Yardlines, November-December 2012

-

Upload

newport-news-shipbuilding -

Category

Documents

-

view

221 -

download

3

description

Transcript of Yardlines, November-December 2012

Yardlines

A Publication of Newport News Shipbuilding November/December 2012

In ThIs Issue

Game-Changing Ideas for CVn 79

Positive Changes Boost shop Productivity

Minnesota Christened and Launched

Phot

o by

Ric

ky T

hom

pson

LOOK iNsiDe fOr the 2013 NewpOrt News shipbuiLDiNg caLeNDar

LOOK iNsiDe fOr the 2013 NewpOrt News shipbuiLDiNg caLeNDar

In 2010, the Pipe Hanger Shop was producing about 65 work packages a week. The work was cumbersome. To build a hanger, an employee had to gather the needed materials before starting the work. Then the employee would travel with the hanger as it went through the welding and painting processes to gradually finish the job and ship it out.

That’s the way it had been done for years. Then after conducting a Rapid Improvement Workshop (RIW), a new assembly-line process was introduced that began transforming the way they did business.

Instead of gathering, employees received a kit containing all the material needed. Instead of traveling, employees completed their work and passed the hanger off to the next employee in the process. The hanger was pushed through the “assembly line” until ready to leave the shop.

By 2011, the Hanger Shop was averaging 139 packages a week, improving cycle time and reducing cost, all without increasing their manning levels. And, productivity levels continue to climb.

“Productivity in the Pipe Hanger Shop keeps improving,” said Jason roach, the shop’s general foreman. “By continuing to improve process flow, adding ‘metrics that matter’ and listening to the floor, the Hanger Shop has averaged 205 packages per week over the last 16 weeks.”

ronnie Diggs, who has worked in the Hanger Shop for more than half of his 33 years at NNS, says working smarter and not harder has made it easier and safer for everyone. “You touch a part once and it is constantly flowing and moving smoothly through the shop floor,” he said. “We keep coming up with new ideas on how to do things better. Our foremen take our ideas seriously and it makes a difference.”

Next door in the Sheet Metal Shop, employees wondered when the positive changes would spread their way.

“We were looking to increase our capacity,” said General Foreman bob conway. “But we couldn’t make the shop any bigger. We knew we’d have to improve the process to be more efficient. ”

They started with a massive clean-up effort, ridding the

shop of scrap and trash. Then they altered their processes with a new floor layout, rearranged work benches, created new work stations and changed roles for employees.

“Many of our shops are beginning to transition from ‘employee operated’ to ‘employee led,’” said Matt Needy, Manufacturing director, Component Fabrication and Assembly. “Our employees are taking more control of their business and it’s producing great results. We are listening to the shop’s needs and taking the appropriate actions to enable continued improvement.”

Positive Change, It’s Contagious

Wesley Wooten works more efficiently in the Sheet Metal Shop because of process improvements that have cut cost and improved productivity. Photo by John Whalen

Like the Hanger Shop, the Sheet Metal Shop increased its throughput by 135 percent, said Conway. Employees were able to complete 134 work packages in a week rather than 57. Quality increased, cost decreased and cycle time was cut by more than 70 percent.

“The new process has made our jobs more efficient. It cut out unnecessary work and has put us at the top of our game. Now, productivity and quality go hand in hand,” said wesley wooten, who has worked all phases of the Sheet Metal Shop’s processes during his nearly 42 years at the shipyard.

“In 38 years I thought we’d tried everything. Now our shop is being used as a model,” Conway said. “They want to spread this across the company.” And they can, he said. “They just have to follow the same concept.” | By Kelly Barlow

CVN 79Changing the game

In 1961, President John F. Kennedy challenged Americans to land a man on the moon and it seemed unimaginable, but our indomitable spirit prevailed.

Today, the same urgency, commitment and out-of-the-box thinking that made Neil Armstrong’s walk on the moon possible will be needed to build CVN 79 — the ship to honor the late President Kennedy.

Tasked with significantly reducing CVN 79’s building cost, Director of CVN 79 Program and Construction Mike butler and his team know everyone involved needs to “think and work differently.”

The next generation of carriers must be built for what the Navy can afford and Newport News Shipbuilding (NNS) can successfully execute.

“It’s not about simply working harder — we’re already doing that,” said Butler. “Our goal is to implement fundamental changes that simplify every segment of our business.”

For months, the CVN 79 team has assessed hundreds of opportunities for simplification and improvement.

“We’re stretching for creative, legitimate solutions that reduce costs in processes from procurement to planning to design and construction,” explained Butler.

stewart brenegar, trade director for the Machinery Installation Department, said, “Ford building teams have contributed countless

The future aircraft carrier CVN 79 will honor the late President John F. Kennedy. Photo illustration by Chris Oxley and Mike Dillard

Ideas that will change the way future aircraft carriers are builtimprovements in cost, schedule and worker safety. Leveraging their experiences can improve how we build the Kennedy.”

The ideas selected for implementation that could significantly change how carriers are built have been dubbed “Game Changers.”

They include pre-assembling outfitting work off the ship by shifting hundreds of stick-built components and piping arrangements to the Final Assembly Platen (FAP) or shop and partially or fully testing them there before installation, and painting interior spaces and exterior units prior to erection.

“Engineering’s approach is to leave ‘no stone unturned,’” said craig byrum, director of CVN 79 Engineering. “We’re looking at requirements we provide to Sourcing, Manufacturing, Assembly, and Test, and processes within Engineering, to ensure we pass on only explicitly necessary requirements and tolerances.“

Other options being explored are reducing the number of welded fittings, and possibly even converting the traditional horizontal structural build plan to vertical so more of the ship is open for outfitting for a longer period prior to deckover.

“No idea is too small or too far out of the box,” added sammy Vreeland, CVN 79 construction director. “Going forward, we’ll break down barriers to cost savings and improved schedule performance so our employees can produce the highest quality products in a safe environment.”

Butler added, “Achieving a significantly different outcome requires real "Game Changers" to make our production teams more efficient. We’ll provide material and equipment so they can work in the most cost-effective way, in the most cost-effective location. And the daily support of every person in the value stream will ensure our shops and ship teams are successful.” | By Gina Chew-Holman

Changing the game

Home Awayfrom Home

Three years ago, The Apprentice School, Foundry and Newport News Shipbuilding (NNS) were foreign to erol carter and shanae hilliard. Today, these shipbuilding institutions have become their home away from home.

Both apprentices were raised more than 800 miles away from Newport News. Carter, one of nine children raised in a small town in northeast Florida, and Hilliard, raised in the dry and mountainous terrain of southeastern New Mexico, never dreamt the start of their careers would begin in Virginia — much less at The Apprentice School.

“I didn’t know what an apprentice school was, but I did know that I wanted to get a good education,” said Carter. “The challenge of going to school, working and playing football caught my eye — so the decision was pretty clear to me from the start.”

Neither Carter nor Hilliard had ever traveled out of their home state prior to arriving at NNS to begin their apprenticeship. “Hampton Roads and the shipyard were a complete culture shock for me,” said Hilliard. “I wasn’t

used to not having family and friends nearby, or working alongside 20,000 unfamiliar faces.”

Carter and Hilliard are two of 14 apprentices currently enrolled in the Foundry Apprenticeship. “Though we have an outstanding group of apprentices in the Foundry, Carter and Hilliard have always stood out for their great leadership skills, character and the level of enthusiasm they display in learning their craft.” said steve robertson, Foundry Apprentice Craft Instructor.

In July, NNS presented Carter with an Ethics Award for rescuing a vehicle that had been overtaken by rain water during a torrential downpour. “It happened as I was leaving the Foundry one day after work,” said Carter. “I immediately approached the car and began helping the victims escape. After the passengers in the first car were

rescued, I noticed a similar situation with a second car and was able to help them out as well.”

In addition to excelling in their apprenticeship, both students are also key members of Apprentice School athletic teams. “At the end of the day when we are at home with our families, these two apprentices are at the gym performing rigorous tasks as part of being on a collegiate team,” said Robertson. “Both have been praised by their coaches for their performance, and last year, Hilliard even broke the school record for the women’s basketball team for the most three-point field goals ever made in a single season.”

Carter and Hilliard both agree that The Apprentice School is their home away from home. “Coming to The Apprentice School is one of the best decisions I have ever made,” said Carter. “Whether it’s the Foundry apprentices or the football apprentices, we all hang out and stick together — the apprentice family is huge!”

Together, both apprentices are on track to graduate on time and with honors. “Hilliard will be the first female Foundry Apprenticeship graduate,” said Robertson. “With more than 100 Foundry graduates to date, this will be quite an honor for her, The Apprentice School and the Foundry.”

This year, The Apprentice School will receive more than 6,000 applications for apprenticeship enrollment. Of those applicants, 251 will be accepted and placed into one of the 19 trades and seven optional advanced degree programs at NNS. | By Lauren Ward

Standout Foundry apprentices and collegiate athletes Shanae Hilliard and Erol Carter never imagined their careers would begin 800 miles from home at Newport News Shipbuilding. Photo by Ricky Thompson

Before she came to work at the shipyard, Marcia Downing served in the U.S. Navy for 20 years. Today, as a retired veteran, she is reaching out to other military veterans at the yard as the chair and initiator of a new Veterans’ Employee Resource Group (VERG).

“Veterans have a unique perspective on the products the shipyard builds,” said Downing. “They bring such a sense of pride and integrity to the job, all of those values that the shipyard upholds.”

VERG has been up and rolling since this summer, with the goal of becoming a valuable resource for veterans working at the shipyard, and those who might seek employment here.

ray sperle, a Structural Fabrication and Assembly asset manager and a 20-year veteran of the Navy, was quick to join VERG. “It was an opportunity to help my fellow

veterans,” he said. “It’s a common link we all have. It doesn’t matter what branch of service, we’ve all been through similar situations and training. We have the same dedication to things like teamwork.”

The VERG board is committed to specific goals. It has a liaison for each branch of the military, who understands how someone’s military experience might best be utilized at the shipyard. “We want to capitalize on the unique skill sets veterans bring to the table,” Downing said. “That goes for employees and potential recruits.”

VERG meetings, special events and a website will keep veterans up-to-date on information they need, such as benefits of all kinds, from shipyard to VA benefits to simple discounts at local stores.

“This goes well beyond the walls of the shipyard,” said Sperle. For example, until he came to a VERG meeting,

VeteransVeterans supporting

he didn’t realize he could register for a veteran’s ID card at the DMV that would allow him discounts of all kinds, even at Home Depot or other places where military discounts aren’t widely publicized. “Our intranet website is growing and will have many links and information to help vets with any issue they may have,” he said.

VERG plans to offer mentoring to new employees, and camaraderie and support for veterans and their families. And, the group will work with the Newport News Shipbuilding Talent Acquisition team to actively support recruitment of veterans. In the community, VERG’s goal is to partner with groups like the USO, Wounded Warriors, Veterans of Virginia and more. | By Kelly Barlow

paul b. M34

Daniel c. a572

craig c. O36

courtney D. X43

grame e. X31

steven g. X43

Jerome h. X88

Kendrick h. X43

Kevin h. X36

stephen h. X10

coleman h. X36

Mark M. O85

Michael M. X36

Laveal M. X32

Mitchell O. O31

edward r. X54

thomas s. O38

John s. e27

christopher s. X31

ramone w. X11

Newport News Shipbuilding is proud of the 20 members of our shipbuilding family who are actively serving in the military at home and abroad. It takes courage, honor and sacrifice to answer the call to serve.

With sincere appreciation and thanks for their service, we send Season’s Greetings to these shipbuilders whose mission continues beyond the gates of the shipyard.

Full names not provided for privacy

Remembering shipbuilders on

aCTIve duTy

Marcia Downing chairs a Nov. 8 Veteran's Employee Resource Group (VERG) meeting. L to R: Dale Baugh, Dr. Mark Costa, Marty Erdossy, Chavis Harris, Hank Harzold, Yank Rutherford, and Kevin Topp. Photo by Chris Oxley

This article continues a series on innovative technologies being developed under Newport News Shipbuilding’s (NNS) Independent Research & Development (IR&D) and Manufacturing & Production Engineering (M&PE) programs that improve shipbuilding processes and potentially expand NNS' business into new industries.

NNS is one of the largest users of welding technology in North America, welding well over a million pounds of filler metal each year. Though much of that welding is thick structural steel, NNS also outfits ships with cabinets, lockers, ventilation and more — often made with welded sheet metal. While it may sound easier than heavy steel, thin-metal welding has always been a bit problematic.

“The challenge with welding thin metal is distortion,” explained garrett sonnenberg, a structural engineer in the Technology Development office. “The current method is complex and slow. It involves holding a torch in one hand, filler wire in the other, and turning the power on and off with a foot pedal. It’s not easy to do, and takes skill and time to control the heat and not distort the part. What if there was a way that could help us do this faster and easier?”

That is where Cold Metal Transfer (CMT) comes in. Sonnenberg has been working with Sheet Metal Shop welders and Welding Engineering to find better welding solutions. “We saw a new technology called CMT that helped with thin-metal distortion problems,” said

the Cool WayWelding

method, which would make it the biggest welding technology update I’ve seen since I got here in 1974. If it passes all our evaluations, we could use it for up to 50 percent of welding production by the end of 2013.”

Keith Dudney, general foreman for medium-to-heavy–grade sheet metal work, is also a believer. “It is user-friendly for the welder… you can just push a button for the setting you need. This is the kind of thing we are looking for to bring our welding process into the 21st century.” | By Peter Stern

Sonnenberg. “It welds using very low heat levels by automatically cycling the power to produce a rapid ‘hot-cold-hot-cold’ cycle. It is controlled by a weld gun that also moves the filler wire in and out of the weld up to 70 times per second, leaving a rapidly cooling weld. Now a 15-minute weld job can be done in about five minutes with CMT.”

bob conway, general foreman of the Sheet Metal Shop — which deals with lighter-grade sheet metal — is starting to use CMT in his shop to test its viability in production environments. “I have never seen anything before this that worked this well on sheet metal or aluminum,” explained Conway. “We are estimating three to five times greater efficiency over the current welding

NNS welders are testing Cold Metal Transfer technology in the Sheet Metal Shop to find a better thin–metal welding solution. Photo by Chris Oxley

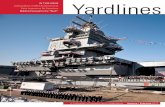

Christened and LaunchedNearly 2,000 guests filled the Newport News Shipbuilding (NNS) Module Outfitting Facility (MOF) on Saturday, October 27, to celebrate the christening of the 10th Virginia–class submarine (VCS) — Minnesota (SSN 783).

The festivities opened with music by the U.S. Fleet Forces Band, the parade of colors by the Navy’s Submarine Squadron 6 Color Guard, and the singing of the national anthem by NNS Insulator phillip Mccoy.

Before performing the traditional breaking of a bottle of sparkling wine across Minnesota’s hull, Ship’s Sponsor ellen roughead, the wife of former Chief of Naval Operations Gary Roughead, praised NNS shipbuilders.

“Minnesota is the sum of all her parts,” Mrs. Roughead said. “Everything and everyone who has contributed will be an ingredient in the spirit and the force that makes Minnesota. The great shipbuilders of Newport News Shipbuilding and the countless men and women across our country who had a hand in the millions of parts and components that have gone into the ship have given Minnesota her backbone, her muscle and her nerves.”

VCS Outside Machinist Jeff price, who attended the christening with his wife and daughter, said, “I’ve worked here for 31 years, and this is my first christening. I’m pretty proud of this boat because I worked on the hydraulic system.”

Father and son VCS shipbuilders Dale wagner and eddie wagner said they enjoyed the christening and were proud of what the VCS team has accomplished. “It doesn’t matter what you are doing on the submarine or what

department you are in, all the people in the different trades, we all work together,” said Dale Wagner, a sheet metal installer who has been working on the submarine’s forward end. “We have been doing this delivery thing for a few boats now. This is a pretty good team. “

As the christening was winding down, VCS shipbuilders were waiting in the wings to continue preparing Minnesota for her next milestone — the launch.

chuck rhodes, a nuclear foreman who has worked on every Virginia-class submarine since the Texas, the first delivered by NNS, said he enjoys the fast pace of getting a submarine ready for launch and sea trials. “At this point of construction, there’s a big push to get things prepped up to get the boat in the water and to make sure things happen when they need to happen,” Rhodes said.

“We have a lot of people who‘ve put in a lot of hard work, hours and commitment into building this submarine. Everybody has given it their all.”

On November 3, with the ship 92 percent complete and on track to deliver 11 months ahead of contract schedule, Minnesota was moved out of the MOF and launched into the James River. The VCS delivery team will complete Minnesota’s final outfitting and testing at NNS’ Pier 6, where the submarine will remain until it’s ready for sea trials. | By Gina Chew-Holman

Ship’s Sponsor Ellen Roughead christened the Navy’s 10th Virginia-class submarine with a bottle of American sparkling wine on Oct. 27. Photo by Chris Oxley

Extracurricular

When he was 12 years old, Joey Meléndez took apart a handheld electronic football game to see how he could disengage the sound. With no sound, he could play with it at school without getting into trouble.

Or so he thought.

Meléndez’s tendency to tinker sometimes got him into trouble as a child, but his desire to learn how things work and share his knowledge has helped to build submarines and aircraft carriers – and even overhaul a few – during his 13 years at Newport News Shipbuilding (NNS).

Meléndez is a systems engineer, a job he has held since 2007.

“When I was a kid, I was always taking things apart to see how they worked, or I would make them change somehow,” he said. “So it comes as no surprise that I’ve ended up in the engineering field.”

His professional achievements and service in the community were recognized in November by the Society of Hispanic Professional Engineers (SHPE) during a national conference in Fort Worth, Texas. Meléndez, a founding member of the organization’s Southeast Virginia professional chapter and its current president, is receiving a 2012 SHPE STAR Award in the community service category.

Jennifer boykin, NNS’ vice president of engineering and design, nominated Meléndez for the honor. “Joey’s commitments to the success of our business, to his community and to the nation all reflect on his strong sense of doing what’s right.”

While studying at Philippa Schuyler Middle School for the Gifted and Talented in Brooklyn, Meléndez participated in an independent study program for science that required him to present to fifth-graders.

The opportunity sparked a fire in him. “I enjoyed seeing the kids get excited about what I was excited about. It was at that point that I felt empowered to mentor others.”

“Extracurricular” became Meléndez’s middle name. After enlisting in the Navy and being accepted into the U.S. Naval Academy (USNA), Meléndez got involved in everything from Special Olympics to serving as a disc jockey for the USNA’s radio station. When he got out of the Navy and moved to Hampton Roads, Meléndez discovered a void in the region’s Latino community. He co-founded Latin Five Productions to serve that population through cultural activities and special projects. He also fosters awareness of STEM education by engaging students, teachers and community leaders as an active participant in a host of community service and civic organizations.

“Today’s world is a technology world, and to succeed, kids need technology acumen to understand what exists and what is yet to exist,” Meléndez said. “Science is important because it allows for the thought process of understanding how things work.”

Meléndez believes the secret to success in life is opportunity. Opportunities are made available to everyone. Taking advantage of them is what makes the difference.

“You have to keep an open mind about opportunity,” he said. “When it knocks, you have to not only identify it, but be brave enough to walk through that door.”

That’s what makes it work. | By Christie Miller

is hisMiddle NameExtracurricular

Systems Engineer Joey Meléndez was honored on Nov. 9 at the Society of Hispanic Professional Engineers National Conference for outstanding community service. Photo by Chris Oxley

A silhouette of the North Dakota (SSN 784) sail that was the first Virginia-class submarine to be built using a redesigned composite sail cusp. Photo by Ricky Thompson

Intense. That’s how Construction Superintendent scott whitmore describes the job of installing a sail cusp on a Virginia-class submarine. The cusp is the smooth, sloped structure that attaches between the lower forward portion of the sail and the hull of the ship.

Made from a series of steel plates and structures, the cusp has typically been welded to the front of the sail — piece by piece by piece. It takes welders, fitters and other departments more than two months, working around the clock, to finish the installation, with welding occupying the vast majority of the work.

So when the Navy challenged Newport News Shipbuilding and its Virginia-class build partner, Electric Boat, to build two submarines a year, all while reducing costs, “we knew we had to do something different,” said Whitmore of the cusp.

As part of the challenge, the two shipyards put together a think tank of employees called the Design for Affordability Team, who tossed all of their ideas into the ring. And the idea that changed everything for the cusp? One made of composites rather than steel, which would shave

weeks off the installation process because, instead of many pieces to weld together, the composite cusp would be one large molded structure.

“It comes ready to install,” said Whitmore, currently in the middle of construction on the submarine North Dakota (SSN 784), the first hull to receive the new cusp. “We can set it topside, drill some holes, and essentially we’re done.”

The new cusp means a 70-percent reduction in cost for installation, and cut time on the job by more than a month. “We’ve seen a greater reduction than we expected to see,” Whitmore said.

But the savings go even deeper. The new cusp eliminates the welding. This means the hot work no longer prevents other trades from completing their tasks around and below the cusp area. It also means workers at NNS can apply the exterior coating to the cusp, off hull, in a clean shop area.

For Shipfitter James clayborne, the new cusp means an easier installation. “The new design has eliminated all of the plate cutting and fitting required to install each individual plate,” he said, “and greatly improved the ergonomics for our bodies by reducing the amount of time we spend on the hull crawling around the cusp.”

stanley britt is also happy with the new design. The structural welder said the new cusp “eliminated a lot of uncomfortable hours crawling around the cusp, welding from multiple angles.” The cost savings were “a big boost to our overall program,” he said, “and it pretty much takes the welders out of the picture, allowing us to work other critical jobs.”

The new composite cusp was just one of the ideas that came from the NNS/EB think tank. “After five or six years of building these subs, we could look at even better ways to build them,” Whitmore said. “We captured more than 100 items for the boat. This is just one of them.” | By Kelly Barlow

Think TankIDEA Takes SAIL

the supplies. I keep the roll. I do the expense reports, traveling. I make the coffee. I hear the complaints,” she said as she chuckled.

The shipyard hasn’t been her whole life, however. Kelley found time to join the Women’s Army Corps and served in the Army Reserves for six years.

“I just wanted to try something and see something different,” she said. She used her vacation for basic training. “It didn’t interfere with me coming to work. The fun part, what I really liked,” said Kelley, “was marching and singing the songs — the sound off.”

Those Army skills likely helped her raise her seven children, which comprise an amalgam of her own, some from marriage and others adopted. “I keep adding,” she said with a laugh.

Kelley will be retiring at the end of the year; just three months shy of her 50th anniversary with the shipyard. Not one to stay idle, though, she plans to take up volunteer work when she leaves. | By Kelly Barlow

For 21 years, trailblazing Administrative Assistant Louise Kelley has called the Machine Shop her “forever home.” Photo by Ricky Thompson

If a Machine Shop employee needs a pen, or perhaps a highlighter, they go to see “Sweet Lou.” But that doesn’t mean they’re going to get that pen or that highlighter.

“They give me a budget to go on for orders and I stick to it, or under it,” said Louise Kelley, at first sounding very serious, and then breaking into a laugh.

Sweet Lou is a nickname bestowed upon Kelley by her co-workers, who appreciate her dry wit and spunk.

For nearly half a century, Kelley has been a fixture at the shipyard, moving from her early days in the typing pool to the heat of the Foundry and beyond. The fact that she was one of the first African-American women hired at the shipyard and helped pave the road for those who came after isn’t a laurel she rests on. It’s just one small part of her story.

Kelley was born on 19th Street, just a few blocks from the shipyard. And after graduating from high school and Peninsula Business College, she applied for a job at the yard. Her father worked at the yard for 40 years as a rigger, but passed away a month before Kelley was hired. “He would have loved to know I was here,” she said.

“When I first came on, we had a typewriter and Dictaphone. Now I’m on a computer, which I love. It’s much better than the typewriters — 12 copies with carbon paper — all those copies to erase through.”

After five years in the typing pool, which had become family for her, she headed to Industrial Park, what she said is now Newport News Industrial. After another five years, she was off to the Foundry. Another five years passed and Kelley moved on to Material Support, then QID. But the Machine Shop is where she found her forever shipyard home. She’s been there ever since.

What does she do there? “Everything,” Kelley said. “You better believe it. In here I maintain the office. I order

Sweet Lou

William Jordan40 years

Long ServiceMASTER SHIPBUILDERS OCTObER

Wallace Winborne40 years

Chuck Nicely 40 years

Waverly “Squire” Charity45 years

Robert Earl45 years

Pat Carmean45 years

Rodney Brock40 years

Tony Bland55 years

Philip Delp40 years

Mark Madeira40 years

Donnell Mitchell40 years

Gary McClenney45 years

Chris Lambert40 years

Marcus Land40 years

David King40 years

David Diggs45 years

Sim Hailey40 years

Chuck Green40 years

Dave Harry40 years

Jeremiah Jefferson40 years

Linwood Gray40 years

Like us on Facebook, where we regularly publish photos of recent events, our shipbuilders, and even historical photos of the shipyard. www.facebook.com/HuntingtonIngallsIndustries

Like our photos?

Long ServiceMASTER SHIPBUILDERS NOVEMbER

Anthony Michura40 years

Michael Hawk45 years

Hermo Harris45 years

Winston Harris40 years

Raymond “Mac Mac” McNair40 years

Barney Lincoln40 years

Joey Bowser40 years

J.T. Bland40 years

Cecil Baker40 years

Shelley Harrell40 years

Richard “Ant” Anthony Jr.40 years

Doc Baker40 years

James Tann40 years

Frank “Hogie” Thorn40 years

Thomas Kukucka40 years

Jerry Owenby45 years

Steve Murdock40 years

Steve Stallings40 years

David Soyars40 years

Dale Porter40 years

Harold Parker40 years

Yardlines is published 10 times a year for the employees of Newport News Shipbuilding.

This issue of Yardlines was produced by: Gina Chew-Holman, Troy Cooper, Mike Dillard, Christie Miller, Eugene Phillips, LaMar Smith, Peter Stern, Susan Sumner and Lauren Ward. Additional writing services by Barlow Communications. Photographs by: Chris Oxley, Ricky Thompson and John Whalen

Send comments, questions and story ideas to Yardlines editor: [email protected] or call 757-380-2627.

To stop receiving Yardlines, go to nns.huntingtoningalls.com/Yardlines to unsubscribe.

Look for more news at nns.huntingtoningalls.com.

Retirements SEPTEMbER/OCTObERKarl D. Boyce O53Johnny S. Boyd X33* Randolph G. Clemm X43James M. Cowan X36

George D. Dawson M53Joseph D. Franceschi O58 Johnny R. Johnson X32 Perry W. Kemplin III E94

Otis C. Moore Jr. X11Franklin W. Morrow O38Jerry L. Nicholson X11Hollis H. Palmer Jr. E65

Robert B. Pope Jr. X18Douglas A. Read Jr. O15John E. Smith X18William S. Smith X31

Cathy J. Stavenger T55George Taylor X32Herbert Taylor X33 John D. Topping X15 * Retired in July

55 YEaRSAnthony R. Bland AMSEC

50 YEaRS Bennie C. Steele O61Theodore Wynder Sr. X36 45 YEaRS Robert E. Blount X71Patrick S. Carmean X89Waverly A. Charity X32David T. Diggs E13James H. Faulk M53McDale Grant X11Rolland C. Hunter X31Eugene F. Jones X70Gary McClenney X71 40 YEaRS Glenn T. Bailey X18Rodney Brock X31Edward E. Bryant X18Wendell Clark X42Philip M. Delp X43David O. Garrison O04Linwood L. Gray X31Charles W. Green O43Sim H. Hailey X36Lawrence D. Harry K78Julian W. Hollowell M53Jeremiah Jefferson X70Ronald W. Jenkins X54Charles P. Jones X42William M. Jordan III X54David C. King O37Chrisley S. Lambert X32Marcus S. Land O53Twanna C. Lewis O04Clyde M. Madeira T54

Woodrow K. Maynor X42Donnell Mitchell X32Charles E. Nicely X88Henrietta L. Rogers O53Melvin Spivey Jr. X71William O. Spratley X33David R. Wade X42Wallace E. Winborne X33 35 YEaRS Bernard R. Arrington X32Paul H. Condron Jr. X11Mark W. Gratton X70Albert D. Harris X11Edward D. Moore X18Garland G. Moore X18Thomas H. Prewitt O22Debra L. Ross N905William S. Ruth X70John A. Sickles Jr. AMSECElla M. Spratley O23Donnell L. Thomas X36Richard M. Wiatt X73Neal H. Winall O19Thomas R. Woodruff M53Oscar H. Woody III X18John H. Zinskie E41 30 YEaRS Lawrence W. Alexander X71Jonathan W. Amos X36Barbara A. Anderson O53David F. Anderson E03Boris C. Bailey X73Glenda C. Bailey O46Myron A. Bailey O43Charles B. Bell O53Keith A. Bennett X31Herman L. Bland X31

Eric L. Bunch X88James M. Butler X18Charles E. Carter X18David Carter X18Dwayne N. Cheeseman X18Joseph S. Christman O22Richard A. Collier X88Jewel Couch III X31Bruce D. Davis T55Paul M. Davis X11Timothy S. Debusk X88Albert L. Dehart Jr. AMSECPaul W. Dubey X42David H. Duncan X54Mark A. Dunford E25Mason O. Dunkley E68Randall L. Durham X88Robert W. Elmore X70Gloria G. Eure X70Reginald L. Everett K78Brian K. Fletcher M20Anthony Garrett X88Glenn G. Gaskins O53Neal W. Gilbert AMSECMichael S. Hammond X32John W. Hancock O26James A. Hargraves O39Keith A. Harper O37Donald M. Harrell Jr. X88James N. Harris III E39Rhonda D. Harrison X36Robert L. Hartoon II X32Felicia K. Harvey O46James H. Hill Jr. X32James B. Holliman X88Michael E. Holmes X32Marvin L. Hooker Jr. X31Dianna L. Hopkins E83Chris M. Hoyer O21

Richard T. Jay M20Jeffrey S. Jeffers E84Christopher F. Jones K78James D. Jones X43Howard G. Jones II X11Patrick O. Karczski X11Thomas D. Lanford X88James S. Lawrence X31Robert S. Lawrence X33Angela C. Lewis O14Leonard W. Lynn N960Jeffrey L. McCurry E22Joel D. McLean X58Johnny S. Morris X43Kenneth L. Naugle X43Kevin W. Newberry X75David A. Nolte E68Sean M. O Neill E45William E. Powell O26Scott J. Ripley AMSECEddie Robinson Jr. X89Robert T. Sampson X36Charles E. Santrock X82Larry D. Snowden X11Kelvin M. Solomon O53Tracy L. Spencer N960Alphonzo F. Spruell Jr. E88Elmer L. Stewart X18Dale V. Stumpf X88Linda R. Taylor O46John E. Thomas X71Joseph R. Trimble O53Shawn L. Valenti X31Brenda S. Viars X75Tyrone Ward X33Beverly P. Ware K89Wayne H. Williams O26Douglas C. Williamson X11Jeffrey C. Woodard O53

Brian S. Wyatt X11Randall W. Wyatt X54 25 YEaRS Dale T. Albert E15Anthony R. Bailey X33Leon Birchette X33Angelia M. Blount X87Roy D. Bond X33Dennis A. Boyce X33Darryl E. Brown X42Cleveland Brown III X75Michael B. Coleman O54Matthew Cooper X11Dwayne T. Copeland X33David V. Crews O46Myron L. Cutchin X33Anthony B. Dodson X33Robert E. Dolak Jr. X18Arnold R. Eason X33Douglas E. Elliott X33Ashford T. Ellison Jr. X42Shirley J. Fennell O51Dean M. Foster E51Jack B. Fowler X76Ann B. Garner AMSECJohn E. Gathers E21Juan M. Giles X33Edward K. Hardwick E64William J. Haupt X75Isaac J. Hawk X33Wayne D. Hedgepeth X33Rodney J. Hines X11Denise P. Hobson O14Joseph K. Ivey X18Timothy Jackson X18Charles C. Jones X31Cornell C. Jones X11James H. Jones M53

Ronald G. Jones X33Willie M. Jones X33Gary D. King X33James B. Lassiter X33Vernon R. Lee X36Lorenzo J. Mallory X42David C. May AMSECJames R. McDonald Jr. X42Alvin C. Minor X11Winfred L. Mitchell X32Thomas F. Moran X71Donald T. Newsome X18Glenn L. Nichols X18Mark L. Nichols E65Tony L. Parker X18John W. Parker Jr. M53Bobby W. Peck Jr. E03Carl R. Pierce X58Kevin A. Pittman X33Montgomery Poston Jr. X11Roy C. Price X33John A. Pugh Jr. X33Eric D. Robinson X18Charles L. Rochelle E17Joseph M. Sammon E71Leroy B. Saunders X33Tracy Thomas X33William C. Thomas X42Morris L. Towns X33Neil W. Voris X42John R. Walker Jr O43Guy E. Walters X42Carlton D. White X18Brent D. Wiggins X88Ricky . Wilder X33Kevin S. Winborne X33Lynne F. Wright E25

45 YEaRS Herman L. Harris X31Michael G. Hawk O53Jerry L. Owenby X36 40 YEaRS Cecil L. Baker X36Donald R. Baker Jr. X43Junious T. Bland Jr. X33Joey L. Bowser X31Shelley R. Harrell X33Winston Harris X36Thomas E. Kukucka E17Barney L. Lincoln E51Raymond L. McNair X33Anthony J. Michura X67Robert S. Murdock X73Harold E. Parker X33Clifton R. Perry X33Dale R. Porter O67David A. Soyars O53Steven W. Stallings X33Bobby R. Stanfield X11Robert E. Swinton X33James V. Tann X33

Frank H. Thorn O27

35 YEaRS George E. Anderson Jr. O26Brent D. Bartley X18Suvious Bland X33Jeffrey H. Bolt X10Michael S. Chittum X18Jerry W. Deaver X11James K. Ferguson X36David E. Holley A572Andra L. Johnson X11Danny T. Johnson X11Garry A. Jones M53William H. Jordan X88James L. Leary X11Andrew L. Markham X70Kenneth L. Mayo A572William S. Norman X58David W. Peterman E65Kelvin P. Reed O14Timothy B. Smith O26Jeffrey D. Thomas X89Herbert L. Todd O43Johnny L. Watts X88

Douglas W. Young X11 30 YEaRS Tyrone Armstrong X88Bryan A. Bailey X18James A. Barner O15Rose D. Bousquet O53Robert E. Brown X71David A. Burianek O35Charles W. Carden III X70Ricky A. Cooper X43Charles Crane Jr. AMSECKevin E. Cross X32Eunice A. Ellis O53Thomas L. Fox X70Mark A. Gillette X36Frederick D. Greene X36Robert T. Gregory X18Randall W. Hall O37Otis L. Holland X36John E. Kitchens X18Kelvin E. Larrimore X18Larry D. Lavinder O37Theodore Majors Jr. O19Edward C. Mason O39

Doris J. McNair O14James D. Mertens X42Michael J. Mugler X67Christopher J. Oxley O29Thomas H. Parker Jr. X11Richard J. Plachta E21Thomas L. Schoolfield K60Gay G. Siekirski E72Robert D. Stallings Jr. X72Vincent R. Taylor X33Harold H. Thorson X89Kenneth L. Tyler N940Lorraine D. West O57Douglas E. Williams X32Dennis E. Williams Jr. X32Egbert J. Wilson X11Cindy D. Winborne O46Cecil M. Womble Jr. X88Keith A. Wood X58 25 YEaRS Kenneth Bond X36Raymond Boone X18David L. Brannan E05Colon Brinkley III X18

Jeffrey G. Brinson X70Gregory W. Britt X18Christopher D. Cherry X33Daryl Copeland X18Linwood C. Copeland Jr. X18Bradford L. Cotton X82Peter J. Devlieg M53Elton E. Dukes X18Jeffrey L. Dutton E10Joseph A. Ellington E03Albert N. Ferguson E65Michael A. Hooker O53Barbara A. Jones X33Shawn D. Jones X71Walter F. Jones T53Christopher D. Kastner N300George A. Lafrance Jr. M71Robert D. McCadden Jr. O51Wallace McCafferty Jr. X11Kenneth Moore X33Charles A. Osbourne X42Tarrance E. Parker X10Kelvin Rascoe X31Ronald I. Reeves AMSECRaymond E. Rountree O67

Christine J. Schaffner T50Rudie L. Simpson III E68Calvin Smith Jr. X32Terry L. Stallings X33John M. Sterne E22Antonio Stovall O14Larry D. Vaughan X36Patrick Walton X73William Watson III X36Ronald W. Weade III E81Michael A. Whidbee O54Terrence E. White O68Tracay A. Williams X75Michael E. Winkles O46Allin J. Woods III X15James L. Wynn X18Ernest Young O14 20 YEaRS David E. Orie E81David W. Park AMSECRonald A. Pulley E88Frankie M. Sims AMSECDavid J. Strahler AMSEC

Long Service OCTObER

NOVEMbER

Four years ago, when Jerry Jenkins was looking for a way to get involved in the community and make a difference to kids in Newport News, he went back to his roots.

“I grew up on the East End,” said Jenkins, an electrical value-stream leader in the shipyard’s Process Excellence organization. “There’s a real shortage of role models to mentor the kids there — in particular, male role models.”

After attending a meeting to learn more about the East End’s community needs, Jenkins decided to approach the C. Waldo Scott Center for H.O.P.E. about forming a Cub Scout pack at the center.

“The Scott Center has a good reputation. The adult leadership there is instilling the morals, discipline and things kids need to know,” explained Jenkins. “But what they were missing most was people to help out.”

Teaming with members of his Masonic Lodge, Jenkins founded and became Cub Master for Cub Scout Pack 357. The men involve the scouts in camping, horseback riding, golf and trips to museums and basketball games.

“For the last three years, we’ve been able to give kids exposure to things they wouldn’t ordinarily have in their neighborhood,” Jenkins said. “Working with the boys at the Scott Center is very rewarding.”

Since 1990, the Scott Center, a United Way partner agency, has been providing youth and families from Southeast Newport News with education, training and support needed to take charge of their lives and develop positive life skills. | By Gina Chew-Holman

Modeling Positive Life Skills

Making a Difference

Shipbuilder Jerry Jenkins instructs a Cub Scout at the C. Waldo Scott Center for H.O.P.E. Photo by John Whalen

In ThIs Issue

Game-Changing Ideas for CVn 79

Positive Changes Boost shop Productivity

Minnesota Christened and Launched4101 Washington Ave.

Newport News, VA 23607

PRST STD U.S. POSTAGE

PAID EAU CLAIRE WI PERMIT NO. 366

Yardlines is printed on recycled paper with vegetable-based inks.November/December 2012

Ford’s Island ComIng TogeTher

LOOK iNsiDe fOr the 2013 NewpOrt News shipbuiLDiNg caLeNDar

LOOK iNsiDe fOr the 2013 NewpOrt News shipbuiLDiNg caLeNDar

The two island structure sections (left and right of the JLG) for the aircraft carrier Gerald R. Ford (CVN 78) are shown under construction in October. The joined structures will make a 490-metric-ton total unit. The distinctive aircraft carrier's island contains primary flight control, the "control tower" for aircraft operations, and the navigation bridge, the "office" for driving the ship. CVN 78's structurally-completed island unit is scheduled to be lifted aboard the carrier in January.

Phot

o by

Joh

n W

hale

n