portland cement plastering 09 24 00 - CMD Group · 2014. 11. 19. · American Concrete Institute...

Transcript of portland cement plastering 09 24 00 - CMD Group · 2014. 11. 19. · American Concrete Institute...

portland cement plastering 09 24 00

ArcusStone Products, LLC

®

SPEC-DATAª and MANU-SPECª are registered trademarks of Reed Elsevier Inc. The ten part SPEC-DATA format conforms to the editorial style of The Construction Specifications Institute and is used with their permission. The manufacturer is responsible for technical accuracy. ©2008 Reed Construction Dataª. All Rights Reserved.

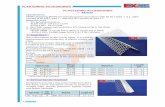

1. Product NameArcusStonecoat« and ArcusPlaster«

2. ManufacturerArcusStone Products, LLC180 Harbor DriveSuite 200Sausalito, CA 94965 (415) 339-4060Fax: (415) 339-4065E-mail: [email protected]

3. Product Description

BASIC USEArcusStoneª products are decorative limestone coatings that replicate cut or dimensioned stone and aged, mottled plaster. ArcusStone products can be used on exterior or interior applications for commercial or residential proj-ects. ArcusStonecoat can be textured, honed and finished like cut stone or given the look of a more rustic fieldstone. ArcusStone products can be applied over a variety of substrates, including Portland cement plaster (stucco), gypsum board, poured-in-place concrete, CMU blocks, brick masonry, cement backer boards, lightweight concrete, ceramic or natural stone tile and EPS foam.

COMPOSITION & MATERIALSArcusStonecoat« and ArcusPlaster«™are com-prised of patented blends of limestone aggre-gates, bonding agents and Portland cement. Both products are colored using mineral oxide pigments, ensuring a high resistance to UV light degradation and fading.

TyPES• ArcusStonecoat material can be used to

create countertops, fireplaces, door and window surrounds, custom columns, arches, flooring, wainscoting, and numerous other decorative stone elements

• ArcusPlaster creates a European look ofmottled, aged stucco that has developed a rich, warm patina over time

COLORDetails concerning standard colors and textures are available from the manufacturer. Color

matching is available. Requests for custom col-ors or textures must be reviewed by an ArcusStone technical representative or a trained applicator.

BENEFITS• Produces the look of quarried stone, cut

stone, aged plaster or stucco finishes with-out the associated expense

• Can be custom colored and textured,offering infinite design flexibility with a vari-ety of natural colors, textures and patinas

• Can be utilized by trained applicators andindependent manufacturers in the production of complementary cast stone, coated foam, tile and mosaics products for cost-effective, coordinated custom designs

• ArcusStonecoatedfoamshapesare light-weight and easy to install, making them ideal for large-scale decorative elements, such as sills, corbels, and moldings in which the weight of solid cast stone is prohibitive

LIMITATIONS• ArcusStonecoatisnevertobeusedtocoat

over or fill in expansion joints• Ifcoatingovercontroljoints,acoursingpattern

(grout lines) must be provided directly above these joints to prevent cracks in the ArcusStonecoat at these locations

• ArcusStonecoatingsarenottobeappliedover EIFS acrylic, elastomeric or urethane finish coats

• Pieces precoated with ArcusStone coatingsshould not exceed 32" (813 mm) in length due to weight and ease of installation considerations

• FiberboardsheathingssuchasCelotexarenot acceptable as substrates for ArcusStone products

• The composition of the underlying structure,design limits, composition and stability of any substrate must be determined before install-ing ArcusStonecoat in order to prevent unfore-seen structural or flexural problems that may result in finish cracking or delaminating

4. Technical Data

APPLICABLE STANDARDSASTM International• ASTM C150 Standard Specification for

Portland Cement• ASTM C926 Standard Specification for

Application of Portland Cement-Based Plaster• ASTM C932 Standard Specification for

Surface-Applied Bonding Compounds for Exterior Plastering

• ASTMD1784StandardSpecificationforRigidPoly(Vinyl Chloride) (PVC) Compounds and Chlorinated Poly(Vinyl Chloride) (CPVC) Compounds

• ASTMD4258StandardPractice forSurfaceCleaning Concrete for Coating

• ASTMD4259StandardPracticeforAbradingConcrete

®

European Village and Resort, Palm Coast, FL ArcusPlaster« façade, ArcusStonecoat« columns, arches, architectural details

portland cement plastering 09 24 00

ArcusStone Products, LLC

®

SPEC-DATAª and MANU-SPECª are registered trademarks of Reed Elsevier Inc. The ten part SPEC-DATA format conforms to the editorial style of The Construction Specifications Institute and is used with their permission. The manufacturer is responsible for technical accuracy. ©2008 Reed Construction Dataª. All Rights Reserved.

• ASTM D4260 Standard Practice for Liquidand Gelled Acid Etching of Concrete

• ASTM D4261 Standard Practice for SurfaceCleaning Concrete Unit Masonry for Coating

American Concrete Institute (ACI) ACI 524R - Guide to Portland Cement Plastering

Florida Building Code, 2001 Edition, or 1997Uniform Building Code

Portland Cement Association - Portland Cement Plaster (Stucco) Manual

FIRE PERFORMANCEArcusStone material is noncombustible.

PHySICAL/CHEMICAL PROPERTIES• TheArcusStonematerialislightweight,aver-

aging approximately 1 psf (4.88 kg/m2) for every 1/8" (3.2 mm) of thickness

• Compressivestrengthisapproximately4650psi (32 MPa) at 3/8" (9.5 mm) thickness after 28 days

• Porosityisapproximately6%

ENVIRONMENTAL CONSIDERATIONSArcusStone products require a low energy investment to produce them, incorporate high recovery and recycling properties and are safe from chemical contaminant emis-sions. In their fully cured state, the aggregates, cement and other components of ArcusStonecoat and ArcusPlaster form a strong bond and are completely stable and nontoxic.

During application and curing, some ventila-tion is recommended. Because dust is created in the process of finishing field-applied stone, the use of face masks is also recommended.

5. Installation

PREPARATORy wORkDelivery and StorageDeliver products in manufacturer’s original, unopened, undamaged containers with identifi-cation labels intact. Store materials under cover and keep them dry and protected against damage from weather, direct sunlight, surface contamination, corrosion, construction traffic and other causes. Avoid prolonged storage of stacked ArcusStone goods at temperatures exceeding 100 degrees F (38 degrees C) if stacked over two pallets in height.

Preinstallation• Priortoinstallation,fabricatepanelsincompli-

ance with ArcusStone Products, LLC, recom-mendations for each type of required finish, application, and trim work in order to verify selections made from sample submittals and demonstrate aesthetic effects of application

• Verify that site conditions are acceptablefor installation in compliance with ASTM C926. Do not proceed with installation until unacceptable conditions are corrected

• Chipbackconcreteasrequiredandreplacemasonry where necessary to avoid thickness greater than indicated for finished systems

• Clean concrete and masonry surfaces incompliance with ASTM C926 to remove oil, wax, grease, sealants, efflorescence, and foreign matter immediately before appli-cation of bonding agent and stucco work

• IncompliancewithASTMC932,applybond-ing agent to fully dry, smooth concrete and masonry exterior surfaces, which must be devoid of form-oils, dirt and residue of any type per manufacturer’s recommendations

Detailed site preparation directions may be obtained from ArcusStone Products, LLC.

METHODSArcusStonecoat is hand tooled to produce the look of quarried or cut stone finishes, com-plete with grout lines. ArcusPlaster is also hand finished to achieve the classic look of aged plaster or stucco. Both products are installed exclusively by trained contracted applicators who have successfully completed an ArcusStone Products, LLC, installation instruc-tion session given by the manufacturer’s agentsorauthorizedrepresentatives.Products

can be either hand-troweled or spray applied. The ArcusStonecoat coating is typically at 3/8" (9.5 mm) thickness and the ArcusPlaster at an average thickness of 3/16" (4.8 mm).

PRECAUTIONSApply and cure ArcusStone coatings to prevent drying out while curing. Use procedures outlined by the manufacturer, and as required by cli-matic conditions, to include providing coverings and barriers to deflect sunlight and wind. Apply ArcusStone materials when ambient tempera-ture is greater than 40 degrees F (4 degrees C) and when temperature is expected to remain above 40 degrees F (4 degrees C) for 48 hours following application. Protect ArcusStone coat-ings against uneven and excessive evaporation and from strong flows of dry air, both natural and artificial. Provide suitable coverings and barriers to deflect sunlight and wind. Protect contiguous work from soiling and moisture deterioration caused by ArcusStone finish appli-cation. Provide temporary covering and other provisions necessary to minimize spattering ofArcusStone materials on other work.

BUILDING CODESInstallation must comply with the requirements of all applicable local, state and federal code jurisdictions.

®

Stix Restaurant, Memphis, TN ArcusStonecoat« façade

Private wine Cellar, Lafayette, CA ArcusStonecoat« columns, arches and floor

portland cement plastering 09 24 00

ArcusStone Products, LLC

®

SPEC-DATAª and MANU-SPECª are registered trademarks of Reed Elsevier Inc. The ten part SPEC-DATA format conforms to the editorial style of The Construction Specifications Institute and is used with their permission. The manufacturer is responsible for technical accuracy. ©2008 Reed Construction Dataª. All Rights Reserved.

6. Availability & Cost

AVAILABILITyProductsareavailablefromauthorizeddistrib-utors who sell exclusively to trained and quali-fied ArcusStone applicators and manufactur-ers. Contact manufacturer for information on local availability.

COSTBudget installed cost information may be obtained from authorized distributors andtrained applicators.

7. WarrantyComplete warranty terms and conditions are available from the manufacturer. For details, consult ArcusStone Products, LLC.

8. MaintenanceArcusStonecoat and ArcusPlaster products are exceptionally durable due to their high strength, minimum porosity, and surface hardness. This durability translates to long life expectancy with negligible maintenance, which contributes to a low life cycle energy cost.

Pre-wet the surfaces to be cleaned, wash with a neutral pH detergent solution and scrubbing brush, then rinse clean. Sealed sur-faces may be pressure washed or steam cleaned following recommended procedures and working pressure given by the machine manufacturer for use on porous surfaces to avoid any potential damage to the surface.

To pressure wash unsealed ArcusStone sur-faces, first test an inconspicuous area, making sure that the machine manufacturer’s recom-mended procedures and working pressure are strictly followed. Unsealed ArcusStone surfaces that have topically applied shading color should not be pressure washed.

It is strongly recommended that the ArcusStonecoat and ArcusPlaster products be sealed to help ensure protection from UV light, graffiti, caustic chemicals or staining from other sources such as tree sap, soot, bird or animal droppings. Information concerning recom-mended sealers and application instructions can be obtained from the manufacturer.

9. Technical ServicesTechnical assistance, including more detailed information, product literature, test results, proj-ect lists, assistance in preparing project specifi-cations and arrangements for application supervision, is available by contacting ArcusStone Products, LLC.

10. Filing Systems• MANU-SPECª• Additionalproduct information isavailable

from the manufacturer upon request.

®

Estate Home, Nashville, TN ArcusStonecoat« foundation, water table and architectural details