2_Santiago Calatrava Outstanding Bridges and Special Structures

-

Upload

shimic32000 -

Category

Documents

-

view

229 -

download

0

Transcript of 2_Santiago Calatrava Outstanding Bridges and Special Structures

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

1/100

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

2/100

SANTIAGO CALATRAVA L.L.C.OUTSTANDING PROJECTS (2001-2010) by

MARIORANDOCAMPOSMScConstructionEngineering

PROFESSIONALEXPERIENCE:Morethan20yearsasstructuralengineerandmanager

From2001to March2010:SANTIAGOCALATRAVALLC

(Valencia)

Director of the Civil and Structural Engineering Department at theValenciaoffice.

Selectedprojects:

WorldTradeCenterTransportationHub(NewYork) Oriente Station. Initial project and renovation for high speed trains(Lisbon) OlympicSportComplexforAthens2004:OlympicStadiumRoof(304mspan),VelodromeRoof,Agora,NationsWallandMainEntreances.TurningTorsohighrisebuilding(192mhigh)(Malm) CityofArtsandScience:OperaHouse,ScienceMuseum,Umbrculo,

goraandSerreraBridge(Valencia)CableStayedBridgeWoodallRodgers(400mlength,200mspan)SamuelBeckett Bridge(95mcantilever)(Dublin)ThethreeBridgesofReggioEmilia(220mspan)(Italy)HighSpeedTrainStationofReggioEmilia(Italy)

FromMarch2010: SEEDWORKSHOP LTD (Simbiosis yEquilibrioentreEcologiayDiseoS.L.)

www.seedworkshop.com

FounderandJointDirector

GAUTEMOMScStructuralEngineering

PROFESSIONALEXPERIENCE:7yearsasstructuralengineer

From2003to2007:NTNU

(Trondheim),AadnesenAS(Oslo),

Polytec.Univ.ofPanama

(Pan.City),Price&MyersLLP

(London)

SelectedProjects:

WhitechapelArtGallery(Price&MyersLLP,London)GjerseBridge(AadnesenAS,stfold)rumfjelletPedestrianBridge(AadnesenAS,stfold)

From2007to2009:SANTIAGOCALATRAVALLC

(Valencia)

SelectedProjects:

SamuelBeckettBridge(95mcantilever)(Dublin)WorldTradeCenterTransportationHub(NewYork)

From2009:GAUTEMOAS

www.gautemo.no

SelectedProjects:SamuelBeckettBridge(95mcantilever)(Dublin)

Vollan

Pedestrian

Bridge

(Hedmark)NebyPedestrianBridge(Hedmark)BarcodeProject(Multiconsult)(Oslo)

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

3/100

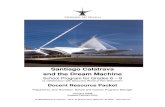

THREESIGNATUREBRIDGES.REGGIOEMILIASUMMARY

ThethreebridgesinReggioEmiliaaresingularsteel structuresdesignedbySantiagoCalatravato improvevehicularaccessand toprovideanimpressivenewentrancefromthenorth.

These infrastructures are important linksbetween the busy motorway A1, which linksMilan to Bologna, passing the city of ReggioEmilia. The three bridges have played animportantroleintheurbanregenerationofthe

city

and

were

inaugurated

in

October

2007

Themain structure is the centralbridge thanspans themotorwayand theadjacent railway.There are also twin bridges across tworoundaboutsnexttothemainbridge.

. Thisworkhasobtained the2009EuropeanSteel Design Award given by the EuropeanConventionforConstructionalSteelwork(ECCS)at the international congress in Barcelona..

.

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

4/100

THREESIGNATUREBRIDGES.REGGIOEMILIA

LOCATION

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

5/100

Client: T.A.V. SpA , Comune Reggio Emilia

General Contractor: Rodano Consortile ScarlSteel Subcontractor: Cimolai S.p.A.

Project Value: 18 Million euros

Total Steel S355 Tonnage: 4000 Tons

Total Concrete Volume poured: 11000m3

Height arch over deck 45m , Main Span 220 m

CENTRALTIEDARCHBRIDGE.MAINDATA

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

6/100

CENTRALBRIDGE.STRUCTURALDESCRIPTION

StructuralLayout:Theprimarymemberinthestructuralschemeisthecentralarch(typeBowString with220mspan

and45mhigh) subjecttodirectcompression.Thecentralbridgeisasinglespanstructurewithoneendfully fixedinthelongitudinaldirection.Theotherendhasalongitudinallyslidingsupportwithashockabsorber.Thedeckisatrapezoidalsinglecellclosedboxgirderfromwhichcantileverribsspringevery3.5mto

configureanoverall27mwidedeck.

.

220m

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

7/100

Themainarchistheprimarymemberinthestructuralschemesubjecttodirect

compression.Many

calculationsweredevelopedinordertostudythebucklingbehaviorduetotheslendernessofthearch,including2ndordernonlinearbucklinganalysisthatwasundertakenonatwostagebasis.Atfirststageadestabilizingloadwasappliedtothemodeltoinvokeanimperfectionatthecrownofthearchof270mmwithinthegeometry.Atsecondstageanonlinearbucklinganalysiswascarriedoutusingthedeformed

shapefromStage1asthestartingpointfortheanalysis.

Inthistypeofstructurethecablesrestraintheinplanebucklingofthearchviathehungdeckwiththeoutofplanebuckling

normallymorerestrictive(seefigure).

CENTRALBRIDGE.STRUCTURALDESCRIPTION.CENTRALARCH

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

8/100

CENTRALBRIDGE.ARCHSECTIONS

The

arch

consists

of

two

4

sided

trapezoidal boxes with 1.02mdistance between them. Bothboxes are intermittentlyconnected which contributessignificantly to the behavior of

thearch for lateral buckling. Theinner face of each box is a trussandnotstandardplate..the arch is easy for inspectionand maintenance during theservice life of the bridge. The

plate thicknesses of the archrangebetween30mmand65mm.

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

9/100

CENTRALBRIDGE.STRUCTURALDESCRIPTION.CENTRALARCH

Thespringingofthearchisoneofthemoreparticularpartsofthebridgeasthebigoculus

capturestheattentionoftheusers.Thispartplaysanimportantroleinthestructuralschemebecauseistheelementwhichcarriesalltheforcesfromthearchtothedeck.Thespringingismainlyaboxmadeofthickplateswithinternal

stiffeners

inordertoavoidthe

localbucklingofthewebs.

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

10/100

CENTRALBRIDGE.STRUCTURALDESCRIPTION.DECK

Thedeckisthetie

ofthestructural

schemeandassuchisthememberwhichissubjectedmainlyundertensionefforts.

Thedeckworksalsolikeabeamsupportedelasticallybyeachpairofcablesbecauseitisthememberofthebridgethatsupportsdirectlythe

liveloads.Thedeckisatrapezoidalsinglecellclosedboxgirder

fromwhichcantileverribsspringevery

3.5mtoconfigureanoverall27mwidedeck

(includinglateralparapets).Theboxgirderismadeofplatesof3060mmthickness.Therunningsurfaceforthevehiclesisasteelorthotropicdeckmadeofa14mmplatewithopenlongitudinalstiffenersof20mm

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

11/100

CENTRALBRIDGE.STRUCTURALDESCRIPTION.CABLES

The 50pairsof44mmdiametercables

ofthemain

bridgearelockedcoil

withthefixedanchoragewithin

thearchandtheactiveanchorageinthecentralboxgirder.Inthiswaythetorsional

rigidityofthe

structureispredominantlycontrolledbythetorsional

stiffnessofthecentralboxgirder.

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

12/100

CENTRALBRIDGE.STRUCTURALDESCRIPTION

SUPPORTCONDITIONS

Thecentralbridge,asatiedarch,isasinglespanstructurewithonesupportfullyfixedinthelongitudinaldirection.Theotherendhasalongitudinallyslidingsupportwitha

3500kNshockabsorber(LockUp

Device

or

LUD) providedinordertoallowthelowvelocitydisplacementsprimarilyfromtemperatureandtorestrainthelongitudinaldirectionfortheseismicevent.Inthiswaythehorizontalforcesfromtheseismicactionaredistributedatbothabutments.

Thereare4potbearingsattheabutments.

Theabutmentsaremadeofreinforcedconcrete

andtheycarrythereactionsfrom

thebridgetothegroundby36unitsof1.5m

diameterspilesateachabutment.

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

13/100

STEELFABRICATION

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

14/100

Thestructurewaserectedtakingintoaccountthatthetrafficflowingalongthemotorwaybelowshouldbemaintainedduringtheerection.

Thecontractorproposedtolaunchfromonesidethedeckwithlargesegments

ofthearchonit.

CENTRAL BRIDGE. ERECTION. LAUNCHING

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

15/100

.Thesegmentsofthearchwereliftbymeansofthreetemporarytowersprovidedwithheavyliftingsystems

CENTRAL BRIDGE. ERECTION.LIFTING ARCH SEGMENTS

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

16/100

CENTRAL BRIDGE. ERECTION.LIFTING ARCH SEGMENTS

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

17/100

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

18/100

CENTRALBRIDGE.FINISHES

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

19/100

TWINBRIDGES.STRUCTURALDESCRIPTION

Structural Layout:

The twin bridges across the roundabouts are cable stayed bridges consisting of 1400tons of

S355 steel for each one. The pylon is positioned in the transversal plane to the direction of the

bridge (Figure) and divides the deck in two symmetrical spans of 90m

.

220m

90m

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

20/100

The mainbearingelementis thecentralsteelpylon,whichisa69mhigharchandrises58movertheplatform

Thepylonispositionedinthetransversalplanetothedirectionofthebridgeanddividesthedeckintwosymmetricalspansof90m.Thetransversalsectionofthepylonisa

nonregular7sidedpolygonmadeof38mmplates.

TWINBRIDGES.STRUCTURALDESCRIPTION.CENTRALARCH

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

21/100

TWINBRIDGES.STRUCTURALDESCRIPTION.CENTRALARCH

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

22/100

TWINBRIDGES.STRUCTURALDESCRIPTION.DECK

Theplatformis12.5mwideandissupportedby25pairsofcables.Itisdividedinonelaneperdirectionforthevehiculartraffic.Theconceptof

thedeckisidenticaltothatofthecentralbridge,acentralhollowboxfromwhichtwocantileverribsspringtoformatotal14.6mwidedeck

(includinglateralparapets).Theribsarespacedlongitudinallyat3.5mcenters.

Theboxgirderismadeof15and22

mm

thick

plates

and

the

floor

for

the

vehiclesisasteelorthotropicdeckmadeofa14mmplatewithopenlongitudinalstiffenersof20mm

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

23/100

TWINBRIDGES.STRUCTURALDESCRIPTION.CABLES

The25pairsof60mmdiameter

cables

ofeachtwinbridgeare

lockedcoiltypeandtheyareanchoredfromthecenterofthe

deck

to

the

pylon

making

a

very

originalpattern

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

24/100

TWINBRIDGES.STRUCTURALDESCRIPTION

SUPPORTCONDITIONS

Bothendsofthedeckareslidingsupported.Thecentralsupport

ofthedeckatthemid

spanconsistsonarigidconnectionwiththepylon.Thissupportisthepointwhich

restrainsthedecklongitudinally.

Duetothefactthatbothendsofthebridgeareslidingsupports,oneofthecriticalloadconditionswastheunsymmetricalcaseofjustonespanloaded. Inthiscasethecablesofthenonloadedspanplaytheroleofbackstays.Inthistypologyofbridgeunderthiseventtheresistingactionisthebendingandaxialstiffnessofthedeck.

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

25/100

TWINBRIDGES.STRUCTURALDESCRIPTION

Forthetorsional

loadcases,thepotbearings(compressiononlysupports)aresuppliedwithacoupleof

bars(tensiononlysupports)placedatbothedgesofthetransversalsection.Inthiswaythetorsional

forcescanbeabsorbedbytakingadvantageoftheleverarmbetweenoneofthebarsandtheoppositepotbearing.Benefitsinthecostofthebearingsarealsoimportantbecauseupliftresistingdevicesarenotnecessaryandthepotbearingcanbestandard.Thebarsareanchoredtotheendoftheribwithaslottedpinwhichallowsthelongitudinalmovementsofthedeck.

Theabutmentsaremadeofreinforcedconcreteandtheycarrythereactionsfromthebridgetothegroundby15unitsof1.5mdiameterspilesateachabutment.Thepylonissupportedbymeansoftwopilescapsof42pilesof1.5mdiameter

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

26/100

TWINBRIDGES.ERECTION

Theerectionofthecablestayedbridgeswasmore

conventional

but

not

less

interesting.Theerectionconsistedonsupportingthedeckwithjusttwotemporary

supports.ThePylonwas

erectedin

three

large

pieces

(twostraightlegsandthetipofthearch)withoutanysupport.Thenthecableswereinstalled

andputintensioninordertoremovethetemporarysupports

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

27/100

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

28/100

TWINBRIDGES.FINISHES

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

29/100

TWINBRIDGES.FINISHES

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

30/100

SUMMARY

OpenedDecember2009

Landmark movable structure spanning themaritimegatewayto theCity, linkingtheouterorbitalroute.

LocatedeastoftheCityscentreandwithinthenewlydevelopedDocklands

area.

Forprivatecaruse,publictransport,cyclistsandpedestrians.

SAMUELBECKETTBRIDGE,DUBLIN

Client&Engineer: DublinCityCouncil

Engineerssupervision:

DublinCityCouncil&

Flint&Neill

Designer: Santiago

CalatravaIndependentChecker:

Roughan

&ODonovan

Contractor:

GrahamHollandiaJV

Projectcost: ca.60000000

Euros

ConstructionPeriod:

30months

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

31/100

GENERALDESCRIPTION

123mlongswingbalancecablestayedbridgewithaninclinedandcurvedpylon,andwithunequalspans.Thebridgerotates90

inthehorizontalplanetoallowshipstopass,withtheaxis

ofrotationapproximately28mfromthesouthquay.

Steeltonnage:Deck

1860t,Pylon373t,Cables

90t

CounterBallasttonnage:Steel+HeavyConcrete2820t

SAMUELBECKETTBRIDGE

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

32/100

STRUCTURALLAYOUTANDDESIGN

AstheSamuelBeckettBridgeisaswingbridge,twomainconditionsneededtobedesigned

for:

1. Openposition: Novehicularloadingandnosupportattheends.

2. Closedposition: Subjecttoliveloadingsandsupportattheembankments.

SAMUELBECKETTBRIDGE.DESIGN

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

33/100

STRUCTURALLAYOUTANDDESIGN

AstheSamuelBeckettBridgeisaswingbridge,twomainconditionsneededtobedesigned

for:

1. Openposition: Novehicularloadingandnosupportattheends.

2. Closedposition: Subjecttoliveloadingsandsupportattheembankments.

SAMUELBECKETTBRIDGE.DESIGN

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

34/100

STRUCTURALLAYOUTANDDESIGN

AstheSamuelBeckettBridgeisaswingbridge,twomainconditionsneededtobedesigned

for:

1. Openposition: Novehicularloadingandnosupportattheends.

2. Closedposition: Subjecttoliveloadingsandsupportattheembankments.

ThebridgewasfirstdesignedfortheOpenposition.

Balancebridge,i.e.obtainminimalnetmomentatcentralsupportbyprescribingthecounterbalance

mass.

Achieverequiredprofileofthestructureandalignmentatabutments:Byspecifyingtensionsinfore

andbackstays.

Designthestructurewithoutvehicularloading.

Secondlythebalanced

bridgewithcorrectshapewasdesignedfortheClosedposition.

Designthestructurewithliveloads.

Therefore,alltheelementsofthebridgeweredesignedaccordingtoanenvelopeofthetwoconditions.

SAMUELBECKETTBRIDGE.DESIGN

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

35/100

DECK

Themain foredeck structure, the front span, is a multicell box girder, made up from relatively thin (1020mm) steel plates stiffened internally using a combination of longitudinal bulb flats, angle sections andtrapezoidalstiffeners.Cantilevered from thismainboxsectionare the ribsandsteeldeckingwhich form thepedestrianandcycletracks.

Thebackspan,whichhousesthecounterbalance,isalsoamulticellboxgirderbut,madeupfromunstiffenedsteelplates(2060mm).Thecellsinthebackspanweregenerallyfilledwithaheavy,selfcompactingconcrete,whichalsosupportsthesteelplates,preventingthemfrombucklinglocally.

SAMUELBECKETTBRIDGE.DESIGN

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

36/100

DECK

Thecrosssectionofthedeckconsistsoftwopedestrianandcycletracksandfour lanes forcartraffic,twoofwhichcanbeadaptedtoaccommodatetramsinthefuture.

Thetopoftheboxatthefrontspanconsistsofa14mmthickplatewith12mmtrapezoidalstiffeners.The36mmmasticasphaltlayerwastakenaccountofinthefatiguecheckforthisorthotropicdeck.

The single, central, line of forestays supporting the front span

from a curved pylon tends to lead to large

torsional

forces in the deck due to unbalanced live loadings either side of the line support. Therefore, an

advantageofusingamulticellboxsectionisitsinherenttorsional

rigidity.

SAMUELBECKETTBRIDGE.DESIGN

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

37/100

PYLON

The

pylonwas

fabricatedfromshapedandweldedthicksteelplates(80120

mm),formingavariableboxsection.

The25forestaysareattachedtothecurved,inclinedandslenderpylon.Thepylon inturntransmits theappliedcablereactions,viaaxial forcesmainly,but also bending moments, to its base where it is fully connected to themain deck and the central lifting cylinder, and to its apex where it isrestrainedbythesixinclinedbackstays.

The pylon is restrained from buckling in the longitudinal direction by theforestays, but is slender in the transverse direction between the top and

bottom where it is restrained by the backstays and deck structure. Thebucklingfactor(forthefirstshapeofbuckling)wasfoundtobe3.6.

SAMUELBECKETTBRIDGE.DESIGN

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

38/100

CABLESTAYS

Thecablestaysarealllockedcoilstrands,withtwentyfive60mmdiameterstrandssupportingthefrontspanandatotalofsix145mmdiameterstrandstowardstheback.

SAMUELBECKETTBRIDGE.DESIGN

BridonLockedCoilStrands:

ForeStayDiameter:

Min.BreakingLoad:

Max.PermanentForce:

Max.WorkingLoad:

BackStayDiameter:

Min.BreakingLoad:

Max.PermanentForce:

Max.WorkingLoad:

60mm

3590kN

961kN

1292kN

145mm

20100kN

9200kN

10050kN

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

39/100

CENTRALSUPPORT

Themainsupportintheriverconsistsofeighteen1200mmdiametercastinplacepilessupportinga15x15mpilecap,3mdeepanda circularconcretepierofvaryingdiameterhousing thehydraulic turningand liftingequipment, and the horizontal and vertical bearings, which support the entire bridge while turning. Theequivalentspringstiffnessofthepierwasfoundandappliedas

circularspringsupportintheFEmodelofthe

steelsuperstructure.

SAMUELBECKETTBRIDGE.DESIGN

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

40/100

LOCKINGPIN&EXPANSIONJOINTSYSTEM

Attheendsofthebridgehydraulicallycontrolledlockingpinsattachthebridgestructuretothehousingscastintotheabutments.The lockingpinsaredesignedaspartofthe

bridgerotationmechanismandprovidethe

finalalignmentofthebridge,verticallyandhorizontally.This

isnecessaryduetotherangeofdeflectionsatthe

bridgeendssuchastemperatureeffectsandcablesag.

Anintelligenthydraulicallycontrolledexpansionjointsystemisinstalled.

SAMUELBECKETTBRIDGE

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

41/100

CENTRALSUPPORT

Siteinvestigationrevealedthepossibilityofwaterpressurein

therockexertinganupliftontheunderside

of the clay, such that it could cause the base of the cofferdam to heave. Pressure relief wells wereinstalledandthepiezometers

indicatedthatthepressureunderthebaseremainedatsafe levelsduring

construction.

Thetopsectionofthepierwascomplex in itsgeometrywiththe

outsidesurfacecurving intwoplanes.

Bespokeformworkwasdesignedandassembledandtheconcretecastinquarters.

SAMUELBECKETTBRIDGE.CONSTRUCTION

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

42/100

CENTRALCYLINDER

Thecentralcylinderhasadiameterof2.5mandhasaplatethicknessof120mm. To reduce the friction moment resistance at the bottom, a 15tonnesconeshapedcastitemwasweldedon.AtthelevelofthehorizontalbearingsIconel(austenitic

nickelchromiumbased

superalloy)waswelded

onandmachined tocreateahardand lowfriction surface.This cylindertransfers the entire weight of the bridge (5,850 tonnes) and any

out of

balancemomentwhenthebridgeisturningorinopenposition.

SAMUELBECKETTBRIDGE.CONSTRUCTION

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

43/100

ROTATIONMECHANISM

SAMUELBECKETTBRIDGE.CONSTRUCTION

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

44/100

FABRICATION,ASSEMBLYANDTRANSPORT

Thedeckwasfabricatedfirstineightsectionsandthepylonin

five.Thesizeoftheindividualelementstowas

dictatedby the facilitiesatHollandias

workshops (amountofhandlingnecessaryand theirpainting facility).

Hollandia

determinedthatthebridgedeckshouldbemadeupofeightsectionsandthatthese,oncepainted,

wouldbejoinedtogetheronapreparedassemblyareawherethecompletedunitcouldbeeasilytransferredontoaseagoingbargefortransporttoDublin.

SAMUELBECKETTBRIDGE.CONSTRUCTION

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

45/100

WELDING

A range of welding processes were used during fabrication with each method selected to suit thejointconfiguration andposition.Automatedprocesses such as submerged arcwereusedwheneverpossible butwithmanualmethods,mainly fluxcore,alsobeingusedextensively.Allbuttweldsandaproportionof fillet

weldswereexaminedusingUTmethodsforburieddefectsandMPIforsurfacebreakingdefects.

Allvisibleweldsweregroundflushduetoarchitecturalreasons.

SAMUELBECKETTBRIDGE.CONSTRUCTION

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

46/100

ASSEMBLY

SAMUELBECKETTBRIDGE.CONSTRUCTION

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

47/100

ASSEMBLY

Asthedeckdecksectionscameoutofthepaintshoptheywerepositionedatthecorrectpositionandheightat theassemblyarea,andwelded to theadjacent section,

finally formingonebridgedeck.The

pylonbasesectionwasprefabricatedandfittedtothebridgedeckandtheremainingfoursectionswereweldedtogether,liftedpositionedandtemporarilysupportedwhilstthefinalcircumferentialweldswere

laid.

SAMUELBECKETTBRIDGE.CONSTRUCTION

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

48/100

LOADOUT

Thebridgewasnoreadytobetransferredontothebarge.Trailerswaspositionedunderneaththebridgeanddroveofftheassemblyareaandontothebargeinaslowand

controlledmanner.

SAMUELBECKETTBRIDGE.CONSTRUCTION

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

49/100

SEATRANSPORT

TheContractor investigatedthesearoutefromHollandias

fabricationyard inRotterdamtoDublin.TheEast

LinkBridge inDublinwasfoundtobethe limitingwidthrestrictionandtheKonigshaven

Bridge inRotterdam

giving theheight limit.Adetailed followup investigation identified that ifsome railingsandstreet furniture

could be temporarily removed from the East Link Bridge it would be possible for the complete bridgesuperstructure,includingpylonandstays,topassthroughonasuitabletidelevel.

SAMUELBECKETTBRIDGE.CONSTRUCTION

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

50/100

SEATRANSPORT

ThesuperstructurewasshippedtoDublin inMay2009.Thejourney fromRotterdamtoDublinwascarefullymonitoredthroughoutthe628milejourney.ThistookeightdaystocompleteastheshipmentwasforcedtoshelterfromhighwindsforaperiodbeforetraversingtheIrish

Sea.

SAMUELBECKETTBRIDGE.CONSTRUCTION

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

51/100

SEATRANSPORT

Theseatransportandthesuddenappearanceofa landmarkstructurereceiveda lotofpositivepublicity inlocalandinternationalmedia.

TheSamuelBeckettBridgethroughEastLinkBridgewhenarriving

inDublin.

SAMUELBECKETTBRIDGE.CONSTRUCTION

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

52/100

C.O.G.ANDSKIDDING

Followingarrival inDublin,withthebridgestillsupportedonthebargeandnowmooredtothequaywall, itwasnecessarytoballastthebackspanusingheavyconcreteandsteelblockstoensurethecentreofgravitywaslocatedcentrallywithinthesupportzone.Thestructurewas

thenskiddedalongtheseagoingbargetoa

positionthatallowedthebackspantobesupportedonasecondbarge,henceleavingthebridgesupportareafreeabovetheriver.Thebridge liftingcylinderhadbeenpositionedwithinthemainsupportpierandwouldlaterbeweldedtothemainstructure.

SAMUELBECKETTBRIDGE.CONSTRUCTION

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

53/100

LOADTRANSFER

With thebridgenowbalancedand supportedon twobarges,athigh tide thebargesweremoved soas toposition the bridge support area directly above the pier that had been cast in the river. As the tide levelcontinued to reduce, thebarges couldbemovedaway from thebridge leaving the structurebalanced andsupportedontherimbearing.

SAMUELBECKETTBRIDGE.CONSTRUCTION

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

54/100

FIRSTROTATION/CLOSINGOFBRIDGE

Onceinposition,thefinalweldedconnectionofthebridgeliftingcylinderwasmadeandthehydraulicsystemconnectedandtemporarilyactivatedtorotatethebridgetospan

theriverforthefirsttime.

SAMUELBECKETTBRIDGE.CONSTRUCTION

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

55/100

COUNTERBALLAST

Someofthecellsarefilledwithacombinationofsteelblocksandconcrete.Inordertoachievethefinalbridgebalancetheamountofsteelballastplacedonsiteduringconstructioninthesecellswasadjustable.Thisallowsfortheadditionorremovalofmass inordertobalanceanyfuturechangesmadetothesuperimposeddeadloadsonthebridge.

The finalbalancingwascarriedoutby removing thehorizontalbearingsat thecentral support, leavingonlythreeverticalsupports. Ifanyofthetwosupportsatthebridgeendsdidordidnotnot

haveanyweighton

itself,thecounterballasthadtobeadjusteduntilbothhadapproximatelynoreaction.Duringthisprocessonecouldeasilycalculatewhat theoutofbalancemomentwasknowing reaction,measuredwith loadcellsandarmofcantilever.

SAMUELBECKETTBRIDGE.CONSTRUCTION

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

56/100

GEOMETRYCONTROL

AstheContractorreportedactualdeadloadsanddeflectionsasignificantamountofreanalysiswasrequiredtoachieveagoodbalancebetweenfinalcableforcesandbridgedeformations.Wherecable

forceswerechangedtoamendthedeformationoftheendsofthedeck,stressesinthebridgestructurechangedaccordinglyandhadtobechecked.Thebackspanofthebridgeisextremelystiff,whilstthepylonandfrontspandeformrelativelyeasily.Thisresultedinacomplexequationwithnumerousvariables,whichwasfinallysolvedbyamendinglevelsattheabutments,ballastquantitiesandcableforces.

SAMUELBECKETTBRIDGE.CONSTRUCTION

SERRERIA BRIDGE VALENCIA (2005-2008)

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

57/100

SERRERIA BRIDGE VALENCIA (2005 2008)Cablestayedbridge.Span155m.Deckwidth38m

Inclinedcurvedpylon

height125m

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

58/100

Client:CACSA(PublicentityoftheValenciaRegionalGovern)

GeneralContractor:Jointventure:FCCandPavasalSteelSubcontractor:HORTACoslada,LaCorua,SpainProjectValue:40MillioneurosProjectCompletionProgramme:3yearsTotalSteelTonnage:5055Tons

TotalConcreteVolumepoured:21160m3Heightpylon125m, MainSpan155m,totalLength350m

SERRERIA BRIDGE - VALENCIA

Erection of Pylon unit. Bolt connected and welded

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

59/100

ErectionofPylonunit.Boltconnectedandwelded

JERUSALEM BRIDGE ISRAEL

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

60/100

Period of Construction: April 2006 to August 2008 (without the track bed)

TransportthefuturelightrailsystemandpedestriansoveramajorintersectionandplazaCurveddeckplanview. Cablestayedbridge.Themastformsanangle

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

61/100

JERUSALEM BRIDGE ISRAEL

GeneralContractor:

RAMET

SteelFabricator:

KOORMetals

(CIMOLAI SPAassubcontractor)

Span=160mHeightofPylon=118m

SteelTonnage:Deck= 2720tonsFootbridge= 48tonsPylon= 1241tons

Concrete:

5500cubicmeter

VENICEFOOTBRIDGE.ITALY

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

62/100

20052008Static scheme:DepressedArch.Span81m.Rise4.8m Rise/Spanratio1/16

Weightsteelstructure408tonsSpecialprecaution:Horizontalreactionscontrolofsettlements

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

63/100

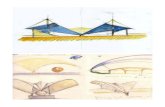

OLYMPICGAMESATHENS2004

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

64/100

OLYMPICSTADIUMANDVELODROMEROOFS

INTRODUCTION

Santiago Calatrava : Project of aesthetic

unification of OAKA area for the 2004OlympicGames

Twosingularstructures:

Olympic

Stadium

RoofVelodromeRoof

OLYMPIC STADIUM ROOF. ATHENS

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

65/100

OLYMPICSTADIUMROOF.ATHENS

Goal: Provide a new roof for the existing stadium

compatible with the renovation works..

Description:

The roof will be composed of a pair of bent leaves,which will cover a surface of some 25,000 m2. The two

halves are simmetrical and connected only at two

points.

Each half-roof is 250 m long and has a variable width

between 45 and 75 m and is suspended by cables

connected to the main arch.

The roof is covered with policarbonat pannels, instead

of the laminated glass pannels designed in the project,

replaced due to time limitations .

The bearing structure is made of steel withe painted..

Main Challenges:

Tight schedule (18 months for fabrication, erection

and finishes).

Special Structural Tipology (tied arches large span).

Analysis difficulties (non-linearity, cables, seismic

loads).

OLYMPICSTADIUMROOF.ATHENS

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

66/100

STRUCTURAL LAYOUT

4bearingpoints

NorthSide:Fullyrestrainedmovementsandrotations

South

Side:

Fully

restrained

but

longitudinaldisplacements.

Mainbearingsystem:2paralellarchestypeBowString 304mspan,80mheightandlocated141.4mapart.

Transmissionof

horizontal

loads

Externalside:diagonalelementsInternalside:diagonalsandvierendeelbeamatthreelastribs.

OLYMPICSTADIUMROOF.ATHENS

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

67/100

Main

bearing

system

:

Mainarch(3.25m) PrimarymemberinCompression.

Torsiontube(3.6m) Tieofthestructuralschemeandmainsupportfortheribsoftheroof,capableofcarryingthe

torsionaleffortsduetounbalanceloads.

STRUCTURAL DESCRIPTION

Connections Bothtubesarefullyfixedatthesupportsandlinkedbymeansof 8pairsofcables diameter 90mmand104mm.Weightbalance: Thecenterofgravityofeachhalfroofis

located at2mfromthearchplane towardsinside.

OLYMPICSTADIUMROOF.ATHENS

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

68/100

TransverseRibs:54ribsperhalfroofevery5m.Theribscarrythe loadofthepannelstothemainbearingsystem.

Otherelementsattheroofplanes:

Edgetubes.Upperandloweranchortubes.Diagonals.ProfilesRHS.PurlinsUPN.

Secondarycables:Theribsarefullyconnectedto

thetorsiontubeandsuspended by meansofapairof cableshangingfromthearch.

Roof structural elements:

STRUCTURAL DESCRIPTION

OLYMPICSTADIUMROOF.ATHENS

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

69/100

ERECTION AND STRUCTURAL IMPLICATIONS ARCH ERECTION

MAINDECISIONS

Erectionofthetwohalfroofsseparatedfromthestadium

Preassemblyandweldingongroundoflargeelements:4

piecesof70m.

Onehalfroofstarted3weeksbefore

OLYMPICSTADIUMROOF.ATHENS

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

70/100

FirstStage

Partial

Removal

of

shoring

towers

of

arches:

Lowering250mmattemporarytowers spanandremovingrestoftemporarytowers.

Thisprocesstransfers1850tononthedefinitivesupports 42%ofthefinalweight.

Benefits:1.Usingtheelementsofthecentraltowerforthesecondarytowers.

2.Reductionofforcesinotherelementsduetoarchesselfweight.

ERECTION AND STRUCTURAL IMPLICATIONS ARCH ERECTION

250mm 250mm

Desapeo Desapeo Desapeo

Reductionupto30%bending

moments transverseribs.

Reductionupto30%axialeffortat

diagonalsandlongitudinalelements.

OLYMPICSTADIUMROOF.ATHENS

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

71/100

ERECTION AND STRUCTURAL IMPLICATIONSERECTION OF HALF-ROOFS

SecondStageErectionHalfRoofs:

Stressingsecondarycables,removalofsecondarytowers,andfinallyremoving

shoringtowers underarches.

Themainstructure(archtorsiontube)is

bearingonfinalsupports9000ton.

Thelongestribshadtobereinforcedwithtemporarytrussesuntilbothroofswereconnected.

OLYMPICSTADIUMROOF.ATHENS

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

72/100

ERECTION AND STRUCTURAL IMPLICATIONS

SKIDDING OF HALF-ROOFS

Equipment:

1. Finalroofsupports equipedwithtemporarysteelbeams mountedon

skidd

shoes

bearing

on

concrete

walls.

2. SteelskiddshoesonPTFElayerslidingonstainlesssteeltracks.

3. Hidraulicjacksformovement.

4. Lateraldampersmountedatnorthside.

Temporarysteelbeamsandskiddshoes

LateraldampersConcretewallandlateralguiding

Hidraulicjacks

Temporarybeams

FinalsupportsSlidingdata:

1. Speed:1.4mm/seg

2. Mximum aceleration:7.2mm/seg2

3. Frictioncoeficient:2.6%

OLYMPICSTADIUMROOF.ATHENS

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

73/100

ERECTION AND STRUCTURAL IMPLICATIONS SKIDDING OF HALF-ROOFS

Finalpositionaftersliding:

Theconnectionjointofthetwohalfroofs wereintentionallyleftseparated160mmaserectiontolerance.Thegapisfilledwithsteelplates.

.

OLYMPICSTADIUMROOF.ATHENS

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

74/100

ERECTION AND STRUCTURAL IMPLICATIONSFINAL SUPPORTS FIXED TO FOUNDATIONS

SupportsNorthSide:Fullyrestrainedallthemovements.

SupportsSouth

Side:Fullyrestrained,butlongitudinalmovement

OLYMPICSTADIUMROOF.ATHENS

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

75/100

STRUCTURAL ANALYSIS

Mostimportant

issues:

1.Archesstability.

2.Constructionstagestakedintoaccountintheanalysis.

3.

Cablesmodelling.

4.Modellingofvariabledepthribs,incluidinglateralbuckling

analysis.

5.Nongeometric

linearity

Precambers

included

in

the

analysis.

6. Acctions:6.1Wind: Windtunneltestsforload

estimation.

6.2Seismicactions,twodifferentanalysis:Responsespectrum lineardynamicanalysisandnonlinearanalysiswithequivalentstaticloads.

OLYMPICSTADIUMROOF.ATHENS

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

76/100

LIST OF PARTICIPANTS AND MAIN DATA

PROJECT: OLYMPIC STADIUM ROOF. OAKA-ATHENS 2004

CLIENT: EYDE / GREEK MINISTRY OF CULTURE

ARQUITECTURAL AND STRUCTURAL DESIGN: SANTIAGO CALATRAVA

GENERAL CONTRACTOR: AKTOR

STEEL SUB-CONTRACTOR: CIMOLAI

CABLE SUPPLIER: TENSO-TECCI

SKIDDING EQUIPMENT: ENERPAC

ROOF PANNELS GALLOP

TOTAL SURFACE COVERED: 24000 m2

STEEL QUANTITY: 17950 ton ( 185 ton cables)

OLYMPIC VELODROME ROOF ATHENS

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

77/100

OLYMPICVELODROMEROOF.ATHENS

DESCRIPTION

The wooden ring of the existing Velodrome

had to be covered with a roof that is wood-

clad on the interior (for acoustical purposes)

and metal-clad on the exterior, with a central

area of sun-protected laminated glass.

The bearing structure is a pair of doublebowstring-tied arches made of tubular steel.

With dimensions of 145 m long by 100 m

wide and rising to a height of 45 m.

The roof will shield the athletes from

potentially disruptive winds. To improveconditions for athletes and spectators, the

interior of the Velodrome will also be

completely renovated.

OLYMPIC VELODROME ROOF ATHENS

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

78/100

Longitudinal Elevation

Plan View

OLYMPICVELODROMEROOF.ATHENS

OLYMPIC VELODROME ROOF ATHENS

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

79/100

ERECTION PROCESS - Sliding

Erection of the roof separated 140m from its final

position .

OLYMPICVELODROMEROOF.ATHENS

OLYMPICVELODROMEROOF.ATHENS

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

80/100

Main data

Steel in structure 3380 tons

Cables 80 tons

Total surface covered 11900m2

Concrete poured 700 m3

Piles lenght 720 m

Participants

Client EYDE. Greek Ministry of Culture

Arquitectural and Structural design Santiago CalatravaL.L.C.

General Contractor AKTOR. Greece

Steel Subcontractor METKA. Greece

Sliding system ALE-LASTRA. Spain

TURNINGTORSO.MALM

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

81/100

SUMMARY

TheTurningTorsoTower isahighrisebuilding forofficesand dwelling designed by Santiago Calatrava in the city ofMalm. The shape of the tower is based on a sculpturecalled Twisting Torso, by Santiago Calatrava, which isinspiredonahumanbodyinatwistingmotion.

The Tower has 55 floors and is composed by ninegeometrically equal cubes, each of one consisting of sixfloors.Thetotalheightis190m.

The floorshaveapentagonalshapewithasurfaceof420

m2.Eachlevelrotate1,62 withrespecttothefloorbelow.The total rotation between the lowerplanand the topofthebuildingis90.

The main load bearing structural element is a centralconcrete core with an internal diameter of 10,5m andvariablethicknessbetween2,5mto0,40m.

Another carachteristic element is the external steel trussthatstiffenedthetoweragainsthorizontalloads.

TURNING TORSO. MALM

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

82/100

TURNINGTORSO.MALM

LOCATION

HSBTurningTorso is located inMalm

(Sweden)at the

WesternHarbour

area,neartheseaandclosetothecity

center. The intention of the owner HSB Malm

was to

createalandmarkforthecity.

FOUNDATION

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

83/100

Main tower foundationThefoundationoftheTurningTorsoconsistsofacylindricalbox withadiameterof30mandadepthof15m.ThefoundationslabrestsonthelimestonebedrockidentifiedintheGeotechnicalSiteInvestigationandhasadepthof7minordertocounteracttheeffectsofthewaterupliftandtoguaranteetherequiredmaximumexcentricity oftheresultantofthegroundreaction forceontheslabandtominimizetherequiredreinforcementamount.

CONCRETESTRUCTURE

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

84/100

Vertical Structural Elements

CentralCore

Themain load bearing structural element for vertical

andhorizontalloadsisthecentralconcretecore,whichhas an internal diameter of 10,5m and variablethicknessbetween2,5minthebasement to0,40matthetopofthetower.

Inside this core there is the elevator and staircasessecondarycore.

ConcreteColumn

There is a continuous reinforced concrete column(aproximate dimensions 1.5x1.5 m) located at thecorneroftheplans.

CONCRETE STRUCTURE

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

85/100

CONCRETESTRUCTURE

Conical slab: 90-40 cm thickness

Deck level : Diagonals and Horizontalsanchorages

Standard Floors: 27 cm thickness

Conical slab: 90-40 cm thickness

CONCRETESTRUCTURE

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

86/100

STANDARD SLAB DECK LEVEL

StandardSlabs

Each cube is composed of 6 rc slabs. The upper 5 arestandard slabs 27 cm thick, fully fixed to the concrete coreandsupported bymeansof steelcolumnsat theperimeterthattransfertheloadtothelowerconicalslab.

Decklevels

:Diagonals

anchorage

Theupperslabofeachcubeor decklevel

iswherethediagonalsand

horizontalsareconnected.Theseslabsarethickerattheanchoragearea

STEELSTRUCTURE

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

87/100

Main Elements

STEELSTRUCTURE

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

88/100

Exterior exoskeletonThe exterior steel truss or exoskeleton providesadditionalhorizontalstiffnesstothebuilding.

It isformedbythemaincolumnorspine (900mmdiameterpipe),which isconnected to thediagonalsand horizontals elements (variable diameter from700mmto300mm)

The main spine is braced at every level to theconcretefloorsbymeansofstabilizers,andhasapin

joint at every cube in order to avoid largehyperstaticalforces.

STEELSTRUCTURE

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

89/100

STRUCTURALLOADS

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

90/100

Wind

ThewindeffectswerestudiedcarefullyattheBoundary Layer Wind Tunnel Laboratory,

Ontario, Canada (Alan G. Davenport Wind

Engineering Group).The determinationof theoverall structural loads and responses wasmade conducting forcebalance tests and

pressuretests onarigidmodel .The resonantresponse of the building due to dynamicamplification of the buffeting response at thenatural frequencies of the building weredetermined analytically through themeasurementofforcespectraandthedynamicproperties of the building.

Together with the

statistical wind climate model of wind speedand direction, predicted values of loads andresponses were determined for various returnperiods.

The studies showed also that the peakacceleration at the top levels for a 100 year

return

period

was

0,02

g,

well

below

the

allowedlimitsforresidentialbuildings.

STRUCTURALLOADS

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

91/100

Shinkrage and Creep

Due to the fact that two different materialswereused forthe vertical bearingstructures,concrete at the core and column and steel atexterior truss, the effects of shinkrage andcreep are important as they will provokeinternal forces of compression at the steelelementsandtensionattheconcreteones.

CONCRETE COLUMN:

Cube Shrinkage(m/m) Creep(m/m) Total(m/m) Equivalent Temp (C)

1 -2.910-4 -3.910-4 -6.810-4 -68

9 -2.910-4 0 -2.910-4 -29

NOTES:

1.- Linear interpolation for the intermediate cubes

2.- The assumed thermal factor of the concrete is c=10-5(C)-1

STRUCTURAL CORE:

Cube Horizontal Direction Vertical Direction

Shrink Creep Total Thermal

factor

Shrink Creep Total Thermal

factor

m/m m/m m/m c,h(C)-1 m/m m/m m/m c,v(C)

-1

1 -310-4 0 -310-4 10-5 -310-4 -1.8510-4 -4.8510-4 1.6210-5

9 -310-4 0 -310-4 10-5 -310-4 -0.210-4 -3.210-4 1.0710-5

NOTES:

1.- Linear interpolation for the intermediate cubes2.- A constant variation of temperature has been applied to the whole core = -30 C

STRUCTURALANALYSIS

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

92/100

Global Model

Thestructuralanalysisofthebuildingwasmadewithaglobalfiniteelementmodel with thesofwareSAP2000.Themodelsimulates all the concrete and steel elements as well as thefoundationsslabsandpiles.

Deck

level

Conicalslab

Standardlevel

Perimetercolumns

ShearWalls

(radialandperimetral)

STRUCTURALANALYSIS

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

93/100

Verification of Concrete elements. Reinforcement area.

Due

to

the

important

hyperstatical

forces

and

the

interaction

between

the

different

elements

(core,

cloumn,

slabs

and

shear

walls ) it isnotpossible toanalyzedeachelement isolatedbut toextract the forces from theglobalFEMmodel.After theanalysis ofthemodeltheoutputresultsoftheshellelementsofthecore,slabsandshearwalls,andforallloadcombinationswereprocessedwithapostprocessingprogram inordertoobtain thenecessary reinforcement inboth localdirectionsandbothfacesoftheelementforthepredominantcase,consideringallforcesandmomentsandthematerialfeatures.

STRUCTURALANALYSIS

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

94/100

Analys is of displacements

ThedisplacementsforserviceabilityLimitState were calculated at the top of thebuiding for the worst wind actions for a100yearreturnperiod.

The maximum drift (lateral deflection)correspondstosouthwindsandthevaluewas 360 mm . This magnitude isf/H=1/528, which is within the limits oftotalbuildingdriftforthisreturnperiod.

ERECTIONPROCESS

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

95/100

Erection Method

Afterfinishingthefoundationsstartedtheconstructionofthe concretecore.Thecorewascastinaslidingform,whichmeansthatthe form is suspended between verticalbeamsandcanslideupwards,oneflooratatime,bywayofjacks.The walls around staircase and lifts werepouredinformssuspendedunderneaththesliding form. The walls were poured inconnection with the casting of the core.Once the concretehadhardened toapre

determineddegree,thecoreformaswellasthe forms for the staircase and lift shaftscouldthenclimbupwardstothenextfloor.

Thenextstep in thepouringcyclewas toform and pour the structural slab aroundthecorebeforethecyclecouldberepeatedwith the core and lift shafts. Most of thereinforcementwasprefabricatedatshop in

order to form largesteel cages

and then

erected to its final position where can beoverlapped..

ERECTIONPROCESS

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

96/100

During thepouring of each slab thetemporary supports were kept atleast7levelsbelow.

The core, lift shafts and structuralslabs were poured with vibrated

concretewhilethetransversalbracingwalls under each cube were madewith socalled selfcompactingconcrete.Becauseofitsflowcapacity,this type of concrete does not needvibrating. This method was usedbecause the transversal walls were

made after the structural slab aboveand below them were finished,making it impossible to insertvibration rods down into theconcrete.Theformsforthefloorswererotatedapprox.1.6degrees foreach floor in

order to create the characteristictwist of the building. The time tabledictated that a new floor tier waspouredevery10thdayontheaverageformorethanayear

ERECTIONPROCESS

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

97/100

The erection of the exteriorexoskeleton started when theconstruction of the concretestructure had reached the 5th

cube and was completed fewweekslaterthantheconcrete.

Finally the faade and interiorfinisheswerecompleted.

MAINDATA

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

98/100

Quantities

Heightofbuilding: 192m.

Numberoffloorsaboveground: 55

Totalsurface: 31,900m2

Apartamentstotal surface(cubes3to9): 16,500m2

Officestotalusefulsurface(cubos1y2): 4,500m2

Concrete: 25,000m3

Reinforcementsteel: 4,400Tons.

SteelstructureExteriorexoesqueleton: 820Tons.

Faadesurface: 20,000m2

Glasssurface: 5,500m2

Elevators:3forapartaments,2foroffices.

PARTICIPANTS

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

99/100

Client HSB Malm Ek Fr

Construction Manager HSB Malm and NCC Construct ion Malm

Architecture and Structural Design Santiago Calatrava SA, Zr ich/Valencia

Interior Design Samark Arkitektur & Design AB, Malm

Geotechnical Advisor Dr. Vollenweider, Zrich

Geotechnical Investigation SWECO, Malm

Structural Checker SWECO, Stockholm

Concrete 1 (Underground concrete structure) PEAB AB

Concrete 2 (Concrete Structure above ground) NCC Construc tion AB

Faade fabrication Grupo Folcr Edificacin SA, Espaa

Steel Fabricator Emesa, Espaa

Steel Erector Promecon, Dinamarca

Elevators KONE AB

-

8/13/2019 2_Santiago Calatrava Outstanding Bridges and Special Structures

100/100