Photolithography chapter by scotten w. jones

Click here to load reader

-

Upload

uc-berkeley -

Category

Engineering

-

view

238 -

download

41

Transcript of Photolithography chapter by scotten w. jones

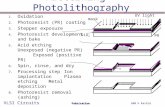

PhotolithographyWritten by: Scotten W. Jones

i

Preface

The following document was written in 2000 as a chapter on Photolithography for inclu-sion in a highly technical - text book on Silicon Integrated Circuit Process Technology. Formarketing reasons we abandoned the book without completing it but this was one of severalchapters that are complete. This chapter is a follow on to the chapters on diffusion and siliconproperties we posted previously. We hope you find it useful.

Please note that this material was written back when we planned to publish it as a hardcover book in black and white and is not in color the way all of the current IC Knowledgereports are.

Scotten W JonesPresidentIC Knowledge LLCFebruary 20, 2008

ii

Contents

1.1. Introduction 11.2. Photoresist chemistry 21.3. Surface preparation 241.4. Coating 271.5. Soft bake 321.6. Optical principles 361.7. Optical exposure 601.8. Process and resolution enhancements 781.9. Non optical exposure 851.10. Post exposure bake 911.11. Develop 921.12. Hard bake 951.13. Photo stabilization 971.14. Photolithography process flows 971.15. Multilevel photoresists 991.16. Multilayer photoresist 1001.17. Metrology and inspection 101

Copyright © 2000 IC Knowledge LLC, all rights reserved 1

5 Photolithography

5.1. Introduction5.2. Photoresist chemistry5.3. Surface preparation5.4. Coating5.5. Soft bake5.6. Optical principles5.7. Optical exposure5.8. Process and resolution enhancements5.9. Non optical exposure5.10. Post exposure bake5.11. Develop5.12. Hard bake5.13. Photo stabilization5.14. Photolithography process flows5.15. Multilevel photoresists5.16. Metrology

5.1. IntroductionThe incredible progress the IC industry has made in packing more and more functionality

onto a single chip has been driven by photolithography to a greater extent than any other area ofprocessing. From 1970 when 10�m lines were the predominant linewidth, to 2000 when0.18�m linewidths are in volume production, linewidths have shrunk by nearly two orders ofmagnitude -see figure 5.1. In this chapter photolithography will be reviewed. The chapter openswith a discussion of photoresist chemistry followed by a detailed step by step discussion of thephotolithography process. Supplemental material on optics that is required to understand opti-cal exposure will be presented along with the latest optical exposure resolution enhancementtechniques. Some candidate post optical exposure systems will be presented and overall photo-lithography process flows will be reviewed. The chapter closes with a discussion of metrologyequipment relevant to photolithography.

2 Copyright © 2000 IC Knowledge LLC, all rights

Figure 5.1: Minimum linewidth trends [1],[2],[3].

5.2. Photoresist chemistryThe word Photoresist comes from the combination of photosensitive and acid resistant, i.e.

a photoresist can be photographically patterned and will stand up to acid etch, enabling pat-terned etching. A photoresist useful for IC fabrication must exhibit several characteristics inaddition to photosensitivity and acid resistance - they are:1. Coating - must be able to form a thin, uniform, pinhole free film.2. Adhesion - adheres to the underlying substrate and does not “lift off” during subsequent

processing. 3. Sensitivity -must be sensitive to the wavelength of radiation utilized for exposure. 4. Resolution - the ability to resolve the required minimum feature size being printed.5. Developing - must exhibit a significant difference in develop rate between the exposed and

unexposed areas without pattern distortion.6. Process resistance - withstands plasma etch processes, high dose ion implantation, and wet

etchants.7. Easy removal - must be removable following processing.8. Thermal stability - must withstand bake processes without pattern distortion.9. Stability - the formulation must be stable enough to be stored for reasonable periods of time

without requiring prohibitively difficult storage conditions.10. Safety - the material cannot present an unacceptable health hazard.

10

1

Intel X86 MPU

ITRS MPU - gateDRAM

IRTS DRAM - 1/2 pitch

0.1

40048008

1K 4K16K 64K

256K

1M

4M

16M

64M64M

256M

8080

80858086

8088

286 386

486P1

P1 PP

PII

PII

PIII

0.011970 1980 1990 2000 2010

Year

Lin

ewid

th (

m)

�

Copyright © 2000 IC Knowledge LLC, all rights reserved 3

Practical photoresists meeting the above criteria are available from a number of supplierssuch as Shipley, Clariant/Az, Olin Microelectronics, Sumitomo Chemical Co., etc.

Practical photoresists are generally composed of three major components:1. Polymer - the polymer is the backbone of the photoresist. Following exposure and develop-

ing the polymer is the major constituent of the patterned photoresist film.2. Photo active compound (PAC) - the PAC is the constituent of the photoresist that undergoes

a reaction when exposed to light. The photoactive compound may be combined with thepolymer.

3. Solvent - keeps the photoresist in liquid form until after coating.Photoresist may be classified as negative or positive photoresist.

• Negative photoresist - relatively developer soluble until exposed to light at which point theexposed portion exhibits decreased developer solubility.

• Positive photoresist - relatively developer insoluble until exposed to light at which pointthe exposed portion exhibits increased developer solubility.Figure 5.2 illustrates negative and positive photoresist behavior.

Figure 5.2: Negative and positive photoresist.

5.2.1. Photochemistry basicsIn order for exposure to light to change the developer solubility of a photoresist film - some

type of photochemical reaction must take place. The 1st law of photochemistry - the Grotthus-Drapper law states• First law of photochemistry - only light that is absorbed can cause chemical change.

When a molecule absorbs a photon of light, the molecule is promoted to an excited state.Most molecules have an even number of electrons in the ground state and the electrons are spinpaired, i.e. the molecule has no net spin angular momentum and the state is referred to as a sin-glet. The singlet ground state is typically denoted as S0. In most absorption processes an elec-tron is excited to a higher energy level, S1, S2, S3 etc. - see figure 5.3a. Each singlet state has acorresponding triplet state where the electrons are not spin paired, denoted, T1, T2, T3, etc. - see

a) Negative photoresist b) Positive photoresist

ExposeExposed area

Unexposed area

Exposing radiation Exposing radiation

Develop

Patternedphotomask

4 Copyright © 2000 IC Knowledge LLC, all rights

figure 5.3b (the states are called triplets because in a magnetic field they break up into threelevels).

Figure 5.3: Singlet and triplet states

Due to the same spin pairing of the outermost electrons in the triplet state, the Pauli exclu-sion principle forces the electrons to be more widely spaced resulting in the triplet state havinga lower energy than the corresponding singlet state. Non radiative transitions between stateswith the same spin are referred to as internal conversions, where an electron transitions from ahigher electronic state to the upper vibrational level of the lower state, for example S2 -> S1 orT2 -> T1. These transitions are isoenergetic. When a non radiative transition occurs betweenstates with different electron spins an intersystem crossing occurs and the transition is followedby a vibrational cascade, for example S1 -> T1 or S2 -> T2. Molecules in an exited vibrationalstate, singlet or triplet may undergo radiative transitions where the molecules relax by emittinga photon, non radiative transitions for example vibrational, or they can undergo a variety ofphotochemical reactions as illustrated in figure 5.4 [4].

The activation energies for chemical reactions are generally in the 0.43 - 4.33eV range. The energy of an incident photon is given by

(5.1)

where, � is the wavelength of the incident light, h is planks constant and C is the speed of lightin a vacuum (see appendix C for the values of h and C).

Table 5.1 presents the photon energy for some current and planned exposure wavelengths.The second law of photochemistry is the Stark - Einstein law (not really a law):

• Second law of photochemistry - one quantum of light is absorbed per molecule of absorb-ing and reacting substance.The quantum yield of the process is defined as

(5.2)

S0 S1 T1

AbsorptionIntersystem

crossing

Photon

a) Absorption b) Intersystem crossing

E hCλ

-------=

φ # of molecules decomposed or formed# of quanta absorbed

--------------------------------------------------------------------------------------------=

Copyright © 2000 IC Knowledge LLC, all rights reserved 5

Quantum yields of photochemical reactions at room temperature range over approximatelyseven orders of magnitude from 1x10-2 to 1x105.

Figure 5.4: Primary photochemical reactions [4].

Two other important laws of photochemistry are:• Lambert law - the fraction of incident radiation absorbed by a transparent medium is inde-

pendent of the intensity of the incident radiation and each successive layer of the mediumabsorbs an equal fraction of the incident radiation.

• Beer law - the amount of radiation absorbed is proportional to the number of absorbingmolecules.If light with an initial intensity I0 is incident on a photoresist film, then the portion of the

incident intensity absorbed in a thickness dx is given by (see figure 5.5)

(5.3)

where, � is the absorption coefficient and C is the absorbing molecules per unit volume.

Table 5.1: Photon energy of exposure wavelengths.

Wavelength(nm)

Energy(eV)

436 2.84

365 3.40

248 5.00

193 6.42

157 7.90

(S ) ABC1

S1 - singlet, T - triplet1

AB + C• •

E + F

Dissociation into radicals

Decomposition into molecules

Intermolecular rearrangement

Photoisomerization

Hydrogen ion abstraction

Photodimerization

Photosensitization

Photoionization

External electron transfer

Internal electron transfer

ACB

(ABCH) + R• •

ABC + prod

ABC + e+ -

AB + C+ -

ABC + D+ (o r-) - (o r+)

(ABC)2

RH

D

ABC

ABC*(S )1

ABC*(S )0

ABC*(T ) or1

(T ) ABC1

ΔII0------ αCdx=

6 Copyright © 2000 IC Knowledge LLC, all rights

The specific value of � depends on the photoresist film and the wavelength of the incidentradiation. Curves for various photoresists are available and may be expressed as optical densityor absorbance versus wavelength, where optical density is defined as (see also figure 5.5)

(5.4)

and

(5.5)

Figure 5.5: Photoresist exposure energy absorption.

Absorbance curves for various photoresist will be presented later in this section.

5.2.2. Negative photoresistThe first commercial photoresist for semiconductor production was a negative photoresist -

Kodak Thin Film Resist (KTFR) invented by Martin Hepher and Hans Wagner [5]. KTFR wenton to become the workhorse photoresist for the semiconductor industry from 1957 untilapproximately 1972 when minimum dimensions reached approximately 2�ms - the resolutionlimit for KTFR [6]. Due to the popularity of KTFR, KTFR will be discussed in detail as anexample of a negative photoresist. It should be noted that there are other successful negativephotoresist formulations.

The polymer in KTFR is a cyclized poly(cis-isoprene) of molecular weight of approxi-mately 150,000. A synthetic rubber is treated with acidic reagents to reduce the degree ofunsaturation in the rubber and stabilize the rubber against O2 mediated cross-linking [6]. • Unsaturation - the total number of multiple bonds or rings in a molecule.

The preparation of synthetic cis-1,4-polyisoprene is illustrated in figure 5.6. Notice howtwo double bonds are replaced by a single double bond, i.e., the degree of unsaturation isreduced.

OD Log I0I----=

I I0 I– 010 αCx–=

I0 at 0

I at x

Film

Incidentradiation

Intensity x

dx

Copyright © 2000 IC Knowledge LLC, all rights reserved 7

Figure 5.6: Preparation of synthetic cis-1,4-polyisoprene [7].

The cyclization process lowers the viscosity of the rubber and raises the softening pointfrom 30 to nearly 60oC [6].

The polyisoprene from figure 5.6 is cyclized to produce resin (see figure 5.7). • Cyclization - formation of a ring compound from a chain by formation of a new bond.

Cyclization is accomplished by reacting acidic reagents with shredded rubber. Suitableacids include: sulfuric acid, p-toluene sulfonic acid, p-toluene sulfonyl chloride, and phenolsulfonic acid derivatives [7].

Figure 5.7: Polyisoprene resin formation [7].

There are several possible cyclization modes that may result (see figure 5.8). The cyclicityis given by

(5.6)

where, n is the number of isoprene units.

CH2 CH2CH2 CH2

CH3 CH3

CH CHC Cnn

CH2

CH2

CH2

CH2

CH2

CH2

CH2

CH2

HC

HCH

HC

HCH

HC

HC

HC

HC

HCH

HCH

HCH

HCH

CH3

CH3

CH3

CH3

CH3

CH3

CH3

CH3

C

C

C

C

C

C

C

C

HCH

HCH

HCH

HCH

Rubber (natural or synthetic)

Repeating structure ofpolyisoprene polymer. Note:there is one double bond foreach five carbon atoms.

Resin

Isomeric after structuremonacyclization(D’Ianni [8])Note: there is one double bondfor each ten carbon atoms.

cyclicity n 1–=

8 Copyright © 2000 IC Knowledge LLC, all rights

Figure 5.8: Cyclization modes [7].

The properties of polyisoprene before and after cyclization are presented in table 5.2.The cyclization process creates a more compact and rigid structure as double bonds are

eliminated. From table 5.2, the density, refractive index and softening point all increase and theviscosity decreases during cyclization. • Viscosity - an internal property of a fluid that offers resistance to flow.

Photoresist properties such as photospeed, adhesion and thermal behavior all depend on thespecifics of the cyclization process [21]. High molecular weight cyclized rubbers show greaterphoto sensitivity but also show poorer adhesion and are more difficult to develop cleanly.Cyclized rubber does not absorb light above 300nms and does not undergo significant curingunder ultraviolet (UV) exposure. In order to render cyclized rubber photosensitive a sensitizeris used. The sensitizer used in KTFR is a bis-arylazide, 2,6-bis(4-azidobenzal)-4-methylcyclo-hexanon.• Azides - compounds containing one or more N3 group.

2,6-bis(4-azidobenzal)-4-methylcyclohexanone is synthesized by condensation of para-azi-dobenzaldehyde with a substituted cyclohexane - see figure 5.9.

Table 5.2: Properties of polyisoprene before and after cyclization [21].

Property Un-cyclized Cyclized

Density 0.920 0.992

Refractive index 1.520 1.545

Softening point (oC) 28 50-65

Intrinsic viscosity 3-4 0.49-0.36

CH2

CH2 CH2

CH2

CH2 CH2

CH3

CH3

CH3 CH3

CH2

CH3 CH3

CH2

CH2

CH3

CH3

a) D’Ianni [8] b) Isomers

c) Bicyclic

Copyright © 2000 IC Knowledge LLC, all rights reserved 9

Figure 5.9: 2,6-bis(4-azidobenzal)-4-methylcyclohexanone sensitizer formation [6].

In order to effectively cross-link cyclized rubber the sensitizer must have two reactive sites.Upon exposure to light, the N3 groups terminating the ends of the sensitizer may give up an N2molecule and leave a reactive nitrogen radical with 6 rather than 8 electrons in the valence shell- referred to as a nitrene - see figure 5.10.

Figure 5.10: bis-arylazide sensitizer reaction with light.

The exposure reaction may be monophotonic with a single photon breaking 2 - N2 mole-cules free leaving a nitrene at each end of the bis-arylazide, or biphotonic where two photonsare required to create a nitrene at each end.

The resulting nitrene may exist in the single or triplet state and is highly reactive. There are5 probable nitrene reactions [21]:1. Addition to olefins - nitrene additions to double bonds to form 3 membered azirdine ring

compounds. This reaction is believed to be restricted by low concentration and sterically hindered nature of the double bond in cyclized rubber.

2. Hydrogen abstraction - nitrene abstraction of hydrogen atoms from cyclized rubber fol-lowed by recombination of the nitrogen and carbon radicals to form secondary amines. These reactions occurring at both ends of the bis-arylazide lead to polymer crosslinking - see figure 5.11. Polymer crosslinking reduces the solubility of the photoresist in developer.

Figure 5.11: bis-arylazide sensitizer - polymer cross - linking.

+ 2

CH3

O C

HO

N3

CH

CH3

O

CH N3N3

NN R

N2 N2

LightLight

NN

Pol

ymer

Pol

ymer

R

10 Copyright © 2000 IC Knowledge LLC, all rights

• Amine - a simple compound containing an ammonia group such as RNH2, R2NH or R3N,where R is either an akyl or aryl hydrocarbon radical.

3. Dimerization - nitrogen-nitrogen double bonds form between bis-arylazide sensitizers by

(5.7)

This reaction competes with crosslinking, but is inconsequential as long as the sensitizerconcentration isn’t too high.

4. Azide decomposition - a nitrene - nitrogen bond forms between bis-arylazide sensitizers by

(5.8)

Once again this reaction competes with crosslinking, but once again is inconsequential aslong as the sensitizer concentration isn’t too high.

5. Oxidation - an oxygen atom reacts with a nitrene preventing cross linking by

(5.9)

Oxidation is minimized by limiting oxygen availability during exposure. Commercialexposure systems typically provide a nitrogen “blanket” during exposure.Due to reactions 3 and 4, there exists an optimum sensitizer level above which reactions 3

and 4 become prevalent and below which the photoresist does not exhibit sufficient photo-sen-sitivity.

Because bis-arylazide sensitizers evolve nitrogen during exposure the exposure reactionrate must be controlled by limiting the incident exposure intensity in order to prevent nitrogenbubble formation in the film. Nitrogen bubbles can break down the film adhesion and effectresolution.

The absorbance of a bis-arylazide sensitizer versus wavelength is illustrated in figure 5.12.Figure 5.12 also illustrates the extended absorbance of bis-arylazide that has undergone

extended conjugation with vinylic groups. Bis-arylazide sensitivity drops off to near zero at400nm, but with extended conjugation the sensitivity can be extended to longer wavelengths.The longer wavelength sensitivity can be useful with exposure systems where the light sourceis filtered to only include a single wavelength such as 436nm (G-Line) systems (see section 5.6and 5.7).• Conjugation - alternating single and double bonds.

In the case of bis-arylzides the single and double bonds connecting the carbon rings asshown in figure 5.13a are “extended” as illustrated in figure 5.13b.

The solvents for cyclized rubber photoresist include, toluene, xylene, and halogenatedhydrocarbons, with xylene being the most common. The structures of xylene and toluene areillustrated in figure 5.14. There are three forms of xylene illustrated that are found mixedtogether in commercial xylene, metaxylene is the predominant form.

Following exposure, cyclized rubber photoresist developing is performed by exposing thephotoresist to solvents with a solubility parameter similar to the solubility parameter of thephotoresist - “like dissolves like” - for example, stodard solvent or xylene � = 8.8. • Solubility parameter - the solubility parameter is defined as

R N:– :N R R N–→–+ N R–=

R N:– N3 R R N–→–+ N R– N2+=

R N– 1 2⁄ O2 R N–→+ O=

Copyright © 2000 IC Knowledge LLC, all rights reserved 11

(5.10)

where, D is density, �HV is the heat of vaporization, T is the temperature in oK and M is themolecular weight. For polymers, � is found by noting the range of � parameter solvents thepolymer dissolves in.

Figure 5.12: Absorbance versus wavelength for bis-arylazide sensitizer [22].

Figure 5.13: Extended conjugation of bis-arylazide [22].

Figure 5.14: Cyclized rubber photoresist solvents.

δΔEV

V----------

D ΔHV RT–( )M

----------------------------------⎝ ⎠⎛ ⎞

1/2= =

0.0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

1.6

bis arylazides

Afterextendedconjugation

360nm

400nm

1.8

2.0

300 400Wavelength (nm)

Ab

sorb

ance

500

CH3

O

a) bis-arylzide b) bis-arylzide after extended conjugation

N3N3

CH3

O

N3 N3

CH3 CH3 CH3 CH3

CH3

CH3

CH3

Orthoxylene Metaxylene Paraxylene

a) Xylenes b) Toluene

12 Copyright © 2000 IC Knowledge LLC, all rights

Upon exposure to the developing solvent the cyclized rubber polymer swells. Where thepolymer is crosslinked from exposure the cross-links hold the polymer together and where thepolymer is not crosslinked the polymer strands are washed away by the developer - see figure5.15.

Figure 5.15: Cyclized rubber photoresist developing.

One consequence of the solvent based developing process is that photoresist swells in boththe un-exposed and exposed area. At the completion of developing the photoresist is rinsedwith a solvent which is miscible with developer but not with the polymer, for example butylacetate, � ~12.4 or a isopropanol/trichlorethylene mixture. The rinsing step halts developingand reduces the photoresist swelling. The final photoresist image is distorted to some degree bythe developing process and ultimately this limits the resolution of cyclized rubber photoresist.Figure 5.16a illustrates cyclized rubber photoresist developing in the presence of “good” adhe-sion and figure 5.16b illustrates the effect of developing on resist with “poor” adhesion.

Figure 5.16: Effect of adhesion on cyclized rubber photoresist developing.

In addition to the base polymer, photo sensitizer and solvent, negative photoresist willcommonly contain additives to improve the performance of the resist. For example, negativephotoresists can react with nitrogen dioxide and ozone to form NO2, NO3 and NO polar groupsthat interfere with the developing of the resist. The result is “scumming” and anti-scummingadditives may be used to prevent the undesired reactions.

5.2.3. Positive photoresistBy 1972 the limitations of negative photoresists had been reached and Diazonaphtho-

quinone/novolac (DQN) based positive photoresist had taken over the IC photolithographymarket. For the next quarter century DQN based photoresists held over 90% market share [6].

a) Unexposed region b) Exposed region

a) "Good" adhesion

Exposure

Exposed regions Exposed regions

Duringdevelop

b) "Poor" adhesion

Copyright © 2000 IC Knowledge LLC, all rights reserved 13

The base resin of DQN is novolak resin. Novolak resin is generated by reacting meta-cresol -figure 5.17a, in excess with formaldehyde - figure 5.17b, the result is novolak resin - figure5.17c. The excess cresol during the reaction results in both ends of the novolac resin being ter-minated by phenol groups, therefore the novolak resin does not cross-link.

Figure 5.17: Novolak resin generation.

The photosensitive element in DQN photoresists is naphthoquinone diazide sulfonylchlo-ride. Naphthoquinone diazide sulfonylchloride generation begins with hydroxy naphthalenesulfonic acid - figure 5.18a, which undergoes nitration and reduction with sodium dithionite orraney nickel catalyst - figure 5.18b, which is then reacted with HCl and NaNO2 -figure 5.18c,and ClSO3H at 60oC to produce the sensitizer [7].

Figure 5.18: Generation of Naphthoquinone diazide sulfonylchloride [7].

The combination of naphthoquinone diazide sulfonylchloride and novolak resin creates aphotosensitive resin - DQN - figure 5.19.

OH OH

C O+

Hacid

HCH3 CH3

CH2

a) Meta-cresol(in excess)

b) Formaldehyde c) Novolak resin

OH OH

OHO

O

SO H3 SO H3

SO H3SO H3

SO Cl2

NO2

NH2N2

N2

a) Hydroxy naphthalenesulfonic acid

b) Reduction bySodium dithionite orraney nickel catalyst

d) ClSO H

at 60 C3o

e) Naphthoquinone diazidesulfonylchloride

c) HClNaNO2

14 Copyright © 2000 IC Knowledge LLC, all rights

Figure 5.19: Generation of light sensitive novolak resin - DQN.

When exposed to light the naphthoquinone diazide sulfonylchloride undergoes a reaction,see figure 5.20.

Figure 5.20: Naphthoquinone diazide sulfonylchloride photochemical reaction.

O

O

+

SO Cl2

SO2

N2

N2

a) Naphthoquinone diazidesulfonylchloride

OH

CH3

CH3

CH2

CH2

b) Novolak resin

O O

+ H O2

N2 + N2

+ H2OHydration

DevelopingNaOH

C

C ONa

O

COOH

H

H H

O

a) Naphthoquinone diazidesulfonylchloride

b) Keto-carbene

c) Ketene d) Indene-3-carboxylic acid

Light

SO Cl2

SO Cl2

SO Cl2

SO Cl2

SO Cl2

Copyright © 2000 IC Knowledge LLC, all rights reserved 15

When it is exposed to light naphthoquinone diazide sulfonylchloride undergoes a pho-tolytic decomposition to an unstable keto-carbene and nitrogen - figure 5.20b. The keto-car-bene immediately rearranges to a more stable ketene - figure 5.20c. The ketene structure is veryhydroscopic and immediately reacts with water to form carboxylic acid - figure 5.20d. This isthe Suss reaction [9] except that Suss believed that the carboxylic acid was indene-1-carboxylicacid which was later shown to be indene-3-carboxylic acid [6]. The carboxylic acid is solublein basic developers.

The absorbance of light versus wavelength for novolak resin and naphthoquinone diazidesulfonylchloride sensitizer is illustrated in figure 5.21.

Figure 5.21: Absorbance of novolak resin and naphthoquinone diazide sulfonylchloride sensitizer versus exposing wavelength.

Also illustrated in figure 5.21 are arrows corresponding to intensity peaks in the output of amercury lamp. Mercury lamps were used as the exposing light source during the time periodwhen DQN was the dominant photoresist. At the beginning of the use of DQN, the broad bandoutput of the mercury lamp was used. As exposure systems became more sophisticated themercury lamp output was filtered to a narrow output band. Initially the 436nm output peak -referred to as the G-line, was the predominant exposure wavelength. As minimum linewidthscontinued to shrink, the 365nm - I-line wavelength began to be used (the effect of exposurewavelength on resolution will be discussed in detail in section 5.6). Throughout the broad bandmercury, G-line and I-line exposure periods, DQN photoresist remained the dominant photore-sist. I-line photoresists were improved formulations of DQN with greater consistency and opti-mized additives.

As the photoresist is exposed at G or I-line, the sensitizer provides the principle absorbanceof the exposing radiation. As the sensitizer reacts to exposure, the sensitizer is “bleached” and

2000

0.1

0.2

0.3

0.4

0.5

0.6

0.7

Resin Sensitizer0.8

0.9

1.0

300Wavelength (nm)

Ab

sorb

ance

400 500

I-lin

e

G-li

ne

16 Copyright © 2000 IC Knowledge LLC, all rights

the absorption drops. The bleaching reactions allows relatively thick photoresist films to beused and as the sensitizer “bleaches” the exposing radiation reaches deeper and deeper into thephotoresist.

During exposure a possible side reaction is the combination of a keto-carbene and a keteneto form a dioxole - figure 5.21. Dioxole formation consumes two reactive specie, but is unlikelyto occur due to the short life of the keto-carbene specie and in dried photoresists the restrictedmovement of molecules [10].

Figure 5.22: Dioxole formation during DQN exposure.

The solvents utilized to keep DQN photoresist in solution were typically cellosolve acetate- ethylene glycol monoethyl ether acetate also referred to as EGMEA. Later in the developmentof DQN photoresists health concerns about EGMEA led to the replacement of EGMEA withPGMEA - propylene glycol monoethyl acetate.

The developing reaction for DQN photoresist is fundamentally different from negativephotoresists. Where negative photoresist developing is a physical reaction - swelling of thepolymer, DQN developing is a chemical etching reaction.

The photoresist in the exposed areas is rendered base soluble by exposure. Bases such assodium hydroxide - NaOH or more commonly tetra methyl ammonium hydroxide - TMAH -(CH3)4NOH, will dissolve the exposed photoresist.

In unexposed regions of the photoresist the sensitizer - figure 5.23a, forms an azo couple -figure 5.23c, with the resin - figure 5.23b, resisting the action of the developer solution. Anunfavorable reaction that can occur during developing is the reaction of the unexposed naph-thoquinone diazide sulfonylchloride - figure 5.24a, with carboxylic acid - figure 5.24b, to formazo dye - figure 5.24b. Azo dye formation is unfavorable unless the photoresist is underex-posed in which case azo dye can cause scumming during develop.

A number of additives are utilized in commercial DQN photoresist formulations. Dyes areadded to mask discoloration of the resist during storage, surfactants are used to improve coatinguniformity, and a variety of additives are used to improve adhesion, heat resistance, dry etchresistance, photospeed, and developing.

O

OO

C

+C O

a) Keto-carbene

c) Dioxole

b) Ketene

SO Cl2

SO Cl2

SO Cl2

SO Cl2

Copyright © 2000 IC Knowledge LLC, all rights reserved 17

Figure 5.23: Unexposed area of DNQ photoresist during developing.

Figure 5.24: Azo dye formation during develop.

5.2.4. 248nm photoresistIn order to continue shrinking minimum linewidths, the industry continued to explore the

use of shorter exposure wavelengths (see section 5.6 for a discussion of the effect of exposurewavelength on minimum linewidths). The first production worthy tool capable of “deep ultravi-olet - DUV” (140 to 300nm wavelength) exposure was the Perkin Elmer 500 Micrascan� sys-tem [6]. The Perkin Elmer 500 utilized a mercury arc lamp with very low output in the DUVregion. Ideally photoresist for DUV would have much higher sensitivity than the “standard”DQN photoresist in order to support short exposure times and therefore high exposure systemproductivity. Another issue with DQN photoresist for DUV is the high absorbance of thenovolak resin in the DUV region - see figure 5.21.

O O

O O

O O

OH OHHO HO

+SO2 SO2

N2 N N

a) Sensitizer inunexposed area

NaOHdeveloper

b) Resin c) Azo coupled resinand sensitizer

C C

OH

OH

CH2

CH2

O

OH

N2

NN

+

COOH

COOH

H

H

H

H

a) Naphthoquinone diazidesulfonylchloride

b) Indene-3-carboxylic acid

c) Azo dye

SO Cl2

SO Cl2

SO Cl2

SO Cl2

18 Copyright © 2000 IC Knowledge LLC, all rights

In 1978, Jean Frechet and Grant Willson set out to design a chemically amplified photore-sist with much higher sensitivity than existing photoresists [6]. In a chemically amplified pho-toresist system a catalytic specie generated by exposure causes a cascade of subsequentchemical reactions to occur. Frechet and Willson were joined by Hiroshi Ito and imaging sys-tems were produced with two orders of magnitude greater sensitivity than DQN photoresists.The original systems lacked sufficient resistance to subsequent processing but fairly quicklythe team developed a practical system based on the poly(p-hydroxystyrene) polymer - PHOST[6] - see figure 5.25a.

Figure 5.25: PHOST and PBOCST polymers [6].

They found that the t-butylcarbonate protected monomer PBOCST - see figure 5.25b, wasmore stable than unprotected p-hydroxystyrene [6]. They further found that the protected poly-mer could be unprotected by acid treatment. The combination of poly(4-t-butoxycarbonloxy-styrene) - PBOCST with a photoacid generator yielded a practical photoresist that couldproduce a positive or negative tone image just by changing the developer. The resulting photo-resist is referred to as tBOC. tBOC photoresists have two components:• Acid generator - an onium salt cationic photoinitiator which upon exposure to light gener-

ates an acid by

(5.11)

- see figure 5.26.• Protected polystyrene - PBHOST

The exposure deprotection reaction of tBOC is illustrated in figure 5.27In figure 5.27 the reaction of the protected polymer PBOCST with an acid - figure 5.27a,

produces a deprotected polymer PHOST - figure 5.27b and additional acid - figure 5.27c. Thegeneration of acid during the deprotection reaction allows a single photo event to catalyze thedeprotection of multiple PBOCST molecules. Partially protected PHOST forms the base resinfor all modern advanced positive photoresists [23].

The tBOC photoresist can produce a positive image if a polar solvent such as alcohol or anaqueous base is used for developing and produce a negative image if a non polar solvent suchas anisole is used.

CH2CH )n(

OH

(CH2CH)

CH3

CH3CH3

O

b) PBOCSTa) PHOST

O

OC C

Ar3S-AsF6- hν AR2S Ar R HAsF6+⋅+⋅+→+

Copyright © 2000 IC Knowledge LLC, all rights reserved 19

Figure 5.26: Onium salt photoacid generators [24].

Figure 5.27: tBOC photoresist deprotection mechanism [23].

Following exposure a post exposure bake (PEB) is required to aide in the diffusion of theacid and to drive the catalytic reaction. A problem occurs with chemically amplified photore-sists when the photoresist is exposed to amines between the exposure and PEB steps. Theamines can neutralize the acids in the surface of the photoresist and lead to overhangs or T topson the photoresist lines. Improved photoresist formulations and filtration to remove amines to<1ppb are effective in eliminating T-topping (amine levels of >10ppb are not uncommon in ICfabrication facilities.

Figure 5.28 illustrates the absorbance of PHOST, PBOCST and an onium salt PAG versus wavelength. It can be seen that the absorbance of PBOCST and PHOST at 248nms is

acceptably low for use as a base polymer.

a) Diazonium salts

b) Diphenyliodonium salts

c) TriphenylSulfonium salts

d) Tetraphenylphosphonium salts

N PF2 6

IAsF6

SSbF6

PbF6

2

3

4

(CH2CH)

CO2

(CH2CH)

CH3 CH3

CH2

CH3

CH3

CH3 CH3CH3

O OH

+

+

a) LipophilicPBOCST

b) HydrophilicPHOST

c) Regenerationof acid

O

O

H C3

C C C

CH

+

H+

+

20 Copyright © 2000 IC Knowledge LLC, all rights

Figure 5.28: Absorption spectra for polyhdroxy styrene photoresist components [24].

5.2.5. 193nm photoresistAt the time that this book is being written, 248nms is the mainstream wavelength for criti-

cal exposures at the current state-of-the-art minimum linewidth (180nms). In order to continueto shrink minimum linewidths, 193nm exposure wavelengths are being investigated for 130nmand smaller minimum linewidth production. From figure 5.28 it can be seen that the absorbanceof PBOCST and PHOST below 248nms is unacceptably high, therefore 193nm photoresist willonce again require a new base polymer - see figure 5.29. The best 193nm polymers availabletoday include [25]:• Acrylic polymers (acrylate based platforms with attached alicyclic structures). Acrylics

provide high resolution but relatively poor etch resistance. The incorporation ofcycloaliphatic side groups in the polymer backbone reduces the etch rate.

• Cyclic olefins provide intrinsically good etch resistance. A nonbornene copolymer with atransition metal catalyst developed by BF Goodrich and IBM demonstrated sub-100nm res-olution in 1999 [25].Issues with PAG selection and photoresist outgassing also remain.

5.2.6. 157nm photoresistThe formulation of photoresist for 157nm exposure wavelengths is still in the very early

stages. A Curtin, et.al. at MIT have found that 157nm absorbance is dominated by C (2p) elec-trons and that the bonding configuration is expected to greatly influence the absorption [26].Acrylic, Phenolic, and Cyclo-olefin based photoresists can all achieve acceptable optical trans-mission at 157nms if the photoresist thickness is <90nms, however, industry experience sug-gests that defect density levels will be unacceptably high at such a thin photoresist thickness

2000

0.1

0.2

0.3

0.4

0.5

0.6

0.7PHOST

Ph l2

AsF6

PBOCST

0.8

0.9

1.0

300Wavelength (nm)

Ab

sorb

ance

400

248n

m

-

+

Copyright © 2000 IC Knowledge LLC, all rights reserved 21

(industry experience to-date is that the defect density increase exponentially as the photoresistthickness is reduced [26] - see figure 5.30).

Figure 5.29: Absorbance of PHOST versus polyacrylate [27].

Figure 5.30: Defect density versus photoresist thickness [26].

5.2.7. Photoresist summaryTable 5.3 summaries the properties of the photoresist presented in the preceding section

1750

0.1

0.2

0.3

0.4

0.5

0.6

0.7p-hydroxystyrene

Polyacrylate

0.8

0.9

1.0

200 300Wavelength (nm)

Ab

sorb

ance

400

193n

m

Photoresist thickness (nm)10

1997 SIA roadmap

Kunz (1992) [31]

Early (1992) [28]

Muller (1992) [29]

Kuan (1988) [30]

0.001

0.01

0.1

1.0

10

100

Def

ect

den

sity

/cm

2

1,000

100 1,000

22 Copyright © 2000 IC Knowledge LLC, all rights

5.2.8. Photoresist critical parametersThere are a number of critical parameters that may be used to define the performance of a

photoresist.

5.2.8.1. Dose to clear (E0)If film thickness versus the natural log of exposure dose is plotted for positive photoresist

following develop, the dose to clear is the exposure dose where the film thickness remainingreaches zero - see figure 5.31.

Table 5.3: Photoresist summary.

Characteristic bis-arylazide -polyisoprene DQN tBoc

Type Negative Positive Negative or

Positive

Exposure wavelength (nm) 350-450 365, 436 248

Usable resolution (nm) ~2,000 ~250 50?

Cost ($/gal) ~$100 $300-$800 ~$2,000

Special sensitivities Oxygen during

exposure

None Amines between

exposure and

PEB

Humidly comments High humidity

causes loss of

adhesion - 30 -

40% RH ideal

Humidity required

during develop - 35 -

45% RH ideal

Adhesion Excellent Good Good

Plasma etch and implant compatibility

Excellent Good Good to fair

Developing reaction Solvent develop

swells polymer

Aqueous develop

dissolves resist

without swelling

Aqueous or sol-

vent develop dis-

solves resist

without swelling.

Wet strip Sulfonic acid strip-

pers that form acid

with water and are

hard to dispose of

NMP or aqueous

based stripper with

reduced moisture

sensitivity and eas-

ier disposal.

Copyright © 2000 IC Knowledge LLC, all rights reserved 23

Figure 5.31: Dose to clear.

Dose to clear is a measure of the sensitivity of the photoresist. The lower the dose to clearthe more sensitive the photoresist is for a given thickness and exposing wavelength. More sen-sitive photoresist are advantageous for high productivity of exposure equipment - high sensitiv-ity photoresist expose more quickly for a given exposure source intensity. Dose to clear isdependent on the thickness of photoresist being exposed due to interference effects (see section5.6.9). A plot of dose to clear versus film thickness is called a swing curve - see figure 5.32.

Figure 5.32: Dose to clear swing curve.

0.0

0.2E0

� =dt/t0

�ln(dose)

t (dark erosion)l

0.4

No

rmal

ized

film

th

ickn

ess

(t/t

) 0

Ln exposure dose (mJ/cm )2

0.6

0.8

1.0

0.90 1.00 1.10 1.20 1.30Photoresist Thickness ( m)�

Do

se t

o C

lear

E(m

J/cm

)o

2

100

120

140

160

180

200

24 Copyright © 2000 IC Knowledge LLC, all rights

5.2.8.2. Gamma (�)Gamma is the slope of the thickness remaining curve between the unexposed region of the

photoresist and E0 - see figure 5.31. Gamma is a measure of contrast, i.e., the difference inexposure required between the exposed and unexposed regions to produce an image. Higher �results in sharper images.

5.2.8.3. Thickness loss (tl)

Thickness loss is the change in photoresist thickness following develop in the unexposedregions of the photoresist - see figure 5.31.

5.2.8.4. Glass transition temperature (Tg)

§ Glass transition temperature (Tg) - the point at which an amorphous polymer undergoes atransition from a brittle glassy state to a flexible rubbery state. Below Tg the polymer is glassyand brittle, and above Tg the polymer is flexible and rubbery. Higher Tg materials showincreased resistance to flow and pattern distortion during bakes, but have poorer mechanicalperformance. Crosslinking increases the stiffness of a polymer above Tg. Following developingit is desirable to crosslink the remaining film to increase the resistance to flow and pattern dis-tortion.

5.2.8.5. Viscosity Viscosity is a measure of the resistance to flow of the photoresist. All other things being

equal, higher viscosities will result in thicker photoresist during coating (see the section oncoating). The viscosity of the photoresist must be properly selected for the desired film thick-ness after coating. Alternately, solid content may be used to characterize the films resistance toflow.

5.2.8.6. Dill parametersFor DNQ photoresist, Dill parameters describe the difference in photoresist absorption ver-

sus wavelength during exposure [32]. Dill A is the absorption of the resist prior to any bleach-ing. Dill B is the residual absorption of the resist after bleaching. Dill C is the rate of absorptionchange or bleaching.

5.3. Surface preparationPhotoresist adhesion to typical wafer surfaces such as SiO2 and metals is critical to faith-

fully replicating the photoresist pattern in etching and ion implantation processes. SiO2 andmetals are considered high-energy surfaces with surface free energies >103dynes/cm, photore-sists are solutions with low surface energy, <36 dynes/cm for typical photoresists. Photoresistsmay therefore be expected to spontaneously wet SiO2 and metal surfaces which might also beexpected to result in good adhesion. There are however several factors which can interfere withphotoresist adhesion:1. If the base solvent has a higher degree of interaction with the wafer surface than the photo-

resist base resin, the solvent can push the resin away from the wafer surface. Later during

Copyright © 2000 IC Knowledge LLC, all rights reserved 25

soft bake the solvent may evaporate, but the resin may be constrained by the photoresist film from filling the resulting gaps. This issue is addressed by good photoresist formula-tions.

2. The resin-resin interaction can be stronger than the resin-substrate interface interaction, par-ticularly if the base solvent is badly matched to the resin. The resin will then form tight coils to minimize it’s energy, lowering it’s interaction with the substrate (� of the solvent must be close to � of the resin). The intrinsic interaction of the resin with the wafer surface is however the most important factor in adhesion and once again this factor is addressed during photoresist formulation.

3. Surface contamination - particularly moisture. Water has a very high affinity for SiO2 - see table 5.4. If we consider photoresist to have an interaction with SiO2, on the order of the solvents listed in table 5.4, it can be seen that moisture has a much stronger interaction. Moisture interaction with SiO2 is a particular problem because SiO2 readily becomes hydrated from humidity.Surface moisture may take the form of adsorbed surface moisture or chemically bonded

OH - Silanol groups. Surface moisture may be reduced by a bake at >100oC, but silanol groupsrequire a much higher temperature bake - too high to be practical immediately before photore-sist coating.

In order to minimize moisture effects on photoresist adhesion, a variety of surface pre-treatment techniques are used. The most common is the application of Hexamethyldisilazane(HMDS) - see figure 5.33.

The hydrated wafer surface - figure 5.33a, reacts with HMDS to remove adsorbed moistureand the reaction releases NH3 - figure 5.33b. The wafer surface is now terminated with silanolwhich further reacts with HMDS - figure 5.33c to release more NH3 leaving a low surface ten-sion - low moisture surface. The critical surface tension of SiO2 at 50% RH is 78 dynes/cmprior to treatment by HMDS, and 21 dynes/cm after treatment, the absorbed surface moistureprior to treatment is >35 H2O molecules/�m2 and after treatment is < 1 molecule of H2O/�m2

[15]. Furthermore, the treated surface has good photoresist adhesion and forms an interface thatis water repellent.

Table 5.4: Polar interaction of SiO2 with selected liquids.

LiquidPolar

Interaction(dynes/cm)

Heptane 0

Benzene 20

Acetone 58

n Propanol 84

Water 368

26 Copyright © 2000 IC Knowledge LLC, all rights

Figure 5.33: HMDS adhesion promotion [15].

When negative photoresist was still widely used it was not unusual to see HMDS spun ontoa wafer surface in a dilute HMDS - xylene mixture just prior to photoresist coating. The HMDSwould be dispensed, allowed to briefly react with the wafer surface and then spun off. Spinningon HMDS was only partially effective for adhesion promotion, consumed a great deal ofHMDS -xylene solution and produced a great deal of HMDS - xylene waste. By the time posi-tive photoresist was becoming popular, HMDS dispense largely switched over to a vacuumbake environment - see figure 5.34.

HMDS vapor prime systems may be batch systems or single wafer systems as illustrated infigure 5.34. The operation of the single wafer system is as follows:1. The wafer input port is a door into the chamber that opens to allow a wafer to be inserted

onto the wafer chuck. Once the wafer is inserted the port is closed.2. The vacuum pump and valve allow the chamber to be pumped down to a vacuum in the 2 -

20 torr range. 3. A heated wafer chuck is used to heat the wafer to 100 to 150oC.4. While the chamber is under vacuum the valve to the HMDS reservoir is opened and the

vacuum draws off HMDS vapor priming the wafer.

SiSi

Si Si

SiSi

Si Si

SiSi

Si Si

SiSi

Si Si

OO

O O

OO

O O

OO

O O

OO

O O

OO

O O

OO

O O

H O2 H O2 H O2

a) HMDS + hydrated SiO surface2

c) HMDS + surface OH (silanol) d) Lower surface tension - lower H O surface2

b) Adsorbed moisture removal

(CH ) SiNSi(CH )3 3 3 3

(CH ) SiNSi(CH )3 3 3 3 NH3

OSi(CH )3 3 OSi(CH )3 3 OSi(CH )3 3

OHOH

OH

OHOH

OH

OHOH

OH

(CH ) SiOSi(CH )3 3 3 3

+ NH3

Copyright © 2000 IC Knowledge LLC, all rights reserved 27

5. Following prime the chamber is pumped back down to remove the residual HMDS and flushed with nitrogen.

6. The wafer output port opens and the wafer is withdrawn.Proper vapor priming results in a contact angle of >60o (see chapter 3 for a discussion of

contact angle).Vacuum bake ovens produce essentially no HMDS waste and consume only a miniscule

quantity of HMDS.

Figure 5.34: HMDS Vapor prime system.

5.4. CoatingAlthough there are several methods by which photoresist can be coated onto a wafer, for IC

fabrication the use of spin coating is virtually universal. In the spin coating process a controlledvolume of photoresist is dispensed onto a wafer and then the wafer is spun at high speed to pro-duce a uniform, partially dried photoresist film. The basic coating process is illustrated in fig-ure 5.35.

Figure 5.35: Photoresist spin-coating process [33].

Waferinputport

Vacuumpump

N feed2

WaferHeater

Wafer chuck

Waferoutputport

ValveValve

Valve HMDSReservoir

a) Dispense acontrolledamount ofphotoresist

b) Allow thePhotoresist tospread across

the wafer

c) Rapidly ramp - upthe coater spin speedthrowing off excess

Photoresist

d) Spin at highspeed to forma thin dry filmof Photoresist

28 Copyright © 2000 IC Knowledge LLC, all rights

The photoresist coating process begins by dispensing a controlled volume of photoresistonto the center of the wafer - figure 5.35a. The initial dispense may be done with the waferstatic or rotating at a few hundred RPMs. The volume of photoresist dispensed depends on thewafer size but is typically 2 to 10ml. The photoresist is allowed to spread through either a staticstep or with the wafer rotating at a few hundred RPMs - figure 5.35b. The wafer is them rapidlyramped up to a high spin speed, typically 1,000 to 10,000 RPMs - figure 5.35c. As the wafer israpidly spun a wave forms in the photoresist within a few RPMs, the wave them forms a“crown-like” structure after approximately 30 RPMs [34]. The crown-like stage indicates thebulk of the photoresist supporting the wave has run-out. Following the formation of the crown-like phase the remaining photoresist is being “scrubbed off” of the wafer generally in the formof a spiral [34]. During the spiral phase thousands of tiny photoresist droplets are propelled offof the edge of the wafer. The spin coater bowl must be properly designed or the droplets ofphotoresist can splash back onto the wafer causing a non-uniform coat. Finally the photoresistis spun further to dry the photoresist by solvent evaporation. The evaporation rate of solventsduring coating is dependent on the photoresist formulation and also on the air flow over thewafer during coating. Coater exhaust must be carefully tuned and controlled to achieve uniformand repeatable photoresist films.

The mathematics of photoresist coating must take into account the multi-component natureof photoresist. The solvents used to keep the photoresist in suspension have relatively highevaporation rate - see table 5.5 During coating the solvent fraction of the photoresist is decreas-ing and therefore the viscosity of the photoresist is increasing.

a evaporation rates are relative to butyl acetate.

Photoresist coating models of varying complexity have been proposed by several research-ers. Sukanek [35],[36] has developed a model of photoresist spin coating taking into accountthe changes in photoresist properties during coating.

The photoresist is assumed to consist of two components, a non volatile and a volatile com-ponent.

Mass balances on a cylindrical control volume on a wafer disc give

Table 5.5: Evaporation rate and solvents for photoresist [39].

Photoresist Solvent Evaporation ratea

Boiling point (oC)

Polybutene SO2 Methyl 2-ethoxyethyl acetate 31 145

DQN Cellosolve acetateButyl acetateDiglyme

20

100

18

156

126

162

PMMA Chlorobenzene 102 126

Rubber azide Xylene 62 140

Copyright © 2000 IC Knowledge LLC, all rights reserved 29

(5.12)

(5.13)

where, CV is the concentration of the volatile component and CN is the concentration of thenon-volatile component, r is the radius, e is the evaporation rate of the volatile component, h isthe film height and q is the flow rate.

The flow rate is given by

(5.14)

where, � is the spin speed and is the viscosity.The evaporation rate is given by

(5.15)

where k is the mass transfer coefficient, CVS is the concentration of the volatile component atthe surface.

If we assume that

(5.16)

then

(5.17)

and if we introduce the distribution or equilibrium constant K, then

(5.18)

For laminar air, i.e., the reynolds number is <2 x 105

(5.19)

where a is a constant.Then combing 5.12, 5.13, 5.14, 5.18 and 5.19 and rearranging give the dimensionless

forms

(5.20)

and

(5.21)

t∂∂ CNh( ) 1

r---

r∂∂ rCNq( )–=

t∂∂ CVh( ) 1

r---

r∂∂ rCVq( )– e–=

q rΩ2h3 3ν( )⁄=

e k(CVS CV∞ )–=

CV∞ 0→

e kCVS=

e KkCVS=

k aΩ1/2=

y∂τ∂

----- 23--- y3

ν ν0⁄------------ αx––=

x∂τ∂

----- αx x 1–( ) y⁄=

30 Copyright © 2000 IC Knowledge LLC, all rights

and the dimensionless parameters are defined as

(5.22)

(5.23)

(5.24)

(5.25)

The kinematic viscosity is of the form used by Meyerhofer [37]

(5.26)

For sufficiently large values of t, the preceding equations provide a solution which is inde-pendent of time. From equation 5.22 the final film thickness is given by

(5.27)

From equation 5.27 it can be seen that the film thickness is inversely proportional to thespin speed.

Studies of spin coated films have shown that film thickness is [38]:• Independent of coating volume.• Independent of spin sped during dispense.• Independent of acceleration rate from dispense speed to final spin speed.• Depends on final spin speed - as expected from equation 5.27 - see figure 5.36.• Depends on viscosity - as expected from equation 5.27 - see figure 5.36.• Depends on time up until 5 - 10 seconds when the final film thickness value saturates - see

figure 5.37.Practically speaking consistent coating thickness requires very careful control of the envi-

ronment that the photoresist sees during dispense and spinning. For sub-micron linewidth pro-duction the photoresist temperature should be controlled at the photoresist storage chamber andright up to the photoresist dispensing nozzle. The temperature and humidity of air over thecoater bowel should be controlled to + or - 1oF and + or - 1% respectively. As previously notedthe exhaust must be well controlled to insure consistent solvent evaporation rates. The coaterspin motor RPMs are typically quartz crystal controlled and accurate to <1%.

As previously mentioned the volume of photoresist dispensed is 2 to 10mls. With theadvent of DUV photoresist with costs of approximately $2,000/gal versus $500 to $800/gal fori-line or g-line photoresist, the minimization of dispense volume has taken on increasing impor-tance. The technique of “pre-wetting” the wafer with the photoresist solvent to aide in photore-sist spreading has become common. With pre-wetting 2 to 4ml dispense volumes may be usedto coat a 200mm wafer.

y hΩ1/2 a1/2ν01/2( )⁄≡

x CV e⁄≡

τ tΩa ν01/2⁄≡

α ν01/4K a1/2⁄≡

ν ν0⁄ νS 1 νS–( ) 1 x–1 x0–--------------⎝ ⎠⎛ ⎞ n

+=

hf yfa1/2ν0

1/4 Ω1/2⁄=

Copyright © 2000 IC Knowledge LLC, all rights reserved 31

Figure 5.36: Film thickness versus final spin speed and viscosity [40].

Figure 5.37: Film thickness versus time [40].

0.51 2

Final spin speed (rpm x 10 )3

Fin

al f

ilm t

hic

knes

s (

m)

�

3 4 5 6 7

0.6

0.70.80.91.0

2.0

3.0

4.0

5.0

6.0

23cP

43cP

1100cP

2040cP

1.4

1.3

1.2

1.1

Film

th

ickn

ess

(m

)�

Spin time (sec)

1.0

0.9

0.8

0.7

0.60 2 4 6 8 10

Final spin speed = 3,000 RPM

Final spin speed = 6,000 RPM

12 14 16 18 20

32 Copyright © 2000 IC Knowledge LLC, all rights

5.4.0.1. Edge bead removalWhen a wafer is spin coated, surface tension causes the thickness of photoresist dispensed

to build up at the wafer edge - see figure 5.38.

Figure 5.38: Photoresist thickness versus distance from the wafer edge [41].

The thicker photoresist at the wafer edge may not be fully exposed during exposure andtherefore will not develop completely. During subsequent processing the “edge bead” can flakeoff creating defects. In order to prevent defects the edge bead is typically removed. there aretwo common methods for edge bead removal:1. During coating a solvent may be dispensed onto the outer-edge of the wafer dissolving the

edge-bead. This is a common method for greater than approximately 0.5�m linewidths.2. Below 0.5�m linewidths optical edge bead removal is employed to allow improved control

over how far in from the edge the photoresist is removed (the loss of photoresist at the edge eliminates the ability to produce ICs near the edge). In optical edge bead removal the wafer is exposed to an intense light source that is masked to only expose the wafer edge. The edge bead is fully exposed and develops away during the normal develop process.Irrespective of edge bead removal technique, the wafer backside is typically washed with a

solvent to remove any photoresist that may accumulate on the backside during coating.

5.5. Soft bakeFollowing coating photoresist solvent levels have been reduced from 65-85% to 10-20%.

The photoresist still contains too much solvent for a sufficient difference to exist in developingrates between the exposed and unexposed portion of the photoresist. In order to reduce theresidual solvent level in the photoresist, a soft bake step is employed. Soft baking has addi-tional benefits:• Reduces photoresist free volume reducing subsequent diffusion lengths for DUV resist

improving resolution.• Anneals out residual stresses in the as-coated photoresist and improves adhesion.

00

0.5

1.0

1.5

2.0

2.5

Ph

oto

resi

st t

hic

knes

s (

m)

�3.0

50 100 150Distance from the edge ( m)�

200 250

Copyright © 2000 IC Knowledge LLC, all rights reserved 33

• Stabilizes the film and reduces the tackiness of the surface.• Reduces residual solvent levels improving the difference in developing rates between the

exposed and unexposed portions of the photoresist.Figure 5.39 illustrates the effect of soft baking on developing rates of DQN photoresist in

0.25N KOH developer after a 30 minute soft bake.

Figure 5.39: Photoresist developing rate versus soft bake temperature [43].

Ideally soft bake would be performed above the Tg of the photoresist to minimize photore-sist free volume and removal of the residual solvent. Figure 5.40 illustrates the effect ofincreasing bake temperature on a photoresist. As the temperature is increased the photoresistfirst loses weight by solvent evaporation, eventually at a high enough temperature the photore-sist begins to break down.

Figure 5.40: Thermal gravimetric analysis of un-baked spun on photoresist [42].

040 60

Hig

h re

sidu

al s

olve

nt

Solventremoval

DQNconvertedto ICA

Compaction,crosslinking,DQNdecomposition

80

Novolak resin

DNQ resist

100 120 140 160

1

2

3

4

5

6lo

g R

Bake temperature ( C)o

20

40

60

80Solvent

loss

Startdecomposition100

% o

rig

inal

sam

ple

wei

gh

t

Temperature

34 Copyright © 2000 IC Knowledge LLC, all rights

Ideally a soft bake would achieve a photoresist with only a few% of solvent, however thisrequires that the solvent boiling point be approached which is approximately 140oC. For DQNphotoresist decomposes at approximately 100 - 120oC. Practically speaking the maximum softbake temperature of a photoresist is typically set by the temperature at which the sensitizerbegins to break down and baking below Tg is required. Table 5.6 presents the Tg and Td (tem-perature of decomposition) for several common photoresist components.

The Tg of a photoresist may vary from the polymer due to the photoresist free volume. Alsofor DUV photoresist PBOCST has a lower Tg than PHOST. For DUV photoresists soft bakecontrol is critical to control acid diffusion. The DUV softbake must be tailored to the propertiesof the photoresist and the temperature must be controlled to a fraction of a oC whereas 1oC con-trol is adequate for DQN photoresist.

Similar to the situation for coating, the mathematics of soft baking require consideration ofa volatile and a non-volatile component. Consider a film of initial thickness Lfi and with a sol-vent free thickness of Lp. As soft baking proceeds the film gets thinner as the solvent diffusesto the photoresist-gas interface and then evaporates.

A mathematical model of soft baking has been proposed by Tseng, et.al., [44].The variation in photoresist density during baking is given by

(5.28)

where, xA is the mass fraction of the solvent in the film, t is time, z is distance from the bottomof the film, D is diffusivity of the solvent and T is the absolute temperature.

The initial conditions for equation 5.28 are

(5.29)

where, xA0 is the initial mass fraction of solvent in the film.The boundary conditions are

(5.30)

Table 5.6: Tg and Td of common photoresist components [39].

Component Tg (oC) Td (oC)

Rubber 54 200

Azide 100

Novolak 70-120 150-300

Diazoquinone 100

PMMA 105 200

Polybutene SO2 65 125

xA∂t∂

--------z∂∂ D xA T,( )

xA∂z∂

--------⎝ ⎠⎛ ⎞=

x xA0, t 0= =

xA∂z∂

-------- 0, z 0= =

Copyright © 2000 IC Knowledge LLC, all rights reserved 35

(5.31)

where, km is the mass transfer coefficient of the solvent. Equation 5.30 indicates that the basematerial under the photoresist is impermeable to the solvent.

A mass balance on the solvent near the photoresist-gas interface yields [46]

(5.32)

where, W is the mass, V is the volume, and 0 is the initial density of the film and S is the den-sity of the solvent. As the soft bake proceeds the film becomes more dense and the diffusivityof the solvent is reduced.

From Fujita, et.al., the diffusivity of the solvent is given by [47]

(5.33)

where, � and � are constants that need to be determined experimentally.The value of D is illustrated in figure 5.41 for D0 = 2.74 x 10-12 cm2/s, � = 0.040, and � =0.043 [45].

Figure 5.41: Solvent diffusivity versus solvent content [45].

Substituting equation 5.33 into equation 5.28 and rewriting equations 5.29 through 5.32 inscaled form, results in

(5.34)

DxA∂z∂

--------– kmxA, z Lf t( )= =

dWdt

--------– ρ– SAdLf t( )

dt--------------- ρ– 0DA

xA∂z∂

--------z Lf t( )=

= =

D D0 T( )xA

α βxA+-------------------exp=

0.010-12

10-11

10-10

10-9

10-8

10-7

10-6

0.2 0.4 0.6 0.8 1.0Mass fraction of solvent

Dif

fusi

vity

(cm

/sec

)2

xA∂τ∂

--------xA

α βxA+------------------- α

α βxA+( )2--------------------------

xA∂

z∗∂--------⎝ ⎠⎛ ⎞

2 2xA∂

z∗2∂------------+exp=

36 Copyright © 2000 IC Knowledge LLC, all rights

(5.35)

(5.36)

(5.37)

(5.38)

where, � = D0t/L2fi, z* = z/Lfi, and L*f = Lf/Lfi.

The preceding moving boundary problem has been solved numerically and the result for aDQN photoresist is illustrated in figure 5.42 [44].

Figure 5.42: Film thickness loss during softbake - m-p cresol novolak photoresist [44].

Photoresist soft baking may be accomplished in a convection oven or more commonlyusing a hot plate mounted onto the coating track equipment. Immediately following coat thewafer is transferred to a hot plat for a 45 - 60 second bake. Ovens hold larger batches of waferbut require ~30 minutes to complete a bake.

5.6. Optical principlesThe dominant method for exposing patterns into photoresist currently in use, is optical

exposure. In order to understand optical exposure and optical exposure systems, it is necessaryto have a basic understanding of some optical principles.

xA xA0, τ 0= =

xA∂

z∗∂-------- 0, z∗ 0= =

xAα βxA+-------------------

xA∂

z∗∂--------exp–

kmD0 Lfi⁄-----------------xA, z∗ L∗f τ( )= =

Lf τ( )ddτ

---------------ρ0ρS-----

xAα βxA+-------------------

xA∂

z∗∂--------

z∗ L∗f=

, z∗exp L∗f τ( )= =

2.00 10 20

70 Co

90 Co

100 Co

30 40 50 60 70

2.1

2.2

2.3

2.4

2.5

2.6

Ph

oto

resi

st t

hic

knes

s (

m)

�

Soft bake time (sec)

Copyright © 2000 IC Knowledge LLC, all rights reserved 37

5.6.1. Huygens’ principleConsider the wavefront A - B moving through space in figure 5.43. According to Huygens’

principle, the next successive wavefront - C - D may be constructed by considering every pointon wavefront A - B to be a secondary point source of waves. After travelling out from the sec-ondary point sources for a period of time, each secondary “wavelet” will be a spherical wave-front centered around the secondary point sources. The surface made up of the tangent of all ofthe secondary wavelets will be the new wavefront - C - D.

Figure 5.43: Huygens’ principle.

5.6.2. ReflectionIf a ray of light is incident on a reflective surface, the light ray will be reflected off the sur-

face at some angle. • Law of reflection - the angle of incidence is equal to the angle of reflection.

Figure 5.44a illustrates the law of reflection and figure 5.44b illustrates the reflection of aplane wavefront.

Figure 5.44: Law of reflection.

If a curved reflecting surface is constructed, a reflective lens results. Reflective lens arereferred to as Catoptric. The characteristics of a mirror lens are given by the mirror equation

(5.39)

A

B

C

D

A

a) Law of reflection b) Plane wavefront reflection

B

C

D�1

�1 2= �

1

1 2=

2

�2

1p--- 1

q---+ 2

R---=

38 Copyright © 2000 IC Knowledge LLC, all rights

where, p is the object distance, q is the image distance and R is the radius of the mirror - see fig-ure 5.45a.

Alternately the lens equation may be expressed as

(5.40)

where, f is the focal length of the lens - see figure 5.45b.

Figure 5.45: Reflective lens calculations.

5.6.3. Focal lengthThe focal length is defined as:• Focal length - the distance from a lens where an incident set of parallel rays exiting the lens

converge.

5.6.4. RefractionOptically transparent mediums have an intrinsic property - index of refraction defined as:

• Index of refraction - the ratio between the speed of light in a vacuum and the speed of lightin a given medium.Refractive index depends on the material of interest, temperature, pressure and also on the

wavelength of radiation passing through the material. The change of refractive index of a mate-rial versus wavelength is referred to as dispersion. Figure 5.46 illustrates the index of refractionversus wavelength for two materials used in lens systems for photolithography exposure tools.Fused silica has been widely used for many years and calcium fluoride (CaF2) is a materialwhich is beginning to see use in the latest generation tools.

When a light ray transits from a material of one index of refraction to a material of anotherindex of refraction, the light ray is bent, i.e. refracted. The degree of bending which results maybe calculated by Snell’s law

(5.41)

1p--- 1

q---+ 1

f---=

Object

a) Mirror calculations b) Focal length

pq f

Image

n1 Θ1sin n2 Θ2sin=

Copyright © 2000 IC Knowledge LLC, all rights reserved 39

where, n1 is the index of refraction of the first medium, n2 is the index of refraction of the sec-ond medium, 1 is the angle of the ray entering the interface and 2 is the angle of the rayleaving the interface - see figure 5.47.

Figure 5.46: Index of refraction for fused silica and calcium fluoride versus wavelength [11],[12].

Figure 5.47: Refraction.

It should be noted here that since the change in angle for a light ray transitioning betweentwo media depends on the index of refraction of each media respectively, the change in angle iswavelength dependent. The practical effect of this will be discussed in the section on lens aber-ations.

For a refractive lens, the characteristics of the lens are given by the lens makers formula

1.42100

Wavelength (nm)

Ind

ex o

f re

frac

tio

n

1,000

1.44

1.46

1.48

1.50

1.52

CaF2[12]

SiO2 [11]

1.54

1.56

1.58

n1

n2

1

2

40 Copyright © 2000 IC Knowledge LLC, all rights

(5.42)

where, n1 is the refractive index of the first medium, n2 is the refractive index of the lens mate-rial, p is object distance, q is the image distance, R1 is the radius of the first lens surface and R2is the radius of the second lens surface - see figure 5.48a.

Refractive lens are referred to as Dioptic.In figure 5.48b, the focal length for a refractive lens is illustrated and is given by

(5.43)

Figure 5.48: Refractive lens calculations.

Refractive lens can be fabricated in a variety of different forms, if both lens surfaces areconvex, the lens is a double-convex lens - figure 5.49a, if both surfaces are concave, the lens isdouble-concave - figure 5.49b. Lens may also have one convex and one concave surfacereferred to as a concave-convex lens or one convex surface with one plane surface, referred toas a plano-convex.

Figure 5.49: Refractive lens.

n1p-----

n2q-----+ n2 n1–( ) 1

R1------ 1

R2------+⎝ ⎠

⎛ ⎞=

f n1 n2–( ) 1R1------ 1

R2------+⎝ ⎠

⎛ ⎞ -1=

Object

p q

Image

f

a) Refractive lens calculations b) Focal length

a) Double convex b) Double concave

Copyright © 2000 IC Knowledge LLC, all rights reserved 41

In figure 5.49a the double-convex lens is shown converging the light rays and in figure5.49b the double concave lens is shown diverging the light rays. As a rule, lens that are thickerin the center of the lens than at the edges are convergent and lens that are thinner in the centerthan at the edges are divergent.

5.6.5. MagnificationMagnifications for lens systems can be defined in terms of the object and the image as:

• Magnification - the image size divided by the object size.

5.6.6. Numerical apertureNumerical aperture is a measure of the “acceptance” angle of a lens and is defined as

(5.44)

where, � is the acceptance angle - see figure 5.50, n is the index of refraction of the background- typically 1, d is the lens diameter and f is the lens focal length.

Figure 5.50: Numerical aperture.

Assuming n equals 1 - such as for air, then the maximum NA is 1 since � cannot exceed90o. For practical lens design, as d increases it is increasingly difficult to achieve high NA.Microscope objectives a few mms in diameter may achieve NAs of 0.9 or even 0.95, but NAsof 0.7 are high for modern exposure tools with field sizes of tens of mms. The limitations ofNA impacts the achievable resolution of an exposure system as will be seen in the section ondifraction.

5.6.7. AberrationsThere are six types of aberration that can occur in a lens system.

5.6.7.1. Chromatic aberrationIn section 5.2.3 it was presented that the characteristics of a refractive lens depend on index

of refraction and that index of refraction depends on wavelength. If light with multiple wave-lengths passes through a refractive lens, the light will be focused at different points dependingon wavelength - see figure 5.51a. For reflective lens systems the angle of incidence equals theangle of reflection irrespective of wavelength and so chromatic aberration does not occur - seefigure 5.51b.

NA n αsin d 2f⁄= =

� d

f

42 Copyright © 2000 IC Knowledge LLC, all rights

Figure 5.51: Chromatic aberration.

Refractive lens system must be restricted to a single narrow wavelength of light for goodfocus or the lens system must be designed to correct for chromatic aberration. If a diverginglens made with a higher dispersion material is combined with a converging lens made with alower dispersion material, chromatic correction may be performed - figure 5.52.

Figure 5.52: Chromatic aberration correction.

In figure 5.52 a converging and a diverging lens are used together to provide correction forchromatic aberration. In order to provide chromatic aberration correction, the diverging lenselement must have higher dispersion than the converging lens element. When typical exposurewavelengths were >300nms, chromatic aberration correction was available, however, at wave-lengths <300nm no suitable high dispersion lens material exists. The fact that reflective lens donot suffer from chromatic aberration is a major advantage in optical system design particularlyas the exposing radiation wavelength is reduced.

5.6.7.2. Spherical aberrationIf a lens is ground with a spherical surface, parallel light rays passing through the outer

edge of the lens will focus to a point closer to the lens than parallel light rays passing throughareas of the lens closer to the center - see figure 5.53a. If the lens is ground with a parabolic sur-face, parallel light rays will focus to the same point irrespective of where they pass through thelens - see figure 5.53b.

Longerwavelength

Longerwavelength

Shorterwavelength

Shorterwavelength

a) Refractive lens a) Reflective lens

Long wavelengthShort wavelength

Copyright © 2000 IC Knowledge LLC, all rights reserved 43

Figure 5.53: Spherical aberration.

5.6.7.3. AstigmatismLight rays transiting a lens at an angle to the optical axis of the lens focus to a point closer

to the lens than rays that pass through the lens parallel to the optical axis - figure 5.54a. Astig-matism only occurs for off-axis light rays. As an object moves in and out of focus, the resultingimage is first stretched in one direction for a positive out-of-focus condition and then stretchedout in a direction at a 90o angle to the original stretching mode for a negative out-of-focus con-dition - figure 5.54b

Figure 5.54: Astigmatism.

5.6.7.4. ComaAn aberration of image points that lie off of the optical axis. - figure 5.55a. Comatic flair

results in a diffuse tail from an image point which may point towards or away from the opticalaxis - figure 5.55b. Coma becomes worse as field size and aperture increase.

5.6.7.5. Curvature of fieldIdeally an image should be in focus for a flat plane. Curvature of field is when the focal

plane forms a curved surface - figure 5.56.

a) Spherical lens b) Parabolic lens

Parallelrays

Parallelfocus

Oblique rays

Obliquefocus

0 focus+ focus

- focus

a) Optical path

b) Image

44 Copyright © 2000 IC Knowledge LLC, all rights

Figure 5.55: Coma.

Figure 5.56: Curvature of field.

5.6.7.6. DistortionThe transverse counterpart to curvature of field. The radial distortion of points towards or

away from the optical axis - figure 5.57. Distortion results from a change in magnification

Figure 5.57: Distortion.

5.6.8. CoherenceCoherency is “the state or quality of being together” [17]. When applied to light coherency

may be broken down into two categories, temporal and spatial:

Periphery

a) Optical path

b) ImageCenter

Curvedfocusarea

a) Undistorted b) Positive b) Negative

Copyright © 2000 IC Knowledge LLC, all rights reserved 45

• The temporal coherence of a light source may be characterized by the coherence lengthwhich relates the light source wavelength and bandwidth, and is given by

(5.45)

• Spatial coherence refers to the phase relationship between the photons or wave fronts. Apoint source produces wavefronts that spread out from a single point and our perfectly spa-tially coherent, larger light sources result in less spatial coherency.Temporal coherency can be controlled by wavelength selection and spatial coherency can

be controlled by the ratio of the illumination system condenser lens NA to the objective lensNA - see figure 5.58 and is given by

(5.46)

where, � = 1.0 is incoherent and � = 0 is coherent.

Figure 5.58: Kohler illumination and factors for determining spatial coherence [18].

• Kohler illumination - a light source that is focused in the entrance pupil of the image form-ing optics is called Kohler illumination.