Photolithography-based realization of Frequency Steerable...

Transcript of Photolithography-based realization of Frequency Steerable...

Photolithography-based

realization of Frequency

Steerable Acoustic Sensors

on PVDF substrate

E. Baravelli1, L. De Marchi2, M. Ruzzene1, N. Speciale2

1School of Aerospace Engineering, GeorgiaTech

2University of Bologna – MAS group

2

Outline

■ Guided-wave based directional sensing

■ Frequency Steerable Acoustic Transducers

(FSATs)

■ FSAT fabrication

■ Experiments

■ Conclusions

3

Structural Health Monitoring (SHM)

■ Long-distance inspection

■ Fast

■ Low cost

■ Embedded applications

■ Local inspection

■ Time-consuming

■ Expensive

■ Offline inspection

Guided Waves (GW) vs. Ultrasonic scanning

Offside crack

4

Directional inspection: phased arrays

Yu and Giurgiutiu, Ultrasonics 48:2 (2008)

Wilcox, IEEE TUFFC 50:6 (2003)

Li and Rose, IEEE TUFFC 48:3 (2001)

■ Many, individually

controlled elements

■ Associated circuitry

(wiring, multiplexing..)

■ Signal processing

Silva et al., DAMAS 2011

5

Inherently directional devices

Salas and Cesnik, Sm. Mat. Str. 18 (2009)

■ Still several channels

■ Bandwidth/angular resolution limitations

Matt and L.di Scalea, Sm. Mat. Str. 16 (2007)

6

Frequency-steerable directivity

Harmonic GW

propagation in a

plate-like structure

Solution in wavenumber domain

FT

Maximization

Maximum

radiation/sensing

conditions

9

Spiral FSAT design

Threshold

IFT

FT

[1] Baravelli et al., IEEE TUFFC 58:7 (2011)

[2] Senesi et al., to appear in JASA

10

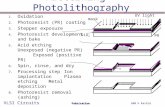

Photolithography-based realization

Preparation

Resist coating

Carrier wafer

PVDF

Metal

Positive photoresist

12

Stripping

Flip sensor &

Repeat on the

back electrode wafer Transparent carrier wafer

Photolithography-based realization

15

Pitch-catch imaging

STFT

WFT

Map

FSAT signal Warped signal

Warped spectrogram Imaging

[1] Baravelli et al., IEEE TUFFC 58:7 (2011)

[2] De Marchi et al., IEEE TUFFC 56:10 (2009)

17

Multi-sensor combination

■ Mirror images (180° uncertainty) ■ Full 360° capabilities

Imaging of plate boundaries Combined source imag.

18

Conclusions

■ FSAT geometry provides spatial filtering and hence

directional sensing

■ 2D imaging with a single FSAT signal

■ Photolithography fabrication on PVDF

■ Low hardware & software complexity enable in-situ and

wireless SHM