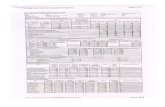

Change Monitoring System CMS 5(S) Baten (DSK), Hannah (shiree) and Sonia (Uttaran)

The 5 s system

-

Upload

aman-pratap-singh-rajvi -

Category

Business

-

view

1.249 -

download

2

description

Transcript of The 5 s system

THE 5S SYSTEM

The Flow Introduction to the system

Elements of 5S system

Case Study

Introduction to the System The original concept of 5S was developed

by Takashi Osadka during the early 1980s The 5S system is designed to create a

visual workplace—that is, a work environment that is self-explaining, self-ordering, and self-improving.

Fundamentally, 5S is a housekeeping technique that enables orderly and neat management of items for ensuring their immediate retrieval.

In a visual workplace, the out-of-standard situation is immediately obvious and employees can easily correct it.

Used for achieving: Continuous quality improvement Faster Services Waste Elimination

Introduction to the System contd.

What 5S can Do? Improves profits, quality and safety Reduces wasted time and

materials Reduce lead time and cost Improves efficiency and morale of

workers Simplifies work environment

Why 5S? Impact on Safety Help us identify and eliminate

waste Low cost and high

impact/aesthetic value Faster services

The 5S ElementsThe 5S is a deceptively simple system

comprising the following system Seiri (Sort) Seiton (Set in Order) Seiso (Shine) Seiketsu (Standardize) Shitsuke (Sustain)

5S Elements

S1—Sort (Seiri) If in doubt, throw it out. --Red-tagging rule of

thumb The first principle of visual order is to sort out what

you don't need The workplace can get overrun with stuff—parts,

work in process, scrap, jigs, storage shelves, bins, filing cabinets, documents, desks, chairs, racks, cabinets, phones, packaging material, tools, machinery, equipment, and so on.

Piles of stuff accumulate and impede the flow of work. Hassles increase, and long lead times become chronic.

S1—Sort (Seiri) Learn how to identify and eliminate

waste Organize your business Learn fundamentals for future efforts

Red Tagging Define what you need to meet your production

objectives and clear out everything else. The key S1 tool is red tagging. The red tag is a simple tag containing the

following information: Item classification. Item ID and quantity. Reason for red tagging. Work section. Date. Red tags are attached to unneeded items during

the sort phase of 5S.

S2—Set in Order (Seiton) A place for everything, and

everything in its place. --------Proverb Now we are ready to organize what's left

so as to minimize wasted motion.

How do we place our machines, tools, storage shelves, and so on, to reduce the muda of motion?

While doing Seiton keep in mind The right location where the things will

be used. FIFO (First in First out) arrangement. Labeling of the area and the equipment

is very important. Keep proper gaps between two things to

avoid confusion

Consequences of not following Seiton Things are seldom(Rarely) available

when needed Items get lost Items get mixed up Visual control not possible Failure to achieve targets

S3—Shine (and Inspect) Nothing raises your team's spirit like a clean,

well-ordered workplace. Nothing depresses the spirit more than a bleak, filthy workplace.

What is our standard? Our 5S team has to decide:

What to clean? How to clean? Who will do the cleaning? How clean is clean?

S3—Shine (and Inspect) Cleaning responsibilities and schedules

should be prominently posted. Team members should sign off on the

sheets when they have completed their cleaning schedules.

Make "5S-minute cleaning" a part of each job. This enhances ownership and mutual respect among your team members.

We want our team members to feel that, "This is my work area and my machinery and I am going to take care of it."

S3—Shine (and Inspect) S3 also means inspect. Your production team

members need to regularly check the condition of their equipment.

Train them so they can recognize minor changes in sound, smell, vibration, temperature, or other telltale signs.

Develop inspection check-sheets for machinery to support this activity.

Finally train your team members to solve the root cause of cleanliness problems.

Why are the chips there? What is causing that leak? How can we prevent these dust emissions?

While Doing Seiso, keep in mind: Cleaning should be done regularly. Use the best cleaning agent . All the nooks and corners should be

cleaned. Keep all the labels intact. All the labels should correct, visible and

legible to all.

Consequences of Not Practicing Seiso: Performance of machines deteriorates. The quality/aesthetic quality deteriorates. Dirty place is unpleasant and hazardous to

health. Sends uncaring and irresponsible message

to the team members and society at large. People working at dirty areas are generally

found to have low desire to excel and their motivation level is low.

S4—Standardize (Seiketsu) We have achieved a good condition: a clean

well-ordered workplace that speaks to us. But things tend to fall apart. This is the second

law of thermodynamics (or Murphy's Law). We must develop and apply standards for S1

to S3. Then, develop standards for how we do our work. This is standardized work, our playbook, so to speak.

The best standards are clear, simple, and visual.

While doing Seiketsu keep in mind The standards should be arrived at

unanimously.

Always keep the standards flexible to changes and improvements.

Standards should be known to all and displayed.

Consequences of not following Seiketsu : Dual standards yield multiple results.

Multiple results lead to conflicts and confusions.

Rework increases.

Rework increases the basic cost of the finished product without any value addition

The Essence of Seiketsu It is the proof that 3-S (SEIRI, SEITON,

SEISO) are being religiously carried out.

It is the barometer which indicates the control level based on the 5-S of all the workers.

S5—Sustain (Shitsuke) If you are disciplined. : Rules will always be followed. Laid down targets will be achieved. Improvements will be promoted . The no. of defects will be reduced. The cost will not increase.

How to practice Shitsuke Train all team members on 4-S. Correct wrong practices on the spot.

Punctuality is the backbone of 5S.

Follow work instructions.

5S Promotion and Communication Here are some 5S promotional ideas: 5S Report boards.

5S Catch of the month.

5S Slogan or Logo Contests.

5S core group

5S Case Study: XXX Case Study is based on ABC Section,

Production Division, XXX

Based on observations during Summer Intern

Case Study Seiri (Sort):

Waste/Reusable papers were kept in boxes in the office.

Boxes for used & reusable safety equipment were different with markings over them.

Nonconforming parts produced were kept in one specific corner

Seiton (Set in order): All tools were classified according to their shapes &

uses. Similarly, in Die maintenance & Storage area, Dies

were stored according to the frequency of use.

Case Study Seiso (Shine and Inspect)

A conveyor belt ran below the presses to carry scrap metal coming from trimming presses.

Vendor bore the responsibility for the proper cleaning of shop floor.

Seiketsu (Standardise) All dies were colour coded according to model. The die storage are was also colour coded. The dustbins were colour coded according to

type of waste as Biodegradable/Non-Biodegradable.

Shitsuke (Sustain) Posters were pasted near the working area Depicted consequencesof not following 5S

All images downloaded from internet