Yardlines, July 2013

-

Upload

newport-news-shipbuilding -

Category

Documents

-

view

226 -

download

8

description

Transcript of Yardlines, July 2013

Yardlines

A Publication of Newport News Shipbuilding July 2013

IN THIS ISSUE

Shipyard Warehousing is Big Business

Operating NNS’ Mighty Tugs

USS Enterprise’s Final Homecoming

Phot

o by

Ric

ky T

hom

pson

BIG E

After a historic 51-year career, the inactivated USS Enterprise was towed from Naval Station Norfolk to Newport News Shipbuilding on June 20 for defueling of the aircraft carrier’s eight reactors. Photo by Ricky Thompson

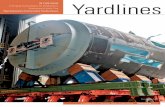

With more than a half-century of service and a life full of historic firsts, “Big E” came home to Newport News Shipbuilding on June 20 for one more first – the inactivation of a nuclear-powered aircraft carrier.

It was the late 1950s, and Newport News Shipbuilding Welder Charles Greene was one of thousands of shipbuilders helping to build the first nuclear-powered aircraft carrier in the world, USS Enterprise (CVN 65). More than 50 years later, his granddaughter Kimberly Thompson is a production planner and scheduler at the shipyard and has been making her own mark on the legendary ship since 2000. Thompson was once part of a team handling Enterprise’s maintenance and repairs, and is now on the team executing her inactivation.

“My grandfather helped to raise me, and it means a lot to me that he helped build the ship and I get to help lay her to rest. I’m really proud to be part of this legacy,” she said.

Over the next three years, members of the CVN 65 team, along with other shipbuilders, will be handling the extensive project, which includes defueling the eight reactors and preparing the ship for open-ocean tow. At its peak, more than 1,200 shipbuilders will be using their shipbuilding skills to complete the process.

Project Manager Jim Calabrese has been working at the shipyard for 25 years, and his first assignment was the refueling and complex overhaul of Enterprise.

“When you service Enterprise, it really is a thought-provoking process. Given the uniqueness of the ship, the geometry of the ship, and the complexity of the ship, it’s a technical challenge,” he said.

Engineer John Bilinski first experienced Enterprise as a sailor and has been assigned to her as a shipbuilder for 10 years. He says that challenges come with the territory. “We’re doing things nobody has done before. There’s a definite learning curve,” he said. “Even after 50 years of service and operations, she’ll still surprise you.”

Like many others who have a deeply-rooted connection with the legendary ship, Bilinksi plans to stick around.

“This ship and I go way back and, God willing, I’ll see her through until the end.” I By Jeremy Bustin

On June 6 when Minnesota was delivered to the U.S. Navy 11 months ahead of schedule, Camden West was among the thousands of shipbuilders who felt a tremendous sense of accomplishment. She had recently completed her first assignment as the chief nuclear test engineer (CTE) on Minnesota – the first female ever to hold the position on a Virginia-class submarine (VCS).

West grew up helping her dad work on his Harley-Davidson, so it’s not at all surprising to her that she ended up in a career that pays her to wear jeans, boots and a little grease under her fingernails every day.

What she didn’t realize is that she would knock down walls in the process.

West started out at Newport News Shipbuilding (NNS) 12 years ago as a mechanical test engineer. In her current position as the CTE, she had daily oversight over the mechanical, electrical and electronic systems testing on the Minnesota to ensure the testing performed met all technical and safety requirements.

West made sure the test team was properly trained and understood the technical operations associated with the system being tested, obtained the required data, and verified that the data was within the required parameters. She also worked alongside the VCS construction team to ensure the building sequence supported the required testing, and in partnership with the Navy to train them on operating temporary systems in the shipyard environment.

“Camden possesses a drive to always improve the program. That is a true testament to being a great shipbuilder,” said Gary Graham, director of engineering. “She had some skeptics in the beginning, given she was coming into a predominantly male environment, but she has made believers out of everyone. It is a true pleasure to have seen her be the first female chief test engineer at

NNS, and I have no doubt that someday, I’ll be calling her ‘Boss!’”

“It takes years of hard work that is worth every minute spent just to watch that boat sail down the river to serve and protect our country,” she said. “I am proud to send the men and women of the military to sea on the finest vessels ever built.”

West has been the first female to accomplish other engineering feats at the shipyard, but she’s especially proud of this one. The Pittsburgh native worked her fair

passes theCAMDEN WEST

TEST

Camden West, a 12-year shipyard veteran, is the first female to serve as chief nuclear test engineer on a Virginia-class submarine. She recently completed the assignment on Minnesota (SSN 783), which delivered June 6. Photo by Ricky Thompson

share of shifts and long hours, and she also credits her success to a team brimming with talent and supportive bosses along the way.

“But I’m especially proud because it means I’m knocking down walls for my daughters, Camden and Cayden,” West said. “I tell them all the time that they can be whatever they want to be.”

She tries to be a role model for her co-workers, too.

“I tell them to worry about their jobs and not what

everyone may be saying or thinking,” she said. “If you pay attention to what you’re doing and you do your job well, you will excel. I also remind them that they are no different than anyone else, so don’t expect any special treatment.” | By Christie Miller

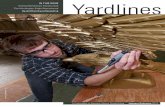

You could call them the tailors of the shipyard. The Sail Loft is filled with rolls of fabric, sewing machines, scissors and hundreds of niche tools. When things get busy, space for the highly-engaged team can quickly become hard to manage. Most of their time is spent creating vitally important containment materials that protect expensive equipment from dust or that protect workers from potentially hazardous materials. Between the USS Enterprise (CVN 65) and USS Abraham Lincoln (CVN 72), work orders are flowing in.

The Sail Loft began implementing an Engagement Action Plan earlier this year in response to the annual Gallup Engagement survey. Jason Roach, the Sail Loft’s general foreman, asked for creative ideas on how the shop could be safer and more efficient. The team came up with a long list of ideas, from reorganizing how templates are stored, to making sure that material rolls are safer to pick up and move. The team quickly engaged as they saw their opinions become realities, resulting in a cleaner, more efficient shop.

“We worked together to create this list… everyone contributed,” said Arlene Quinn, a Sail Loft craftsman and the safety task team leader who was instrumental in creating the list of ideas. “We came up with the ideas,

Sail Loft General Foreman Jason Roach (left) listened and helped make ideas presented by Arlene Quinn and Duck Manuel on how to improve the shop’s safety and efficiency a reality. Photo by John Whalen

but Jason showed us he was serious about making our ideas become reality.”

One idea was to organize the rolls of material in a way that made it safer for Sail Loft craftsmen to look through and pick up the material. Roach had the Hanger Shop create a special rack that solved the problem. Many of the ideas made simple everyday tasks safer, like adding a handle to a floor pedal so that it could be moved without bending over. Many of the ideas on the list were implemented within days of being identified.

Duck Manuel, who has worked at the shipyard for 34 years, felt a shift in the attitudes of the shop. “Everything is easier. We’re working together better. We’re communicating better, and we feel more like a family now,” said Manuel.

Roach gives all the credit back to his team. “I’m smart enough to know that they’re smarter than I am!” he said. “I have discovered that I just need to listen to their ideas.” I By Peter Stern

TAILORING

IN MOTION

According to Docking Pilot Captain Fred Burns and his crew, “Any tuggin’ day is a good day!”

Capt. Burns and his four-person crew are assigned to Huntington, one of Newport News Shipbuilding’s (NNS) three tugboats that are responsible for safely transporting NNS vessels in and out to sea and to various docking locations around the shipyard’s waterfront.

Huntington Deck Hands Glenn Alligood and Cedric Moore describe the tugboat crew as family. “Although Huntington is the largest tugboat at NNS, we still work in very close quarters, so we’ve gotten to know each other really well,” Moore said.

Alligood added, “Our crew also works closely with the tug crews aboard Captain Ambrose and Dauntless. During a move, the tug crews and riggers on land have to be in sync to successfully move a vessel to its new location – so it’s crucial that we have each other’s back at all times.”

Capt. Burns likes to think of the moves as poetry in motion. “All things must come together for the move to be successful,” he said. “The planning, the weather, the tides – everything.”

This year alone, NNS’ tugs have successfully made several large moves. “We have repositioned USS Theodore Roosevelt (CVN 71), escorted Minnesota (SSN 783) in and

Poetry

out to sea for trials, and transported USS Abraham Lincoln (CVN 72) and USS Enterprise (CVN 65) from Naval Station Norfolk to the shipyard,” said Captain Allen Sutton, NNS docking pilot. “We stay busy, to say the least.”

Aside from planning and executing large transports, tugboat crews are also responsible for conducting preventive maintenance on their tug, participating in various drills, including collaboration drills with the U.S. Coast Guard, and assisting McAllister Towing and Transportation Company Inc. with moves in the James River as needed.

The crews have offices both on the tug and on land, but

they prefer to be out on the water on their tug.

“One of the most complicated parts of our job is that there are no do-overs,” said Capt. Burns. “You only get one chance, so you have to be on your ‘A-Game’ all the time. But nothing beats looking back after a job is completed, with a cup of ‘tugboat coffee,’ and realizing all the planning and aggravation were well worth it.” I By Lauren Ward

Huntington’s tugboat crew attaches itself to Minnesota (SSN 783) in the James River prior to transporting her back to NNS following sea trials. Photo by John Whalen.

Newport News Shipbuilding likes big things.

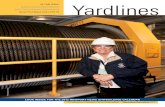

But for the shipyard’s largest footprint – its 2.1 million square feet of warehouse space and the 500 shipbuilders charged with receiving, stocking, organizing and delivering thousands of pieces and parts to more than 300 material stops on the waterfront on a daily basis – bigger is not always better.

Newport News Shipbuilding (NNS) Director of Material Distribution Terry Voltz oversees the lifeblood of the shipyard. If materials don’t flow when they are needed, nothing happens, and Voltz knows where to find every screw, bolt or piece of pipe that’s stacked in the shipyard’s more than 40 warehouses, some of which are behind the gates. Others are as far away as Suffolk.

Like much of the shipyard, schedule and budget drive movement of materials, and organization is key to the Material Logistics Department’s success.

Stacey Schrier, material handling supervisor and 16-year NNS veteran, understands organization. She is preparing the yard’s newest warehouse, the Spiegel Building, to accept everything NNS is currently storing in Suffolk. The items coming over include new materials for the Gerald R. Ford (CVN 78) aircraft carrier, and some of them are so big that modifications are being made to the building to get the items inside.

Her latest challenge: the storage of 450 cabinets that will eventually hold on-board repair parts aboard CVN 78. She points out short ones, tall ones, red and gray ones – all needing a place to stay until they can be moved to the ship.

Organization would be easy if everything came in a stackable box, she said, but when the items range from valves and hoses to televisions and workout equipment, it’s not that simple.

Schrier enjoys the challenge, which has carried over

into her personal life. “It drives my son crazy and people make fun of me. I’m one of those people who has drawers inside of drawers, and everything is color-coded.”

Color coding is just one of many ways Material Logistics organizes NNS materials inside each warehouse. NNS methods are fairly typical of other logistics operations, Voltz admits, but there is one thing that sets the shipyard apart: controlled material.

“We have to trace forward and backward any nuclear material we are handling,” he said. “It’s one of the things that make us unique.”

To do it, materials such as piping system components, fasteners and fittings are permanently etched with information needed to provide traceability to that specific part.

Etching is done by hand. It’s a precise job, and Barbara Anderson and Malcolm Campbell are the shipbuilders who do it.

On average, Campbell averages 40-50 large parts per day. He said he prefers smaller parts over the larger, more awkward ones, adding that he can whip through about 100 small parts per day.

“It doesn’t suit everybody, but it suits me,” Campbell said, taking a break from etching on a bronze valve. “I have a knack for doing this because I’ve been doing it for so long.”

Voltz agrees. The warehouse environment doesn’t suit everyone.

“The amount of work Logistics and Transportation performs daily always amazes me,” Voltz said. “The work is hard, much more diverse and complex than most people realize, and we have to do it safely each and every day.” | By Christie Miller

Material handlers Christy Carson (left) and Rodney Thornton check inventory in the surplus sales warehouse. Photo by Ricky Thompson

The Lifeblood of the Shipyard

It looks like a mountain of metal spaghetti. Metal shavings from the Machine Shop, chunks of scrap from Foundry pours, and discarded cable from facilities are all part of the recipe that creates a huge pile of scrap metal in Newport News Shipbuilding’s (NNS) scrapyard. The mountain is sorted into ferrous and non-ferrous metal by a 20-ton gantry crane equipped with a 6-ton magnet. It’s all part of a highly-efficient recycling program that takes the shipyard’s trash and turns it into treasure.

Scrap-metal recycling may seem like a small endeavor for the nation’s largest shipbuilder, but the scrapyard team hands a lot of money back to the Navy. Over the last five years, the team has processed, sorted and sold 150 million pounds of scrap metal, reeling in $36 million in sales. Though the shipyard has recycled its scrap metal for many years, higher global demand for recycled metal has changed the game. According to the National Recycling Coalition, recycling metal takes about 60 percent less energy than the mining process. The scrapyard’s clients include major players like Sims Group USA, which is part of the largest metal recycling company in the world.

Bob Pye, who manages the metals recycling program for NNS, from strategic planning of special sales, to the implementation of annual contacts with metal processors, keeps a close watch on the metals market pricing, which changes like the stock market. “Our success is tied to the metals market pricing as well as how efficiently we process the material we receive. The sorting team is the backbone of this operation,” said Pye. “They are out here – rain or snow, heat or ice – sorting scrap metal, which can be dangerous work. It’s sharp, often heavy and the scrapyard can be a busy place. You’re working around a crane with a powerful magnet that sorts materials and loads the buyer’s tractor trailers, handling skiffs and containers with forklifts, and sorting metals by hand. But I can’t tell you the last time we had an injury; it’s been several years.”

James Hogge, the scrapyard’s foreman, manages day-to-day operations. “We’re all pretty close, and many of us have been doing this for a long time,” said Hogge. “When it comes to processing scrap metal, we know what we’re doing and we do it safe.”

Another element that adds to the program’s success is the team’s commitment to properly identifying the metal they are selling, a challenge in the scrap-metal business. Several years ago, the team invested in a Niton metal analyzer (X-ray gun) that looks like a big grocery store label scanner. Point the gun at the metal, pull the trigger and a report on the metal’s chemical makeup reveals what the metal is and how to sell it.

“We don’t want to have a reputation for selling anything that’s not what we said it was,” said Hogge. “Our clients trust us, which means we are able to sign annual contracts where they buy whatever we have. Our guys are committed to that kind of excellence.” I By Peter Stern

TreasuretoFrom Trash

Newport News Shipbuilding has processed, sorted and sold 150 million pounds of scrap metal over the last five years. Photo by Ricky Thompson

Newport News Shipbuilding (NNS) won FM 99’s Second Annual Cardboard Boat Building competition on June 15, earning bragging rights to call itself “The Yard” of Hampton Roads.

To determine which Hampton Roads shipyard would win, each team had one hour to build a vessel out of cardboard and duct tape. The boats were judged on three criteria – best resemblance to a naval vessel, the least amount of duct tape on display, and the vessel that could hold the most weight for 10 seconds without sinking.

NNS’ winning entry – a replica of the dredge barge Norfolk (Hull 282) originally built by the company in 1925 – held 344 pounds, which included the 114-pound son of team member Kevin Miller.

“We put a lot more planning into it this year,” said Michael Nyberg. “Our engineering colleagues helped with

calculations to ensure we had everything right.”

In 2012, NNS won first place in two categories, but Norfolk Naval Shipyard’s 233-pound vessel won first in the weight category, giving their team five extra points to win the contest.

“Every member went above and beyond to make this endeavor a success,” said Test Engineering Technician and NNS Team Captain Stiles Bliss. “We put an awesome team together this year that embodied what our shipyard is all about.”

Other members of the winning NNS team included Mayranne Brock, Kevin Doyle, Kevin Miller, Dasha Nyberg, Melynda Roberts, Darryl Trautner, Corrie Wright, Matthew Wright, and Mike Yankanwich.

The community-wide event hosted by FM 99 and the Virginia Ship Repair Association was held in Suffolk, Va. I By Gina Chew-Holman

Newport News shipbuilders (L to R) Michael Nyberg , Corrie Wright, Mike Yankanwich, Stiles Bliss, Mayranne Brock and Kevin Doyle built a cardboard replica of the Norfolk (Hull 282) to win the FM 99 “The Yard” competition. Photo by Dar Deerfield Mook

Newport News Shipbuilding isT he Yard

Long ServiceMASTER SHIPBUILDERS

Kenny Wyatt40 years

Anson Blevins50 years

Jerry Buchanan40 years

Vance Eason40 years

Jim Allen40 years

Tom Brady45 years

Wave Dryden40 years

Kenny Hargrove45 years

Lee Jones40 years

Allen Kreicar40 years

Hjalmar Fond45 years

C.P. Jones40 years

Neal Jones40 years

Gilbert “Meko” Meekins40 years

John “Blue” Parks40 years

Charlie Smith45 years

Robert Maker45 years

Stumpy Newbern40 years

Mike Shelton40 years

Howard Smith40 years

Mike Sowder40 years

Keith Strayer40 years

Don WeIss40 years

Dan White40 years

John Teague45 years

Bill West40 years

JUNE

Long ServiceJUNE

50 YEARSAnson L. Blevins O43

45 YEARSThomas H. Brady Jr. T53John N. Cary Jr. X82James E. Everette X42Hjalmar J. Fond E63Kenny L. Hargrove X73Robert A. Maker X31Welford B. McElwee X32Charlie E. Smith Jr. O22John N. Teague Jr. X58

40 YEARSJames S. Allen Jr. E26Randy L. Batten X87Jerry T. Buchanan X89Waverly V. Dryden X36Vance S. Eason E84Lynn C. Folks X70Lee B. Jones X18Neal R. Jones K93Allen O. Kreicar X18Gilbert E. Meekins X10William T. Newbern O98John L. Parks X18 Michael A. Shelton X74Howard L. Smith X42Joseph M. Sowder E81Calvin K. Strayer X18Allen H. Thacker X11Donald W. Weiss X82William L. West X67Daniel L. White X88Kenneth R. Wyatt E26

35 YEARSDaniel O. Bochman X89

Wesley M. Copling M53George H. Cotsimopoulos X50Donald G. Curnutte Jr. AMSECSteven P. Gurvich E24 Gregory H. Harju E26Alan D. Harvey E49William E. Hilbmann IV E88Keith Jefferson O46Gary L. Morton E73Rudolph S. Powell E30John M. Schoch Jr. O62Jonathan Spielberger M53Josephine F. Stith O53William W. Trevathan X10Catherine M. Weisskopf X36Elwood A. Whitley E25

30 YEARSCarlos R. Acosta X42Jorge C. Antezana M30Reginald E. Bagley X10Alvin V. Bailey X11James H. Bailey Jr. O46Gregory L. Baize X73Milton J. Banks X32James C. Boyce Jr. X18James G. Bridges X58Sharon H. Bryant O14Gerald T. Bulles O67William P. Carr X73James A. Carroll X18Louis A. Carter X36Abel L. Cary X33David M. Cassell X88Howard A. Chamblee X88Mark R. Coast E17Jackson M. Copeland Jr. X33Donald W. Cribb E25Jesse L. Davis X36

Oscar J. Deloatch X18Keith O. Dennis X36Bernard D. Dickson X11Joseph F. Diggs X33Phillip T. Dildy Jr. X18Robert B. Eagan Jr. O39Rufus T. Edwards Jr. O53Kenneth S. Evans X11Melvin L. Everette X31George R. Foreman X33Dean W. Fyfe O53James D. Garrow X32Michael W. Gibson X82Michael D. Guzik X31William J. Handy Jr. O87Cynthia G. Hanna M30Thomas A. Hawkins E45Gregory F. Heinrich E26Robert B. Hill E51Dennis K. Holmes X31Reginald L. Holmes X69Tracy L. Howard E03William C. Howard O39Norman A. Jacobs E47Wade H. Jenkins X42David Johnson O53Marvin E. Johnson X36Tracy J. Johnson M25Antonio L. Jones X18Kevin Jones X43Larry D. Jones E81Michael H. Jones X11Ronald W. Jones X42Rickie A. Joyner X36Michael E. Justice O43David P. King E75Richard S. Knorowski E22Douglas K. Kruschke AMSECGeorge E. Landis X31

Jasper J. Lashley X18Christopher P. Lee X10Warner Lee X11Antony A. Mann O15Ronald D. March X43Leslie H. Matthews Jr. X67David A. McBride X36Charles H. McElrath Jr. X10Christopher J. Miner K70Henry L. Moody X43William E. Muhich O45Kenneth D. Parker E25Harrie A. Pearson X89Shelton L. Perkins O53Phillip A. Perry X33Richard A. Pippins X11Timothy Pope X43Timothy D. Pope M30Stanley C. Reams O67Donald K. Reid X33James T. Rodgers X43Edward O. Ross K60Jerald L. Saunders X18Willie N. Sears X73Mark A. Shaffer O15Morris A. Shaw X31Robert L. Sheppard Jr. X18George M. Siegel O53Stephen E. Speight O19Patricia S. Spradlin E68James F. Stamper X31Douglas Stephenson X36Gary L. Sullivan X42Ricky R. Turner X36Raymond S. West O39Kelvin L. White X42Robert F. Whiteman Jr. E25Alan R. Wiley E84John R. Winsley E45

James Wright Jr. X42

25 YEARSMelanie P. Alvey E24James N. Anderson Sr. E85William I. Beaver E85Garry A. Bonds X11John H. Bowser Jr. E85Jordan N. Brown Jr. X33Graeme S. Buchwald E17Todd A. Cannon E83Donald R. Carter O14Roxane U. Carter X11Sergio E. Ceballos E49Daniel W. Cerny E88Kenneth L. Chapman E27Michael J. Conway E73Garreth J. Cooke E21Terry L. Cooley X18Matthew Coyle E85Mark R. Crowley E71Charles J. Dalrymple O19David D. Delvecchio T56William G. Doucette X83Simon R. Esperanza E71Jackie R. Everett E82Kevin S. Fallon O76Joel R. Griffen E46Russell R. Hollingsworth X57Kenneth D. Hubbard E82Adel R. Ibrahim E15Kathy M. Johnson O51Alton P. King X33John M. Liberta E81Robert L. Lisle Jr. K76Samuel L. Lovett E85Christopher M. MacPherson X88Daniel J. Mahar III E25Robert W. Marcella E82

Kelly M. Martin X33Russell T. Massengill O67James A. McDonald O41Andre C. McKie X33Neila E. Menser O35Derrick B. Moore E85Timothy W. Nelson AMSECJames E. Olmsted E85John W. Ormond O82Reginald W. Powell X33Robert E. Prior X76Tracy W. Renn M25Stephen B. Rosen E83Catherine J. Ruehe E83Brenda L. Satterwhite X33James E. Sawyer E85Gerald J. Sazio Jr. E83Ronald S. Slaughter E13James E. Steinke E87Kenneth A. Stewart E83Joseph F. Stumpo E82Hal R. Thompson Jr. E81Daniel J. Ulishney E22Andra R. Weatherford X32Pamella H. Weathers E83Paul W. Weathers E69Michael J. Webb E85Norman E. Whittaker E83Edward G. Williams E84Clarence D. Wyatt O67James C. Yoko E60

20 YEARSKevin C. Beckner X88Jermaine R. Bellamy O46Ernesto B. Bisco AMSECJohn J. Keegan AMSECMichael A. Wallace E13

RetirementsMAY

Clarence B. Harrell X33Joyacelyn Y. Harris X33

James M. Hartman X43Melton W. Mitchell X18

Thomas J. Ransom X33Forest M. Sanders X18

Frank A. Taylor Jr. X31David B. Turner E81

Kenneth J. Walker O15

Yardlines is published 10 times a year for the employees of Newport News Shipbuilding.

This issue of Yardlines was produced by: Jeremy Bustin, Gina Chew-Holman, Troy Cooper, Mike Dillard, Christie Miller, Eugene Phillips, LaMar Smith, Peter Stern, Susan Sumner, Lauren Ward and Kimberly Zayakowski. Photographs by: Chris Oxley, Ricky Thompson and John Whalen.

Send comments, questions and story ideas to Yardlines editor: [email protected] or call 757-380-2627.

To stop receiving Yardlines, go to nns.huntingtoningalls.com/Yardlines to unsubscribe.

Look for more news at nns.huntingtoningalls.com.

July 2013

4101 Washington Ave.

Newport News, VA 23607

PRST STD U.S. POSTAGE

PAID EAU CLAIRE WI PERMIT NO. 366

Yardlines is printed on recycled paper with vegetable-based inks.

On May 17, USS Theodore Roosevelt (CVN 71) was turned and positioned with the stern of the ship to the river to complete testing on the main engines and combat systems. Through a combination of tug boats and the power of the natural tide, Roosevelt performed an about-face maneuver and shifted 180 degrees at its pier, putting it another step closer to the end of its Refueling Complex Overhaul (RCOH) and return to the U.S. Navy operational fleet.

This operation marks the first time CVN 71 has left her dock at Pier 3 in two years. Roosevelt arrived at the shipyard for her mid-life RCOH in August 2009. It’s the fourth Nimitz-class ship to undergo this major life-cycle milestone. Photo by John Whalen

Turns at PierUSS Roosevelt