Non-Concurrence On Vogtle Electric Generating …York, 1996, pp. 14-15; see also “The January 17,...

Transcript of Non-Concurrence On Vogtle Electric Generating …York, 1996, pp. 14-15; see also “The January 17,...

ML20197A032

Attachment A

Page 1 of 32

I respectfully non-concur on Inspection Report (IR) 05200025/2019010. I am doing so because I disagree with the closure of Unresolved Item (URI) 05200025/2018-01, “Welded Reinforcing Bar Splices.”

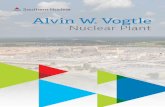

This URI concerns inspection of welded reinforcing bar splices that are being used in construction of the new AP1000 reactors at the Vogtle Electric Generating Plant (VEGP). These splices are critical structural items that must perform satisfactorily during design basis events.

Commensurate with their importance to safety, welded reinforcing bar splices are typically subject to destructive testing, nondestructive examination (NDE),1 or a combination of both to verify that they meet tensile and quality requirements, respectively. These inspections are in addition to visual examination. Southern Nuclear Operating Company (SNC) is only performing visual examination of welded reinforcing bar splices. As a result, completed welded reinforcing bar splices are not being adequately inspected. Without additional measures being taken, there is insufficient basis to conclude with reasonable assurance that structural integrity will be maintained during design basis events and the plant will be safe to operate.

Welded reinforcing bar splices were not approved as an alternative to lap splices in the AP1000 Design Control Document (DCD) and VEGP Units 3 & 4 Updated Final Safety Analysis Report (UFSAR). As a result, the use of welded reinforcing bar splices in the construction of VEGP Units 3 was determined to be a violation of regulatory requirements. The significance of this violation was screened as minor. I do not believe, however, that the limitation placed in the VEGP Units 3 & 4 UFSAR on the use of welded reinforcing bar splices is by accident or insignificant.

In closing this URI, the NRC will be, in effect, providing SNC with relief from the commitments of the VEGP Units 3 & 4 UFSAR and allowing them to administratively revise their licenses to allow the use of welded reinforcing splices. As a result, nonconforming construction will be accepted “use-as-is” without adequate technical justification.

Welded reinforcing bar splices are important structural connections that are relied upon for overall structural integrity and the performance of safety-related functions. There are no indications that the AP1000 design is inadequate or construction of VEGP Units 3 & 4 deficient. However, the splices must be subject to appropriate quality assurance measures2 to provide confidence that the structure will perform satisfactorily during design basis events. One would not expect a safety-related piping system to be put in service without conducting appropriate inspections to verify the system will perform as designed. Likewise, Seismic Category I structures require adequate inspections to verify they will maintain structural integrity and perform their safety-related functions during design basis events.3 Without performing

1 Also referred to as nondestructive testing (NDT). As used in this document, NDE refers to inspection methods other than visual examination such as ultrasonic or radiographic examination. 2 The introduction to 10 CFR Part 50 Appendix B states that “quality assurance” comprises all those planned and systematic actions necessary to provide adequate confidence that a structure, system, or component will perform satisfactorily in service. Quality assurance includes quality control, which comprises those quality assurance actions related to the physical characteristics of a material, structure, component, or system which provide a means to control the quality of the material, structure, component, or system to predetermined requirements. 3 Structures designated as Seismic Category I must be designed to review functional if the Safe Shutdown Earthquake Occurs. The pertinent requirements of Appendix B to 10 CFR 50 apply to all activities affecting the

NCP-2019-002

Attachment A

Page 2 of 32

appropriate inspections, the quality of the structural components that utilize welded reinforcing bar splices is indeterminate. Additionally, closure of Inspection, Tests, Analyses, and Acceptance Criteria (ITAAC) may be affected.

Safety concerns associated with welded reinforcing bar splices prompted the State of California to conduct significant investigations of as-built structural components to verify the adequacy of splices installed in highway structures.4 It is reported that many of the welded reinforcing bar splices examined during these investigations did not meet minimum quality requirements and some had to be replaced.5

Concerns about the performance of welded reinforcing bar splices are well founded: inadequate welded reinforcing bar splices have contributed to catastrophic structural failures, most notably during the 1995 Kobe earthquake.6

This URI is being closed based on guidance provided by the Office of New Reactors (NRO) in Technical Assistance Requests7 (TARs) AP V-M-0428 and AP V-M-045.9 The responses to these TARs, however, do not provide a sufficient basis for concluding that the actions SNC has taken to verify the splices meet quality and performance requirements comply with the VEGP Units 3 & 4 UFSAR or are technically adequate. Neither NRO or SNC has provided adequate information to draw these conclusions.

The inspections being performed by SNC at VEGP Units 3 & 4 to verify the adequacy of welded reinforcing bar splices do not meet the commitments of the VEGP Units 3 & 4 UFSAR, are not

safety-related functions of Seismic Category I Structures, Systems, or Components, Regulatory Guide 1.29, “Seismic Design Classification, Revision 4, March 2007. 4Paul Hefner, “Caltrans Reveals Quake Fix Problems; Bad Welds Found at 210-118 Interchange,” Daily News (Los Angeles, California), November 19, 1997; “Editorial: Bungled Bridges?; Independent Probe into Substandard Welds in Retrofit Program is Essential,” Daily News (Los Angeles, California), November 20, 1997; Meg James, “Orange Crush Contains Faulty Welds, Caltrans Says,” Los Angeles Times, September 13, 1999; Meg James, “Welds Suggest Bridge Quake Risk,” Los Angeles Times, September 13, 1999; Charles F. Bostwick, “Freeway Welds Pass Caltrans Test,” Daily News (Los Angeles, California), September 14, 1999; Charles F. Bostwick, “Freeway Welding Being Tested: Inspections Ordered at 5-14 Interchange,” Daily News (Los Angeles, California), September 14, 1999. Meg James, “Caltrans Refused to Use Weld Alternative,” Los Angeles Times, September 19, 1999; Charles F. Bostwick, “Interchange Being Tested; Engineers Examine Bridge Welds at 5-14 Freeway Crossings,” Daily News (Los Angeles, California), September 21, 1999; Associated Press, “Freeways Lacked Review, Only 1 Inspector Checked Welds at Height of Project,” Daily News (Los Angeles, California), October 7, 1999; Sean Holstege, “Defective Welds have Cropped Up Before,” East Bay Times, April 5, 2005, Updated August 17, 2016. 5 See articles referenced in previous footnote. 6 Priestley, M.J.N., Seible, F. Calvi, G.M., “Seismic Design and Retrofit of Bridges,” John Wiley & Sons, Inc., New York, 1996, pp. 14-15; see also “The January 17, 1995 Hyogoken-Nanbu (Kobe) Earthquake, Performance of Structures, Lifelines, and Fire Protection Systems,” United States Department of Commerce Technology Administration, National Institute of Standards and Technology, NIST Special Publication 901, (ICSSC TR18), Gaithersburg, MD, July 1996, p 177 & p 181; and Bruneau, M., “Performance of steel bridges during the 1995 Hyogoken–Nanbu (Kobe, Japan) earthquake—a North American perspective,” Engineering Structures, Vol. 20, No. 12, pp. 1063–1078, 1998. Specifically, Section 3.1, Reinforced Concrete Substructure Failures 7 A TAR is the mechanism that NRO and Region II use to request and document the results of formal construction inspection related interactions. The TAR is used to document regulatory decisions and interpretations based on the existing licensing basis and previous safety findings, Technical Assistance Request (TAR) Process Desktop Guide, 2018. 8 ML18149A340 9 ML19016A408

NCP-2019-002

Attachment A

Page 3 of 32

commensurate with the importance to safety of the splices, in alignment with NRC guidance on use of welded reinforcing bar splices, or on par with the measures used for inspection of welded reinforcing bar splices in the construction of other U.S. nuclear plants. These measures are also not consistent with the requirements of other design certifications, common practices for structures with potential impacts to public health and safety, or the recommendations of respected and widely adopted industry standards.

NRC guidance on the use of welded reinforcing splices is that they meet the requirements of American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel (BPV) Code Section III, Division 2 (ASME Division 2). This guidance, to my knowledge, is based on the importance to safety of welded reinforcing bar splices used in Seismic Category I structures and a reasonable concern with achieving adequate performance and quality requirements. ASME Division 2 requires destructive testing and NDE of welded reinforcing bar splices.

SNC committed to ASME NQA-1-1994, Part II, Subpart 2.5, “Quality Assurance Requirements for Installation, Inspection, and Testing of Structural Concrete, Structural Steel, Soils, and Foundations for Nuclear Power Plants” (Subpart 2.5)10 in their Nuclear Development Quality Assurance Manual (NDQAM). Subpart 2.5, Paragraph 7.13 requires the inspection of welded reinforcing bar splices to comply with ASME Division 2. SNC failed to incorporate these requirements into the VEGP Units 3 & 4 construction specifications.

URI 05200025/2018-01 should be closed to an ITAAC finding and associated more-than-minor violation of the Code of Federal Regulations (10 CFR) Part 50, Appendix B, Criterion III, “Design Control” for SNC’s failure to correctly translate the design basis into specifications, drawings, procedures, and instructions. The significance of this violation should be dependent on whether SNC can provide evidence demonstrating that the Structures, Systems, and Components (SSCs) that rely on welded reinforcing bar splices will meet their safety functions. Absent enforcement action, I do not have confidence that appropriate corrective actions will be taken to address this issue.

Background

Concrete is strong in compression but weak in tension. When subjected to loads that create tension, cracks will occur in a concrete structure if the tensile strength of the concrete is exceeded. These cracks can lead to a sudden catastrophic failure due to the inability of the concrete to resist the tensile forces. In a reinforced concrete structure, deformed steel bars, typically referred to as reinforcing bars, are embedded in the concrete in such a way that the tensile forces can be resisted by the bars after the concrete cracks.11 The tensile forces are the result of internal stresses that develop in the concrete and are associated with axial, shear, and torsion forces and bending moments. In some instances, the reinforcing bars may also be used to supplement the concrete in resisting compression forces. The reinforcing bars resemble circular rods with raised ridges to lock the bar to the surrounding concrete. The reinforcing bars are essential components of a reinforced concrete structure that are necessary to resist the loads imposed on the structure and maintain structural integrity. Ideally, continuous reinforcing bars would be installed. However, this is generally not feasible given the standard manufactured lengths of the bars, structural details, and construction considerations. As a

10 When referenced in this document, Subpart 2.5 refers to that of ASME NQA-1-1994 as this is what is adopted in the SNC quality assurance program. 11 James G. MacGregor, Reinforced Concrete Mechanics & Design, 2nd ed., Prentice-Hall, Englewood Cliffs, N.J., 1992, p. 1

NCP-2019-002

Attachment A

Page 4 of 32

result, the reinforcing bars are typically spliced together at various locations within the structure. The design function of the splice is to join two reinforcing bars together so that the assembly behaves as one continuous reinforcing bar, typically, having the same diameter as the spliced bars but a longer length.

It should be clear from the above description that reinforcing bar splices are key components in reinforced concrete construction.12 The splices are used to provide continuity for the transfer of forces within reinforced concrete structures. They are a potential “weak link” in the structural system and must be installed correctly to ensure acceptable performance. Inadequately installed reinforcing bar splices can lead to structural failure.

Reinforcing bars may be spliced together with lap splices, mechanical connections13, or welded splices.14 Lap splices are typically the most frequently encountered type of reinforcing bar splice. In a lap splice, two bars are laid adjacent to one another with the end of each bar overlapping the other for a calculated distance known as the lap splice length. The force is transferred from one bar to another through the concrete between the bars. For large diameter bars, the lap splice length can be many feet. While prevalent in reinforced concrete construction, lap splices are not allowed for very large bar sizes, increase reinforcement congestion, require adequate space to be installed, and have other limitations that may make them impractical or impossible to install in some instances. In these situations, a mechanical or welded splice may be installed.

A mechanical connection or splice typically makes use of a sleeve that overlaps each bar end to provide a connection between two bars. The sleeve and ends of the bars may be threaded much like a nut and bolt, or the sleeve filled with metal or grout to form a connection. There are many different systems of mechanical connections. All of them rely on a mechanical connection between the bars to transfer forces. In a welded splice, on the other hand, the bars are fused together either directly or indirectly by electric arc welding.

Of the three types of reinforcing bar splices, welded splices require the most stringent controls over the splicing process and the highest level of skill to install correctly. Welding is also typically the least cost-effective method of splicing reinforcing bars. Given these factors, welded splices have generally been used sparingly in the general construction industry. Recommended practice is to minimize their use if possible.15 This recommendation is partly due to concerns about consistently producing welded reinforcing bar splices that meet the specified performance and quality requirements. If used, however, careful consideration should be given to the quality assurance measures implemented to ensure that welded reinforcing bar splices are installed correctly and will perform adequately.

12 ACI 439-3R-07, “Types of Mechanical Splices for Reinforcing Bars” 13 “Manual of Standard Practice,” Concrete Reinforcing Steel Institute (CRSI), 28th Edition, 2nd printing, 2011 defines a mechanical splice in the glossary as a complete assembly of an end-bearing sleeve, a coupler, or a coupling sleeve, and possibly additional material or parts to accomplish the splicing of reinforcing bars; ACI 439-07 has a similar definition and indicates that a mechanical splice was “mechanical splice” was formerly called “mechanical connection” in ACI 318-95 and earlier editions. 14 The CRSI Manual of Standard Practice defines a welded splice in the glossary as a means of joining two reinforcing bars by electric arc welding. Bars may be lapped, butted, or joined with splice plates or angles. 15 “Manual of Standard Practice,” Concrete Reinforcing Steel Institute (CRSI), 28th Edition, 2nd printing, 2011, p 1-4 and Flathua, W.J., “Dynamic Tests of Large Reinforcing Bar Splices,” U.S. Army Engineer Waterways Experiment Station, Technical Report N-71-2, Vicksburg, MS, April 1971 p. 141.

NCP-2019-002

Attachment A

Page 5 of 32

Welding is a special process that is highly dependent on control of the process and the skill of the welder.16 As a result, both the welding procedure and welder must be qualified to provide confidence that the completed weld will be sufficient. In addition, completed welds must be inspected to verify they meet requirements. The type of inspections conducted to verify weld quality often correlate to the type of weld and associated stress. Highly stressed welds that are used in critical applications typically receive a greater level of inspection than lower stressed welds used in secondary applications.

The main type of welded splice being installed at VEGP Units 3 & 4 is a direct butt joint.17 In this type of splice, the ends or the bars are beveled at an angle such that a groove is formed when the bars are butted together end to end. The groove between bars is filled with weld material to fuse the two bars together. The weld joining the bars together is referred to as a complete joint penetration (CJP) groove weld. By design, the weld has the same strength as the bars and can be highly stressed.

Given their importance, CJP welds are typically subject to ultrasonic or radiographic examination to verify weld quality. These inspections are in addition to visual examination and are important because visual examination only looks at the surface of the weld. Visual examination cannot identify any subsurface defects such as lack of fusion, porosity or slag inclusions that could impact the strength of the weld, nor can it reliably identify microscopic surface cracks or defects. All welds subject to ultrasonic or radiographic examination must first pass visual examination. Typically, all welds are visually examined, and ultrasonic or radiographic examination is conducted on a sampling basis. If defects are found using NDE methods other than visual, a greater number of welds may be inspected using these methods to determine if there is a larger problem with the welding procedure or welder. Welds that do not meet quality requirements are typically repaired.

Historically, destructive testing of welded reinforcing bar splices has also been performed on a sampling basis to verify welded reinforcing bar splices meet tensile strength requirements. This testing may be conducted on production joints cut directly from in-place reinforcement or removable “sister joints” made adjacent to production joints and under the same conditions. If the tested joints do not meet strength requirements, additional joints are tested, and the cause of the problem investigated.

For structures having a high risk to public health and safety in the event of damage or failure, it is common practice to specify that welded reinforcing bar splices be subject to either destructive testing, radiographic examination, or a combination of both, in addition to visual examination, to verify that the required performance and quality requirements have been met. NRC guidance on the use of welded reinforcing bar splices aligns with this practice.

Welded Hoops at Main Steam Line Penetrations through Wall 11

During a routine ITAAC inspection of VEGP Unit 3 conducted the week of January 21, 2018, welded reinforcing bar hoops were observed being installed at the main steam line penetrations

16 A special process is defined as “a process, the results of which are highly dependent on the control of the process or the skill of the operators, or both, and in which the specified quality cannot be readily determined by inspection or test of the product,” ASME NQA-1-1994, “Quality Assurance Requirements for Nuclear Facility Applications,” Terms and Definitions, p 7. Given this definition, I would submit that some destructive testing and NDE other than visual is required to verify welded reinforcing bar splices meet specified requirements. 17 Also referred to as a direct butt splice when two reinforcing bars are spliced together.

NCP-2019-002

Attachment A

Page 6 of 32

through Wall 11 of the auxiliary building. The design details called for closed hoops. These hoops could not be fabricated from one continuous piece of reinforcing steel. As a result, the design drawings specified for them to be fabricated from two pieces joined together with mechanical or welded splices. Each piece was bent in the form of a U and the pieces were welded together in two places using CJP welds to form one continuous closed hoop of rectangular shape. Two bars sizes were used to form hoops of different diameters. The smaller hoops were formed with #9 bars and the larger hoops used #11 bars. The #9 bars have a diameter of 1.28 inches and the #11 bars have a diameter of 1.41 inches. The #9 and #11 hoops were bundled together in groups of two and installed radially around the main steam line penetration in the wall. The section of Wall 11 at the east main steam line penetration is identified as a critical structural section in the VEGP Units 3 & 4 UFSAR.18 The design of Wall 11 is addressed in VEGP Units 3 & 4 UFSAR Section 3H.5.1.4 and depicted in VEGP Units 3 & 4 UFSAR Figure 3H.5.5. The areas identified as critical sections in the VEGP Units 3 & 4 UFSAR, including this section of Wall 11, are characterized as high risk.19 VEGP Units 3 & 4 UFSAR Section 3H.5.1.4 states the following:

“The wall (Wall 11) is designed to withstand loads such as the dead load, live load, seismic load and the thermal load. The MSIV compartments are break exclusion areas, but the design also considered the compartment pressurization load associated with a one square foot pipe rupture in the MSIV compartments. Wall 11 in the east MSIV compartment is also designed to withstand the jet loads and the reactions at the pipe anchors for the main steam and feedwater line breaks assumed to occur in the east MSIV compartment. Additionally, the Wall 11 design for both MSIV compartments considers loads from postulated breaks in the turbine building, which include turbine building first bay pressurization, jet loads, reactions at the Wall 11 pipe anchors, and pipe whip.”20

According to Westinghouse Electric Company (WEC) structural calculations, the #9 bundled hoops resist any out-of-plane shear forces and the #11 bundled hoops are considered to resist out-of-plane, radial axial forces, and torsion.21 These forces develop in the wall from normal, environmental and abnormal loads. Normal loads are associated with normal plant operation and shutdown, environmental loads are due to winds including tornados, and earthquakes; and abnormal loads are generated by a postulated high-energy pipe break accident. The anchorages at Wall 11 are considered terminal ends of the main steam and feedwater lines. These are safety-related systems between the steam generators and Wall 11 anchorages and are designed to ASME Class 2 or 3 requirements as described in VEGP Units 3 & 4 UFSAR Sections 10.3.1.1 and 10.4.7.1.1, respectively.22

18 VEGP Unit 3 & 4 UFSAR, Tier 1, Table 3.3-7, Revision 6, p 3.3-33 (ML18179A250) 19 Inspection Manual Chapter 2519, “Construction Significance Determination Process,” System/Structure Risk Importance Table for AP1000 Construction SDP Matrix X-Axis, Appendix A, 12/06/17, p. AppA-10. 20 VEGP Unit 3 & 4 UFSAR, Section 3H.5.1.4, Wall at Column Line 11, Revision 7, p 3H-12 (ML18179A277) 21 Westinghouse Electric Company Document No. APP-1200-S3C-101, “Auxiliary Building Wall 11 Reinforcement Design EL 117’-6” to EL 135’-3”,” Revision 0, p. 31. 22 VEGP Units 3 & 4 UFSAR, Revisions 5 & 7, respectively (ML18179A284).

NCP-2019-002

Attachment A

Page 7 of 32

One of the most critical events for the design of Wall 11 is a postulated high-energy line break of the main steam line occurring in the penetration sleeve through Wall 11, or in the turbine building North of Wall 11. Such an event would place significant out-of-plane forces on Wall 11 at the steam line anchorages.23 The welded hoops are required to resist these forces. This is a non-redundant system. There is no other means of resisting these forces other than the welded hoops. Failure of the welded reinforcing bar splices during such an event could compromise the integrity of Wall 11. Failure of Wall 11 at the main steam line anchorages could, in turn: compromise the integrity of the MSIV compartments; impact the operability of the safety-related equipment and components housed within; and invalidate the assumptions in the accident analysis leading to unanticipated impacts to safety-related structures, systems, and components (SSCs). The VEGP Units 3 & 4 auxiliary buildings are Seismic Category I structures that are designed and constructed in accordance with American Concrete Institute, “Code Requirements for Nuclear Safety Related Concrete Structures (ACI 349-01).”24 ACI 349-01 section 12.14.3.2 requires that all welding conform to American Welding Society, “Structural Welding Code – Reinforcing Steel,” (AWS D1.4-98). The welded reinforcing bar splices were visually examined in accordance with AWS D1.4-98. However, no destructive testing or NDE other than visual was conducted, to my knowledge, of completed welded reinforcing bar splices installed in the structures as required by Subpart 2.5. Unresolved Item (URI) 05200025/2018-01, “Welded Reinforcing Bar Splices” The following paragraphs describing the URI are taken from inspection report 05200025/2018-01.25 During the week of January 22, 2018, the inspectors determined the licensee was not performing destructive tests or NDE of welded reinforcing joints as required by the ASME Code, Section III, Division II, "Code for Concrete Reactor Vessels and Containments." Specifically, testing or NDE reports were not available for the welded reinforcing steel hoops used in the north wall of the main steam east compartment at column line 11, between elevations 117'-6" and 153'-0". The reinforcing hoops at this location were fabricated with direct butt joints using complete joint penetration groove welds. SNC committed to comply with ASME NQA-1-94, Subpart 2.5, in its Nuclear Development Quality Assurance Manual. Specifically, the SNC Nuclear Development Quality Assurance Manual, Version 17, Part II, Section 10.4.1 states, in part, SNC commits to compliance with the requirements of [ASME NQA-1-94, Part II] Subparts 2.5 and 2.8 for establishing appropriate inspection requirements. ASME NQA-1-1994, Subpart 2.5, Paragraph 7.13, "Welded Reinforcing Bar Splices," states, in part, welded reinforcing bar splices shall be subject to the requirements of paragraph 8.5, except provisions of the ASME Code, Section III, Division 2 (ACI 23 Westinghouse Electric Company Document No. APP-GW-P0C-161, “Bulk Flow, Fluid Induced Penetration Loads Due to Postulated Pipe Ruptures Occurring within Penetration Sleeves in the Turbine Building along Line 11 Wall,” Revision 1, 149 pp; Westinghouse Electric Company Document No. APP-GW-P0C-008, “Impact of High-Energy Line Breaks in the Turbine Building on the Line 11 Wall and its Penetrations,” Revision 3, 175 pp. 24 VEGP Unit 3 & 4 UFSAR, Section 3.8.4 (ML17172A242) 25 ML18134A348

NCP-2019-002

Attachment A

Page 8 of 32

Standard 359) shall also apply. The ASME Code, Section III.2 (2001 Edition with 2003 Addenda), Article XI-1560, "Continuing Joint Performance Tests," requires destructive testing on a sampling basis of welded reinforcement splices to ensure the joints met tensile requirements. Additionally, the ASME Code, Section III.2 (2001 Edition with 2003 Addenda), Article XI-1600, "Examination of Welded Joints of Reinforcing Bar," requires RT examination of joint samples to verify weld quality. The north wall of the main steam east compartment at column line 11, between elevations 117'-6" and 153'-0", is a reinforced concrete wall in the auxiliary building. The inspectors noted Section 3.8.4.4.1 of the UFSAR states, in part, ACI 349-01 is the applicable code for the design and analysis of Seismic Category I reinforced concrete structures in the auxiliary building. ACI 349-01, Subsection 12.14.3.2, requires, in part, all welding to conform to AWS D1.4-98. Neither ACI 349-01 nor AWS D1.4 require inprocess tests or NDE of welded reinforcing splices. As a result, the inspectors questioned whether the ASME NQA-1-94 provisions for the inspection of welded reinforcing steel splices that incorporate by reference the ASME Code, Section III.2 requirements are quality assurance measures that supplement ACI 349-01 requirements and provide confidence that welded joints will perform satisfactorily in service. The licensee provided the inspectors with a position paper (CR 10465176) concerning the applicability of ASME NQA-1-94, Subpart 2.5, Paragraph 7.13 requirements. 52 This issue is an Unresolved Item pending the inspectors' review and evaluation of the licensee's position paper on the applicability of ASME NQA-1-94, Subpart 2.5, Paragraph 7.13 requirements. (URI 05200025/2018001-01, Welded Reinforcing Bar Splices) SNC Response to URI SNC provided a position paper26 concerning the applicability of Subpart 2.5, Paragraph 7.13 requirements for the inspection of welded reinforcing bar splices. In this “white paper”, SNC asserted that the language in the SNC NDQAM and ASME NQA-1-1994 allowed them broad latitude in implementing the requirements of Subpart 2.5. It was also their opinion that Subpart 2.5, Paragraph 7.13 only applies to concrete containment structures. As a result, SNC’s position was that they were in full compliance with the VEGP Units 3 & 4 COLs and no exceptions were required in the SNC NDQAM if the provisions of ASME Division 2, referenced in Subpart 2.5, were not implemented. NRC regional inspectors reviewed the SNC “white paper” and did not believe the arguments presented in it to have much merit. Well it is true that the organization invoking NQA-1-1994 may use judgement in applying the entire standard or portions of the standard, the inspectors felt that the extent of application of the standard should be clearly defined in the organization’s quality assurance program description (QAPD). In their NDQAM, SNC states their commitments, exceptions, and clarifications to specific paragraphs of NQA-1-1994. The inspectors believed that SNC’s position in their “white paper” 26 ML18149A340

NCP-2019-002

Attachment A

Page 9 of 32

that the language in their NDQAM and NQA-1-1994 provided them broad discretion to implement the requirements of Subpart 2.5 as they see fit did not appear to be consistent with the language in their NDQAM, or the nature of a commitment in general. In effect, it would result in a non-binding commitment. This seemed to be an oxymoron that could, by extension, lead to uncertainty in how SNC is satisfying the requirements of Appendix B.27 Additionally, the inspectors did not find SNC’s position that the requirements of Subpart 2.5, Paragraph 7.13 do not apply to construction of VEGP Units 3 & 4 to be consistent with the scope of NQA-1-1994 Part II, relevant NRC guidance, or other information that was reviewed. Technical Assistance Request (TAR) The language in the SNC NDQAM committing to Subpart 2.5 is taken verbatim from NEI 06-14A, Revision 7. The QAPD template provided in NEI 06-14A, Revision 7 is based on ASME NQA-1-1994 and was endorsed by the NRC28 as a means of satisfying Appendix B. Since the language in the SNC NDQAM had been previously reviewed by the NRC, and because the licensee was challenging the applicability of Subpart 2.5, Paragraph 7.13 to VEGP Units 3 & 4, regional inspectors and management believed it would be beneficial to get NRO perspective on these issues. As a result, a TAR was submitted to NRO to assist in closing the URI. TAR AP-V-M-4229 Two simple questions were asked in TAR AP-V-M-42:

1. In general, when a licensee commits to NQA-1-94 Subpart 2.5 without exception and performs work activities that are within the scope of the subpart, must the relevant requirements of the subpart be implemented?

2. When a licensee commits to NQA-1-94 Subpart 2.5 without exception, do welded

reinforcing splices in Seismic Category I structures designed and constructed to ACI 349 need to conform to the relevant provisions of ASME BPVC SEC III.2?

Regional inspectors held the opinion that the answers to these questions should be yes. March 29, 2019 Response to TAR AP-V-M-42 Question 1 and comments30 The response to this question went through three iterations based on interactions between NRO and Region II. Initially, NRO staff provided the following response: It is the responsibility of the entity applying NQA-1, in this case SNC, to determine to what extent the supplemental requirements of NQA-1 Part II are necessary in order to meet the requirements of Appendix B to 10 CFR Part 50. That evaluation will take into consideration the specific type of nuclear facility, items, or services involved and the nature and scope and the relative importance of the activities being performed. 27 10 CFR 52.79(a)(25) requires an applicant for a combined license (COL) to submit a description of the quality assurance program applied to the design and to be applied to the fabrication, construction, and testing of the facility, and to include a discussion of how the applicable requirements of 10 CFR Part 50, Appendix B have been and will be satisfied. 28 ML092650695 29 ML18149A340 30 In the discussions concerning the TARs, NROs response is provided in italics and my comments in standard text.

NCP-2019-002

Attachment A

Page 10 of 32

[SNC is committed to NQA-1-94 which the staff found to be acceptable (https://www.nrc.gov/reactors/new-reactors/oversight/quality-assurance/qual-assure-safety.html)]. The staff agrees that the licensee’s exception to certain portions of Subpart 2.5 should have been addressed as an exception in its QAPD. However, from an enforcement standpoint, the staff determines that the issue would be no more than minor as a failure to meet a commitment. This response appears reasonable except for the characterization of the issue as minor in the last sentence. Determining the significance of an inspection issue is typically not the responsibility of NRO staff. I agree that it is the responsibility of the organization invoking NQA-1-1994 to determine the extent to which the standard should be applied.31 However, it is important to recognize that the extent to which the standard is applied needs to be documented in the licensees QAPD which must be submitted to the NRC for approval during licensing.32 Subsequent changes to the QAPD are governed by NRC regulations.33 The licensee does not have the discretion to arbitrarily reduce the commitments of their QAPD. As a result, the flexibility afforded by ASME NQA-1-1994 in determining the extent to which the standard should be applied is constrained by regulation after issuance of a license. If this were not the case, the commitments made in a QAPD would be nonbinding and there would be insufficient basis for determining in licensing actions that the requirements of Appendix B will be met. This point is not one that SNC or NRO staff appear to accept. The SNC NDQAM is based on NEI 06-14A.34 In the safety evaluation report (SER) of NEI 06-14A35, the NRC concluded that the QAPD template:

1. Commits the applicant to the quality standards described in NQA-1-1994, Basic Requirement 10, Supplement 10S-1, and Subparts 2.4, 2.5 and 2.8.36 (No exceptions to Subpart 2.5 are listed)37;

31 The forward to ASME NQA-1-1994 states: “The arrangement of the basic and supplementary requirements in Part 1 (from former NQA-1), requirements for work practices in Part II (from former NQA-2), and nonmandatory guidance and applications appendices in Part III (from former NQA-1 and NQA-2) permits judicious application of the entire Standard or portions of the Standard. The extent to which this Standard should be applied will depend upon the specific type of nuclear facility, items, or services involved and the nature and scope and the relative importance of the activities being performed. The extent of application is to be determined by the organization imposing the Standard. For example, it may only involve the Basic Requirements; Basic Requirements in combination with selected Supplements; Basic Requirements in combination with Supplements with appropriate changes. This Standard is written to allow application to any structure, system, component, or activity that is essential to the satisfactory performance of the facility.” 32 10 CFR 52.79(a)(25) 33 10 CFR 50.54(a)(3) and 10 CFR 50.55(f)(4) 34 VEGP Unit 3 UFSAR, Section 17.8, Reference 201, Nuclear Energy Institute, Technical Report NEI 06-14A, “Quality Assurance Program Description,” Revision 7, July 2009. 35 ML092650695 36 Final Safety Evaluation for Technical Report NEI 06-14, “Quality Assurance Program Description,” Revision 7, Section 3.2.10, “Inspection”, p 11. 37 The parenthetical comment is mine.

NCP-2019-002

Attachment A

Page 11 of 32

2. Includes regulatory commitments to ASME NQA-1-1994, “Quality Assurance Requirements for Nuclear Facility Applications,” Parts I and II, as described in Sections 3.2.1 through 3.2.18 of this SER;38 and

3. Provides an acceptable format and adequate guidance for establishing a QA program that complies with Appendix B to 10 CFR Part 50.39

Based on the regulations governing the QAPD, the NRC SER of the QAPD template provided in NEI 06-14A, and the wording of the SNC NDQAM, it seems reasonable to conclude that SNC committed to NQA-1-1994, Subpart 2.5 and expect that the supplemental measures for the inspection of concrete construction, including those associated with welded reinforcing bar splices, be implemented. SNC failed to incorporate these requirements into the VEGP Units 3 & 4 construction specifications. March 29, 2019 Response to TAR AP-V-M-42 Question 2 and comments NRO staff initially provided the following response: QVIB staff presented this question to the staff from DEI/SEB with regards to the applicability of ASME BPVC Sec III.2, specifically the welded reinforcing steel hoops that are used as part of the main steam line penetration through wall 11. Based on the design requirements and the location of the reinforcing splices, the staff determined that the requirements of ASME BPVC Sec III.2 are not applicable. The staff evaluated the DCD and UFSAR to verify the applicability of RG 1.94 and RG 1.142. RG 1.94 is not applicable and RG 1.142, as documented in Table 1.9-1, concluded that the additional requirements of ACI 359 (ASME BPVC Sec III.2) are not applicable to the AP1000 design. The staff determined this was acceptable during its evaluation of the DCD, COLA, and subsequent LARs. The staff determined that the performance of additional NDE requirements of ASME BPVC Sec III.2 as stated by paragraph 7.13 are not applicable to the welded reinforcing steel hoops. As mentioned in our response to Question 1 the staff did not identify any safety significance by SNC not performing the amplified information contained in paragraph 7.13. It is unclear how NRO staff arrived at these conclusions. A review of the AP1000 DCD, AP1000 Final Safety Evaluation Report (FSER), VEGP Units 3 & 4 UFSAR, and License Amendment 51 (LAR 15-021) which is specific to Wall 11 did not identify any instances in which the NRC stated that the additional requirements of Division 2 referenced in Subpart 2.5 Paragraph 7.13 are not applicable to the welded hoops used in wall 11 or VEGP Units 3 & 4 in general. On the contrary, welded reinforcing bar splices are not identified as an acceptable substitute for lap splices in the AP1000 DCD and VEGP Units 3 & 4 UFSAR. The NRO position appears to be based on a belief that the ASME Division 2 requirements for welded reinforcing bar splices are not applicable because the area in question is not part of a concrete reactor vessel or containment. 38 Final Safety Evaluation for Technical Report NEI 06-14, “Quality Assurance Program Description,” Revision 7, Section 3.4, “Regulatory Commitments”, p 17. 39 Final Safety Evaluation for Technical Report NEI 06-14, “Quality Assurance Program Description,” Revision 7, Section 4, “Conclusion”, p 17.

NCP-2019-002

Attachment A

Page 12 of 32

The acceptable types of reinforcing bar splices addressed in the AP1000 DCD and VEGP Units 3 & 4 UFSAR are limited to lap splices or mechanical connections. Welded splices are not discussed. AP1000 DCD and VEGP Units 3 & 4 UFSARs Section 3.8.4.6.1.2 states, in part, “where reinforcing steel splices are necessary and lap splices are not practical, mechanical connections (e.g. threaded splices, swaged sleeves or cadwelds) are used.” Concerning the applicability of ASME Division 2 to the AP1000, the AP1000 FSER documents that the qualification and performance requirements of ASME Division 2 are applied to the mechanical connections used in the shield building.40 It seems reasonable to assume that similar requirements would have been applied if welded reinforcing bar splices were proposed to be used in the AP1000. Regardless, SNC committed to these requirements, in effect, by invoking Subpart 2.5 without exception in the SNC NDQAM. In subsequent discussions, NRO staff agreed that the use of welded reinforcing splices in the construction of VEGP Units 3 & 4 is not consistent with the VEGP Units 3 & 4 UFSAR. I do not believe this limitation is by accident or insignificant. In the Construction Reactor Oversight process (cROP), the critical structural sections are assigned a higher risk than a concrete containment. It is true that Regulatory Guide (RG) 1.94 was not applicable to the AP1000 Design Certification. WEC took exception to this regulatory guide because it was not relevant to the scope of the design certification document (DCD) which focused on design. WEC stated in WCAP-15799, “AP1000 Conformance with SRP Acceptance Criteria,”41 that quality assurance during construction is the responsibility of the combined license (COL) applicant and the AP1000 would comply with ASME NQA-1 Subpart 2.5. SNC’s commitment to RG 1.94 for the COL is addressed in VEGP Units 3 & 4 UFSAR Appendix 1A. Concerning RG 1.94, SNC states that “Quality assurance requirements utilize the more recently NRC endorsed NQA-1 in lieu of the identified outdated standards [ASME N45.2.5-1974]”. This commitment to NQA-1-1994 includes Subpart 2.5 which has comparable requirements for the inspection of welded reinforcing splices as those provided in ASME N45.2.5 and RG 1.94. Moreover, the commitment to RG 1.14242 as documented in VEGP Unit 3 & 4 UFSAR Appendix 1A does not take exception to any requirements of Subpart 2.5 or state that the additional requirements of ASME Division 2 are not applicable to VEGP Units 3 & 4. It seems to be a leap to infer that this is the case simply because WEC took exception to regulatory positions C.9 and C.14 of RG 1.142 in VEGP Units 3 & 4 UFSAR Appendix 1A. The endorsement of ASME NQA-243 in RG 1.142 is not limited to these two regulatory positions, which clearly are not applicable to the AP1000. April 3, 2019 Response to TAR AP-V-M-42 Question 1 and comments After discussion with regional inspectors, NRO revised the response to: 40 NUREG-1793, “Final Safety Evaluation Report Related to Certification of the AP1000 Standard Plant Design Docket No. 52-006,” Supplement 2, p 3-150 (ML112061231). 41 ML032541010 42 Regulatory Guide 1.142, “Safety-Related Concrete Structures for Nuclear Power Plants (Other than Reactor Vessels and Containments,” Revision 2, November 2001. 43 NQA-2 is the predecessor of NQA-1, Part II.

NCP-2019-002

Attachment A

Page 13 of 32

QVIB staff agrees that if the licensee does not intend to implement portions of ASME NQA-1-1-94 Subpart 2.5, they must take an exception to their QAPD. The above response appears reasonable and consistent with the structure of the SNC NDQAM in which the commitments and exceptions to ASME NQA-1-1994 are documented. April 3, 2019 Response to TAR AP-V-M-42 Question 2 and comments After discussion with regional inspectors, NRO revised the response to: ASME NQA-1-94 Subpart 2.5 Paragraph 7.13 refers to “the requirements of para. 8.5” which states that “inspection shall include visual examination of preparations, welding processes . . . and if deemed necessary, some NDE inspections which are appropriate to the application.” However, based on the telephone conversation QVIB staff held with Region II staff during the week of March 19th, it appears the licensee made a determination for the welded reinforcing steel hoops that are used as part of the main steam line penetration through wall 11 that it was not necessary to perform NDE. Furthermore, QVIB staff consulted the Structural Engineering experts in NRO who informed us that the performance of additional NDE requirements of ASME BPVC Sec III.2 as stated by paragraph 7.13 are not applicable to the welded reinforcing steel hoops since it is not considered a structural item but rebar embedded in concrete. Consequently, it appears the licensee is in compliance with their licensing basis, as they are appropriately following the criteria in ASME NQA-1-1994, Subpart 2.5. This response focuses only on one requirement of Subpart 2.5, Paragraph 7.13. In doing so, it gives the misleading impression that the inspection of welded reinforcing splices only need to conform to the requirements of Subpart 2.5, Paragraph 8.5. The full wording of Subpart 2.5, Paragraph 7.13 is:

“Welded reinforcing bar splices shall be subject to the requirements of para. 8.5, except that the provisions of the ASME Boiler and Pressure Vessel Code, Section III, Division 2 (ACI Standard 359) shall also apply.”

Subpart 2.5, Paragraph 8.5 provides requirements for the inspection of structural steel welding.44 In the construction industry, welding of reinforcing bars and structural steel have typically been treated separately. Each has its own codes and standards and practices. Consistent with this differentiation, Subpart 2.5 distinguishes between the two. Inspection of welded reinforcing bar splices are addressed in Paragraph 7.13 and inspection of structural steel welding is addressed in Paragraph 8.5 of the standard. Yes, Paragraph 7.13 references Paragraph 8.5, as some of these measures are applicable to the inspection of welded reinforcing steel splices as well. The reference to Paragraph 8.5 in Subpart 2.5, Paragraph 7.13, however, should not be taken out of context or given exceptional status: reinforcing steel bars do not fall within the definition of structural steel, nor is the welding of reinforcing bar splices within the scope of AWS D1.1, the welding code which is referenced in Paragraph 8.5.45 44 Structural steel consists of elements of the structural frame that are shown and sized in the structural design drawings, essential to support of design loads. Explicitly excluded from this definition are concrete reinforcing steel bars. “Code of Standard Practice for Steel Building and Bridges,” American Institute of Steel Construction, April 14, 2010. 45 It is also important to recognize that in the nuclear industry, structural steel buildings typically are required to conform to ANSI/AISC N690, “American National Standard Specification for the Design, Fabrication, and Erection of

NCP-2019-002

Attachment A

Page 14 of 32

The position taken in the TAR response appears to be that the Subpart 2.5, Paragraph 7.13 requirement to comply with ASME Division 2 is made optional by the reference to Paragraph 8.5. It appears NRO staff draws this conclusion because the ASME Subpart 2.5 requirements for the inspection of structural steel welding provided in Subpart 2.5, Paragraph 8.5 do not reference destructive testing and leave it to the discretion of the Engineer to determine if NDE is necessary based on the application. There is little basis for this interpretation. It would subordinate the requirements specific to the inspection of welded reinforcing bar splices to those for structural steel welding. These are apples and oranges. Destructive testing is typically impractical and not used for the acceptance of structural steel welding. Also, for structural steel welding, the requirements for NDE other than visual are addressed in the steel design code. A more reasonable interpretation, in my view, would be that for the inspection of welded reinforcing bar splices, ASME Division 2 provides the specific inspection requirements that are appropriate to the application. Subpart 2.5, Paragraph 7.13 clearly states that the provisions of ASME Division 2 shall also apply for welded reinforcing bar splices. The ASME Division 2 provisions for the inspection of welded reinforcing bar splices are of at least equal standing to the requirements of Paragraph 8.5. Given that ASME Division 2 provides requirements specific to the inspection of welded reinforcing bar splices, which is the scope of Paragraph 7.13, it also seems reasonable to conclude that the provisions of ASME Division 2 would take precedence over the requirements of Paragraph 8.5 if there was a conflict. I do not believe that it is coincidence that the Standard Review Plan and Subpart 2.5 are in alignment that welded reinforcing bar splices should conform to ASME Division 2. The Subpart 2.5 provisions for the inspection of welded reinforcing bar splices originated in RG 1.94 to my knowledge. These provisions were subsequently incorporated into ASME N45.2.5, the predecessor of Subpart 2.5. The NRC appears to have been involved in this process.46 The provisions were also understood at the time to apply broadly to reinforced concrete structures of nuclear facilities not just concrete reactor vessels or containments.47 There appears to be difficulty with accepting that the provisions of ASME Division 2 could be used for concrete structures other than concrete reactor vessels or containments. However, NRO staff seems to hold the opinion that, for the inspection of welded reinforcing bar splices, the measures provided in Subpart 2.5 for the inspection of structural steel welding should take precedence over those specific to welded reinforcing bar splices. A concrete containment and a non-pressure retaining concrete structure may be different apples, but they’re still apples. Before the development of ASME Division 2, both were typically designed and constructed to the same codes. A reinforced concrete structure and a steel structure, on the other hand, are

Steel Safety-Related Structures for Nuclear Facilities.” This code requires NDE other than visual of partial and complete joint penetration welds. 46 Proposed Revision 2* to Regulatory Guide 1.94, ‘Quality Assurance Requirements for Installation, Inspection, and Testing of Structural Concrete, Structural Steel, Soils, and Foundations during the Construction Phase of Nuclear Power Plants’,” Division 1, Task RS 908-5, September 1979, Section 1.3.1, p 6. (ML12298A122) 47Letter from S.B. Jacobs, Chief Licensing Engineer, Stone & Webster Engineering Corporation, dated April 8, 1980, providing comments on draft on Proposed Revision 2 to Regulatory Guide (RG) 1.94 "Quality Assurance Requirements for Installation, Inspection, and Testing of Structural Concrete, Structural Steel, Soils and Foundations During the Construction Phase of Nuclear Power Plants,” September 1979, Section 2 and 3rd Paragraph of Section 7, p 2. (ML17192A356)

NCP-2019-002

Attachment A

Page 15 of 32

apples and oranges by comparison. A piece of reinforcing steel does not know or care what type of reinforced concrete structure it is used in. It’s still a piece of reinforcing steel and acts in a similar manner to resist design loads. Place that same piece of reinforcing steel in a steel structure, however, and it’s a fish out of water. More surprising is the statement that the welded reinforcing steel hoops are not structural items. This characterization does not appear to have any basis. Wall 11 at the location of the main steam lines is defined as a critical structural section in the AP1000 DCD and VEGP Unit 3 & 4 UFSAR.48 The WEC structural calculations for Wall 11 indicate that the welded steel hoops are required to resist design basis loads.49 April 6, 2019 Response to TAR AP-V-M-42 Question 1 and comments After more discussion between regional inspectors and staff, NRO revised the response to: If a licensee commits to Subpart 2.5 of the NQA-1 standard, then the licensee must meet all the requirements under that Subpart. However, for any Codes and Standards referenced within the Subpart that are not applicable to the scope of work, the licensee is not required to implement those referenced Codes and Standards. NRO staff communicated to regional inspectors that, in their opinion, ASME Division 2 is not applicable to construction of VEGP Units 3 & 4 because the scope of ASME Division 2 is limited to concrete reactor vessels or containments. The AP1000 plants have neither. The Subpart 2.5 requirements are associated with the construction activity, however, not the code of record. Subpart 2.5 Section 7 addresses the inspection of concrete construction. If a licensee is engaging in work activities that fall within the scope of this section than these requirements are relevant whether the code of record is ACI 318, ACI 349, or ASME Division 2. Subpart 2.5 does not assume that any particular code has been invoked. Subpart 2.5 Paragraph 2, “General Requirements” states:

The requirements of Subpart 2.5 apply to any organization or individual participating in work relating to production, preparation, placement, installation, inspection, and testing of structural concrete…”

Work performed under ACI 318, ACI 349, or Division 2 is classified as structural concrete. If Subpart 2.5 was not intended to supplement the requirements of the code of record, what use would it serve? Wouldn’t it be redundant and compliance with the code of record sufficient in itself? ASME Division 2 is referenced in Subpart 2.5 Paragraphs 7.11, 7.12, and 7.13. Assuming these paragraphs only apply to concrete reactor vessels and containments because they reference ASME Division 2 ignores the scope of NQA-1-94 Part II,50 the history and intent of

48 AP1000 DCD and VEGP Unit 3 UFSAR, Section 3.8.4.5.4 and 3H.5.1.4. 49 Westinghouse Electric Company Document No. APP-1200-S3C-101, “Auxiliary Building Wall 11 Reinforcement Design EL 117’-6” to EL 135’-3”,” Revision 0, p. 31. 50 “Quality assurance requirements for the planning and execution of identified tasks during fabrication, construction, modification, repair, maintenance, and testing of systems, components, and structures for nuclear

NCP-2019-002

Attachment A

Page 16 of 32

these provisions, established NRC guidance, and the common engineering practice of adapting provisions of a design code for use beyond their original intent. Moreover, this interpretation places unreasonable limitations on the applicability of Subpart 2.5 to an extent that would not make sense. Subpart 2.5 provides amplified requirements for the inspection of concrete construction. The requirements of Subpart 2.5 Paragraphs 7.11, 7.12, and 7.13 provide the backbone of an inspection program intended to verify that the construction meets specified requirements. Such a program is applicable to Seismic Category I concrete structures, in general, not just concrete reactor vessels or containments.

The use of ASME Division 2 for the inspection of welded reinforcing bar splices is consistent with NRC guidance provided in the Standard Review Plan (SRP).51 During design review of the AP1000, NRC staff clearly believed that some provisions of ASME Division 2 were applicable to other aspects of the AP1000 as well.

Concerning the proposed use of mechanical couplers in the AP1000 enhanced shield building, NRC staff stated:

“It is the opinion of RES staff that acceptance criteria for qualification and production testing of the mechanical couplers for the SC/RC connections of the AP1000 shield building should be that used for repair of existing RC shield buildings following steam generator replacement operations, which are the criteria in ASME Boiler and Pressure Vessel Code, Section III, Division 2, “Code for Concrete Containments”.52

If the licensee had proposed the use of welded reinforcing steel splices during the AP1000 design certification or VEGP Units 3 & 4 COL licensing processes, it is likely that the NRC would have required compliance with ASME Division 2 for production testing of welded reinforcing bar splices as was done for mechanical connections. Regardless, SNC committed to these measures by invoking Subpart 2.5 without exception in the SNC NDQAM.

April 6, 2019 Response to TAR AP-V-M-42 Question 2 and comments

After more discussion between regional inspectors and staff, NRO revised the response to:

The auxiliary building is built to ACI 349 standards, and therefore welds only need to conform to AWS welding requirements and are excluded from meeting ASME BPV Section III, Division II requirements, as supported by the following:

• The Vogtle Auxiliary Building is designed to ACI 349-01, which states“Specifically excluded from this Code are those structures covered by “Code forConcrete Reactor Vessels and Containments,” ASME Boiler and PressureVessel Code Section III, Division 2, and pertinent General Requirements (ACIStandard 359).”

facilities are contained in Part II,” ASME NQA-1-1994, “Quality Assurance Requirements for Nuclear Facility Applications,” Forward, p iv. 51 NUREG-0800 52 Summary Evaluation Report, Enhanced Shield Building Structure, Westinghouse Electric Company Report APP-1200-S3R-003. Revision 2 AP1000 Design Control Document, Revision 17, U.S. NRC, Office of Nuclear Regulatory Research, October 29th, 2010, pp 42 (ML103080129).

NCP-2019-002

Attachment A

Page 17 of 32

• Concerning welding, ACI -349, paragraph 12.14.3.2 states that “Except as provided in this code, all welding shall conform to “Structural Welding Code—Reinforcing Steel” (ANSI/AWS D1.4)”

The supporting information provided in the response is taken directly from ACI 349-01. This information does not address NRC guidance on the welded reinforcing bar splices, or the requirement for construction work activities to be conducted under a quality assurance plan meeting Appendix B. In this response, NRO staff appears to confuse conformance with a design and construction code and implementation of appropriate quality measures to verify that construction meets specified requirements. The URI is not associated with meeting ACI 349-01 performance or AWS D1.4-98 welding requirements for welded reinforcing bar splices. It is not a question that the welded splices need to meet the requirements of ACI 349-01 and AWS D1.4-98, or whether these requirements are adequate from a performance standpoint. The URI is associated with the appropriate quality assurance measures that are necessary to verify that the requirements of ACI 349-01 and AWS D1.4-98 are being met. These quality assurance measures are not adequately addressed in ACI 349-01 or AWS D1.4-98, but in Subpart 2.5. The response does not appear to recognize the relationship between ACI 349-01 and Subpart 2.5 and seems to be predicated on a belief that ACI 349-01 provides adequate quality assurance measures for the inspection of concrete construction. This view is inconsistent with the guidance provided in RG 1.142. Reliance on measures solely provided in ACI 349-01 and/or AWS D1.4-98 is inadequate to meet Appendix B. ACI 349-01 and AWS D1.4-98 must be used in conjunction with a quality assurance plan meeting Appendix B. The use of Subpart 2.5 and the standards it references for the inspection of concrete structures is fully consistent and compatible with ACI 349-01 and AWS D1.4. The Subpart 2.5 measures do not replace or alter any provisions of ACI 349-01 and AWS D1.4. Failure to enforce the Subpart 2.5 requirements as committed to in the SNC NDQAM will result in an inspection program for Seismic Category I concrete structures that is not consistent with the requirements of Appendix B. TAR AP-V-M-4553 This TAR was submitted to seek more clarity and justification for the NRO positions on the use of welded reinforcing bar splices in VEGP Units 3 & 4. One question was asked in TAR AP-V-M-45: Is the licensee subject to the requirements of the ASME BPV Code, Section III, Division 2 via NQA-1-1994 Subpart 2.5. for all safety related welded reinforcing bar splices (regardless whether they are located in concrete containments or not)? Please provide a response with technical justification. Response to TAR AP-V-M-45 and comments: The licensee is not subject to the requirements of the ASME B&PV Code, Section III, Division 2 via NQA-1-1994, Subpart 2.5 for all safety related welded reinforcing bar splices. The NRC staff determined that the licensee is committed to Subpart 2.5, “Quality Assurance Requirements for Installation, Inspection, and Testing of Structural Concrete, Structural Steel, Soils, and Foundations for Nuclear Facilities,” of the NQA-1-1994 ASME quality assurance 53 ML19016A408

NCP-2019-002

Attachment A

Page 18 of 32

standard as a method of meeting Appendix B to 10 CFR Part 50. Subsection 4.0 of Section 10 of Rev. 19 of the NDQAM states that, “SNC commits to compliance with the requirements of Subparts 2.5 and 2.8 for establishing appropriate inspection requirements.” Subpart 2.5 of NQA-1-1994, states that it provides amplified requirements for installation, inspection, and testing of structural steel, soils, and foundations. It supplements the requirements of Part I and shall be used to the extent specified by the organization invoking the Subpart. Therefore, the licensee would specify the extent of the subpart’s applicability. Additionally, the licensee’s commitment encompasses Basic Requirement 10, and Supplement 10S-1 of NQA-1. Basic Requirement 10 states that “Characteristics to be inspected and inspection methods to be employed shall be specified.” Supplement 10S-1, Section 2, states, “Inspection requirements and acceptance criteria shall include specified requirements contained in the applicable design documents approved by the responsible design organization.” Subsection 2.0 of Section 10 of the NDQAM describes the Inspection Program at Units 3 and 4. It requires the establishment of inspections necessary to verify quality, such as for the final acceptance of fabricated and/or installed items during construction. Furthermore, Section 8.5 “Welding,” of Subpart 2.5 states that: “Inspection of structural steel welding shall be performed in accordance with the provisions of Section 6.0 of AWS DI .I, Structural Welding Code - Steel. This inspection shall include visual examination of preparations, welding processes, post-welding operations, and if deemed necessary, some NDE inspections which are appropriate to the application [emphasis added.]” As provided in the discussion above, SNC should be able to provide a documented basis for the inspection requirements deemed necessary for the welded splices application. In this response, NRO staff acknowledges that SNC committed to Subpart 2.5 in the SNC NDQAM, however, they appear to view this as a “soft” commitment. As such, SNC may use discretion in implementing these requirements. My opinion as stated previously is that an exception should be taken in the SNC NDQAM to Subpart 2.5 Paragraph 7.13 if these measures are not going to be implemented for construction of VEGP Units 3 & 4. Please refer to comments on April 3, 2019 Response to TAR AP-V-M-42 Question 2 for discussion of reference to Subpart 2.5 Paragraph 8.5 in Subpart 2.5 Paragraph 7.13. Additional Comments on TAR Responses In discussions with regional inspectors and documented in the notes in the TAR database for TAR AP-M-V-42, NRO staff stated that they consulted with ASME committee members about the applicability of Subpart 2.5 Paragraph 7.13 in developing the TAR responses. While I respect the opinion of the ASME committee members and do not take issue with reaching out to others to inform a response, it is hard to assign much weight to these discussions as I did not participate in them, do not know who was involved, and there is no record of what was discussed. The NRC was involved in the development of Subpart 2.5 and was responsible for approval of the AP1000 DCD and VEGP Units 3 & 4 COLs. The Subpart 2.5 Paragraph 7.13 requirements for welded splices were originally provided as guidance in RG 1.94. It is surprising that the NRC apparently has lost track of the intent of these requirements which correspond to the guidance provided in the SRP. The NRC is empowered to enforce the requirements of the VEGP Units 3 & 4 COLs and should not rely on informal off the record discussions with ASME committee members to make regulatory decisions. Hopefully, this is not

NCP-2019-002

Attachment A

Page 19 of 32

the case. If much stock was placed in these discussions, then they should have been conducted in a public meeting with the participation of all interested parties. Moreover, the NRC is not bound to accept the opinions of ASME committee members or ASME code cases or interpretations. These should be evaluated using the appropriate regulatory decision-making process on a case by case basis before they are accepted for use.

Follow-up Inspection to Close URI

As documented in the inspection report, a follow-up inspection was conducted to close the URI during the 1st quarter of 2019. The focus of this inspection was on the types of reinforcing steel splices allowed by VEGP Unit 3 & 4 UFSAR Section 3.8.4.6.1.2 and the quality assurance measures being implemented for acceptance of welded reinforcing steel splices.

For this inspection, SNC provided a “white paper”54 asserting that welded reinforcing bar splices were a form of mechanical connection and therefore allowed by the VEGP Units 3 & 4 UFSAR. SNC also took the position in this “white paper” that quality assurance measures being implemented for acceptance of welded reinforcing bar splices were adequate.

The regional inspectors reviewed the SNC “white paper” and did not find the arguments in it convincing. It is true that the purpose of a mechanical or welded reinforcing bar splice is the same and they share similar performance requirements. The design function does not differ between a lap splice, mechanical connection, or welded splice. However, each form of splice has a different means of transferring forces between bars and, historically, each type of splice has been treated separately with its’ own unique requirements. As a result, the inspectors concluded that the use of welded reinforcing bar splices was not in conformance with the VEGP Unit 3 & 4 UFSAR. The significance of this finding was determined to be minor based on the TAR responses. I do not agree with this determination.

For the reasons discussed in this nonconcurrence, the inspectors questioned the conclusion of the SNC “white paper” that the quality assurance measures being implemented at VEGP Units 3 & 4 for the acceptance of welded reinforcing bar splices are adequate. Clearly, in my opinion they are not. Given the TAR responses, however, the inspectors saw no means of compelling SNC to provide more substantial justification for the installed splices.

Supporting Information/Other Considerations

NRC Endorsement of ACI 349-97 and Guidance on the Use of Welded Reinforcing Bar Splices

The NRC endorsed the use of ACI 349-07 in Regulatory Guide (RG) 1.142, “Safety-Related Concrete Structures for Nuclear Power Plants (Other than Reactor Vessels and Containments),” Revision 2.55 The scope of this regulatory guide does not include concrete reactor vessels or containments. These are addressed in another RG.56

54 “ACI 349 AWS D1.4 Basis NDE Welded Rebar,” SNC White Paper on Equivalency of Welded Reinforcing Bar Splices with Mechanical Splices 55 ML013100274 56 Regulatory Guide 1.136, “Design Limits, Loading Combinations, Materials, Construction, and Testing of Concrete Containments, “ Revision 3, March 2007 (ML070310045)

NCP-2019-002

Attachment A

Page 20 of 32

NRC guidance on the use of welded reinforcing bar splices is that the splices should meet the requirements of ASME Division 2.57 This guidance is provided in Section 3.8 of the SRP and is for all areas inside and outside of containment, regardless of specific reactor type.58 SRP Section 3.8.4.I.6.B is applicable to the VEGP Units 3 & 4 auxiliary buildings: This section states:

“If welding of reinforcing bars is proposed, it should comply with American Society of Mechanical Engineers (ASME), Boiler and Pressure Vessel Code (Code) Section III, Division 2. Any exception to compliance should be supported with adequate justification.”59

Similar requirements are included in the Design-Specific Review Standard for the mPower iPWR Design.60 Concerning these requirements, NRC staff provided the following comment:

“[ASME Division 2, Article] CC-4334 refers to the Mandatory Appendix XI for qualification requirements for arc welding procedures, welders, and welding operators used to arc weld reinforcing bars. These qualification requirements are not in ACI 349, and further ACI 349-2001 is not currently endorsed in RG 1.142. The intent of the referenced provision in the DSRS is that when rebar is spliced by welding for nuclear safety-related applications, the qualification and other requirements for arc welding in ASME Section III, Division 2 should be met.”61

ASME Division 2 and AWS D1.4 have a lot of commonality. As a result, the NRC guidance for welded reinforcing bar splices can largely be satisfied for direct butt splices by either specifying compliance with ASME Division 2 or AWS D1.4, provided Subpart 2.5 is also invoked for the inspection of welded reinforcing bar splices. Either approach is the same for all intents and purposes. Hopefully, some of the discussion that follows will make this clear. The NRC guidance on the use of welded reinforcing bar splices was formerly provided in RG 1.94.62 It is also reflected in the endorsement of ASME NQA-263 in RG 1.142 as a means of addressing shortcomings in ACI 349-97 and satisfying 10 CFR Part 50, Appendix B64 (Appendix B) for safety-related reinforced concrete structures designed and constructed in accordance

57 ANSI/ASME, “Code for Concrete Reactor Vessels and Containments,” Boiler and Pressure Vessel Code, Section III, Division 2. 58 Standard Review Plan for the Review of Safety Analysis Reports for Nuclear Power Plants: LWR Edition — Design of Structures, Components, Equipment, and Systems (NUREG-0800, Chapter 3) 59 NUREG-0800 - Chapter 3, Section 3.8.4, Revision 2, Other Seismic Category I Structures, dated March 2007 p 3.8.4-6 (ML070550054) 603.8.4 Other Seismic Category I Structures, Design-Specific Review Standard for mPower iPWR Design, Revision 0, May 2013, p 3.8.4-6 (ML13099A316) 61Public Comments on mPower Design Specific Review Standard (DSRS) Section 3.8.3, “Concrete and Steel Internal Structures of Steel or Concrete Containments,” Comment 11, Page 6, September 12, 2013 (ML14050A273). 62 Regulatory Guide 1.94, “Quality Assurance Requirements for Installation, Inspection, and Testing of Structural Concrete and Structural Steel during the Construction Phase of Nuclear Power Plants,” Revision 1. This regulatory guide endorsed ASME N45.2.5-1974. RG 1.94 was withdrawn in September 2010 after ASME N45.2.5 was replaced by Subpart 2.5 which incorporated NRC guidance on use of welded reinforcing bar splices. 63 ANSI/ASME, “Quality Assurance Requirements for Nuclear Facility Applications,” NQA-2, 1983 64 “Quality Assurance Criteria for Nuclear Power Plants and Fuel Processing Plants,” Appendix B to 10 CFR Part 50.

NCP-2019-002

Attachment A

Page 21 of 32

with ACI 349-97.65 Specifically, the following guidance is provided in RG 1.142 concerning the use of ACI 349-07 and other related standards:

“The ACI 349-97 commentary recommends the use of various ANSI standards for developing quality assurance programs related to the design and construction of safety-related concrete structures. Quality assurance programs developed in accordance with the applicable portions of these ANSI standards and the regulatory guides that endorse them provide an acceptable means of complying with the requirements of Appendix B, "Quality Assurance Criteria for Nuclear Power Plants and Fuel Reprocessing Plants," to 10 CFR Part 50. ASME NQA-2-1983 provides standards, such as those for in-process testing of concrete, concrete materials, and reinforcing bar splices and for repairs and inspection of concrete construction, that are not adequately included in ACI 349-97. Hence, ASME NQA-2-1983 provides supplementary provisions for the construction of safety-related concrete structures.”

Supplementing ACI 349-01 with ASME Subpart 2.5 is necessary because ACI 349-01 has minimal requirements for the inspection of concrete construction. ACI Section 1.3.1 states:

“The Owner is responsible for the inspection of concrete construction throughout all work stages. The Owner shall require compliance with design drawings and specifications. The Owner shall also keep records required for quality assurance and traceability of construction, fabrication, material procurement, manufacture, or installation.”

ACI 349-01 is to be used in conjunction with a quality assurance program meeting Appendix B. ACI 349-01 Section 1.5, “Quality Assurance Program” states:

“A quality assurance program covering nuclear safety related structures shall be developed prior to starting any work. The general requirements and guidelines for establishing and executing the quality assurance program during the design and construction phases of nuclear power generating stations are established by Title 10 of the Code of Federal Regulations, Part 50 (10CFR50), Appendix B.”

Moreover, the commentary to this section explicitly references ASME NQA-1 and NQA-2 as being applicable to this quality assurance plan:

“Title 10 CFR 50, Appendix B, requires that the Owner have a quality assurance program approved by the Regulatory Authority and states that the Owner is responsible for the establishment and execution of programs developed by his engineers, construction contractors, and suppliers. More detailed requirements for development and implementation of a quality assurance program are contained in ANSI/ASME NQA-1 and ANSI/ASME NQA-2.”66

65 NQA-2 and ACI 349-97 are the predecessors of NQA-1, Part II and ACI 349-01, respectively. The differences between the different versions of each standard are minimal as they relate to welded reinforcing bar splices: The provisions for welded reinforcing bar splices in NQA-1-1994 are equivalent to those in NQA-2-1983. Likewise, the provisions in ACI 349-01 for welded reinforcing bar splices do not differ materially from those in ACI 349-97. 66 Theses references are to NQA-1-1989 and NQA-2-1989, respectively. NQA-2-1989 Subpart 2.5 Section 8.13 is the same as ASME NQA-1 Part II Subpart 2.5, Section 7.13. Additionally, 10 CFR Part 50 Appendix B is adopted by reference is ACI 349-01 Section 3.8.3.

NCP-2019-002

Attachment A

Page 22 of 32

Given the lack of detail provided in ACI 349-01, it is reasonable to assume that the quality assurance program would make use of standards that are not directly referenced in ACI 349-01. AP1000 and VEGP Units 3 & 4 Compliance with Standard Review Plan (NUREG-0800) Compliance with the acceptance criteria of the Standard Review Plan (NUREG-0800) is addressed in Section 1.9.2 of the AP1000 DCD and VEGP Unit 3 & 4 UFSAR. This information was required to be provided by NRC regulations, specifically 10 CFR 57.79(a)(4) to my knowledge. WEC furnished WCAP-15799, “AP1000 Conformance with SRP Acceptance Criteria,” with this information. This document was also referenced in the VEGP Units 3 & 4 COLs. In this document, it is stated that construction of the AP1000 will comply with Subpart 2.5 and no exception is taken to the NRC acceptance criteria for welded reinforcing splices given in SRP Section 3.8.4.I.6.B.67 ASME NQA-1-1994, Part II, Subpart 2.5 (Subpart 2.5)68 and ASME Division 2 Significant portions of the VEGP Unit 3 & 4 containment internal structures (CIS), shield buildings, and auxiliary buildings are constructed of reinforced concrete. Subpart 2.5, Section 7 provides requirements for the Inspection of concrete construction. As a result, the requirements of Subpart 2.5, Section 7, except for those associated with pre-stressed concrete,69 are relevant to work being performed at VEGP Units 3 & 4. Subpart 2.5, paragraphs 7.11, 7.12, and 7.13 are associated with the in-process tests of concrete and reinforcing steel, mechanical splice testing, and welded reinforcing bar splices, respectively. These paragraphs are central to the requirements provided in Subpart 2.5 for the inspection of concrete construction and form the framework of an inspection program intended to verify the material and construction meet specified requirements. They rely heavily on provisions of ASME Division 2 to specify the types of inspections and tests that are required and the frequency of performing these inspections and tests. As a result, they reference ASME Division 2 for convenience. Apparently, these references have caused confusion because ASME Division 2 was originally developed for the design and construction of concrete reactor vessels and containments. The specific sections of ASME Division 2 referenced in Subpart 2.5, however, can be leveraged for use in other types of structures because they are general provisions: they are not associated with any features that are unique to concrete reactor vessels or containments; nor are they dependent on the analysis or design methodology adopted by a specific design code. The Division 2 provisions referenced in Subpart 2.5 are relevant for the inspection of structural concrete, in general, regardless of the type of structure and have general adaptability for use with other codes and standards.70 67 WCAP-15799, “AP1000 Conformance with SRP Acceptance Criteria,” dated August 2003, Revision 1, September 9, 2003, p 3-22 and 3-27, respectively 68 ASME NQA-1-1994, Part II, Subpart 2.5, “Quality Assurance Requirements for Installation, Inspection, and Testing of Structural Concrete, Structural Steel, Soils, and Foundations for Nuclear Power Plants” 69 VEGP Units 3 & 4 Nuclear Island structures do not make use of prestressed concrete. As result, ASME NQA-1-1994, Part II, Subpart 2.5, Paragraphs 7.8 and 7.9 are not applicable. 70 These provisions rely on conformance with ASTM Standards that apply to all types of facilities, or splicing systems or methods that have general use as well.

NCP-2019-002