NASA Test and Evaluation Master Plan

-

Upload

nugroho-aditya -

Category

Documents

-

view

2.115 -

download

22

description

Transcript of NASA Test and Evaluation Master Plan

SDM 5004 System Engineering and Project Management

Multi-satellite Operations Control Center (MSOCC)

Communications Switching System (MCSS)

Test and Evaluation Master Plan (TEMP)

Revision 01

(SDM5004-TEMP-MSOCC-0000)

May 2011

Division of Engineering & Technology Management (D-ETM)

National University of Singapore

Faculty of Engineering

Block EA, #05-34 (Building EA, Level 5, Room 34)

9 Engineering Drive 1

Singapore 117576

ii

SDM5004-TEMP-MSOCC-0000 REV 01

WBS: 00

SDM 5004 System Engineering and Project Management

MULTI-SATELLITE OPERATIONS CONTROL CENTER (MSOCC)

COMMUNICATIONS SWITCHING SYSTEM (MCSS)

TEST AND EVALUATION MASTER PLAN (TEMP)

Revision 01

May 2011

Submitted by:

02 May 2011 A0000660B

Aditya Nugroho

Project Manager

Date Matriculation Number

Approved by:

May 2011

Dr. Joseph E. Kasser

Director Operational Test

and Evaluation

Date

iii

RECORD OF CHANGES

*A - ADDED M - MODIFIED D – DELETED

VERSION

NUMBER DATE

NUMBER OF

FIGURE, TABLE

OR

PARAGRAPH

A*

M

D

TITLE OR BRIEF

DESCRIPTION AUTHOR

00 18.04.2011 TEMP Paragraph M

D

Knowledge component in the

TEMP shall appear in the

footnotes.

Dr. Joseph E.

Kasser

iv

REQUIREMENT TRACEABILITY MATRIX

ID SUMMARY OF REQUIREMENT TYPE SECTION

01 An introduction to Project Management and

Systems Engineering Written Section 4 Page 17

02 Modern project management Written Section 4 Page 17

03 Project Selection and Strategy Written Section 3 Page 11

04 Project Organisation Written Section 3 Page 8

05 Project Planning Written Section 4 Page 17

06 Scheduling Written Section 4 Page 20

07 Cost Estimating Written Section 4 Page 30

09 Performance Monitoring Written Section 4 Page 35

10 Project Leadership Written Section 3 Page 11

11 Project Teams Written Section 3 Page 12

Section 4 Page 39

12 Constraint Management Written Section 4 Page 40

14 Project Audit and Closeout Written Section 4 Page 43

Lessons Learned Written Section 5 Page 46

Footnotes the knowledge component Written Appropriate Section

v

Table of Contents

RECORD OF CHANGES ............................................................................................................. III

REQUIREMENT TRACEABILITY MATRIX ........................................................................... IV

1. INTRODUCTION ................................................................................................................. 1

1.1 Purpose ............................................................................................................................. 1

1.2 Scope ................................................................................................................................ 1

1.3 Assumptions ..................................................................................................................... 1

1.4 References ........................................................................................................................ 2

1.5 Definitions ........................................................................................................................ 3

2. DESCRIPTION ..................................................................................................................... 4

2.1 MCSS Mission Description .............................................................................................. 4

2.2 MCSS System Description ............................................................................................... 4

3. PROGRAM SUMMARY ..................................................................................................... 6

3.1 Test and Evaluation Objectives ........................................................................................ 6

3.2 Test and Evaluation Methodology ................................................................................... 7

3.3 Management Organization and Responsibilities .............................................................. 8

3.3.1 External Interfaces ..................................................................................................... 8

3.3.2 Internal Interfaces ...................................................................................................... 9

3.3.3 Project Team Roles and Responsibilities ................................................................ 11

3.3.4 Documentation ........................................................................................................ 13

3.4 Resources Summary ....................................................................................................... 14

3.4.1 Integrated Test Master Schedule and Budget Summary ......................................... 14

3.4.2 Staff Resource Summary ......................................................................................... 15

3.5 Test Location and Equipment ........................................................................................ 16

4. TEST AND EVALUATION PROCESS PLAN ................................................................ 17

4.1 Work Planning ................................................................................................................ 17

4.1.1 Test and Evaluation Work Breakdown Structure (WBS) ....................................... 17

4.1.2 T&E Schedule Allocation Plan ............................................................................... 20

4.1.3 T&E Staff Resources Allocation Plan ..................................................................... 27

4.1.4 Budget Allocation Plan ........................................................................................... 30

4.2 Test and Evaluation Control Plan ................................................................................... 35

4.2.1 Budget and Schedule Control .................................................................................. 36

4.2.2 Quality Control ........................................................................................................ 37

4.2.3 Reporting and Communication ............................................................................... 39

4.3 Risk Management Plan ................................................................................................... 40

4.3.1 Risk Identification ................................................................................................... 40

4.3.2 Risk Mitigation ........................................................................................................ 40

4.4 Project Closeout Plan ..................................................................................................... 43

4.4.1 Post Performance Analysis ...................................................................................... 43

4.4.2 Project Closeout Schedule Allocation ..................................................................... 43

4.4.3 Project Closeout Critical Path ................................................................................. 43

4.4.4 Project Closeout Resource Allocation ..................................................................... 44

4.4.5 Project Closeout Budget Allocation ........................................................................ 45

vi

5. LESSON LEARNED ........................................................................................................... 46

6. BIBLIOGRAPHY ............................................................................................................... 48

7. APPENDIX 1. WORK PACKAGES DESCRIPTION .................................................... 50

APPENDIX A: PRELIMINARY DESIGN (SRR-PDR) .............................................................. 50

APPENDIX B: DETAILED DESIGN (PDR-IRR) ...................................................................... 60

APPENDIX C: DEVELOPMENT AND INTEGRATION (IRR-TRR) ....................................... 71

APPENDIX D: QUALIFICATION AND INSTALLATION (TRR-DRR) ................................. 82

APPENDIX E: PROJECT CLOSEOUT ....................................................................................... 92

8. APPENDIX 2. RISKS FACTORS CATEGORIZATION............................................... 98

vii

List of Tables and Figures

Table 1. 1 T&E Assumptions .......................................................................................................... 1

Table 1. 2 Document Reference ...................................................................................................... 2

Table 3. 1 Requirements Verification Matrix ................................................................................. 6

Table 3. 2 T&E Document Deliverables ......................................................................................... 7

Table 3. 3 Roles and Responsibilities of organization team for T&E activities ........................... 12

Table 3. 4 Basic rate of project team cost ..................................................................................... 13

Table 3. 5 T&E Documentation .................................................................................................... 13

Table 3. 6 Total budget allocations ............................................................................................... 14

Table 3. 7 Staff allocations per development phase ...................................................................... 15

Table 4. 1 WBS Dictionary of T&E activities .............................................................................. 19

Table 4. 2 Budget allocation Preliminary Design Phase ............................................................... 31

Table 4. 3 Budget allocation Detailed Design Phase .................................................................... 32

Table 4. 4 Budget allocation Detailed Design Phase .................................................................... 33

Table 4. 5 Budget allocation Qualification and Installation Phase ............................................... 34

Table 4. 6 T&E Management Control System .............................................................................. 36

Table 4. 7 Sub lower level work packages budget and schedule control ...................................... 37

Table 4. 8 Work packages depict the quality control process ....................................................... 38

Table 4. 9 Communication matrix ................................................................................................. 39

Table 4. 10 Work packages of risk management plan .................................................................. 40

Table 4. 11 SRR-PDR Initial Risk Identification and Mitigation ................................................. 41

Table 4. 12 PDR-IRR Initial Risk Identification and Mitigation .................................................. 41

Table 4. 13 IRR-TRR Initial Risk Identification and Mitigation .................................................. 42

Table 4. 14 TRR-DRR Initial Risk Identification and Mitigation ................................................ 42

Table 4. 15 Budget allocation Project Closeout Phase .................................................................. 45

Figure 2. 1 Switch configuration ..................................................................................................... 4

Figure 3. 1 MCSS T&E Vee Model ................................................................................................ 8

Figure 3. 2 MCSSRP External Interfaces ........................................................................................ 9

Figure 3. 3 MCSSRP Matrix Organization Structure ................................................................... 10

Figure 3. 4 MCSSRP Organization Structure ............................................................................... 10

Figure 3. 5 Integrated T&E Master Schedule ............................................................................... 14

Figure 3. 6 Summary T&E Manpower Cost ................................................................................. 15

Figure 4. 1 Work Breakdown Structure for T&E activities .......................................................... 18 Figure 4. 2 Preliminary Design T&E schedule ............................................................................. 20 Figure 4. 3 Detailed Design T&E schedule ................................................................................... 21 Figure 4. 4 Development and Integration T&E schedule .............................................................. 21 Figure 4. 5 Qualification and Installation T&E schedule .............................................................. 22 Figure 4. 6 PERT-CPM Preliminary Design. ................................................................................ 23 Figure 4. 7 PERT-CPM Detailed Design ...................................................................................... 24 Figure 4. 8 PERT-CPM Development and Integration ................................................................. 25

viii

Figure 4. 9 PERT-CPM Qualification and Installation ................................................................. 26 Figure 4. 10 Resource allocation Preliminary Design Phase ........................................................ 27 Figure 4. 11 Resource allocation Detailed Design Phase .............................................................. 28 Figure 4. 12 Resource allocation Development and Integration Phase ......................................... 29 Figure 4. 13 Resource allocation Qualification and Installation Phase ......................................... 30 Figure 4. 14 Budget accumulative Preliminary Design Phase ...................................................... 32 Figure 4. 15 Budget accumulative Detailed Design Phase ........................................................... 33 Figure 4. 16 Budget accumulative Development and Integration Phase ...................................... 34 Figure 4. 17 Budget accumulative Qualification and Installation Phase ...................................... 35 Figure 4. 18 Project closeout schedule .......................................................................................... 43 Figure 4. 19 PERT-CPM Project Closeout Phase ......................................................................... 44 Figure 4. 20 Resource allocation of Project Closeout Phase ......................................................... 44 Figure 4. 21 Budget accumulative Project Closeout Phase ........................................................... 45

1

1. INTRODUCTION

1.1 Purpose

Test and Evaluation Master Plan (TEMP) describes the program Test and Evaluation (T&E)

objectives, requirements, general methodology (test flow and description of each T&E phase),

responsibilities, and scheduling of test phases for the the Multi Satellite Operations Control

Center (MSOCC) Communications Switching System (MCSS) switch upgrade. This TEMP is

a program-level management planning document for all MCSS T&E activities and as a guide

for developing T&E plans. In the MCSS Systems Engineering Management Plan (SEMP) that

is described the TEMP is subordinate to the program SEMP1.

1.2 Scope

The process described in this TEMP applies to engineering activities associated with the

design, development, and operation of the MCSS over the life cycle of the program. These

activities include the testing of manufactured items. Activities related to items on the T&E

activities will comply with requirements specified in the MCSS System Requirements

Document (SRD) Section 5. Test and evaluation plans which specify actions to be taken in

implementing test and evaluation at the project level, will be prepared by project manager.

1.3 Assumptions

This section lists assumptions that are specific to the test planning.

Table 1. 1 T&E Assumptions

Assumptions ID Description

T&E

Budgeting

BA.01

BA.02

• The project manager will be responsible for reviewing all

cost/budget changes for this project.

• Sufficient capital will be available to fund the MCSSRP.

1 Test and evaluation is an integral part of the systems engineering process. Key aspects of the systems

engineering process, more fully described in the SEMP, are discussed in this TEMP to illustrate how T&E

supports the overall systems engineering process. Bell, David.W and Brown, David.C. Systems Engineering and

Test and Evaluation—The Integrated Process. ITEA Journal 2010; 31: 57–62

2

T&E

Schedule

TA.01

TA.02

TA.03

• The critical path method (CPM) schedule and milestone list that

details the timeframes and deadlines for the completion of T&E

activities are given based on fixed time estimation.

• No resource limitations for T&E (i.e, resource personnel) and all the

resources currently available for this project.

• The project will be conducted with resources from a matrixed

organization structure.

T&E Staff SA.01

SA.02

• Personnel will be properly trained on the tools and techniques

needed to support this effort.

• Upon completion of each T&E activities in project phase, staff will

transition to the next phase of the project, return to their previous

work on a full time basis.

Testing QA.01

QA.02

• Testing environments will be stable during execute the system test

• Users will commit adequate resources to User Acceptance Testing

1.4 References

This section lists all the documents referenced in the TEMP.

Table 1. 2 Document Reference

Doc

No Document Name

1

An Enhanced Framework for the Management of Information Technology Projects, PPTO-

TM-002 Project Plan Template, Chief Information Officer Branch, Treasury Board of

Canada Secretariat January 2000.

2 MSOCC MCSS Systems Engineering Management Plan (SEMP). Presented in Session 8.

3 Defence Acquisition University Press. Test and Evaluation Management Guide 5th Edition.

FORT BELVOIR, VA, January 2005.

4 NASA/GSFC, Multi-Satellite Operations Control Center (MSOCC) Communications

Switching System (MCSS) System Requirements Document, 511-4SRD/0489.

5 Processes for Engineering a System, Electronic Industries Alliance (EIA) Standard 632,

ANSI/EIA-632-1998.

6

Systems Engineering – System Life Cycle Processes, International Organization for

Standardization (ISO)/International Electrotechnical Commission (IEC) 15288, ISO/IEC

15288:2002

3

1.5 Definitions

This section contains definitions for any specific terminology or acronyms used in this plan.

ACRONYM DESCRIPTION

CI Configuration Item

COTS Commercially available Off-The-Shelf

DOD Department of Defense

DRR Delivery Readiness Review

GSFC Goddard Space Flight Center

IRR Implementation Readiness Review

ISO International Organization for Standardization

MCSS MSOCC Communications Switching System

MCSSRP MCSS Replacement Project

MSOCC Multi Satellite Operations Control Center

NASCOM NASA Communications Network

NASA National Aeronautics and Space Administration

PDR Preliminary Design Review

PM Project Manager

QA Quality Assurance

RAM Reliability, Availability and Maintainability

SEMP System Engineering Management Plan

SOW Statement Of Work

SRD System Requirement Document

SRR System Requirement Review

T&E Test and Evaluation

TEMP Test and Evaluation Master Plan

TRR Test Readiness Review

V&V Verification and Validation

4

2. DESCRIPTION

2.1 MCSS Mission Description

The MSOCC uses a switching system to route special synchronous RS-422-A type digital

data within the MSOCC and between the National Aeronautics and Space Administration

(NASA) Communications Network (Nascom) and the computer equipment within MSOCC.

The mission is to replace the data switch that routed signals from multiple low earth orbit

(LEO) satellites to data processing computers without loss of LEO satellite scientific data2.

2.2 MCSS System Description

The need were recognized for a single switch to replace the three existing switches with at

least twice the capability of the three switches combined. The switch will be controlled by the

DOCS, will handle data at rates of up to 6.312 Mbps, and will have a capacity of 255 full-

duplex connections (see Figure 2.1). The new switch system will henceforth be referred to as

MCSS. The MCSS function requirements are grouped into 4 subsystems which are:

1) Switch Matrix

2) Switch Control

3) Timing Generator and

4) Test And Monitoring.

Figure 2. 1 Switch configuration

2 Kasser, J. E. and Mirchandani, C. J., ―The MSOCC Data Switch Replacement: A Case Study in Elicitating and

Elucidating Requirements‖, proceedings of the 15th International Symposium of the International Council on

Systems Engineering (INCOSE), Rochester, NY, 2005. Page 2-3

Replace

5

From the result of the preliminary discussions with potential switch vendors have shown that

many of the MCSS requirements can be met by COTS switch available in the market. The

requirements not met by the purchase would be taken care of by inhouse development.

Therefore, the decision is to purchase a standard industry switch which will be modified to

meet the design requirements. The Timing Generator subsystem and Test and Monitoring

subsystem will be developed in-house.

6

3. PROGRAM SUMMARY

3.1 Test and Evaluation Objectives

Test and evaluation is an integral part of the systems engineering process that is used to attain

system objectives. T&E objectives have been derived to support the systems engineering

process. Two general objectives of the T&E program for MCSS are:

(1) to support system design and development, and

(2) to verify compliance with requirements3.

To ensure conformance with requirements contained in the System Requirements Documents

(SRD), following Table 3.1 described the example of Requirements Verification Matrix for

each subsystems to be performed during test execution.

Table 3. 1 Requirements Verification Matrix

Req No Description Priority WBS

Reference

5.2 SWITCH MATRIX

5.2.1 The MCSS shall contain 255 ports

High Q101, Q201 5.2.2 The MCSS shall switch binary digital signals

5.2.3 The MCSS shall switch serial signals

5.2.4 This subsystem shall switch Data and Timing as signal pairs

5.3 SWITCH CONTROL

5.3.1 This subsystem shall be the MCSS operator’s control interface

High Q301

5.3.2 This subsystem shall require the use of passwords to control, assign or

modify switch connections.

5.3.3 This subsystem shall perform a self test on the MCSS upon power up

5.3.4 This subsystem shall provide the capacity to allow the control interface to

select the active switch control unit

5.4 TIMING GENERATOR

5.4.1 This subsystem shall contain identical primary and backup Terminal Timing

signal generators High Q302

5.4.2 This subsystem shall distribute Terminal Timing signals to a minimum of

255 ports

5.5 TEST AND MONITORING

5.5.1 This subsystem shall not affect the signals being monitored

High Q303 5.5.2 This subsystem shall contain at least 10 NBG’s

5.5.3 The NGB shall be able to generate predefined valid Nascom blocks at the

timing frequencies identified

3 In the MCSS T&E integration, verification and validation will takes place over the systems engineering

lifecycle to show that the systems meets the objectives of each phase are satisfied. INCOSE., ―System

Engineering Handbook Version 2.0‖, Seattle, 2000

7

3.2 Test and Evaluation Methodology

The approach used to conduct T&E is based on achieving the T&E objectives described

above.Test approach defined in the MCSS SRD will involve Development Team and

Transition Team. Operations personnel, the Development Team and Transition Team will be

involved in testing the MCSS at MSOCC.

Test procedures will develop to perform the test in four categories; factory acceptance test,

site acceptance test, integration acceptance test and final acceptance test. Thus, each of T&E

activity will deliver the documents as described in Table 3.2.

Table 3. 2 T&E Document Deliverables

Phase ID Document Deliverables Due Date

Preliminary

Design F100 Test Plan Document 31 January 2011

Detailed

Design F200 Test Procedures Document

28 February

2011

Development

and Integration F300 Final Subsystem Test Report 30 March 2011

Qualification

and Installation F400

Final Test Acceptance Report Document

(Verification and Validation) 30 April 2011

Closeout F500 Project Final Report 14 May 2011

MCSS T&E will start from the subsystems development until the subystem installation is

replace the current MSOCC switching system. The T&E activity except the Purchased Switch

Test is interdependence and can be illustrated by using a Vee model4 in the project lifecycle

as described in Figure 3.1.

As we bought the COTS Industry Switch from the market, those purchase switch should have

immediately test for immediate feedback result and will be served as independent testing. The

4 The Vee model illustrate here is only for the purpose the interdependence testing; not all of the phases in the

Vee-model (especially validation phase) according to the MCSS System Engineering Management Plan would

be partof this document. Vee model was adapted from 1204 Test and Evaluation lecture notes and modified for

MCSS from Forsberg, K., Mooz, H. and Cotterman, H., Visualising Project Management, John Wiley & Sons,

Inc., 3rd edition, 2005. Page 145

8

black box in the Vee model indicated that the phase is already tested in the beginning and will

not be incorporate in this TEMP.

Figure 3. 1 MCSS T&E Vee Model

The Test Pass and Fail criteria for each T&E activity will be develop according to the MCSS

System Requirement Document in Section 4. This Test Pass and Fail criteria will be

explained more detail in the Test Plan work packages following IEEE 829-1998 Standard for

Software Test Documentation5.

3.3 Management Organization and Responsibilities

3.3.1 External Interfaces

This section describe the organizational between the project and external entities6.The

external interfaces for the MCSSRP project would be the members of the project committee

(Computer Sciences Corporation), MCSSRP project manager, Ford Aerospace

(subcontractor) and NASA Goddard Space Flight Center who is the stakeholder for this

project.

5 MCSS T&E Work Packages will adapted the Test Plan format which contain: How the testing will be done,

Who will do it, What will be tested, How long it will take and What the test coverage. IEEE 829-1998 Standard

for Software Test Documentation. 6 With identifying project external interfaces it would covers the significance of stakeholders to project success.

Forsberg, K., Mooz, H. and Cotterman, H., Visualising Project Management, John Wiley & Sons, Inc., 3rd

edition, 2005. Page 12

Identify User Needs

and Test Concept

Document

Develop Test and

Evaluation Master Plan

Expand performance

specifications into

―design-to‖ Subsystem

Evolve ―design-to‖ into

documentation and

implementation plan

Validate components

against ―build-to‖

documentation

Assemble configuration

item and subsystem and

perform verification

Integrate system and

verifify to performance

specifications

Demonstarate and

validate system

capability

Fabricate, Assemble

and Code to ―build-to‖

documentation

Subsystem

Test Plan and

Procedure

Integration

Test Plan and

Procedure

Acceptance

Test Plan and

Procedure

Requirement

specification

System

specification

Preliminary

design

Detailed

design

Handover

Acceptance

test

Integration

Test

Subsystem

Test

9

Figure 3. 2 MCSSRP External Interfaces

3.3.2 Internal Interfaces

This section describe the internal structure of the MCSS T&E project organization to include

the interfaces among the units of the development team. The matrix organization7 will be use

to create succesful implementation of the T&E activities and provide efficient project

execution environment with emphasis on the functionality of each discipline8.

The organizational interfaces between the MCSS T&E project and organizational entities that

provide supporting processes, such as quality assurance, and verification and validation, will

be specified in support T&E and system engineering process. Organizational charts in Figure

3.3 and Figure 3.4 described the lines of authority, responsibility, and communication within

the project.

7 As MCCSRP is considered medium tech project with low risk involved, matrix organization would be

appropriate for describe the internal structure of the project. Shenhar, A. J. and Bonen, Z., ―The New Taxonomy

of Systems: Toward an Adaptive Systems Engineering Framework‖, IEEE Transactions on Systems, Man, and

Cybernetics – Part A: Systems and Humans, Vol. 27 (1997), no. 2, 137 – 145 8 Under the matrix organization, all project tasks in WBS are assigned to each discipline through work packages.

This is what we will applied in this TEMP. Ichiro Koshijima and Tomio Umeda. Human Resource Allocation in

Project Management. Management Science Approach.

http://www.sba.muohio.edu/abas/2001/brussels/Koshijima_Koshijima-Umeda.pdf

MCSSRP

Project

Manager

Vendor of

MCSS

switches

External

Environment

Project Team

Major

stakeholder –

NASA - GSFC

Project Sponsor –

CSC Exec. Mgt

Sub-contractor -

Ford Aerospace

10

Figure 3. 3 MCSSRP Matrix Organization Structure

Figure 3. 4 MCSSRP Organization Structure

Executive Management

Build & Development Department

MCSSRP Project Manager

Test & Evaluation Department

Configuration Department

MCSS System and Development Team

MCSS Test and Evaluation Team

MCSS Configuration Team

Quality Assurance Department

MCSS Quality Assurance Team

Administrative Office

MCSSRP Project Manager

MCSS Test and Evaluation Team

MCSS Configuration Team

Quality Assurance Team

Configuration Item Test Team

Integration Test Team

Delivery Team

MCSS System and Development Team

Requirements Team

Design Team

Implementation Team

LibrarianQuality Assurance

Engineer

• System engineer

• Architecting eng• Software eng• Hardware eng

• System eng• Software eng• Hardware eng

• System engineer• CM Specialist

• Logistic engineer

• System eng• Senior Test

Engineer• Test Engineer

11

3.3.2.1 Project Manager (PM)9

1) Internal responsibilities:

a. Approve all cost and schedule-related planning documents.

b. Approve all organizational work and WBS.

c. Control of all organizational resources.

d. Monitor and report all project performance

e. Evaluate trade-offs prior to major decisions and approve any deviations to approved

plans.

f. Monitor and assure that all corrective actions are completed in the specified time.

2) External responsibilities: The PM is the principal point of contact for maintaining

liaison with the Computer Science Corporation, coordinating and supporting meetings,

conducting program reviews, approving all deliverables and managing all subcontractor

(Ford Aerospace) activity.

3.3.3 Project Team Roles and Responsibilities

This section identify the organizational units or project team that are responsible for T&E

processes and activities. The Maturity Model10

will be use for assessment of competency in

allocating the resources in each work activity. Next table describe the roles and

responsibilities and basic unit rate for each team organization who is responsibles for T&E

activities.

9 Project Manager has roles in three different arena; the customer’s, executive management’s, and the project

team’s. Project Manager is like a conductor of orchestra, providing the guidance for all project teams to achieve

common goal. Forsberg, K., Mooz, H. and Cotterman, H., Visualising Project Management, John Wiley & Sons,

Inc., 3rd edition, 2005. Page181 – 195. 10 The Maturity Model will helps to allocate the human resources more efficient in the MCSSRP project based

on assesment of Type of Engineers (Type I, Type II, Type III, Type IV, and Type V).Joseph E. Kasser and Moti

Frank, 2010. A Maturity Model for the Competency of Systems Engineers. Proceedings of the 20th International

Symposium of the INCOSE, Chicago, IL.

Table 3. 3 Roles and Responsibilities of organization team for T&E activities

Position Roles and Responsibilities Staff and Resources Code Type of

Engineers WBS Activities Status Organization Unit

MCSSRP Project

Manager

Provides testing management oversight.

Responsibilities:

provide technical direction

acquire appropriate resources

provide management reporting

Project Manager (R1) Type V

M101, M102, M201,

M202, M301, M302,

M401, M402, M403

Full Time MCSSRP Project

Manager

MCSS Test and

Evaluation (T&E)

Team

An organizational team, responsible for CI

and Integration T&E, who reports to the

Project Manager .

Responsibilities:

execute tests, log results

recover from errors, document change

requests

System Engineer (R2)

Senior System Engineer (R3)

Senior Test Engineer (R4)

Test Engineer (R5)

Logistic Engineer (R6)

Type II

Type III

Type V

Q101, Q102, Q103,

Q104, Q201, Q202,

Q203, Q204, Q205,

Q301, Q302, Q303,

Q304, Q305, Q401,

Q402, Q403, Q404

Full Time

Part Time

Test and Evaluation

Department

Configuration

Item Test Team Engineering staff responsible for CI Testing.

System Engineer (R2)

Senior System Engineer (R3)

Type III

Type V

Q101, Q103, Q203,

Q205, Q302, Q303 Part Time

Configuration

Department

Integration Test

Team

Engineering staff responsible for

CI/Hardware Configuration Item (HWCI)

Testing.

Senior Test Engineer (R4)

Test Engineer (R5)

Type V

Type III Q204, Q304, Q305 Full Time

Test and Evaluation

Department

Delivery Team Engineering staff responsible for on-site

deliveries, training, and testing.

Test Engineer (R5)

Logistic Engineer (R6)

Type III

Type II

Q401, Q402, Q403,

Q404

Full Time

Part Time

Test and Evaluation

Department

Quality Assurance

(QA) Team

An organizational team, responsible for QA

functions, that reports to the Project

Manager.

Responsibilities:

decide on the scope of the Q/A testing in

agreement with Project Manager

verification and validation

QA Engineer (R7) Type III

Q101, Q103, Q203,

Q205, Q302, Q303,

Q204, Q304, Q305,

Q401, Q402, Q403,

Q404

Full-Time Quality Assurance

Department

Table 3. 4 Basic rate of project team cost

R1 Project Manager (R1) V $500

R2 System Engineer (R2) III $250

R3 Senior System Engineer (R3) V $350

R4 Senior Test Engineer (R4) V $350

R5 Test Engineer (R5) III $250

R6 Logistic Engineer (R6) II $200

R7 QA Engineer (R7) III $150

Resource

CodeLabor Category Type

Unit Rate/Day

(8 hours)

3.3.4 Documentation

The MCSS TEMP is the top-level test and evaluation planning document. Project manager

will be responsible for developing test and evaluation plan. Documents11

will be produced by

using microsoft word and spread sheet. Test and evaluation plan documents will identify the

following:

Table 3. 5 T&E Documentation

Documents Section

The methodology to be used for implementing test and evaluation. Section 3 Page 7

The organizational structure and responsibilities for implementing T&E. Section 3 Page 8

An integrated T&E schedule depicting major project milestones and T&E

activities in support of those milestones. Section 4 Page 17

An basic work packages of each of the major T&E phases including

identification of the subsystem being tested, test objective, and scope of

the test.

Appendix 1 Page 50-97

A summary of the T&E resources required for execution of the T&E

program. Section 3 Page 14-15

Documentation to be developed and maintained, including traceability and

conformance verification matrices. Section 3 Page 6

11 Good engineering documents are critical to the cost effectiveness of systems engineering. Reducing the cost of

preparing effective documents is an approach that applied in any organization and will reduce the cost of the

SDLC (systems development life cycle). Kasser, J. E., ―Improving the Systems Engineering Documentation

Production Process‖, proceedings of the 5th Annual International Symposium of the INCOSE, 1995, pages 6-9.

14

3.4 Resources Summary

This section provide a summary of the schedule, budget and staff resources for the T&E

activities.

3.4.1 Integrated Test Master Schedule and Budget Summary

Master Schedule as depicted in Figure 3.5. Budget allocations are contained in Table 3.6 and

Figure 3.5. The supporting Work Breakdown Structure (WBS), cost, schedule, and staffing

requirements for the each increment of the Master Schedule are contained in Section 4.

Week

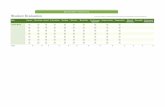

WBS 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

100

200

300

400

500

January February March April May

SRR PDR IRR TRR DRR Closeout

Figure 3. 5 Integrated T&E Master Schedule

Table 3. 6 Total budget allocations

1 Labor Cost Unit Rate/Day Working Days Subtotal

Project Manager $500 52 $26,000

System Engineer $250 8 $2,000

Senior System Engineer $350 10 $3,500

Senior Test Engineer $350 12 $4,200

Test Engineer $250 88 $22,000

Logistic Engineer $200 3 $600

QA Engineer $150 44 $6,600

$64,900

2 Material Cost Features Quantity

Nascom Block Generator (NBG) MCSS 10 $10,000

Block Error Detector (BED) MCSS 10 $10,000

Oscilloscope MCSS 2 $14,800

Test Rigs Test and Monitoring 5 $5,000

288 Ports Switch Matrix Switch Matrix 1 $360,000

$399,800

$464,700

$46,470

Total Budget

Fixed Fee Contract (10% )

Total Labor Cost

Total Material Cost

15

SRR-PDR PDR-IRR IRR-TRR TRR-DRRProject

Closeout

Cost $12,950 $12,800 $19,050 $15,100 $5,000

Cumulative Cost $12,950 $25,750 $44,800 $59,900 $64,900

$0

$10,000

$20,000

$30,000

$40,000

$50,000

$60,000

$70,000

MCSS T&E Manpower Cost

Figure 3. 6 Summary T&E Manpower Cost

The T&E activities total budget cost is $464,700 and fixed fee contract $46,470

3.4.2 Staff Resource Summary

Required staffing allocations by development phase are defined in Table 3.7. The table

provides guidance for staff allocations for the overall T&E activities.

Table 3. 7 Staff allocations per development phase

Labor CategoryPreliminary

Design

Detailed

Design

Development

and

Integration

Qualification

and

Installation

Closeout

Project Manager 1 1 1 1 1

System Engineer 1 0 0 1 0

Senior System Engineer 1 1 1 1 0

Senior Test Engineer 1 3 0 0 0

Test Engineer 2 2 6 2 0

Logistic Engineer 0 0 0 1 0

QA Engineer 1 1 3 1 0

Subtotals 7 8 11 7 1

16

3.5 Test Location and Equipment

The T&E activity other than Site Acceptance Test will be performed in in–house

Development Lab. The Site Acceptance Test is done at the first delivered location (EDF). The

in-house Development Lab has a sufficient facility and equipment for running the required

Test. However some of the equipment is not available and purchased independently in System

Requirement Phase. The complete listing of the Equipment used in the MCSS T&E is given

below.

Frequency counters, serial data analyzer, logic analyzer

Oscilloscope

Block Error Detector (BED)

Nascom Block Generator (NBG)

Test Rigs

Software test programs

17

4. Test and Evaluation Process Plan

4.1 Work Planning

This section specify specify the work activities, schedule, resources, and budget details for the

MCSS T&E activities. Work packages for each work activity, necessary resources, estimated

duration, work products to be produced, acceptance criteria for the work products, and

predecessor and successor T&E work activities are contained in Appendix 1.

4.1.1 Test and Evaluation Work Breakdown Structure (WBS)

System Life Cycle Processes ISO/IEC 15288 would be adopted in support of WBS T&E

activities. Detail of the phases will describe in next section. The MCSS project phases after

SRR is divided into 5 phases, they are:

1) Preliminary Design (SRR-PDR)

2) Detailed Design (PDR-CDR)

3) Development and Integration (CDR-IRR)

4) Qualification and Installation (IRR-DRR)

5) Project close out phase

The WBS will use the Top-Down approach12

which identifies the needed tasks, resource

allocations, and cost estimates. Figure 4.1 described the WBS of T&E and coding scheme.

4.1.1.1 Work Breakdown Structure Dictionary

To better understand the nature of the work required to satisfy each element, a complete WBS

dictionary13

will be use in MCSS T&E activities. Table 4.1 described the WBS dictionary of

this project.

12 Top-Down approach of work breakdown structure (WBS) will be use to explained the test planning from the

highest level into the lowest level for each phase. By using WBS the Project Manager could identifying the

implications of WBS to budgeting, scheduling, risk assessment, and cost collection during planning of MCSS

T&E activities. Forsberg, K., Mooz, H. and Cotterman, H., Visualising Project Management, John Wiley &

Sons, Inc., 3rd edition, 2005. 13 By using WBS dictionary it will help clarify the distinctions between WBS elements. Practice Standard for

Work Breakdown Structures (Second Edition), published by the Project Management Institute, ISBN

1933890134, page 8

Figure 4. 1 Work Breakdown Structure for T&E activities

MCSS T&E

100

Preliminary Design

Management

M101-Technical direction and

acquire resources

M102-Risk identification and

management

Testing

Q101 Execute purchased switch

test

Q102 Prepare modified switch matrix test plan

Q103 Prepare integration test plan

and procedure

Q104 Introductory training

200

Detailed Design

Management

M201 Technical direction and management

reporting

M202 Risk management

Testing

Q201 Execute modified switch

matrix test

Q202 Prepare modified Switch Control test plan

Q203 Prepare Timing Generator

test plan

Q204 Prepare Test and Monitoring test

plan

Q205 MCSS Subsystem design

RAM analysis

300

Development and Integration

Management

M301 Technical direction and management

reporting

M302 Risk management

Testing

Q301 Execute Switch Control test

Q302 Execute Timing Generator

test

Q303 Execute Test and Monitoring test

Q304 Finalize whole subsystem integration test

Q305 MCSS integration test

(verified)

400

Qualification and Installation

Management

M401 Handing over documentation

M402 Risk management

M403 Test and Evaluation

completion review

Testing

Q401 Final MCSS subsystem

operational test

Q402 Final MCSS subsystem factory

acceptance test

Q403 Final MCSS subsystem site acceptance test

Q404 Final MCSS subsystem customer

acceptance test

500

Project closeout

Management

M501 Perform client closeout

M502 Perform organizational

closeout

M503 Conduct subcontractor

closeout

M504 Write the project final report

M505 Conduct team closeout

Table 4. 1 WBS Dictionary of T&E activities

WBS ID Work Package Name Description Milestones

M101Technical direction and

acquire resources

To facilitate a smooth running of T&E activities including required

resources at SRR-PDRSRR-PDR

M102Risk identification and

management

This element include how to identify and conduct risk management at

each T&E activities at SRR-PDRSRR-PDR

Q101Execute purchased Switch

testTo test whether Purchased Switch is meet the requirements MCSS SRD SRR-PDR

Q102Prepare modified Swith

Matrix test planPlanning the Modified Switch Matrix Test Plan SRR-PDR

Q103Prepare integration test

plan and procedureTo provide a MCSS integration test pland and procedure for the tester SRR-PDR

Q104Implement Introductory

training

To train the manpower who will performed in the T&E with the MCSS

system to maintain the Test Quality SRR-PDR

M201Technical direction and

management reporting

To facilitate a smooth running of T&E activities including management

report at PDR-IRRPDR-IRR

M202 Risk managementThis element include how to conduct risk management at each T&E

activities at PDR-IRRPDR-IRR

Q201Execute modified Switch

Matrix test

To test whether the Modified Switch Matrix is meet the requirements in

System requirements Document Section 5PDR-IRR

Q202Prepare modified Switch

Control test planPlanning the Modified Switch Control Test Plan PDR-IRR

Q203Prepare Timing Generator

test planPlanning the Modified Timing Generator Test Plan PDR-IRR

Q204Prepare Test and

Monitoring test planPlanning the Modified Test and Monitoring Test Plan PDR-IRR

Q205MCSS Subsystem RAM

analysis

Assurance that design maturity is sufficient to begin detailed design and

review the status including achieved resultsPDR-IRR

M301Technical direction and

management reporting

To facilitate a smooth running of T&E activities including management

report at IRR-TRRIRR-TRR

M302 Risk managementThis element include how to conduct risk management at each T&E

activities at IRR-TRRIRR-TRR

Q301 Execute Switch Control testTo test whether the Modified Switch Control is meet the requirements in

System requirements Document Section 5IRR-TRR

Q302Execute Timing Generator

test

To test whether the Modified Timing Generator is meet the requirements

in System requirements Document Section 5IRR-TRR

Q303Execute Test and

Monitoring test

To test whether the Modified Test and Monitoring Test is meet the

requirements in System requirements Document Section 5IRR-TRR

Q304Finalize whole subsystem

integration testCombined 4 separate review subsystems integration test IRR-TRR

Q305MCSS subsystem

integration test (verified)

Verified combined 4 separate review subsystems integration test meet

the requirementsIRR-TRR

M401Handing over

documentation

The purpose of this document is to assist a smooth handover for the

customerTRR-DRR

M402 Risk managementThis element include how to conduct risk management at each T&E

activities at TRR-DRRTRR-DRR

M403Test and Evaluation

completion reviewTo review project completion and identify any lesson learnt TRR-DRR

Q401Final MCSS subsystem

operational test

A Factory Acceptance Test witnessed by the transition test to test

whether each subsystems of the integrated MCSS is meet the requirement

in SRD section 5 and can operate as expected by customer

TRR-DRR

Q402Final MCSS subsystem

factory acceptance test

Review the result of the test documented in the Factory Acceptance Test

Report for verification and validation of the MCSSTRR-DRR

Q403Final MCSS subsystem site

acceptance test

To ensure reliable performance of MCSS subsystem and minimum impact

to the MSOCCTRR-DRR

Q404Final MCSS subsystem

customer acceptance test

To test fully integrated MCSS after being installed but before Final

Acceptance Test by NASA to be considered fully operationalTRR-DRR

20

4.1.2 T&E Schedule Allocation Plan

This section provide scheduling relationships among MCSS T&E work activities. Techniques

will be use for depicting schedule relationships in activities include activity Gantt charts,

critical path networks14

, and PERT chart15

. Bottom-Up approach16

will be use to estimate the

project time. Thus the schedule plan will follow one iteration of the Waterfall system and

system development lifecycle (SDLC) in T&E activities and fit within a timeline of 16 weeks.

Following section describe of the schedule plan fot each phase.

4.1.2.1 Preliminary Design (SRR-PDR)

The schedule for SRR-PDR phase will be start on 01 January 2011. This phase will cover the

technical direction for T&E activities, risk identification, test plans, resources and

introductory training.

TASK

IDACTIVITY 1 2 3 4 5 1 2 3 4 5 1 2 3 4 5 1 2 3 4 5

M101Technical direction and

acquire resources

M102Risk identification and

management

Q101Execute purchased Switch

test

Q102Prepare modified Swith

Matrix test plan

Q103Prepare integration test

plan and procedure

Q104Implement introductory

training

Week 1 Week 2 Week 3 Week 4

Figure 4. 2 Preliminary Design T&E schedule

14 A good project network is very useful to determine the critical path and slack time, and a good start to project

resource scheduling. Larson,Eriik W, and Gray,Clifford F.,Project Management, McGraw-Hill ., 5th Edition,

2011. Page 188 15 PERT chart can shows the dependencies between the various tasks and activities unlike Gantt Chart. Howard

Eisner, Essentials of Project and Systems Engineering Management, John Wiley & Sons, Inc., 2nd Edition,

2002, Page 91 - 122 16 The Bottom-up (micro) approach is suitable in MCSSRP project, where the cost and time is important

Larson,Eriik W, and Gray,Clifford F.,Project Management, McGraw-Hill ., 5th Edition, 2011. Page 188

21

4.1.2.2 Detailed Design (PDR-IRR)

The schedule for PDR-IRR phase will be start on 01 February 2011. This phase will cover the

management reporting (budget and schedule review), Reliability Avalilability and

Maintainability subsystem designs, test plan and procedures, and execute subsystem test.

TASK

IDACTIVITY 1 2 3 4 5 1 2 3 4 5 1 2 3 4 5 1 2 3 4 5

M201Technical direction and

management reporting

M202 Risk management

Q201Execute modified Switch

Matrix test

Q202Prepare modified Switch

Control test plan

Q203Prepare Timing Generator

test plan

Q204Prepare Test and

Monitoring test plan

Q205MCSS Subsystem RAM

analysis

Week 5 Week 6 Week 7 Week 8

Figure 4. 3 Detailed Design T&E schedule

4.1.2.3 Development and Integration (IRR-TRR)

The schedule for PDR-IRR phase will be start on 01 March 2011. This phase will cover the

management reporting (budget and schedule review), risk management, final design, execute

susbystem test and verified subsystem integration test.

TASK

IDACTIVITY 1 2 3 4 5 1 2 3 4 5 1 2 3 4 5 1 2 3 4 5

M301Technical direction and

management reporting

M302 Risk management

Q301Execute Switch Control

test

Q302Execute Timing Generator

test

Q303Execute Test and

Monitoring test

Q304Finalize whole subsystem

integration test

Q305MCSS subsystem

integration test (verified)

Week 9 Week 10 Week 11 Week 12

Figure 4. 4 Development and Integration T&E schedule

22

4.1.2.4 Qualification and Installation (TRR-DRR)

The schedule for PDR-IRR phase will be start on 01 April 2011. This phase will cover the

handing over documentation, risk management, final MCSS subystem test results and delivery

final MCSS subsystem to the customer.

TASK

IDACTIVITY 1 2 3 4 5 1 2 3 4 5 1 2 3 4 5 1 2 3 4 5

M401Handing over

documentation

M402 Risk management

M403Test and Evaluation

completion review

Q401Final MCSS subsystem

operational test

Q402Final MCSS subsystem

factory acceptance test

Q403Final MCSS subsystem

site acceptance test

Q404Final MCSS subsystem

customer acceptance test

Week 13 Week 14 Week 15 Week 16

Figure 4. 5 Qualification and Installation T&E schedule

4.1.2.5 Critical Path Preliminary Design (SRR-PDR)

The T&E Critical Path (CP) 17

during SRR-PDR phase is the longest path of the expected time of the T&E activity. The time metrics is a

week which is 5 working days. Critical Path for SRR-PDR phase = M101+Q101+Q1012+Q103+Q104 = 5+4+3+3+5 = 20 Days

Figure 4. 6 PERT-CPM Preliminary Design.

17 By using the Critical Path analysis, the Project Manager will easy to identify the minimum length of time needed to complete a project and reducing project risk.

Larson,Eriik W, and Gray,Clifford F.,Project Management, McGraw-Hill ., 5th Edition, 2011. Chapter 6-Developing Project Plan.

24

4.1.2.6 Critical Path Detailed Design (PDR-IRR)

The T&E Critical Path (CP) during PDR-IRR phase is the longest path of the expected time of the T&E activity. The time metrics is a week

which is 5 working days. Critical Path for PDR-IRR phase = M201+Q201+Q203+Q205 = 7+4+3+4 = 18 Days

Figure 4. 7 PERT-CPM Detailed Design

25

4.1.2.7 Critical Path Development and Integration (IRR-TRR)

The T&E Critical Path (CP) during SRR-PDR phase is the longest path of the expected time of the T&E activity. The time metrics is a

week which is 5 working days. Critical Path for IRR-TRR phase = M301+Q302+Q304+Q305 = 7+5+3+5 = 20 Days

Figure 4. 8 PERT-CPM Development and Integration

26

4.1.2.8 Critical Path Qualification and Installation (TRR-DRR)

The T&E Critical Path (CP) during SRR-PDR phase is the longest path of the expected time of the T&E activity. The time metrics is a

week which is 5 working days. Critical Path for TRR-DRR phase = M403+Q401+Q402+Q403 = 5+4+4+4 = 20 Days

Figure 4. 9 PERT-CPM Qualification and Installation

4.1.3 T&E Staff Resources Allocation Plan

This section provide a detailed itemization of the resources allocated to each major work

activity in the MCSS T&E work breakdown structure. Resources18

include the numbers and

required skill levels of personnel for each work activity. Required staffing allocations by

development phase are defined in the following section. The tables and figures represents

number of resource required to complete each work package. It shows the types of personnel

by Maturity Model and project roles.

4.1.3.1 Preliminary Design Phase (SRR-PDR)

TASK

IDACTIVITY RES DUR ES LF TS 1 2 3 4 5 1 2 3 4 5 1 2 3 4 5 1 2 3 4 5

M101Technical direction and

acquire resources1 5 0 5 0 1 1 1 1 1

M102Risk identification and

management1 2 0 2 0 1 1

Q101Execute purchased

Switch test3 4 5 9 0 3 3 3 3

Q102Prepare modified Swith

Matrix test plan1 3 9 12 0 1 1 1

Q103Prepare integration test

plan and procedure1 3 12 15 0 1 1 1

Q104Implement Introductory

training1 5 15 20 0 1 1 1 1 1

2 2 1 1 1 3 3 3 3 1 1 1 1 1 1 1 1 1 1 1

Week 1 Week 2 Week 3 Week 4

Total Resource Load

0 1 2 3

Project Manager (R1)

System Engineer (R2)

Senior System Engineer (R3)

Senior Test Engineer (R4)

Test Engineer (R5)

Logistic Engineer (R6)

QA Engineer (R7)

SRR-PDR Staff Allocation

0

1

2

3

4

I II III IV V

Engineers Type

Figure 4. 10 Resource allocation Preliminary Design Phase

18 In this MCSS T&E activities, scheduling would allocates resources personnel to jobs (tasks) in order to

minimize total lateness. Project Management Institute A Guide to the Project Management Body of Knowledge,

Third Edition, 2004 Project Management Institute, Inc. ISBN 193069945X

28

4.1.3.2 Detailed Design Phase (PDR-IRR)

TASK

IDACTIVITY RES DUR ES LF TS 1 2 3 4 5 1 2 3 4 5 1 2 3 4 5 1 2 3 4 5

M201Technical direction and

management reporting1 7 0 7 0 1 1 1 1 1 1 1

M202 Risk management 1 3 4 7 0 1 1 1

Q201Execute modified Switch

Matrix test3 5 7 12 0 3 3 3 3 3

Q202Prepare modified Switch

Control test plan1 3 12 15 0 1 1 1

Q203Prepare Timing Generator

test plan1 3 12 15 0 1 1 1

Q204Prepare Test and

Monitoring test plan1 3 12 15 0 1 1 1

Q205MCSS Subsystem RAM

analysis1 4 15 19 0 1 1 1 1

1 1 1 1 2 2 2 3 3 3 3 3 3 3 3 1 1 1 1

Week 5 Week 6 Week 7 Week 8

Total Resource Load

0 1 2 3 4

Project Manager (R1)

System Engineer (R2)

Senior System Engineer (R3)

Senior Test Engineer (R4)

Test Engineer (R5)

Logistic Engineer (R6)

QA Engineer (R7)

PDR-IRR Staff Allocation

0

1

2

3

4

5

6

I II III IV V

Engineers Type

Figure 4. 11 Resource allocation Detailed Design Phase

29

4.1.3.3 Development and Integration Phase (IRR-TRR)

TASK

IDACTIVITY RES DUR ES LF TS 1 2 3 4 5 1 2 3 4 5 1 2 3 4 5 1 2 3 4 5

M301Technical direction and

management reporting1 7 0 7 0 1 1 1 1 1 1 1

M302 Risk management 1 3 4 7 0 1 1 1

Q301Execute Switch Control

test3 5 7 12 0 3 3 3 3 3

Q302Execute Timing Generator

test3 5 7 12 0 3 3 3 3 3

Q303Execute Test and

Monitoring test3 5 7 12 0 3 3 3 3 3

Q304Finalize whole subsystem

integration test1 3 12 15 0 1 1 1

Q305MCSS subsystem

integration test (verified)3 5 15 20 0 3 3 3 3 3

1 1 1 1 2 2 2 9 9 9 9 9 1 1 1 3 3 3 3 3

Week 10 Week 11 Week 12

Total Resource Load

Week 9

0 1 2 3 4 5 6 7

Project Manager (R1)

System Engineer (R2)

Senior System Engineer (R3)

Senior Test Engineer (R4)

Test Engineer (R5)

Logistic Engineer (R6)

QA Engineer (R7)

IRR-TRR Staff Allocation

0

1

2

3

4

5

6

7

8

9

10

I II III IV V

Engineers Type

Figure 4. 12 Resource allocation Development and Integration Phase

30

4.1.3.4 Qualification and Installation (TRR-DRR)

TASK

IDACTIVITY RES DUR ES LF TS 1 2 3 4 5 1 2 3 4 5 1 2 3 4 5 1 2 3 4 5

M401Handing over

documentation1 3 0 3 0 1 1 1

M402 Risk management 1 3 0 3 0 1 1 1

M403Test and Evaluation

completion review1 5 0 5 0 1 1 1 1 1

Q401Final MCSS subsystem

operational test3 4 5 9 0 3 3 3 3

Q402Final MCSS subsystem

factory acceptance test3 4 9 13 0 3 3 3 3

Q403Final MCSS subsystem

site acceptance test3 4 13 17 0 3 3 3 3

Q404Final MCSS subsystem

customer acceptance test1 3 17 20 0 1 1 1

3 3 3 1 1 3 3 3 3 3 3 3 3 3 3 3 3 1 1 1

Week 13 Week 14 Week 15 Week 16

Total Resource Load

0 1 2 3 4 5 6 7

Project Manager (R1)

System Engineer (R2)

Senior System Engineer (R3)

Senior Test Engineer (R4)

Test Engineer (R5)

Logistic Engineer (R6)

QA Engineer (R7)

IRR-TRR Staff Allocation

0

1

2

3

4

5

6

7

8

9

10

I II III IV V

Engineers Type

Figure 4. 13 Resource allocation Qualification and Installation Phase

4.1.4 Budget Allocation Plan

This section provides a detailed breakdown of necessary resource budgets for each of the

major work activities in the work breakdown structure. The activity budget will estimated the

cost for activity personnel where the type of cost is price contract19

. The estimating project

19 In this MCSS, as there is low risk involved (using mostly existing technology), the cost contract for personnel

could be awarded as a fixed price contracts. Howard Eisner, Essentials of Project and Systems Engineering

Management, John Wiley & Sons, Inc., 2nd Edition, 2002, Page 91 - 122

31

cost will use the Bottom-Up approach20

21

. Required budget allocations by development phase

are defined in the following section.

4.1.4.1 Preliminary Design Phase (SRR-PDR)

Below is a listing work packages from SRR-PDR. The amount allocated for each is

determined by the daily rate (8 hours), and the number of people assigned to each work

package . Total manpower cost from is $12.950.

Table 4. 2 Budget allocation Preliminary Design Phase

Code Activities Description

100 Preliminary Design Phase Engineers Type Number Unit

Rate/day

M101Technical direction and

acquire resources$6,000 $6,000

M101.1 Resources plan for T&E Project Manager Type V 1 $500 5 $2,500

M101.2 Cost and schedule plan Project Manager Type V 1 $500 5 $2,500

M101.3 Subsystem test direction Project Manager Type V 1 $500 2 $1,000

M102Risk identification and

managementProject Manager Type V 1 $500 2 $1,000 $1,000 $7,000

1) Test Engineer Type III 2 $250 4 $2,000

2) QA Engineer Type III 1 $150 4 $600

Q102Prepare modified Swith Matrix

test plan

Senior Test

EngineerType V 1 $350 3 $1,050 $1,050 $10,650

Q103Prepare integration test plan

and procedure

Senior System

EngineerType V 1 $350 3 $1,050 $1,050 $11,700

Q104Implement Introductory

trainingSystems Engineer Type III 1 $250 5 $1,250 $1,250 $12,950

Sub-total $12,950 $12,950

Manpower

cost

High level

sub-total

cost

Cumulative

cost

Manpower resourcesWorking

days

$2,600 $9,600Q101 Execute purchased Switch test

20 In the MCSSRP project, every phase or milestones have applied WBS packages. Which component of WBS

packages has contain, budget, schedule, resource. Bottom-Up approach can serve as a check on cost elements in

the WBS by rolling up the work packages and associated cost accounts to major deliverables at the work package

level. Larson,Eriik W, and Gray,Clifford F.,Project Management, McGraw-Hill ., 5th Edition, 2011. Chapter 5.

Page 126-155 21 In addition Bottom-Up approach could provide accurate estimate of the cost during product life cycle. Hari,

A., Shoval, S. and Kasser, J. E., ―Conceptual Design to Cost: A new systems engineering tool‖, proceedings of

the 18th International Symposium of the INCOSE, Utrecht, Holland, 2008.

32

M101 M102 Q101 Q102 Q103 Q104

High level sub-total cost $6,000 $1,000 $2,600 $1,050 $1,050 $1,250

Cumulative cost $6,000 $7,000 $9,600 $10,650 $11,700 $12,950

$0

$2,000

$4,000

$6,000

$8,000

$10,000

$12,000

$14,000

Preliminary DesignPhase

Figure 4. 14 Budget accumulative Preliminary Design Phase

4.1.4.2 Detailed Design Phase (PDR-IRR)

Below is a listing work packages from PDR-IRR. The amount allocated for each is

determined by the daily rate and the number of people assigned to each work package . Total

manpower cost is $12.800.

Table 4. 3 Budget allocation Detailed Design Phase

Code Activities Description

200 Detailed Design Phase Engineers Type Number Unit

Rate/day

M201Technical direction and

management reporting$3,500 $3,500

M201.1 Resource plan review Project Manager Type V 1 $500 3 $1,500

M201.2 Budget and schedule review Project Manager Type V 1 $500 2 $1,000

M201.3 Subsystem integration test

directionProject Manager Type V 1 $500 2 $1,000

M202 Risk management Project Manager Type V 1 $500 3 $1,500 $1,500 $5,000

1) Test Engineer Type III 2 $250 5 $2,500

2) QA Engineer Type III 1 $150 5 $750

Q202Prepare modified Switch

Control test plan

Senior Test

EngineerType V 1 $350 3 $1,050 $1,050 $9,300

Q203Prepare Timing Generator test

plan

Senior Test

EngineerType V 1 $350 3 $1,050 $1,050 $10,350

Q204Prepare Test and Monitoring

test plan

Senior Test

EngineerType V 1 $350 3 $1,050 $1,050 $11,400

Q205MCSS Subsystem RAM

analysis

Senior System

EngineerType V 1 $350 4 $1,400 $1,400 $12,800

Sub-total $12,800 $12,800

Cumulative

cost

$8,250$3,250

Manpower resourcesWorking

days

Manpower

cost

High level

sub-total

cost

Q201Execute modified Switch Matrix

test

33

M201 M202 Q201 Q202 Q203 Q204 Q205

High level sub-total cost $3,500 $1,500 $3,250 $1,050 $1,050 $1,050 $1,400

Cumulative cost $3,500 $5,000 $8,250 $9,300 $10,350 $11,400 $12,800

$0

$2,000

$4,000

$6,000

$8,000

$10,000

$12,000

$14,000

Detailed Design Phase

Figure 4. 15 Budget accumulative Detailed Design Phase

4.1.4.3 Development and Integration Phase (IRR-TRR)

Below is a listing work packages from IRR-TRR. The amount allocated for each is

determined by the daily rate and the number of people assigned to each work package . Total

manpower cost is $19.050.

Table 4. 4 Budget allocation Detailed Design Phase

Code Activities Description

300Development and Integration

PhaseEngineers Type Number

Unit

Rate/day

M301Technical direction and

management reporting$3,500 $3,500

M301.1 Resource plan review Project Manager Type V 1 $500 3 $1,500

M301.2 Budget and schedule review Project Manager Type V 1 $500 2 $1,000

M301.3 MCSS subsystem integration

test direction (verified)Project Manager Type V 1 $500 2 $1,000

M302 Risk management Project Manager Type V 1 $500 3 $1,500 $1,500 $5,000

1) Test Engineer Type III 2 $250 5 $2,500

2) QA Engineer Type III 1 $150 5 $750

1) Test Engineer Type III 2 $250 5 $2,500

2) QA Engineer Type III 1 $150 5 $750

1) Test Engineer Type III 2 $250 5 $2,500

2) QA Engineer Type III 1 $150 5 $750

Q304

Prepare finalize whole

subsystem integration test

procedure

Senior System

EngineerType V 1 $350 3 $1,050 $1,050 $15,800

1) Test Engineer Type III 2 $250 5 $2,500

2) QA Engineer Type III 1 $150 5 $750

Sub-total $19,050 $19,050

$19,050

Cumulative

cost

$8,250

$11,500

$14,750

$3,250

Working

days

Manpower resourcesManpower

cost

High level

sub-total

cost

$3,250

$3,250

$3,250Q305MCSS subsystem integration

test (verified)

Q301 Execute Switch Control test

Q302 Execute Timing Generator test

Q303Execute Test and Monitoring

test

34

M301 M302 Q301 Q302 Q303 Q304 Q305

High level sub-total cost $3,500 $1,500 $3,250 $3,250 $3,250 $1,050 $3,250

Cumulative cost $3,500 $5,000 $8,250 $11,500 $14,750 $15,800 $19,050

$0

$5,000

$10,000

$15,000

$20,000

$25,000

Development and Integration Phase

Figure 4. 16 Budget accumulative Development and Integration Phase

4.1.4.4 Qualification and Installation (TRR-DRR)

Below is a listing work packages from TRR-DRR. The amount allocated for each is

determined by the daily rate and the number of people assigned to each work package . Total

manpower cost is $11.950.

Table 4. 5 Budget allocation Qualification and Installation Phase

Code Activities Description

400Qualification and Installation

PhaseEngineers Type Number

Unit

Rate/day

M401 Handing over documentation System Engineer Type III 1 $250 3 $750 $750 $750

M402 Risk management Project Manager Type V 1 $500 3 $1,500 $1,500 $2,250

M403Test and Evaluation

completion review$2,500 $4,750

M403.1 Budget and schedule review Project Manager Type V 1 $500 3 $1,500

M403.2 Project completed review Project Manager Type V 1 $500 2 $1,000

1) Test Engineer Type III 2 $250 4 $2,000

2) QA Engineer Type III 1 $150 4 $600

1) Test Engineer Type III 2 $250 4 $2,000

2) QA Engineer Type III 1 $150 4 $600

1) Test Engineer Type III 2 $250 4 $2,000

2) QA Engineer Type III 1 $150 4 $600

Logistic Engineer Type II 1 $200 3 $600 $600 $13,150

1) Test Engineer Type III 2 $250 3 $1,500

2) QA Engineer Type III 1 $150 3 $450

Sub-total $15,100 $15,100

$7,350

$9,950

$12,550

Cumulative

cost

$2,600

$2,600

$2,600

Q401

Q402

Q403

Final MCSS subsystem

operational test

Final MCSS subsystem factory

acceptance test

Final MCSS subsystem site

acceptance test

Manpower resourcesWorking

days

Manpower

cost

High level

sub-total

cost

Final MCSS subsystem

customer acceptance testQ404

$1,950 $15,100

35

M401 M402 M403 Q401 Q402 Q403 Q404

High level sub-total cost $750 $1,500 $2,500 $2,600 $2,600 $2,600 $2,550

Cumulative cost $750 $2,250 $4,750 $7,350 $9,950 $12,550 $15,100

$0

$2,000

$4,000

$6,000

$8,000

$10,000

$12,000

$14,000

$16,000

Qualification and Installation Phase

Figure 4. 17 Budget accumulative Qualification and Installation Phase

4.2 Test and Evaluation Control Plan

This section will specify the metrics, and control procedures necessary to measure the

requirements, schedule, budget, and the quality of work processes and work products22

.

The control plan will place at each project milestones23

. Project Manager, will develop

detailed plans based on established work assignments for T&E activities. The Management

Control System (MCS)24

tools will be used to document and track the work against major

program milestones. Table 4-6 identifies the primary tools that support T&E control plan.

22 The purpose of the Control function is to provide adequate visibility into actual project progress to allow

effective management action when the project performance deviates significantly from the plans. Forsberg, K.,

Mooz, H. and Cotterman, H., Visualising Project Management, John Wiley & Sons, Inc., 3rd edition, 2005.

Chapter 14 Project Control Page 254 – 277 23 Project control process should be in place at all level of the project. So that any deviation from planned events

can be quickly corrected. Kezsbom, D. S., Schilling, D. L . and Edward, K.A., Dynamic Project Management. A

practical guide for Managers and engineers, John Willey and Sons, New York, 1989. 24 Management control system is an integrated technique for collecting and using information to evaluate

performance. The MCS tools, supported by the WBS, cost, schedule, requirements and quality to be reviewed at

any T&E activities phase. Horngren, C., Sundem, G. and Stratton, W., 2005. Introduction to Management

Accounting, New Jersey, Pearson. Page 404.

36

Table 4. 6 T&E Management Control System

Tool Description SRR-PDR PDR-IRR IRR-TRR TRR-DRR

Bottom-Up Cost Estimating x x x x

Bottom-Up Time Estimate x x x x

Earned Value

Analysis

Schedule

Controlx x x x

Earned Value

AnalysisBudget Control x x x x

Verification

and ValidationQuality Control x x x x

Microsoft

Word

Reporting and

Communicationx x x x

Microsoft

WordDocumentation x x x x

4.2.1 Budget and Schedule Control

Project Manager is responsible for monitoring cost and schedule for the activities and for

estimating cost to complete and schedule completion on a monthly basis. The PM shall take

immediate corrective actions necessary to minimize project deviation from cost and schedule

baselines.

Using Earned Value Analysis (EVA)25

for each product component, the PM generates

variance analysis reports by comparing Actual Cost of Work Performed (ACWP), Budgeted

Cost of Work Scheduled (BCWS), Budgeted Cost of Work Performed (BCWP), and Estimate

at Completion. In addition, the Critical Path Method (CPM) will be used to control the

activities most crucial to completion of the project on-schedule.

The critical path illustrated in the section 4.1.2.5 shall receive special attention with respect to

completion on schedule26

. Following Table 4.7 sub lower level work packages depict the

budget and schedule control performed by Project Manager.

25 Earned Value Analysis (EVA) is used to assess the current cost situation as a function of performance to date.

Three cumulative cost curves (budgeted cost of work scheduled – BCWS, budgeted cost of work performed –

BCWP, Actual cost of work performed – ACWP) are shown from project initiation time to current reporting

time. HE: Eisner, H., Essentials of Project and Systems Engineering Management, 3rd Edition Page103 26 Failure to complete these activities within their allotted time will cause slippage of the entire schedule. HE:

Eisner, H., Essentials of Project and Systems Engineering Management, 3rd Edition Page103

37

Table 4. 7 Sub lower level work packages budget and schedule control

WBS ID Work Package Name Description Milestones

M101.2Cost and schedule

plan

To plan estimating cost tocomplete and schedule completion for the

T&E activitiesSRR-PDR

M201.2Cost and schedule

review

To monitor cost and schedule for the activities and for estimating cost

to complete and schedule completion on a monthly basis at PDR-IRRPDR-IRR

M301.2Cost and schedule

review

To monitor cost and schedule for the activities and for estimating cost

to complete and schedule completion on a monthly basis at IRR-TRRIRR-TRR

M403.1Cost and schedule

review

To monitor cost and schedule for the activities and for estimating cost

to complete and schedule completion on a monthly basis at TRR-DRRTRR-DRR

4.2.2 Quality Control

This section specifies the mechanisms to be used to measure and control the quality of the

work processes and the resulting work products. Verification and validation27

will be use as

quality control mechanisms.

The Quality Assurance team under the direction of the QA Manager provides the Project

Manager with the assurance that all quality and control requirements are being accomplished.

In performing these duties, the QA Manager monitors adherence to all processes, procedures,

and plans through the delegation of responsibilities to the QA Team.

Following Table 4.8 work packages depict the quality control mechanism performed by

Quality Assurance team.

27 Verification: proof of compliance with specifications ―Was the solution built right?‖ Validation: proof that the

user(s) is satisfied ―Was the right solution built?‖ This Is a whole life-cycle process - V & V must be applied at

each stage in the system process. Forsberg,K.,Mooz,H., and Cotterman,H., Visualising Project Management,

John Wiley & Sons,Inc., 3rd Edition, 2005. Pages 361

Table 4. 8 Work packages depict the quality control process