal intensity but of reverse polarity. Thus, the current penetrates & the surface of the piece is hardened but a soft core remains.

(ii) Carburizing: - Carburizing is the process of saturating the surface layer of steel with carbon. The main purpose of carburizing is to obtain a hard & wear-resistant surface on machine parts by the enrichment of the surface layer with carbon. The various machined parts are directly carburized after getting machined & after carburization they are sent for final grinding. There are various techniques of carburizing like pack carburizing, gas carburizing & liquid carburizing. At GNAU gas carburizing in the electrical carburizing furnace is done.

Heat treatment equipments: -

1) Induction hardening machine (medium frequency)2) Carburizing furnace (electrical)3) Tempering furnace (electrical)4) Magnetic particle tester (MPT)5) Hardness Testing machine6) Grinding machine7) Gas welding machine

Procedure for Induction hardening: -

(i) Machining After forging the components are sent to the machine shop for the subsequent machining which is to be done & after machining the components are ready for the case hardening.

(ii) Induction hardening After the subsequent machining is done in the machine shop the components are ready to be induction hardened & the induction hardening is done on the induction hardening machines which are of medium & low frequency. The main tooling of these machines is the induction coil.

(iii) Hardness tests After the Induction hardening is completed the hardness testing of the hardened pieces is done. The hardness tester is used for testing the hardness.

(iv) Checking case hardness After hardness testing is done the checking of the case hardness of the components is done to find the depth of the hardened layer. The micro-measure is used for checking the case hardness.

(v) Magnetic particle testing (MPT) In this step the components are checked for any cracks which might have been developed during the induction hardening. First of all the components are sprayed with kerosene oil & then they are viewed under the ultrasonic light for finding any crack. If any crack might be present it would be illuminated with green light.

(vi) Tempering Tempering is done to remove the brittleness which might have been developed during heat treatment & thus it restores the ductility of the hardened component. The tempering is done in the tempering furnace which is electrical in its operation.

(vii) Grinding Grinding is the final step which is involved. In this step any unwanted material which is present at the edges is removed & a smooth finish is provided.

Procedure for carburizing: -

1) Carburizing After the machining of the components is done then they are sent for carburization. The carburizing is done in the carburizing furnace which is electrical in operation. The gas carburizing is done in which the work-pieces are placed in a medium of oxygen & a carbon containing gas & at high temperature the oxygen decomposes the carbon present in the other gas to evolve free carbon which then enters the surface layers of the components. Thermocouples are used for the temperature indication during the carburizing process.

2) Quenching After the carburization is done the components are quenched inside a quenching tank which can be either a water quenching or an oil quenching tank.

3) Hardness & case-depth checking After the quenching process is complete the hardness & the case depth checking of the components is done by using a hardness tester & a micro-measure.

4) Tempering In this step the tempering of the case hardened components is done to remove the brittleness. The tempering is done the tempering furnace.

5) Grinding This is the final step involved in which the unwanted material is removed from the edges of the components on the grinding machine.

The heat treatment process does not involve any chemical reaction but involves time-temperature cycle. It is very important process in the fabrication and manufacturing processes. Heat treatment process is of following types:-

Normalizing Hardening Tempering 100% hardness test Shot blasting Carburization Grinding

HEAT TREATMENT PLANT

After the process of forging the items enter heat treatment shop to impart some more mechanical properties. In the heat treatment shop the following processes are carried out on the items:-

1. First the process of Normalizing is followed. It is a process of heating the metal at 860C, and keeping the metal at that 860C, for a period of two hours in oil fired furnace and then allows cooling at the room temperature.

2. Then follows the process of Hardening , after the process of normalizing the metals are again heated to 860C in the electric furnace and then keeping the metal at that constant temperature for two hours and then the metal is directly quenched in the water or oil depending on the grade of metals used.

3. Then follows the process of Tempering. After the process of hardening the process of tempering is carried out. It is the process of heating the metal to 500C-600C either in oil or furnace and keeping the material at that temperature for two hours and then allowing the material to cool at that temperature.4. After tempering 100% Hardness test is done in Brinells Hardness Tester. Here we see the surface hardness of an item according to brinells hardness number prescribed or desired for the different items by customers.

5. Then the process of short blasting is done to give the surface if the items a smooth and a good finishing as well as remove all scales from the surface of the items.

The surface hardening of items like MARUTI GYPSY and TATA 1312 is done by the process of Carburization. It is a process of impinging the liquid gas to a desired depth in the surface of the metal to get a uniform surface hardness. This carburization is carried out in a gas furnace at a temperature of 920C, and quenched in water or oil depending on the grade of material used. The items like intermediate steering column, front and rear teeth of the propeller shafts, surface hardening is done, by the process of induction coil. Induction Hardening is done, where the surface hardness of an item vary from its one end to the other end. By induction hardening we can import different surface hardness in a metal by varying the resistance of the evil. The items are set in the induction hardening raises the temperature to 920C to 1000C. And the items are simultaneously cooled by layer of water in the form of jet. The resistance moves throughout the items giving the desired surface hardness of that of item.

INDUCTION MACHINE: - Initially the receivers receives the A.C supply at 440V & 50HZ and rectify it into D.C. which is sent to a invertors circuit with SCR switches with preset firing timing which converts the D.C supply again into A.C supply at medium frequency i.e. 6.6khz. The output is supplied to a transformer circuit in which job act as a secondary coil and output from invertors circuit is fed to primary coil. Tremendous heat is produced in the job due to:- Hysteresis losses Eddy current losses

This heat can be controlled according to the required case depth of job at various cross-sections for e.g. in case of intermediate shaft. Quenching of the job is done simultaneously after heating the job to 1100C (approx) by spraying cold water at 45 angle on the surface of the job. After induction hardening of intermediate steering column, no process of shot blasting is required, but directly sent for hardness test. Where also sample for hardness test is done.

MAGNETIC PARTICLE TEST: -

The magnetic particle test is carried out to check whether there are any cracks in the metal. Work piece is set in the M.P.T machine where it gets magnetized and then it is sprayed with iron cased fluid. Then the sample is inspected in ultra-violet rays to see whether there are any cracks in metal.

METALLURGICAL LAB

This labs main purpose is of do inspections of raw materials do acceptance or rejection of the material. This also helps to now various contents of material in the made specimen after forging processes. So therefore this department is an essential part of the industry. This lab performs the following functions:

(i) Macro Etch test in which HCl is being used to clean structure of given metal.

(ii) Jominy hardenabily test is performed in which we do heating and then end quenching and then check the hardness of the specimen.

(iii) Step down test is the test in which magnaflux on step down sample is being done.

(iv) Cracks detection is the test in which magnaflux powder and kerosene mixture is used to clean the surface and the checking of cracks is done in microscope.

(v) Grain size checking test is a test in which the grain size is being checked with the help of microscope.

(vi) Microstructure checkup up is being done after normalizing, tempering, hardening, carburizing etc.The main frequently performed work in this lab is estimation of percentage of carbon in the specimen in between the production processes. In this the chips of the material is being produced using the drilling machine. Then their chips are heated in the furnace with cupric oxide (CuO) in presence of dry oxygen free from carbon dioxide. The reaction took place is as below:C + 2CuO = CO2 + 2CuOther gases and carbon dioxide are absorbed in U tubes containing anhydrous (CaCl2) and solution of (KOH) respectively. The volumes of containers are noted before and after the combustion. These volumes are compared with the charts and thus percentage of carbon is estimated.

Similarly there are some equipments and apparatus required for performing various tests which are mentioned as in following:

Treatment or experimental zone:

(i) Combustion table furnace(ii) Control unit for carbon apparatus {used to know about carbon content and working temperature kept is 1200 degree Celsius}(iii) Strohlein apparatus {used to know carbon content in steel}(iv) Weight balancing machine(v) Barometer {used to know the atmospheric pressure}(vi) Volumetric section {used to check % of Mn, Cr, Ni, Cu, molebedinum, sulphur, phosphorus &vanadium}(vii) Fume chamber(viii) Distillation plant(ix) Microscope(x) Drilling machine(xi) Phosphating tank(xii) Surface grinder(xiii) Muffle furnace{temperature ranges from 0 to 1200 degree Celsius}(xiv) Jominy apparatus for quenching test

Sample preparation zone: -

(i) Polishing machine(ii) Belt grinder(iii) Abrasive machine {used for sample cutting}(iv) Muffle furnace {used for tempering, normalizing etc.}(v) Quenching tank

PRODUCT PLANNING CONTROL {PPC}PPC includes the investigation, co-ordination and it ensures timely production of products through efficient and optimum use of facilities like man, machine, and material evaluation of manufacturing capabilities and requirements and money. PPCs function serves as the brain of the organization. Its objective is to provide a physical system together with a set of operational guidelines to efficiently convert materials, human skills and other inputs into finished products. The highest efficiency in production is obtained by manufacturing the required quality, at the required time by the best and cheapest method. Management employs production planning and control {PPC} to coordinate all manufacturing activities.Products are manufactured by the transformation of raw materials. Planning looks ahead, anticipates possible difficulties and decide that in advance as how to production and how it can be carried out in best way. A production planning control system has main function to perform some before arrival of raw material and tools and other while the raw material process undergoes processing. The main function of this section is to plan about production of the product. This includes many things such as raw material ordering, processing time management etc. This department calculates the total production time of each product and thinks it advance process working period. The main motive of this department is to reduce the inventory of raw material. So therefore the planning is done such that the total amount of steel kept in unit is under control. Following mentioned are step by step calculations which are planned for raw material planning by PPC department:1) Number of components in 1) Cutting section2) Forging3) Forging vendor department4) Vendor5) Machine shop2) Total3) Target of the month (say February)4) Steel stock5) Pieces that can be made from stock6) Due steel7) Pieces that can be made from the due steel8) Total9) Balance for next month(say march)10) Weight of piece11) Net steel required

From above all steps we can see that the main motive of PPC department in raw material planning is that overhaul process will start 2 months before the need so that forging takes place in 1st month and rest work in last month. Thus by all this planning the department decides the need of net steel as raw material.Objectives of PPC:1. To maintain adequate but not excessive stocks of raw materials, work in process and of finished goods to meet production requirements and delivery schedules.2. To coordinate the production activities of different departments.3. To ensure effective utilization of production facilities.4. To prepare production schedules advertisements to meet delivery schedules.5. To operate the plant at optimum level of efficiency.6. To ensure production of right product in right quality at the right time.Importance of PPC:1. PPC acts as factorys nervous system as it regulates all plant operations just as nervous system regulates muscular movements.2. PPC acts as an effective instrument for cost control.3. PPC is helpful in accelerating industrial productivity.4. PPC rationalizes plant operations.5. PPC benefits the society.Functions of PPC: Following are the main functions of PPC:-1. Planning: It is necessary to plan things properly for getting best results. Similarly for production planning in advance, it is very necessary that how planning should be done and controlled. It is the department which decides about each element of the job, what should be done, where, how & when?Functions of Planning: To investigate about the complete details and requirements of the product to be manufactured. Predetermination of future achievements. Planning about quality and quantity of material. Planning the design of the product to be manufactured. Planning about the sequence of the operations. Planning about interval transportation.

2. Routing: Routing may be defined as the selection of path, which each part of the product will follow being transferred from raw material to finished products. Path of the product will also give sequence of the operations to be adopted.In other words routing means determination of most advantageous path to be followed from department to department and machine to machine till raw material gets its final shape.Routing in industry depends upon the nature and the type of industry: Continuous industry As such these industries are also automatic. Therefore the problem of routing in these industries is very simple. Once the route is decided in the beginning, generally no further control over the route is needed. Assembly industry Such industries require various components to be assembled at a particular time therefore it is necessary that no component should fail to reach at proper time and proper place in the required quantity otherwise whole of production line will be upheld resulting in wastage of time and production delay.(v) Scheduling: - Scheduling determines the program for the operations. In scheduling, order of sequence of each operation and their starting time and finishing time is decided so that the required materials, machines may be kept ready as schedule. Thus, it may be defined as a fixation of time and the date for each operation as well as determines the sequence of operations to be followed. This program is prepared by the planning department and assigns things for various operations.Types of schedules:- Master schedule It shows the dates on which important production items are to be completed. It is a monthly or a weekly break of the production requirements of each product. Shop schedule After preparing master schedule, shop schedules are prepared. It assigns a definite period of time to a particular shop for manufacturing products in the required quantity.(vi) Dispatching: - It is concerned with starting the processes. It gives necessary authority to start a particular work, which has already been planned under routing and scheduling.

Functions of dispatching;- The materials are removed from stores to machines. To distribute machine loading and schedule charts, route sheets and other necessary instructions and forms. To issue inspection orders clearly stating the type of inspection required at various stages. To order tool sections for issuing proper tools, jigs and fixtures and other essential articles.(vii) Follow-up:- After dispatching production orders to various shops, it is necessary to regulate the process of job through various processes. For this purpose follow-up section is formed.Functions of follow-up:- It assures that material should reach the shop in required time so that work should progress in a smooth way. It observes that particular product is passing through all its operations from raw material to its final shape as per schedule.We can divide PPC department in following mentioned 3 phases:-I. Planning phase: Forecasting : It includes type of estimation, quality and quality of future work Order writing: It provides authority to one or more persons to undertake a particular job. Product design: It is done for collection of information regarding specifications bill of material and drawings. Process planning: It is to find out the most economical process of doing the work and deciding how and where the work will be done. Tool control: It determines the requirements and control of the tool used in manufacturing processes. Material control: It determines the requirements and control of the material for the production of the product. Loading: It is the assignment of the work to manpower, machinery etc. Scheduling: It is time phase of loading and determines when and in what sequences the work will be carried out.II. Action phase: Dispatching: It is the transition from planning to action phase. In this workers are ordered to start work.III. Control phase: The control of production is necessary to be sure that the production schedules are being met and job will be delivered as per the predefined plans, a production control group. Receives work progress report Compare them with scheduled plans Removes causes of delays in production Modifies the schedules or plant capacities Expedites the workAdvantages of PPC:- Better service to customer in promised delivery dates. Fewer risk orders in plant and less overtime. Lower inventory work in progress. Less finished stock required to give the same service to customer. Better control of raw material. More effective use of equipment.PPC department acts as a bridge between the production section and the management. It gets manufacturing order from marketing department, raw material and other equipments from purchase department, specifications from engineer department and then makes plan accordingly. The PPC department gets the manufacturing order 3 months before the product issuing date because it has to make plannings for production and gets material for 20 days before start of production. 10% extra material is supplied to the production section because some pieces may be rejected while inspection. If the work is more or the machines are not free due to some other work then work has to be given to vendors. If there is any problem comes whether in small or large way the PPC department has to answer for it. So therefore the perfect planning is to be made so that there is negligible amount of mistakes.

MACHINE SHOP-1

Following table show the sequence of processes of manufacturing of different components in Machine Shop-1: -

MACHINE SHOP-1

ROCK SHAFT (M&M)FRONT TEETH (TATA)REAR TEETH (TATA)INTERMEDIATE SHAFT (SWIFT)

Receipt Inspection Hobbing (38 splines) Milling Key Way (3 Place) Hobbing (34 Splines) Dimple Hole Drilling Induction Hardening Magnetic Particle Test Tempering Power Brushing Straightening Final Inspection Receipt Inspection Hobbing Threading Bearing Dia. Grinding Drilling Countering Tapping Final Inspection Receipt Inspection S.O.D. Grinding Hobbing Induction Hardening Tempering Sand Blasting Thinnering Glide Coating Trimming Final Inspection Receipt Inspection Forging Turning Spline Rolling Grooving Induction Hardening Tempering Straightening Turning Grinding Radius Cutting Final Inspection

ROCK SHAFT

Rock Shaft Assembly

The brief descriptions of operations are as follow: -

I. HOBBING: - A machine tool operation designed mainly for cutting gear teeth or splines by means of rotating worm-like cutter (called a hob) fed into the gear blank and rotating the blank during the operation as if in mesh with it, are known as Hobbing.

HOB

HOBBING PROCESS

In this operation component is located from the centre and clamped between face drive units and to centre. The m/c used for this operation is hobbing m/c and tool used is hob cutter. The inspection is done with micrometer standard pins (D.O.P.), vernier caliper & spline ring gauge (dimensions & splines).

There are different types of hobs these are: -

1) Roller chain sprocket hobs2) Worm wheel hobs3) Spline hobs4) Chamfer hobs5) Spur and helical hobs6) Straight side spline hobs7) Involute spline hobs8) Serration hobs9) Semitopping gear hobs

II. MILLING KEY -WAY: - It is the process of removing metal by feeding the work piece against a rotating multipoint cutter. The m/c used for this operation is called milling m/c and tool used is milling cutter (multipoint). The component is clamped between centers and located from spline location, and then machine is driven for keyway milling. The inspection methods used are vernier caliper (dimensions), v-block with D.T.I. (key-way).

III. DIMPLE HOLE DRILLING: - It is a process of making a hole by forcing a rotating tool called drill. The m/c used for this operation is drilling m/c and jig used are taper shank twist drill and drilling jig respectively. The drill is aligned with the help of drilling jig ensures almost same place for each component drilling. The inspection is done with the help of plug gauge (diameter), flush pin gauge & vernier caliper (dimension), visual (deburr dimple hole), receiving gauge (angle).

IV. INDUCTION HARDENING: - This process of surface heating is based upon inductive heating in which a high frequency current is first transformed from high to low voltage and the heavy low voltage current is passed through the inductor blocks which surround the bearing journal to be harden without actually touching it. The inductor blocks induces current in the surface of the metal, it is this induced current which heats the surface to be harden. When the area in question has been thus subjected to an accurately controlled high frequency current for proper length of time, the electrical circuit is opened and simultaneously the heated surface is quenched by a spray from a water jacket built into the inductor block. The coolant used for this is p-11 (Polymer 5-10%).

INDUCTION HARDENING PROCESS

V. MAGNETIC PARTICLE TEST (M.P.T.): - The M.P.T. is carried out to check whether there are any cracks in the metal. Work piece is set in the M.P.T. machine where it gets magnetized and then it is sprayed with iron cased fluid. Then the sample is inspected in ultra-violet rays to see whether there are any cracks in metal.

VI. TEMPERING: - It is a process generally applied to steel to relieve the strains or residual stresses induced during the hardening process to improve toughness. In this the component is heated to temperature (170C-270C) and maintained at same temperature for 1-2 hours, then cooled in water, oil or air according to requirement. For example- Rock shaft NH-I (250C-270C, 2 hours).

VII. STRAIGHTENING: - The shaft is checked with dial indicator & then if needed press hydraulically to straighten it. This process is also called run out. The pressure is applied to only those areas which are specified by dial indicator. Machine used for this purpose is hydraulic press. Straighten adaptor is used or jigs & fixture. Inspection is done using vernier. The maximum pressure which can be applied is 4kg/m2 (max).VIII. SEAL DIAMETER GRINDING: - In order to control the metal removal and obtain better finish by multi cutting edge tool, grinding is done. The m/c used for this operation is grinder. The tool used id grinding wheel (made of abrasive particle) and diamond dresser carat (0.5) is used to make a wheel true. The component is located between centers and then drive from spline with dog carrier, ground seal diameter one side, then other side. The inspection is done with the help of carbide snap gauge (diameter), also grinding wheel is dressed after every 20 pieces. After this, seal diameter grinding (final) is done. The m/c & tool used are same as in case of rough grinding. Surface roughness tester is used to check the surface roughness of component.

IX. DRILL END HOLE: - In this operation, work piece is located from v-block and clamped from keyway. Machine is driven for drilling one side then other side. The m/c used is drilling machine and the tool & jig used are taper shank twist drill & drilling jig respectively. The inspection is done with the help of plug gauge (diameter), vernier caliper (dimension).

X. DRILL CORE HOLE: - In this operation, component is located from splines and clamped from outer diameter and machine is driven for core drilling one side then for other side. The tool used is core drill & m/c used is called drilling m/c. The inspection is done with the help of vernier caliper (diameter), flush plug gauge (dimension).

XI. COUNTER SINKING: - As we know it is the operation of a cone-shaped enlargement of the end of a hole. Machine used for this operation is bench drill. The tool used for this operation is counter drill. The component is located from the splines mandrel in fixture. Inspection is done with vernier (diameter & dimension).

XII. TAPPING: - It is the process of making or cutting internal thread of small diameter using a multi point cutting tool called tap. Tap required is held on a special fixture. The machine used is drilling machine with tapping attachment. Tool used is tap. The tool material is high speed steel. Inspection is done with the help of thread plug gauge (threads), height gauge (dimension), also the not go portion of thread plug gauge should enter only up to one complete revolution of thread.

XIII. TAPER GRINDING: - The work piece is located between centers hen drive from splines with dog carrier, ground the taper & maintained dimension. The m/c used is grinder. Tool used are abrasive wheel and diamond dressed (0.5 carat) inspection is done with dial type inspection fixture (dimension), bevel protractor (angle). Also wheel should be dressed after every 50 pieces.

INTERMEDIATE SHAFT

MACHINE SHOP-2

In this shop, propeller shaft and steering components are manufactured. Propeller shaft consist of:-

For rear drivea) Steel tube (hollow)b) Cross holder (2 nos)c) Sleeve yoked) Rear teethe) Half yokef) Cross (2 nos)g) Cups (8 nos)h) Lock (2 nos) i) Nut & bolt

For front drive:-a) Bracketb) Bearing(2 nos)c) Front teethd) Nute) Couplingf) Crossg) Cups (4 nos)h) Lock (4 nos)i) Cross holderj) Steel tube (hollow)

STEERING COLUMN

There are several operations what are performed on different components. They are as follow:-

1) BROACHING: - It is the method of removing metal by a tool that has successively higher cutting edges in a fixed path. The component (sleeve yoke) is located from outer diameter, rest from the face and forks are aligned properly on a vertical broaching m/c table. The tool used for operation is a broach which made of hard steel or brass. The inspection methods used for the operation are spline plug and gauges. (Go & no go).

2) COPY TURNING: - In this operation we remove the rough layer of the material, which is produced during forging operation on the particular component. The process is called copy turning because it copies a master profile. Also in the operation single point cutting tool is used and m/c used for operation is called copy turning m/c. The work piece is located from splines with spline mandrel and clamped between centers of m/c. The inspection method for this operation are veriner-caliper (diameter & dimension), radius gauge (to check radius), bevel protractor (to check chamfer).

3) U-DRILLING: - In this operation, forks of sleeve yoke is drilled from both sides by two drills simultaneously. The sleeve yoke is located from the outer diameter and clamed from the top. The m/c used for this operation is called u-drilling m/c. The tool used for this is short hole drill. The inspection is done by vernier caliper (diameter), height gauge (dimension).

CROSS HOLDER

4) FINE BORING & GROOVING: - In this operation, boring and grooving operations are done on the component .The m/c used for this operation is called fine boring & grooving M/C. The tool used are boring bar and grooving insert with grooving tool holder. The components is located from outer diameter and clamped from the top. The inspection methods used are dial bore gauge with setting ring (diameter of bore), dial gauge (diameter), groove caliper & height gauge (dimension).

5) TOOL END GROOVING: - Some component require turning of groove or neck in the order to provide adequate clearance for mating piece. The m/c used for operation is lathe m/c, the components is located from the splines with the help of splines mandrel & clamped between centers of m/c. The inspection is done with snap gauge (diameter), vernier caliper (dimension), and radius gauge (radius).

6) DRILLING: - It is process of making hole or enlarging a hole in an object by forcing a rotating tool called drill. The bench drilling m/c is used for this operation the drill used in this operation is taper shank drill. The component is located from splines with the help of mandrel in fixture. The inspection is done with the vernier (diameter), height gauge (dimension).

7) COUNTER SINKING: - As we know it is the operation of a cone-shaped enlargement of the end of a hole. M/c used for this operation is bench drill. The tool used for this operation is counter drill. The component is located from the splines mandrel in fixture. Inspection is done with vernier (diameter & dimension).

8) TAPPING: - It is the operation of forming internal threads by means of a tool called tap. Machine used for this operation is tapping m/c. The work piece is located from the splines with mandrel. Inspection is done by thread plug gauge (thread), height gauge (dimension).

9) ROLLER BURNISHING: - In this operation, work piece is located from spigot diameter. The m/c used for this operation is bench drill. Tool used is burnishing tool. Inspection is done with help of dial gauge with setting ring (diameter).

10) MULTI-DRILLING: - This operation is used with a purpose of drilling several holes simultaneously. Machine used in this operation is drilling machine (multi-spindle). The component is located from spigot diameter and bore is aligned with mandrel and clamped from flange face in drilling jig. Tool used is taper shank drill. The diameter of component is checked with the help of vernier caliper & pitch circle diameter (P.C.D.) with receiving gauge.

11) SPOT FACING: - After drilling, spot facing is done. This operation is carried out for making or creating a seat for the grease nipple. Spot facing gives a plane uniform surface on the face of drilled holes. Tool used for this operation is spot cutter and machine used is spot facing m/c. Inspection method used is vernier caliper.

12) FINE BORING & MILLING: - In this operation, component is located from spigot diameter & clamped from flange. The machined used for boring and milling is fine boring and milling m/c. The inspection is done by air gauge or dial bore gauge with setting ring (diameter) and limit gauge & height gauge (dimension).

ASSEMBLY SHOP (PROPELLER SHAFT)

The process of assembly consists of following operations: -

1) PRESSING: - The main point regarding propeller shaft is its centre. For every assembly process centre of shafts is to be taken as reference point. In pressing process centre of the shaft is taken as reference point. In pressing process half yoke is pressed on both side of the hollow shaft with the help of hydraulic press. (E.g. the length of shaft in case of Omni (Maruti) is 573mm).

DIFFERENT PROPELLER SHAFTS

2) WELDING PROCESS (MIG WELDING): -Welding is a process of joining different components together by heating them to their molten state with or without application of pressure and with or without addition of filler metal. In assembly shop to weld the pressed components with the shaft, the MIG Welding is used. Where the metal deposits uniformly in the weld. Here also centre of the shaft is taken as reference point. In the MIG Welding gas used is co2. Machine used is MIG Welding machine. Welding wire has diameter of 2mm, inspection is done with height guage. Inspection is done for proper welding in order to produce good quality products.

3) STRAIGHTENING OPERATION: - In the straightening operation the propeller shaft is checked with the help of dial indicator & then if needed pressed hydraulically to straighten it. This process is also called run out. The pressure is applied only on those areas which are specified by dial gauge. Machine used for this purpose is hydraulic press. Straighten adaptor is used jig & fixtures. The maximum pressure which can be applied is 4kg/m (max).

4) BALANCING: - Balancing is the operation of balancing the propeller shaft so that it cannot whirl at high speeds. The r.p.m to which propeller shaft is subjected is specified by the customer. For balancing, the propeller shaft is set in the rotor where it is revolved to desired revolutions per minute e.g. In case of maruti (Gypsy) propeller shafts are rotated to r.p.m. and in case of Leyland shafts and then read the data on the display of balancing machine, which is the unbalanced weight on the right and left side of the shaft respectively. In case of maruti gypsy shafts unbalanced amount up to 10gm. on either side is acceptable and in case of Leyland shaft unbalanced amount up to 35gm. on either side is acceptable. The rest unbalanced amount on the left side and right side are respectively balanced by metal chips of desired weight which are fixed on the shafts at a particular angle as identified in the display, by means of spot welding.

After the proper balancing is done the shafts are sending to painting section.

PROPELLER SHAFT ASSEMBLY

PAINTING SECTION

Painting is the process of coating the surface of the object (to be painted) with some suitable solution of metal in order to avoid the corrosion at the surface with the passage of time. Corrosion occurs due to oxidation of metal at surface of object. The coating applied thereby breaks the contact of oxygen with the surface of the metal thus avoids the corrosion. Moreover painting improves the life, look and shining of the object which are the most important factors, which a customer seeks while, searching for quality products in market.

Painting section involves the following section of operations:-

1. Automatic phosphate paint

2. Primer section

3. Paint section

4. Flash-off section

5. Paint baking oven

6. Inspection

A closed roller conveyor is installed all over the paint section. This chain conveyor step wisely passes through all the process stated above. The component to be painted is hanged on the chain conveyor through the hooks which are rotatable.

1. AUTOMATIC PHOSPHATE PLANT: - After the assembly of propeller shaft, it is send to paint section for paint but the shaft is not clean enough to undergo painting straight away. Some particles of dust and grease are sticked to it which has to be removed properly for obtaining better results after painting. Moreover the surface of the shaft should be adaptor enough to the solution of primer i.e. primer and paint should stick on the surface properly after phosphating.

AUTOMATIC PHOSPHATE PLANT

The automatic phosphating plant is further divided on the bases of different processes as following: -

i. Pre-degreasingii. Degreasingiii. Washing iv. Activationv. Phosphatingvi. Passivationvii. Washing

i. PRE-DEGREASING: - Degreasing is the process of removal of grease, oil, dust or other foreign particles from the surface of the components. Degreasing is done by spraying degreasing water on the propeller shaft which is made mixing 25-30 kg of ACLIEN 60 with 1000 its of ordinary water. The temperature during spray should be of range 55-65C. Now the mixture of degreasing water is checked every time before spray for optimum strength, suitable for spraying. This is done by titration of degreasing water against hydraulic acid(HCL) 10ml of degreasing water is put in a titration flask. 2-3 drops of indicator named as phenolphthalein is put in it which changes the colorless solution of degreasing water to pink. Now hydraulic acid or HCL is put in burette and it is put drop wise in the pink solution of flask. The color of solution changes from pink to colorless. So, initial and final Readings are noted down and subtracted. The above process is repeated 4-5 times. Concurrent reading is the desired one. This reading should be of range 22-25ml. if the reading came by titration is less than 22 then 3.5kg of Adein is added for every 1ml low value in reading in degreasing water solution to make the strength or the same appropriate to remove the grease and dust to optimum level.

ii. DEGREASING: - This is the final process of degreasing in which the steps involved in pre degreasing are repeated to get of the impurities like grease, oil, dust etc. completely.

iii. WASHING: - Washing of propeller shaft is done there after with ordinary water in washing zone of automatic phosphating plant. Some quantity of chemical might have stick to propeller shaft which is now removed by washing.

iv. ACTIVATION: - Activation is process to activate the propeller shaft for phosphating. In this process accelerator known as IETA CELL is used which produces large quantity of foam instantaneously which helps to activate phosphating process.

v. PHOSPHATING: - In this process a mixture of Meta phosphate and de-mineralized water is sprayed on the propeller shaft at 45-55C to produce very small pores of micron on the surface of shaft. The grain size layer thus produced on surface facilitates the grip of paint on the same, making the surface aesthetic. Thus phosphating enhance the strength of grip of paint over the surface of shaft giving good paint without any defect at the end.

vi. PASSIVATION: - In this the phosphating process is repeated on the component to achieve quality surface over the whole component. Thus covering the surfaces left in initial phosphating process.

vii. WASHING: - After phosphating component is washed with de-mineralized water which is free from any mineral or salt. The purpose of using de-mineralized water is due to the fact that in ordinary water, impurities like salt or minerals can react with surface of metal of shaft and can stick to it and surface can become rustic resulting in non-proper sticking of paint with the surface.

If the customer does not want to undergo automatic phosphating process on his component then the same is wiped with a sponge dipped in adeobond and de-mineralized water for removing the impurities from the surface of component. Finally the component is air-dried for further operations.

2. PRIMER SECTION: - Before painting, the component is sprayed with the primer to avoid paint consumption since primer has less cost than paint and it results in more gripping of paint. Primer is applied before painting. Primer solution is made by adding 1000ml of primer with sufficient amount of thinner which settles the viscosity of primer.

3. PAINT SECTION: - A solution of 1000ml of paint with 300ml of thinner is sprayed on primer component. The primer and paint used here are of L.C.I. Company.

PAINT CONVEYER

4. FLASH-OFF ZONE: - This zone is dust free, maintained at room temperature and is attached with exhaust fan or impeller at the top. The purpose of impeller is to evaporate the thinner inside the paint baking oven, as temperature is high and thinner can catch fire. Moreover some suitable gap is maintained between primer section, painting section and flash-off zone. The time the component travels from one section to another thinner evaporates.

5. PAINT BAKING OVEN: - The component is kept in baking oven for 45 minutes which is maintained at 82C from inside. Baking oven is a large steel chamber through which the component is made to enter from one side through conveyer and it gets out after 45 minutes of baking from the same side.

PAINT BAKING OVENBaking is the most important part of the whole painting process because it imparts many qualities to the component which are very necessary for a component in a long run. Some of them are listed below: -

Baking imparts glossiness or shining to the component, making it good looking. Since the inside of baking oven is dust proof therefore there is no chance of dust particle sticking on the surface of component. The appearance otherwise might have been dull if the whole procedure would have been done is open air for long time. Baking takes just around 45 minutes for its completion. Thus it saves lot of time as compared to ordinary process in which we keep the component straight in sunlight taking lot of time to import the desired qualities to product. Painting strength on the surface is significantly increased which increases the life of component and its working under several conditions The paint moreover gets dried-up after baking more early.

After automatic phosphating and painting the product is finally send to dispatch section, but before that product is finally inspected.

6. FINAL INSPECTION: - Though the inspection process is performed in various stages of operation, but final inspection of the whole assembly is necessary for the supplier and customer satisfaction at the final dispatch stage. Following points are kept in mind during inspection of propeller shaft:-

a) FACE ALIGHMENT: - The faces of the half yoke welded with the propeller shaft should be in alignment with each other. If found guilty the pieces found rejected and send to re-welding or it sold in scrap.

b) CIRCLIP CHECK: - Circlip is checked which is attached on bearing cup. If not properly wound on the bearing cup should be cured.

c) CHECK BALANCING: - The balancing weights attached on the propeller shaft are hit by the alight hammer for proper fixation of the weights on the shaft.

d) SLEEVE YOKE CHECKING: - Movement of sleeve yoke should be easy with no jerk. If jerk is observed, roller bearing should be checked and if necessary reinstalled.

e) PAINTING THICKNESS CHECKING: - Painting thickness is checked with micro test which should be 40 micron. Small variation in thickness is bearable.

f) PAINT CHECK: - Paint should not detach from the surface while rubbing it with nail. Moreover there should be no corrosion below the paint if found means automatic phosphating is not done properly which can lead to rejection of materials.

g) NO DUST MARK: - There should be no mark of dent on the surface of the shaft if found the same should be corrected.

In the way various other factors like shining, paint strength, resistance of paint to water and air, and scratch capability etc. are inspected and finally satisfied in every respect, the component is sent to dispatch store for dispatch.

CROSS SHOP

(a) CENTERING & FACING: - In centering and facing operation of all the four arms are done besides this centre of the four arms are also marked. The machine used for this is centering and facing M/C. Tool used are centers drill, insert. The material of the tool is tungsten carbide with coating the inspection method used for this operation is snap gauge, venire.

(b) COPY TURNING: - In this operation we remove the rough layer of the material, which is produced during forging operation on the particular component. The process is called copy turning because it copies master profile. Also in this operation single cutting tool is used. The M/C used is ACE copy turning .Tool used is made of material is carbide. Inspection method for this operation is venire.

(c) THROUGH DRILLING: - As we know that drilling is the process of making a hole through drilling in the process of making a drill over the whole length of the arms of cross. Tool used is known as drill tool. Material of tool is H.S.S. inspection method venire. Drilling grease (nipple):-in this operation a hole for the grease nipple is made. The machine used is bench drill. Tool used is drill. Material of tool is H.S.S. Inspection is done with the help of venire.

CROSS OF PROPELLER SHAFT

(d) TAPPING: - It is the process of making or cutting internal thread of small diameter using a multi point cutting tool called tap. Tap required is held on a special fixture. The machine used is drilling machine with tapping attachment. Tool used is tap. The tool material is high speed steel.

(e) SPOT FACING: - After drilling, spot facing is done. This operation is carried out for making or creating a seat for the grease nipple. Spot facing gives a plane uniform surface on the face of drilled holes. Tool used is spot face cutter. Material of cutting is H.S.S inspection method is venire caliper.

(f) LENGTH GRINDING: - As we know that grinding is the operation of removing metal in the form of minute chips by feeding the work against a rotating abrasive wheel known as grinding wheel. Grinding is done on a lathe for finishing a job, sharpening a cutter. In length grinding operation grinding on whole length of four arms is done. Tool used is grinding wheel. Method of inspection is dial gauge.

(g) FACE MILLING: - Milling is the operation of removing metal by feeding the work against a rotating cutter having multiple cutting edges. It is performed on lathe. In face milling, Milling of the face is done. In face milling, milling of the face is done. The machine used is milling M/C. Cutter used is milling cutter. The tool material is high speed steel. Inspection is done with the help of vernier calliper.

(h) ARM DIA. GRINDING (1st pass): - In this method grinding of all the arms of cross is done. IT is the rough grinding and in this more feed is given.(i) ARM DIA.GRINDING (FINAL): - In this final grinding of arms are done or finishing touch is given. The tool used is grinding wheel. The machine used is centre less grinding. Testing is dial gauge.

PARTS OF CROSS

JCB SHOP

Sequence of operations of manufacturing of JCB pin is as follow: -

1) Blank Cutting2) Facing & Centering3) Copy Turning4) Lengthening5) Chamfering6) Side Drilling7) Drilling (At End)8) Countering9) Tapping10) Induction Hardening11) Magnetic Particle Test (M.P.T.)12) Tempering13) Straightening14) Grinding15) Welding16) Blackening17) Packing

JCB PINS

Detail of different operation is given below: -

1) FACING & CENTERNING: - It is lathe operation of finishing the ends of the work, to make the ends flat & smooth and to make the piece of the required length. For this purpose, the work piece is held in a chuck. A side tool is used for facing operation. The M/C used for the operation is lathe. The inspection is done with the help of vernier calliper.2) COPY TURNING: - In the operation we remove the rough layer of the material, which is produced during forging operation on the particular component. The process is called copy turning because it copies a master profile. Also in this operation single cutting tool is used. The M/C used ACE copy twining. Tool used is inserting & tool material is carbide. Inspection method for this operation is vernier.3) CHAMFERING: - It is the operation of beveling the extreme end of a work piece. Chamfer is provided for better look. To remove burs and protect the end of the work piece from being damaged. The M/c use for operation is lathe. The work piece held between chucks and tail stock. The inspection is done with the help of vernier calliper.

4) SIDE DRILLING: - As we know the drilling is the operation of providing a circle hole, using a drill, by removing solid metal. In this the work piece is clamped in vice of drilling m/c. And drill of required diameter is inserted in drill chuck and aligned to specified position where drilling is done.

5) DRILLING: - It is the process of making hole or in enlarging a hole in an object by forcing a rotating tool called drill. The bench drilling m/c is used for this operation. The drill used in this operation is tapper shank drill. The component is located from splines with the help of mandrel in fixture. The inspection is done with vernier (diameter), height gauge (dimension).

6) COUNTER SINKING: - As we know it is the operation of a cone-shaped enlargement of the end of a hole. M/c used for this operation is bench drill. The tool used for this operation is counter drill. The component is located from the splines mandrel in fixture. Inspection is done with the help of vernier (diameter & dimension).

7) TAPPING: - It is the process of making or cutting internal thread of small diameter using a multi point cutting tool called tap. Tap required is held on a special fixture. The machine used is drilling machine with tapping attachment. Tool used is tap. The tool material is high speed steel. Inspection is done with the help of thread plug gauge (threads), height gauge (dimension), also the not go portion of thread plug gauge should enter only up to one complete revolution of thread.