Photolithography at 193 nm - Massachusetts Institute of ......Photolithography at 193 nm ous...

Transcript of Photolithography at 193 nm - Massachusetts Institute of ......Photolithography at 193 nm ous...

VOLUME 10, NUMBER 1, 1997 THE LINCOLN LABORATORY JOURNAL 19

• ROTHSCHILD ET AL.Photolithography at 193 nm

Photolithography at 193 nmMordechai Rothschild, Mark W. Horn, Craig L. Keast, Roderick R. Kunz, VladimirLiberman, Susan C. Palmateer, Scott P. Doran, Anthony R. Forte, Russell B. Goodman,Jan H.C. Sedlacek, Raymond S. Uttaro, Dan Corliss, and Andrew Grenville

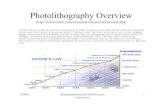

■ For the last two decades photolithography has been the principal technologyfor patterning the progressively smaller and denser features required inmicroelectronic devices and circuits. In recent years, the increasingsophistication of photolithographic techniques using radiation at wavelengthscomparable to the feature size has enabled the mass production of circuits inwhich critical dimensions are 0.25 µm. The drive to smaller dimensions isexpected to continue in the future to critical dimensions of 0.18, 0.13, and even0.07 µm, which necessitates a shift to radiation at shorter wavelengths. LincolnLaboratory has been at the forefront of the development of next-generationphotolithographic technology, namely, the use of 193-nm laser radiation. Thisarticle presents the rationale behind the transition to this new wavelength, andreviews the status of critical issues encountered in its implementation as amanufacturing process. These issues concern the suitability of optical materialsand coatings for lens fabrication, the use of photoresists and wafer processingfor device fabrication, and the outlook for extending the usefulness of 193-nmlithography to printing at critical dimensions approaching 0.1 µm.

T in the functionalityof microelectronic chips over the past twodecades has been a fundamental reason for the

explosive utilization of this technology in so manyaspects of modern life. The driving force behind thegreater utilization of microchips has been the contin-ued miniaturization of these devices, which enablesan increase in the complexity and speed of circuitswithout a corresponding increase in cost, size, andpower consumption. To illustrate this progress inminiaturization and the increase in functionality, wenote that 256-kbit dynamic random access memory(DRAM) microchips, with minimum feature sizes of1.5 µm, were introduced in 1983. In 1997, only four-teen years later, 256-Mbit DRAM chips (with onethousand times the capacity of the 1983 chips) wereintroduced with minimum feature sizes of 0.25 µm.

The trend in microchip development is clear. Anew generation of DRAM chips has been introducedevery three years, with four times the capacity of theprevious generation and 0.7 times the feature size.

This trend is expected to accelerate in the next fewyears. We thus expect that 1-Gbit DRAM chips with0.18-µm printed dimensions will go into advancedmanufacturing in the year 1999, followed by 4-GbitDRAM chips with 0.13-µm printed dimensions in2003 and 16-Gbit DRAM chips with 0.10-µmprinted dimensions in 2006. Chips with 0.07-µmfeatures are already being contemplated for mass pro-duction in 2009. These dimensions are found inmemory chips with high-density patterns such asDRAMs. The semiconductor industry projects thatthe development of microprocessor chips, where thedevice architecture requires a lesser density of struc-tures (transistor gates) at minimum feature size, willexperience a similar shrinking trend, only at an evenmore aggressive pace, namely, 0.14 µm in 1999 and0.10 µm in 2003.

Trends in Photolithography

The ongoing and seemingly inexorable trend in mi-crochip development has been fueled by the continu-

20 THE LINCOLN LABORATORY JOURNAL VOLUME 10, NUMBER 1, 1997

• ROTHSCHILD ET AL.Photolithography at 193 nm

ous advances in lithography, and in particular in itsmain branch, projection photolithography. Concep-tually, projection photolithography is similar to tradi-tional optical photography: the “flashbulb” is a high-power lamp (and recently a laser), the camera “lens” isnear-perfect projection optics, the “scenery” is a set ofcarefully designed patterns on a mask or reticle, thephotographic “emulsion” is a high-resolution photo-resist, and the “film” is a wafer (usually silicon).

The conceptual simplicity of projection photoli-thography belies its great complexity. In particular,the camera, while abiding by the laws of optics, mustreproducibly provide a sharp aerial image of verysmall features with a comfortable process margin. Re-producibility is largely determined by the processmargin, or the allowable error, of each step of the pro-cess. The most critical process margin in photolithog-raphy is the depth of focus (DOF), which must belarger than any variations in the flatness of the photo-resist surface. Such variations in flatness, which areunavoidable, are caused by the surface deviations ofthe wafer and by the topography added to it throughthe deposition and etching of various thin films in thecourse of fabricating a device.

The laws of optics that govern the sharpness of theaerial image can be distilled into two rules. In the firstrule, the smallest feature size that can be printed—thelinewidth W—is determined by the wavelength λ andthe numerical aperture NA of the projection optics:

W k= 1λ

NA, (1)

where the parameter k1 ≥ 0.25. The processing condi-tions of the wafer determine the exact value of k1,which at present is larger than approximately 0.5. Inthe second rule, the DOF is also determined by λ andthe numerical aperture NA:

DOFNA

= k2 2λ

( ), (2)

where the parameter k2 may also depend on the valueof k1. The value of the parameter k2 must be largeenough to enable a minimum DOF of no less than0.5 µm (although until recently a minimum DOF of1.0 µm was considered necessary for an acceptablyhigh yield in manufacturing).

Equations 1 and 2 indicate the direction in whichphotolithography should evolve if it is to printsmaller and smaller linewidths; these equations alsopoint out the challenges to be expected on the way.Specifically, in order to decrease the linewidth wemight attempt to reduce the parameter k1, reduce thewavelength λ, or increase the numerical aperture NA.Reducing the value of k1 alone, however, may cause adecreased process yield (and k1 has an absolute lowerlimit of 0.25), and reducing the other two valuescauses an unwanted reduction in DOF. The remark-able success of photolithography in the past severalyears can be attributed to pursuing all three of theseapproaches to decrease linewidth, while at the sametime learning to sustain a high yield despite a gradu-ally shrinking DOF.

In the choice between reducing the wavelength λand increasing the numerical aperture NA, Equations1 and 2 indicate that reducing λ causes less of a de-crease in DOF and therefore should be preferable.The microchip fabrication industry has successfullymade the transition from a wavelength of 436 nm(the so-called G-line of mercury arc lamps) to 365nm (the I-line of mercury arc lamps), and is now inthe process of making a transition to 248 nm (thekrypton-fluoride excimer laser). This article reviewsthe status of the next expected transition to a wave-length of 193 nm (the argon-fluoride laser), which iscurrently under active development throughout theworld, and in which Lincoln Laboratory has played,and continues to play, a pivotal role. Indeed, theDARPA-funded program at Lincoln Laboratory,started in 1988, has provided the seminal resultsupon which the present worldwide activities in thisfield are based.

The shift to a new wavelength of 193 nm in photo-lithography has centered on the development of threekey components: a new light source (the argon-fluo-ride laser, which has been available commerciallysince the late 1970s but only as a laboratory tool), anew projection system, and new photoresists. This ar-ticle concentrates on studies of the properties of opti-cal materials used in projection systems, on new de-velopments in designing and processing photoresists,and on initial studies to fabricate devices and to ex-tend the resolution limits of 193-nm lithography.

VOLUME 10, NUMBER 1, 1997 THE LINCOLN LABORATORY JOURNAL 21

• ROTHSCHILD ET AL.Photolithography at 193 nm

Optical Materials at 193 nm

The shorter wavelength of the argon-fluoride lasercauses many unexpected phenomena to occur in theoptical materials used in a photolithography system.We must understand the behavior of these opticalmaterials at 193 nm in order to build high-perfor-mance lithographic systems suitable for a manufac-turing environment.

The near-diffraction-limited projection optics inphotolithography can be classified as all refractive (us-ing only lenses) or catadioptric (a combination oflenses and mirrors). A catadioptric system has an in-herent advantage in that it can accommodate a rela-tively broad bandwidth of the laser. Systems classifiedas all reflective (using only mirrors) are excluded fromthis discussion. An all-reflective system with high nu-merical aperture and near-diffraction-limited perfor-mance over a large field—properties required of litho-graphic systems—has not yet been designed.

The argon-fluoride laser emits radiation over arange of wavelengths centered around 193 nm. Thisrange, frequently referred to as linewidth, is 250 pm(picometers) in a free-running laser. Although thelinewidth is only slightly larger than one-thousandthof the center wavelength, it can have profound impli-cations on the design of the projection optics. Thereason for this effect is the dispersion inherent in alloptical materials, i.e., the variation of the refractiveindex n with wavelength. Because of the dispersion,refractive elements (lenses) react to the slightly differ-ent wavelengths emitted by the laser in slightly differ-ent ways, but enough so that the final image may be-come too blurred. This phenomenon, known aschromatic aberration, is also encountered in ordinarycameras designed for use in visible light.

In the case of near-diffraction-limited projectionoptics for 193-nm lithography, the dispersion in anall-refractive or catadioptric system imposes limits onthe acceptable linewidth of the laser and on the de-sign of the projection optics. Specifically, the bestknown design of a projection-optics system with anumerical aperture of 0.5, that of SVG LithographySystems, works with the full 250-pm linewidth of afree-running argon-fluoride laser, or it may requiremodest line narrowing (to δλ ≥ 20 pm) at higher nu-

merical apertures. All-refractive designs, however, ne-cessitate line narrowing to a range of 0.3 to 1.0 pm,which places a significant burden on the performancecharacteristics of the laser, such as energy per pulseand long-term stability of the center wavelength.

All refractive elements, whether components of all-refractive systems or catadioptric systems, must beprepared from transparent optical materials. Few op-tical materials, however, are fully transparent at theshort wavelength of 193 nm and meet the other re-quirements of size, uniformity, and mechanical andchemical stability as well. Because of limitations onsize, homogeneity, reproducibility of volume manu-facturing, and other factors, practical choices for theoptical material are synthetic fused silica and single-crystal calcium fluoride. Of these, the synthetic fusedsilica is widely preferred because of an established in-frastructure of supply, polishing, and testing.

The requirement of unvarying refractive index, inaddition to limiting the laser linewidth, imposes animportant constraint on the optical material itself—itmust be nearly fully transparent at 193 nm. In otherwords, it should absorb no more than a minute frac-tion of the laser power incident on it. The ability ofthe material to transmit radiation (and its converse, toabsorb it) is commonly expressed in terms of thematerial’s absorption coefficient α, which should bezero for fully transparent materials. Quantitatively, asample of optical material of thickness L transmits afraction of incident power, neglecting surface losses,which is given by 10–αL.

While the requirement that α be equal to zeroseems like an easily achieved goal, it is far from beingso. Even a small absorption coefficient such as 0.01cm–1, combined with typical laser powers of approxi-mately 10 W, can cause a small temperature rise of ap-proximately 0.1 K. However, the refractive index nvaries with temperature T as well as with wavelengthλ. In fact, dn/dT ≈ 22 ppm/K (where ppm is parts permillion) at a wavelength of 193 nm for the material ofchoice, synthetic fused silica [1]. Thus if the refractiveindex n cannot vary by more than 1 ppm (and oftenless), then the hypothetical temperature rise of 0.1 Kmentioned above would be unacceptable. Indeed, atarget value of 0.002 cm–1 as the upper limit of theabsorption coefficient α has been established by

22 THE LINCOLN LABORATORY JOURNAL VOLUME 10, NUMBER 1, 1997

• ROTHSCHILD ET AL.Photolithography at 193 nm

SEMATECH, the consortium of U.S. semiconductormanufacturers, in consultation with all the majorlithographic lens suppliers.

An accurate determination of such small values ofthe absorption coefficient is critical to the feasibilityof 193-nm lithography, and has proven to be quitedifficult. By using spectrophotometric and calorimet-ric methods, we have established that at least twogrades of fused silica and two grades of crystalline cal-cium fluoride meet the above specifications, whileother grades of fused silica have absorption coeffi-cients that are too high [2].

Optical materials, even if mostly transparent, maydevelop laser-induced defects after prolonged irradia-tion. Calcium fluoride has been observed to developcolor centers, which effectively reduce its transmis-sion [3]. Fused silica exhibits a more complex array oflaser-induced phenomena [4]. It also forms color cen-ters that reduce the transmission and increase the ab-sorption, and it is densified, or compacted, so that itsthickness and refractive index change over time.

Figure 1 shows the spectrum of laser-inducedadded absorbance to two grades of fused silica, desig-

nated here as A and B, which are both irradiated at1.2 mJ/cm2/pulse for one billion pulses. The samplelengths were 2.5 cm each. Although both grades ofsilica are similar in composition and level of impuri-ties, this figure shows that their response to laser irra-diation is markedly different. Material A has an addedabsorbance of almost 0.02 at the 193-nm wavelengthof interest, while material B shows practically nochange in absorption. Clearly, material B would bemuch more suitable, from the standpoint of a lesserdegree of damage, for use in 193-nm lithography. Thecompaction in fused silica also causes stress-inducedbirefringence in areas adjacent to the areas compactedby the laser. Furthermore, a recently observed phe-nomenon is the formation of microchannels thatpropagate in the fused-silica material along the direc-tion of the laser beam.

The underlying processes that occur on the atomiclevel, and whose manifestations are the various effectslisted above, are far from being fully understood.While such fundamental understanding is clearly de-sirable, it has become imperative in the near term (theindustry time frame is short) to quantify the magni-

FIGURE 1. Added absorption spectra of two grades of fused silica, each 2.5 cm in length,and both irradiated under identical conditions. Although both grades of fused silica aresimilar in composition and level of impurities, fused silica A has an added absorbance ofnearly 0.02 at the 193-nm wavelength of interest. Fused silica B is clearly much more suit-able for use in 193-nm lithography because it is less susceptible to laser-induced damage.

0.02

200

Add

ed a

bsor

banc

e

Wavelength (nm)

0.01

0

400 600 800

Fused silica B

Fused silica A

VOLUME 10, NUMBER 1, 1997 THE LINCOLN LABORATORY JOURNAL 23

• ROTHSCHILD ET AL.Photolithography at 193 nm

tude of the various effects and their scaling with laserintensity, pulse count, and geometry of irradiation.We must also understand how universal these phe-nomena are across suppliers and grades of material.

Lincoln Laboratory, in collaboration with SEMA-TECH, has established a test and evaluation facilityfor optical materials at 193 nm. Figure 2 shows partof this facility, with samples of fused silica being irra-

diated at 193 nm. Optical materials are irradiated un-der conditions similar to those expected in projectionlithography systems (where the fluence is less than1 mJ/cm2/pulse) for one billion pulses and more, andthen tested for transmission and compaction. Ourstudies with fused silica have shown that color-centerformation saturates with exposure dose and can bekept at an acceptably low level. On the other hand,

FIGURE 2. Samples of fused silica being irradiated at 193 nm in the Lincoln Laboratory testand evaluation facility for optical materials. Research at this facility is being done to quantifythe magnitude of various laser-induced effects on optical materials, and their scaling with la-ser intensity, pulse count, and geometry of irradiation. The visible fluorescence seen aboveindicates that the fused-silica materials in this experiment are not fully transparent at 193 nm.

24 THE LINCOLN LABORATORY JOURNAL VOLUME 10, NUMBER 1, 1997

• ROTHSCHILD ET AL.Photolithography at 193 nm

compaction grows as (NI 2)x, where N is the numberof pulses, I is the peak intensity, and x is a parameterin the range from 0.5 to 0.7. The fractional change involume can exceed tens of ppm if I is not kept lowenough, when the number of pulses N is on the orderof 1011 (this value of N is typical of a ten-year opera-tion of a projection lithography system). Such appar-ently small values of compaction are still much toohigh. Thus an upper limit on I may exist, which hasan impact on the choice of material (e.g., calciumfluoride versus fused silica) and system throughput.Indeed, current designs of projection systems call forsome elements to be fabricated with fused silica, whileother elements are to be fabricated with calcium fluo-ride. The choice is made to a large extent on the basisof expected levels of laser-induced damage.

Projection Systems at 193 nm

Several projection systems have been constructed tooperate at 193 nm. Most of these systems are in-tended to be research tools used in the developmentof photoresists. They therefore have fields only severalmillimeters in diameter and are not capable of level-to-level alignment, a key requirement in the fabrica-tion of devices. The one exception is a full-field step-and-scan system built by SVG Lithography Systemsin collaboration with Lincoln Laboratory. This sys-tem is a prototype microchip manufacturing toolwith a large field (32.5 × 22 mm) and an off-axisalignment subsystem. It is currently the first and only193-nm tool in the world with which devices and cir-cuits can be fabricated. Table 1 lists the experimen-tally measured performance characteristics of thisprototype system.

The prototype system at Lincoln Laboratory hasbeen adapted from the commercially available SVGLithography Systems Micrascan II, which was de-signed for operation at 250 nm. As with theMicrascan II, the projection optics of the prototypesystem are catadioptric, and therefore it requires nonarrowing of the argon-fluoride laser linewidth. Therefractive elements are made of fused silica, whose ab-sorption coefficient at 193 nm was measured to be0.002 cm–1. The numerical aperture is 0.5, which wasconsidered high in the early 1990s when the systemwas built. Today, numerical apertures greater than 0.6

are found in state-of-the-art steppers (248 nm andI line), and numerical apertures of 0.7 and above willbe available in a few years when 193-nm manufactur-ing systems go into production.

This prototype 193-nm Micrascan system, whichhas been operational in the Microelectronics Labora-tory at Lincoln Laboratory since late 1994, has beeninstrumental in several projects, including thosefunded by the Department of Defense and thosefunded under cooperative research and developmentagreements with resist companies. The absorption co-efficient of fused silica, small as it is, has been demon-strated to have profound effects on the imaging. Lensheating can cause a change in magnification of severalparts per million and a shift in best focus of over onemicron. These are large values, but future productiontools can be designed to compensate for them.

Table 1. Experimentally MeasuredPerformance Specifications of the 193-nm

Micrascan Prototype System

Property Performance

Resolution ≤150 nm

Depth of focus >1 µm at 200 nm

Dynamic distortion

(maximum vector) 76 nm

(average vector) 28 nm

Field curvature 0.25 µm

Dynamic astigmatism 0.19 µm

Flare

(99% bright field mask) 9%

(50% bright field mask) 4.50%

Overlay (mean + 3σ) <75 nm

Laser-to-wafer transmission 0.014

Maximum laser power >10 W

Laser polarization >85%

Wafer-plane laser power ~150 mW

Exposure time

(15 mJ/cm2 resist) <800 ms

VOLUME 10, NUMBER 1, 1997 THE LINCOLN LABORATORY JOURNAL 25

• ROTHSCHILD ET AL.Photolithography at 193 nm

Photoresists at 193 nm

As we stated earlier, the photoresist can be seen as the“emulsion” in the photolithography process. The de-vice-circuit pattern is “exposed” on the photoresist bythe laser and the projection optics. A number of tech-niques have been developed over the years to createresists at progressively smaller critical dimensions.Practically all photoresists developed for use at longerwavelengths are classified as single-layer resists; i.e.,they have uniform composition through their thick-ness. They are applied by spin coating from solution,followed by baking to remove residual solvents.

The photoresists developed for 248 nm have sev-eral characteristics that must be present in 193-nmresists as well. They are chemically amplified; i.e.,they employ photoacid generators so that suitablepost-exposure baking activates the photogeneratedacids and changes the dissolution properties of the re-sist [5]. Furthermore, positive resists (in which the ex-posed area is removed in the development step afterpost-exposure baking) are developed in aqueousbases. The bulk of the resist is typically a polymer orcopolymer that contains benzene derivatives, or aro-matic rings. These rings endow the polymer withcritical resistance to plasma etching in subsequentsteps, when the pattern must be transferred to theunderlaying layers of silicon oxide, polysilicon, ormetal. Unfortunately, the same aromatic rings exhibitsuch strong absorption at 193 nm that the polymercannot be exposed to more than approximately 100-nm thickness at this wavelength. In order to utilizeresists with thicknesses of 0.5 to 0.7 µm, we must useother polymers that do not have the highly absorptiveconjugated carbon-carbon bonds. Such polymersmay be found among the class of polyacrylates (ofwhich polymethylmethacrylate, or PMMA, may bethe best known). Indeed, the first single-layer resists,developed in a collaboration between IBM/AlmadenResearch Center and Lincoln Laboratory, were basedon copolymers of polyacrylates [6]. These photore-sists were appropriate for evaluating the performanceof projection optics and for patterning silicon-oxidelayers in fluorine-based plasmas. However, in orderfor the resist to stand up in the more aggressive chlo-rine-based plasmas used to etch metal and polysilicon

layers, a higher ratio of carbon to hydrogen is re-quired in the resist. Future photoresists are expectedto be as resistant to plasma etching as novolac (themain constituent of I-line resists), if not more.

Figure 3 shows the effect of polymer compositionand molecular structure on the etch rate in a chlorine-based plasma of polymers that are candidate 193-nmresists. The ring parameter, which is used here as therelevant metric, is defined as the ratio of the mass ofcarbon atoms that exist in ring structures (both con-jugated and alicyclic) to the total mass of the polymer.The figure clearly indicates the overall trend that thehigher the ring parameter the lower the etch rate. Asthe graph in Figure 3 indicates, only polymers withring parameters in excess of 60% have etch rates thatare low enough to be compatible with future device-fabrication needs.

In recent years, several photoresist systems havebeen developed that have alicyclic groups (cyclic con-figurations with single carbon-carbon bonds) and arethus more plasma etch resistant and also semitrans-parent at 193 nm [7]. None of these systems is yetcommercially available, since numerous technicalproblems still need to be resolved, including the pho-tosensitivity of the resist (less than 20 mJ/cm2 is pre-ferred), the intrinsic resolution of the resist (whichshould be capable of printing 0.10-µm features), andvarious processing issues. Nevertheless, we expect thatexperimental quantities of first-generation 193-nmsingle-layer resists will become available in the nextyear.

We have successfully developed a different type of193-nm resist by using a process that is a variation ofso-called top-surface imaging [8]. In this process anabsorptive polymer (polyvinylphenol) is crosslinkedby 193-nm radiation. Following exposure, the waferis placed in a vapor of organosilicon compound(dimethylsilyldimethylamine), which diffuses intothe unexposed areas, and then the wafer is processedin an oxygen-based plasma etch. The latter step etchesthe crosslinked unsilylated regions down to the un-derlying substrate. Careful optimization of the expo-sure, silylation, and plasma-etching steps is requiredin top-surface imaging, but the resultant high-resolu-tion wide-latitude patterning proves the value of theprocess [9].

26 THE LINCOLN LABORATORY JOURNAL VOLUME 10, NUMBER 1, 1997

• ROTHSCHILD ET AL.Photolithography at 193 nm

Figure 4 demonstrates the results that can beachieved by top-surface imaging. The scanning elec-tron micrographs in the figure show 0.175-µm linesand spaces printed in a silylation resist over a doserange of 20% and a defocus range of 1.4 µm. The fea-ture size corresponds to a value of k1 = 0.45 in Equa-tion 1, which is lower than that used in current mi-crochip manufacturing. In spite of this small value,the process latitude of the resist is quite remarkable:20% exposure dose at best focus and 1.2-µm DOF atbest dose. In particular, the experimentally achievedDOF is twice as large as the minimum DOF require-ment described earlier, and therefore provides a wideprocess margin. Unfortunately, top-surface imagingrepresents a significant deviation from common resistprocessing procedures, and therefore it entails certainrisks and challenges. Nevertheless, given the uncer-tainties of single-layer resists described above, it iscurrently being studied carefully as a potential manu-facturing technology.

An unusual variation of the top-surface imagingprocess described above has also been developed atLincoln Laboratory. This variation involves the depo-

sition of the polymer on the wafer not by conven-tional spin coating from solution and baking, but byplasma-enhanced chemical-vapor deposition, orPECVD [10]. The PECVD photoresist deposition,followed by silylation and plasma etching, has beendemonstrated, and raises the prospect of all-dry re-sists. Figure 5 shows the resolution capability of suchresists. In this figure we show scanning electron mi-crographs at two different magnifications of 0.2-µmfeatures printed in a PECVD resist deposited fromthe plasma of the vapor of cycloheptatriene mixedwith oxygen. This process does not require solvents orother liquids, and thus has the potential advantage ofreducing both the environmental impact and the as-sociated cost of handling and disposing of solvents.

Devices Fabricated with 193-nm Lithography

The first-ever complementary metal-oxide-semicon-ductor (CMOS) devices fabricated with all-193-nmlithography were recently completed at LincolnLaboratory [11]. Their successful processing requiredintegration of single-layer resists, top-surface imag-ing, and organic bilayer resists with ion implantation

FIGURE 3. The etch rate of resists in a chlorine-based plasma as a function of the ringparameter. The ring parameter is the ratio of the mass of carbon atoms that exist in ringstructures to the total mass of the resist. The etch rates are compared to that of novolac,which is widely used in I-line resists. Future resists must have etch rates no higher thanthat of novolac. Therefore, polymers with ring parameters in excess of 60% have etchrates low enough to be compatible with future device-fabrication needs.

0Ring parameter (%)

Etch

rate

in c

hlor

ine

plas

ma

(rel

ativ

e to

that

of n

ovol

ac) 2

1

6020 40

VOLUME 10, NUMBER 1, 1997 THE LINCOLN LABORATORY JOURNAL 27

• ROTHSCHILD ET AL.Photolithography at 193 nm

FIGURE 4. Exposure-defocus matrix of silylated resist profiles for 0.175-µm gratings. The left side of each scan-ning electron micrograph shows 0.15-µm gratings. Each 193-nm dose unit corresponds to 1 mJ/cm2. This figuredemonstrates the process latitude of silylation resists at 193 nm. The 0.175-µm features are sharply delineatedeven when the exposure dose is varied by ± 10% of the optimal value of 146, and even when the resist surface ismoved out of best focus by approximately ±0.5 µm.

133 146 161

–0.2

0

+0.2

+0.4

+0.6

–0.8

–0.6

–0.4

Dose units Defocus ( m)µ

28 THE LINCOLN LABORATORY JOURNAL VOLUME 10, NUMBER 1, 1997

• ROTHSCHILD ET AL.Photolithography at 193 nm

and plasma-etching steps, and the use of the proto-type 193-nm Micrascan system described above.These devices were fully scaled metal-oxide-semicon-ductor field-effect transistors (MOSFET) on silicon-on-insulator (SOI) wafers, with a minimum featuresize of 0.2 µm. Eleven levels of lithography were per-formed, all at 193 nm. Figure 6 shows two scanningelectron micrographs of a section of a ring oscillatorcomposed of transistors manufactured by the 193-nmsystem. The electrical characteristics of the deviceswere well within the designed values, which indicatedsuccessful processing. For instance, a 49-stage ring os-cillator had a 29-psec delay/stage at a supply voltageof 3 V, and a 57-psec delay/stage at 1 V.

FIGURE 6. Scanning electron micrographs of 200-nm polysilicon transistor gates patterned over 50-nm-thick silicon islands, allon a substrate of silicon dioxide on a silicon wafer. The gates were patterned by using the silylation top-surface-imaged resistprocess. When these devices were fully fabricated, the maximum switching speed measured from a 49-stage ring oscillator was29 psec when the devices were run at 3 V and 57 psec when they were run at 1 V, indicating successful processing.

1 µm 100 nm

FIGURE 5. Scanning electron micrographs of 200-nm features printed with a positive-tone all-dry silylation resist depositedfrom cycloheptatriene and oxygen. The process of plasma-enhanced chemical-vapor deposition, or PECVD, that was used todeposit this resist on a silicon wafer does not require solvents or other liquids, and thus has potential advantages of reducingthe environmental impact and the associated cost of handling and disposing of solvents in microchip manufacturing.

Limits of Resolution with 193 nm

Several optical and computational methods have beenunder intense development for several years to extendthe usefulness of photolithography at longer wave-lengths (e.g., 365 nm and 248 nm). In effect, thesemethods can reduce k1 in Equation 1 while increasingthe corresponding k2 in Equation 2. The terms wave-front engineering and resolution enhancing techniqueshave often been used to describe these methods.Some of the methods include off-axis illumination,phase-shifting masks, and optical proximity correc-tion. Lincoln Laboratory has begun investigating theapplicability of these methods to 193 nm [12]. One

VOLUME 10, NUMBER 1, 1997 THE LINCOLN LABORATORY JOURNAL 29

• ROTHSCHILD ET AL.Photolithography at 193 nm

example, using top-surface imaging and the proto-type 193-nm Micrascan system, is shown in Figure 7.The example involves a chromeless phase-shiftingmask instead of the traditional chrome-on-quartzreticle. The chromeless edge shifter enhances thesharpness of the image of edges on the mask by rely-ing on destructive interference, and is capable of reso-lution approaching the fundamental limit of k1 =0.25. Figure 7 illustrates the power of this method byshowing that 0.11-µm features can be printed in thelaboratory with a DOF approaching 1 µm. The mag-nitude of this value of the DOF is significantly higher

FIGURE 7. Scanning electron micrographs of 0.11-µm lines on 0.27-µm pitch. These features were made by usinga chromeless phase-shifting mask and a 0.5-numerical-aperture lens. We obtained a depth of focus larger than1 µm, which is significantly more than the 0.6-µm value the semiconductor manufacturing industry expects for aminimum depth of focus.

than the minimum required. The combination ofvery high resolution and large DOF strongly indi-cates that 193-nm lithography may be extendable in amanufacturing environment to at least 0.13 µm andpossibly beyond.

Conclusions

Optical projection lithography has had a remarkabletrack record in the last two decades. It has always met,sometimes against expectations, the need for higherand higher resolution at a reasonable cost. Its nextfrontier is 193-nm lithography, which is now in the

0 m

0.27 m

–0.15 m –0.30 m –0.45 m

+0.15 m +0.30 m +0.45 m +0.60 m

Defocus

µ

µ µ µ µ

µ µ µ µ

30 THE LINCOLN LABORATORY JOURNAL VOLUME 10, NUMBER 1, 1997

• ROTHSCHILD ET AL.Photolithography at 193 nm

R E F E R E N C E S1. R.N. Shagam (unpublished results); G. Ghosh, “Temperature

Dispersion of Refractive Indexes in Some Silicate FiberGlasses,” IEEE Photonics Technol. Lett. 6 (3), 1994, pp. 431–433.

2. A. Grenville, R. Uttaro, J.H.C. Sedlacek, M. Rothschild, andD. Corliss, “Calorimetric Measurements of Optical Materialsfor 193 nm Lithography,” J. Vac. Sci. Technol. B 14 (6),1996,pp. 4184–4187.

3. J.H.C. Sedlacek and M. Rothschild, “Optical Materials forUse with Excimer Lasers,” SPIE 1835, 1992, pp. 80–88.

4. M. Rothschild and J.H.C. Sedlacek, “Excimer Laser InducedDegradation in Bulk Fused Silica,” SPIE 1848, 1992, pp. 537–544.

5. H. Ito and C.G. Willson, “Applications of Photoinitiators tothe Design of Resists for Semiconductor Manufacturing,” inPolymers in Electronics, T. Davidson, ed. (American ChemicalSociety, Washington, 1984), pp. 11–23.

6. R.R. Kunz, R.D. Allen, W.D. Hinsberg, and G.M. Wallraff,“Acid-Catalyzed Single-Layer Resists for ArF Lithography,”SPIE 1925, 1993, pp. 167–175.

7. R.R. Kunz, S.C. Palmateer, A.R. Forte, R.D. Allen, G.M.Wallraff, R.A. DiPietro, and D.C. Hofer, “Limits to Etch Re-sistance for 193-nm Single-Layer Resists,” SPIE 2724, 1996,pp. 365–376.

8. M.A. Hartney, M. Rothschild, R.R. Kunz, D.J. Ehrlich, andD.C. Shaver, “Silylation Processes Based on Ultraviolet Laser-Induced Crosslinking,” J. Vac. Sci. Technol. B 8 (6), 1990, pp.1476–1480.

9. S.C. Palmateer, R.R. Kunz, M.W. Horn, A.R. Forte, and M.Rothschild, “Optimization of a 193-nm Silylation Processorfor Sub-0.25-µm Lithography,” SPIE 2438, 1995, pp. 455–464.

10. M.W. Horn, M. Rothschild, B.E. Maxwell, R.B. Goodman,R.R. Kunz, and L.M. Eriksen, “Plasma-Deposited SilylationResist for 193 nm Lithography,” Appl. Phys. Lett. 68 (2), 1996,pp. 179–182.

11. M. Rothschild, J.A. Burns, S.G. Cann, A.R. Forte, C.L. Keast,R.R. Kunz, S.C. Palmateer, J.H.C. Sedlacek, R. Uttaro, A.Grenville, and D. Corliss, “How Practical Is 193 nm Lithog-raphy?” J. Vac. Sci. Technol. B 14 (6), 1996, pp. 4157–4161.

12. M. Chan, R.R. Kunz, S.P. Doran, and M. Rothschild, “Photo-lithography at 0.10- and 0.13 µm Using ArF Excimer LaserLithography in Combination with Resolution EnhancementTechniques,” J. Vac. Sci. Technol. B, 15 (6), 1997, pp. 2404–2411.

midst of a transition from proof of concept to manu-facturing technology. There are still many concerns,however, regarding the practical implementation of193-nm lithography in manufacturing. These con-cerns include the commercial development and effec-tiveness of optical materials, optical coatings, projec-tion systems, photoresists, process integration, andextendability to smaller features. Apparently, 193-nmlithography is already too late for the first generationof 0.18-µm devices. It will probably become themainstream technology for second-generation 0.18-µm devices, as well as for 0.15-µm and 0.13-µm de-vices. It will almost certainly require the use ofwavefront engineering methods being developed atlonger wavelengths, and maybe new optical and pro-cessing techniques, which could push it down to 0.10µm or even less.

Acknowledgments

We thank S. Cann, D. Downs, L. Eriksen, and B.Maxwell for expert technical assistance. The LincolnLaboratory portion of this work was sponsored bythe Defense Advanced Research Projects Agency, un-der its Advanced Lithography Program, and bySEMATECH.

VOLUME 10, NUMBER 1, 1997 THE LINCOLN LABORATORY JOURNAL 31

• ROTHSCHILD ET AL.Photolithography at 193 nm

is the leader of theSubmicrometer Technologygroup. His research specialityis in laser processing andlithography. He received a B.S.degree in physics from Bar-Ilan University and a Ph.D. inoptics from the University ofRochester. Following researchat the University of Illinoisand the University of SouthernCalifornia in the areas of laserphotochemistry and laser-induced nonlinear processes,he joined Lincoln Laboratoryin 1984. His responsibilitiesinclude managing projects inadvanced lithography, binaryoptics, and several othermicrofabrication activities.

. is the leader of the AdvancedSilicon Technology group. Hereceived a B.A. degree fromHamilton College, in Clinton,New York, and S.M., E.E.,and Ph.D. degrees in electricalengineering and computerscience from MIT. His doc-toral research included thedevelopment of a CCD/CMOS process technology,and the design and fabricationof a parallel analog focal-planeprocessor for real-time early-vision signal processing usingthis technology. From 1981 to1988 he was employed atLincoln Laboratory, where heworked on semiconductorprocessing and technologydevelopment for the DigitalWafer-Scale Electronics group.After completing his Ph.D.degree, he returned to LincolnLaboratory, where he firstworked with the Submicro-meter Technology group ondeeply scaled device develop-ment using advanced opticallithography techniques. Inaddition to his duties in theSilicon Technology group, heis currently the director ofoperations for the Microelec-tronics Laboratory. His presentresearch activities center onsub-0.25-µm, low-powerCMOS process developmenton both bulk silicon andsilicon-on-insulator wafers.

. is a staff member in theSubmicrometer Technologygroup. He received a B.S.degree in 1982, an M.S. de-gree in 1985, and a Ph.D.degree in 1989, all in engi-neering science and mechanicsat the Pennsylvania StateUniversity. He has been atLincoln Laboratory since1988, and he is currentlyworking on optical materials,photoresist processes, andnear-field optical lithographyusing 193-nm and 157-nmphotons.

32 THE LINCOLN LABORATORY JOURNAL VOLUME 10, NUMBER 1, 1997

• ROTHSCHILD ET AL.Photolithography at 193 nm

. is an assistant staff member inthe Submicrometer Technol-ogy group. His primary area ofresearch is in 193-nm semi-conductor lithography. Hereceived an S.B. degree fromMIT and an M.S. degree fromNortheastern University, bothin electrical engineering. Hehas been at Lincoln Labora-tory since 1985.

. is a senior staff member in theSubmicrometer Technologygroup. His focus of research isin many areas of advancedphotolithography, includingphotoresist development andformulation, exposure-toolevaluation, application ofresolution enhancements tolithographic exposure tools,laser-surface reactions limitinglens durability, and pellicletesting. He received a B.S.degree in chemistry fromRensselaer Polytechnic Insti-tute and a Ph.D. degree inchemistry from the Universityof North Carolina, ChapelHill. He has been at LincolnLaboratory since 1988.

is a staff member in theSubmicrometer Technologygroup. He received a B. S.degree in physics fromPrinceton University in 1986and a Ph.D. degree in appliedphysics from Columbia Uni-versity in 1991. From 1991 to1993 he was a postdoctoralfellow at the University ofCalifornia, Santa BarbaraCenter for Quantized Elec-tronic Structures. From 1994to 1996 he was employed atLawrence Livermore NationalLaboratory, where he wasinvolved in characterization ofvapor-deposited polyamidesand their implementation intoadvanced packaging processes.Currently he is working onoptical material characteriza-tion for 193-nm lithographicapplications.

. is a staff member in theSubmicrometer Technologygroup. She received a B.S.degree in chemistry fromMonmouth University, andM.S. and Ph.D. degrees inelectrical engineering andelectrophysics, respectively,from Cornell University. Priorto joining Lincoln Laboratoryshe worked at the ElectronicsLaboratory of General ElectricCorporation, where she wasresponsible for the develop-ment of high-purity molecu-lar-beam epitaxial GaAs andAlGaAs for microwave deviceapplications. She joined Lin-coln Laboratory in 1985 andworked on the development oforganometallic chemical vapordeposition and gas-sourcemolecular-beam epitaxy forthe growth of group III-arsenides and phosphides foroptoelectronic applications. In1993 she joined theSubmicrometer Technologygroup, where she is developingresist processes for 193-nmlithography.

VOLUME 10, NUMBER 1, 1997 THE LINCOLN LABORATORY JOURNAL 33

• ROTHSCHILD ET AL.Photolithography at 193 nm

. is an assistant staff member inthe Submicrometer Technol-ogy group. He received anA.E. (Associate of Engineer-ing) degree in computer engi-neering from the FranklinInstitute in Boston. He beganworking at Lincoln Laboratoryin 1980 with the Microelec-tronics group, concentratingprimarily on the developmentof dry-etched processes formetals. He also worked on thedevelopment of noncrystallo-graphic dry-etch processes forGaAs, as well as high-aspect-ratio dry etching of silicon forpermeable base transistors. Hejoined his current group in1988 and developed plasma-deposited electrochromic thinfilms for use in 193-nm lithog-raphy. Currently, he is devel-oping silylation processes fortop-surface imaging and thecorresponding dry-etch pro-cesses for pattern transfer in193-nm lithography.

. is an assistant staff member inthe Submicrometer Technol-ogy group. He received aB.S.E.E. degree in controlsystems and communicationsfrom the University of Massa-chusetts at Amherst. He hasbeen at Lincoln Laboratorysince 1981. The current em-phasis of his research is in thestudy of optical materials forlithography.

. is an assistant staff member inthe Submicrometer Technol-ogy group. His primary re-search interests are in advanceddeep-ultraviolet lithography.He received a B.S. degree inpremedical studies and a B.A.degree in classical languagesfrom the University of Massa-chusetts at Amherst, where hewas a member of Phi BetaKappa and Phi Kappa Phi.Before coming to LincolnLaboratory in 1983, he was amiddle-school science teacherfor five years.

.. is an assistant staff member inthe Submicrometer Technol-ogy group. He received a B.A.degree in physics from ReedCollege in 1976. After joiningLincoln Laboratory in 1982,he worked on laser photo-chemistry for laser direct-writeprocessing. Since 1989 he hasbeen involved in studies ofoptical materials for 193-nmlithography. He is a memberof AAAS and SPIE.

34 THE LINCOLN LABORATORY JOURNAL VOLUME 10, NUMBER 1, 1997

• ROTHSCHILD ET AL.Photolithography at 193 nm

is a staff member at IntelCorporation in Santa Clara,California, where his researchspeciality is 193-nm photoli-thography. He is currently onresearch assignment at LincolnLaboratory under theSEMATECH-sponsoredCooperative Research andDevelopment Agreement onthe study of optical materials.He received a B.S. degree inengineering physics fromQueen’s University inKingston, Ontario, and aPh.D. degree in applied phys-ics from Stanford University.His graduate research was onshort-wavelength limits ofoptical lithography.

is a member of the technicalstaff at Digital Semiconductor(a Digital Equipment Corpo-ration business) in Hudson,Mass. He was a Digital Semi-conductor assignee toSEMATECH as the programmanager for 193-nm opticalsystems development at Lin-coln Laboratory from August1994 through March 1997.He received the SEMATECHCorporate Excellence Awardfor establishing and managingthis program. Dan joinedDigital Semiconductor afterreceiving a B.S. degree inchemical engineering from theUniversity of Massachusetts atLowell in 1985. He spent ayear with the ManufacturingEngineering group at DigitalSemiconductor, then moved tothe Advanced SemiconductorDevelopment group, where hehas been a strategic player ingenerations (G-line, I-line,248 nm, 193 nm, and X ray)of lithographic research anddevelopment. He is currentlyresponsible for the explorationof novel process enhancementsto extend 248-nm lithography,leadership of the 193-nmlithography developmentprogram, and the evaluationand integration of strategicforward-looking technologiesin photolithography.