MICAFIL High Current Transformer Bushings HIRIP / RTXF ... · IEC 60137 (2017) IEEE C57.19.01...

Transcript of MICAFIL High Current Transformer Bushings HIRIP / RTXF ... · IEC 60137 (2017) IEEE C57.19.01...

—MICAFIL High Current Transformer BushingsHIRIP / RTXF 36kV up to 40kA

—

MIC

AFI

L H

igh

Cur

rent

Tra

nsfo

rmer

Bus

hing

sH

IRIP

/ R

TX

F 36

kV u

p t

o 4

0kA

• MICAFIL HIRIP bushings build on 100 years of experience to deliver total safety and reliability over an extended service life that ensures maximum asset availability.

• Standard and customized designs offer the flexibility to suit a wide variety of customer applications, while the bushings remain partial discharge free even when operating at twice the nominal service voltage.

2 M I C A F I L H I G H CU R R E NT TR A N S FO R M E R B U S H I N G S H I R IP/RT X F 3 6 K V U P TO 4 0 K A

ABB Switzerland’s MICAFIL bushings factory, based in Zurich, developed the first Resin Impregnated Paper (RIP) bushings in the 60’s, along with traditional OIP (Oil Impregnated Paper) and RBP (Resin Bonded Paper) bushings. Subsequently, we were the first company worldwide to start production of 420 kV RIP bushings at the end of the 80’s and 550 kV RIP bushings in 1996. Today, and for the last 30 years, we have exclusively produced RIP bushings. The latest new paperless RIS (Resin Impregnated Synthetics) technology launched in 2012.

ABB Switzerland Ltd, Insulation and Components has access to comprehensive resources, especially in the areas of high-voltage engineering, materials research and applied physics. The continuously improved design of our RIP high voltage bushings sets new standards regarding quality, reliability and safety.

We would like to support electrical utilities with achieving increasingly efficient performance of their assets, in addition to the ambitious targets of improved availability, higher safety standards

MICAFIL RIP bushing advantages• Excellent electrical and thermal properties• Partial discharge-free up to double

service voltage• High temperature resistance (class E, 120°C)• Low dielectric losses (tan δ ≤0.40 %)

Superb design• Compact conductor design• The materials are selected to provide the lowest

possible environmental impact over the whole product life cycle

Highest operational safety• Installation, transportation and operation

permitted in any position• Completely dry bushing, meaning no oil leakage

and lowest risk of explosion

Maintenance free• Maintenance and inspection-free bushing• A measuring tap allows for the assessment of

the insulation condition (capacitance and dissipation factor)

Standards• MICAFIL RIP high current bushings are specified

and tested according to the latest IEC 60137 (2017) and IEEE C57.19.00/01 (2000) standards

Benefits of the HIRIP series• Reduced number of components• High mechanical rigidity• Operation at low temperatures, down to -60°C• No joints (welding/brazing) in the current path

straight-through design• Smooth transition from the round hollow

conductor to the parallel terminals reduces the electrical resistance

• The integrated terminal pads of the conductor guarantee a better current distribution in the aluminum conductor

• Very long creepage distance • Integrated cooling ribs, mechanically protected

and cost reduction. Most utilities worldwide now recognize that our RIP technology makes a valuable contribution to achieving overall better performance figures. It is well worthwhile taking a brief look at the technical details of MICAFIL’s RIP technology.

MICAFIL RIP bushing technology The bushing condenser body consists of a solid core, made of wound crepe paper and inserted aluminum foils for electrical field control. The paper winding is vacuum dried and subsequently impregnated under vacuum with a high-temperature epoxy resin.

Vacuum drying, the impregnation of the paper winding with epoxy resin, and the final curing are very sensitive processes. They are carried out under vacuum in a controlled and hermetically sealed environment.

We are proud of our leading position in this technology field, providing our customers with profound expertise in the latest state-of-the-art technology, based on over 120,000 RIP bushings successfully in operation.

—High-voltage test laboratory up to BIL 1050 kV.

—Leading edge technology

MICAFIL brand products are the world leader in RIP and RIS technology for oil-free, dry bushings.

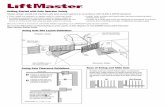

—High current transformer bushing in detail

Cross-section of the HIRIP bushing1 .Aluminum conductor 1a. Silver plated terminals (air side)1b. Silver plated terminals (oil side)2. Porcelain insulator3. Dry filling Micagel4. RIP condenser core5. Mounting flange with integrated measuring tap6. Current transformer extension (L6), if required

3

1a

1

2

3

4

5

6

1b

ØD1+10

L6

L

131.

5L2

ØD6

A

O

20

L1 +

L6

178

70

ØD1ØD2

ØD5

c1

c1

(b1)

ØD3

ØD4

(b2)

(b2)

c2

y1M12 (h1)

4020

85

y1

100

25.4

44.4

5

h1

1/2" UNC-2B (h1)

y2

100

44.4

525

.4

44.45

1/2" UNC-2B

y2

100

44.4

525

.4

44.45

1/2" UNC-2B

y2

M12

2040

(h2) (h2)

(h2) (h2)

85

50 y2 50 2040 85

M12

ØD2

ØD8

19

5x45

°

nxØv

Sealing area

ØD1+10

L6

L

131.

5L2

ØD6

A

O

20

L1 +

L6

178

70

ØD1ØD2

ØD5

c1

c1

(b1)

ØD3

ØD4

(b2)

(b2)

c2

y1M12 (h1)

4020

85

y1

100

25.4

44.4

5

h1

1/2" UNC-2B (h1)

y2

100

44.4

525

.4

44.45

1/2" UNC-2B

y2

100

44.4

525

.4

44.45

1/2" UNC-2B

y2

M12

2040

(h2) (h2)

(h2) (h2)

85

50 y2 50 2040 85

M12

ØD2

ØD8

19

5x45

°

nxØv

Sealing area

ØD1+10

L6

L

131.

5L2

ØD6

A

O

20

L1 +

L6

178

70

ØD1ØD2

ØD5

c1

c1

(b1)

ØD3

ØD4

(b2)

(b2)

c2

y1M12 (h1)

4020

85

y1

100

25.4

44.4

5

h1

1/2" UNC-2B (h1)

y2

100

44.4

525

.4

44.45

1/2" UNC-2B

y2

100

44.4

525

.4

44.45

1/2" UNC-2B

y2

M12

2040

(h2) (h2)

(h2) (h2)

85

50 y2 50 2040 85

M12

ØD2

ØD8

19

5x45

°

nxØv

Sealing area

ØD1+10

L6

L

131.

5L2

ØD6

A

O

20

L1 +

L6

178

70

ØD1ØD2

ØD5

c1

c1

(b1)

ØD3

ØD4

(b2)

(b2)

c2

y1M12 (h1)

4020

85

y1

100

25.4

44.4

5

h1

1/2" UNC-2B (h1)

y2

100

44.4

525

.4

44.45

1/2" UNC-2B

y2

100

44.4

525

.4

44.45

1/2" UNC-2B

y2

M12

2040

(h2) (h2)

(h2) (h2)

85

50 y2 50 2040 85

M12

ØD2

ØD8

19

5x45

°

nxØv

Sealing area

ØD1+10

L6

L

131.

5L2

ØD6

A

O

20

L1 +

L6

178

70

ØD1ØD2

ØD5

c1

c1

(b1)

ØD3

ØD4

(b2)

(b2)

c2

y1M12 (h1)

4020

85

y1

100

25.4

44.4

5

h1

1/2" UNC-2B (h1)

y2

100

44.4

525

.4

44.45

1/2" UNC-2B

y2

100

44.4

525

.4

44.45

1/2" UNC-2B

y2

M12

2040

(h2) (h2)

(h2) (h2)

85

50 y2 50 2040 85

M12

ØD2

ØD8

19

5x45

°

nxØv

Sealing area

ØD1+10

L6

L

131.

5L2

ØD6

A

O

20

L1 +

L6

178

70

ØD1ØD2

ØD5

c1

c1

(b1)

ØD3

ØD4

(b2)

(b2)

c2

y1M12 (h1)

4020

85

y1

100

25.4

44.4

5

h1

1/2" UNC-2B (h1)

y2

100

44.4

525

.4

44.45

1/2" UNC-2B

y2

100

44.4

525

.4

44.45

1/2" UNC-2B

y2

M12

2040

(h2) (h2)

(h2) (h2)

85

50 y2 50 2040 85

M12

ØD2

ØD8

19

5x45

°

nxØv

Sealing area

ØD1+10

L6

L

131.

5L2

ØD6

A

O

20

L1 +

L6

178

70

ØD1ØD2

ØD5

c1

c1

(b1)

ØD3

ØD4

(b2)

(b2)

c2

y1M12 (h1)

4020

85

y1

100

25.4

44.4

5

h1

1/2" UNC-2B (h1)

y2

100

44.4

525

.4

44.45

1/2" UNC-2B

y2

100

44.4

525

.4

44.45

1/2" UNC-2B

y2

M12

2040

(h2) (h2)

(h2) (h2)

85

50 y2 50 2040 85

M12

ØD2

ØD8

19

5x45

°

nxØv

Sealing area

ØD1+10

L6

L

131.

5L2

ØD6

A

O

20

L1 +

L6

178

70ØD1ØD2

ØD5

c1

c1

(b1)

ØD3

ØD4

(b2)

(b2)

c2

y1M12 (h1)

4020

85

y1

100

25.4

44.4

5

h1

1/2" UNC-2B (h1)

y2

100

44.4

525

.4

44.45

1/2" UNC-2B

y210

0

44.4

525

.4

44.45

1/2" UNC-2B

y2

M1220

40

(h2) (h2)

(h2) (h2)

85

50 y2 50 2040 85

M12

ØD2

ØD8

19

5x45

°

nxØv

Sealing area

ØD1+10

L6

L

131.

5L2

ØD6

A

O

20

L1 +

L6

178

70

ØD1ØD2

ØD5

c1

c1

(b1)

ØD3

ØD4

(b2)

(b2)

c2

y1M12 (h1)

4020

85

y1

100

25.4

44.4

5

h1

1/2" UNC-2B (h1)

y2

100

44.4

525

.4

44.45

1/2" UNC-2B

y2

100

44.4

525

.4

44.45

1/2" UNC-2B

y2

M12

2040

(h2) (h2)

(h2) (h2)

85

50 y2 50 2040 85

M12

ØD2

ØD8

19

5x45

°

nxØv

Sealing area

ØD1+10

L6

L

131.

5L2

ØD6

A

O20

L1 +

L6

178

70

ØD1ØD2

ØD5

c1

c1

(b1)

ØD3

ØD4

(b2)

(b2)

c2

y1M12 (h1)

4020

85

y1

100

25.4

44.4

5

h1

1/2" UNC-2B (h1)

y2

100

44.4

525

.4

44.45

1/2" UNC-2B

y2

100

44.4

525

.444.45

1/2" UNC-2B

y2

M12

2040

(h2) (h2)

(h2) (h2)

8550 y2 50 20

40 85

M12

ØD2

ØD8

19

5x45

°

nxØv

Sealing area

4 M I C A F I L H I G H CU R R E NT TR A N S FO R M E R B U S H I N G S H I R IP/RT X F 3 6 K V U P TO 4 0 K A

—Dimensions —

Vacuum impregnation and casting vessels.

Fig 1

Fig 20a

Fig 30a

Fig 10

Fig 20b

Air side terminal Oil side detail

Fig 30b

Fig 20c

Fig 30c

Terminal geometry (version 2)

Terminal geometry (version 1)

FlangeBushing details Flange details

Air side terminal Oil side terminal

6 M I C A F I L H I G H CU R R E NT TR A N S FO R M E R B U S H I N G S H I R IP/RT X F 3 6 K V U P TO 4 0 K A 7

—Technical data

Notes:1. Reference current with current transformer extension = 0 mm, maximum daily mean oil temperature = 90 °C

and maximum daily mean air temperature = 70 °C in bus duct, frequency = 50Hz 2. Recommended for 48mm wide flexible connector

Common specifications

Please consult ABB Switzerland Ltd, High Voltage Components for conditions that are outside of the standard specification below.

Application Generator step-up-transformersClassification Dry, Resin Impregnated Paper (RIP), capacitive gradedDry filling MicagelAmbient temperature -60°C, minimum value acc. to temperature class 2 of IEC60137 (2017) Bus duct air temperature see Fig. 100 – 117Altitude of installation max. 1000 mPollution level HeavyMounting angle Vertical up to horizontalMarkings According to IEC/IEEE

Type and DrawingsElectrical characteristics Insulator

dataMechanical

designWeight

Dimensions

IEC 60137 (2017) IEEE C57.19.01 (2000) Current Total Oil side Air side Flange Air side terminal Oil side terminal

Rod conductor bushings

Out

line

dra

win

g nu

mb

er

Bus

hing

dim

ensi

ons

Rat

ed v

olt

age

Phas

e-to

-ear

th

AC

tes

t vo

ltag

e d

ry /

wet

Lig

htni

ng im

pul

se

volt

age,

1.2

/50

μs

No

min

al s

yste

m v

olt

age

Rat

ed m

ax. l

ine-

to-g

roun

d vo

ltag

e

AC

tes

t vo

ltag

e d

ry /

wet

Lig

htni

ng im

pul

se

volt

age,

1.2

/50

μs

Ref

eren

ce c

urre

nt N

ote

1

Max

imum

op

erat

ing

curr

ent

The

rmal

sho

rt-t

ime

curr

ent

Min

. cre

epag

e d

ista

nce

Min

. Arc

ing

dis

tanc

e

Can

tile

ver

test

load

1 m

in.

Can

tile

ver

op

erat

ing

load

Wei

ght

Bus

hing

leng

th w

ith

term

inal

s

Cur

rent

tra

nsfo

rmer

ex

tens

ion

(CT

)

Low

er c

ore

leng

th

Co

re d

iam

eter

Air

sid

e le

ngth

of

the

bus

hing

Max

. Hea

d d

iam

eter

Max

. She

d d

iam

eter

Pit

ch c

ircl

e d

iam

eter

Out

sid

e fl

ang

e d

iam

eter

Seal

ing

area

: min

. dia

met

er

Seal

ing

area

max

. dia

met

er

Num

ber

of

hole

s

Ho

le d

iam

eter

Flan

ge

dim

ensi

ons

Min

. air

sid

e te

rmin

al t

hick

ness

Term

inal

pad

dis

tanc

e (a

ir s

ide)

Min

. air

sid

e co

nnec

tio

n ar

ea w

idth

Num

ber

of

air

sid

e co

nnec

tio

n su

rfac

es e

ach

No

te 2

Term

inal

ver

sio

n 1

Term

inal

ver

sio

n 2

Min

. oil

sid

e te

rmin

al t

hick

ness

Wid

th o

f te

rmin

al a

rea

(oil

sid

e)

Min

imum

oil

sid

e co

nnec

tio

n ar

ea w

idth

Num

ber

of

oil

sid

e co

nnec

tio

n su

rfac

es e

ach

No

te 2

Term

inal

ver

sio

n 1

Term

inal

ver

sio

n 2

Um Um/√3 AC BIL Usys UL-G AC BIL Ith 2sec L L6 L16 D1 L2 D5 D6 D3 D4 D2 D8 n v b1 c1 h1 y1 (b2) c2 (h2) y2

Fig. kV kV kV kV kV kV kV kV kA Fig. kA mm mm N N kg mm mm mm mm mm mm mm mm mm mm mm - mm Fig. mm mm mm - Fig. Fig. mm mm mm - Fig. Fig.

36–200/7000 1ZCD061816 1 36 21 77/70 170 34.5 22 80/75 200 7

100

100 1080 310 5000 2500

72 875 0 120

220 486 280 400 290 335 230 260 12 15 10 20 150 53 8

20a 30a

19 108 152 6

20b20c

30b 30c

101 77 975 100 220

102 87 1175 300 420

36–200/11000 1ZCD061556 1 36 21 77/70 170 34.5 22 80/75 200 11

103

100 1080 310 5000 2500

107 875 0 120

300 486 360 480 400 450 310 360 12 20 10 22 234 53 12 19 148 200 8104 114 975 100 220

105 129 1175 300 420

36–200/15500 1ZCD061820 1 36 21 77/70 170 34.5 22 80/75 200 16

106

100 1080 310 5000 2500

153 875 0 140

400 486 470 585 535 590 410 490 16 22 10 23 335 52 20 19 208 250 10107 163 975 100 240

108 184 1175 300 440

36–200/22000 1ZCD061826 1 36 21 77/70 170 34.5 22 80/75 200 22

109

100 1080 310 5000 2500

208 875 0 140

525 486 590 710 620 680 535 585 16 22 10 23 462 52 28 19 238 350 14110 222 975 100 240

111 251 1175 300 440

36–200/26000 1ZCD061855 1 36 21 77/70 170 34.5 22 80/75 200 26

112

100 1080 310 5000 2500

255 875 0 175

625 486 695 815 720 780 635 675 16 22 10 23 557 53 32 19 233 450 18113 273 975 100 275

114 309 1175 300 475

36–200/37000 1ZCD061892 1 36 21 77/70 170 34.5 22 80/75 200 37

115

100 1080 310 5000 2500

362 875 0 140

835 486 905 1025 930 990 845 885 24 22 10 24 768 53 44 19 358 550 22116 387 975 100 240

117 436 1175 300 440

8 M I C A F I L H I G H CU R R E NT TR A N S FO R M E R B U S H I N G S H I R IP/RT X F 3 6 K V U P TO 4 0 K A 109

—Operating current diagrams

The rating plate current value, also given in the designation of the MICAFIL high current bushing, is a reference current and not the permissible current for the bushing. The permissible current depends on the temperature conditions around the bushing. Based on the temperature of the surrounding transformer oil and the ambient temperature of the air side of the bushing, one can calculate the permissible current by using the diagrams in Fig. 100 to 117.

4.5

70

60

80

5.0

5.5

6.0

6.5

7.0

7.5

8.0

8.5

9.0

L6 = 0

I r (kA

)

Tair (°C)

4.5

70

60

80

5.0

5.5

6.0

6.5

7.0

7.5

8.0

8.5

9.0

L6 = 100

I r (kA

)

Tair (°C)

4.5

4.0 4.0 4.0

70

60

8090

90

90

5.0

5.5

6.0

6.5

7.0

7.5

8.0

8.5

9.0

70 80 90 100

Toil (°C)

70 80 90 100

Toil (°C)

70 80 90 100

Toil (°C)

L6 = 300

I r (kA

)

Tair (°C)

10.0

70

70

60

80

80 90 100

11.0

12.0

13.0

14.0

16.0

15.0

18.0

17.0

19.0

20.0

10.0

11.0

12.0

13.0

14.0

16.0

15.0

18.0

17.0

19.0

20.0

10.0

11.0

12.0

13.0

14.0

16.0

15.0

18.0

17.0

19.0

20.0

Toil (°C)

L6 = 0

I r (kA

)

Tair (°C)

70

70

60

80

80 90 100

Toil (°C)

L6 = 100

I r (kA

)

Tair (°C)

70

70

60

80

80 90 100

Toil (°C)

L6 = 300

I r (kA

)

Tair (°C)

7.0

70

60

80

8.0

9.0

10.0

11.0

12.0

13.0

14.0

7.0

8.0

9.0

10.0

11.0

12.0

13.0

14.0

7.0

8.0

9.0

10.0

11.0

12.0

13.0

14.0L6 = 0

I r (kA

)

Tair (°C)

70

60

80

L6 = 100

I r (kA

)

Tair (°C)

70

60

8090

90

90

70 80 90 100

6.0 6.0 6.0

Toil (°C)

70 80 90 100

Toil (°C)

70 80 90 100

Toil (°C)

L6 = 300

I r (kA

)

Tair (°C)

70

70

60

80

80 90 100

27.0

26.0

25.0

24.0

23.0

22.0

21.0

20.0

19.0

18.0

17.0

16.0

28.0

27.0

26.0

28.0

27.0

28.0

25.0

24.0

23.0

22.0

21.0

20.0

19.0

18.0

17.0

16.0

15.0

14.0

26.0

24.0

23.0

22.0

21.0

20.0

19.0

18.0

17.0

16.0

15.0

14.0

13.013.0

15.0

14.0

13.0

25.0

Toil (°C)

L6 = 0

I r (kA

)

Tair (°C)

70

70

60

80

80 90 100

Toil (°C)

L6 = 100

I r (kA

)

Tair (°C)

70

70

60

80

80 90 100

Toil (°C)

L6 = 300

I r (kA

)

Tair (°C)

Tair – maximum daily mean ambient temperature on the air side of the bushing. This depends on the type of installation. Usually, a busduct is used to encapsulate the bushing.

Toil – maximum daily mean temperature of the oil around the bushing (With forced cooling Toil is often relatively low compared to the maximum allowed temperature given in transformer standards).

L6 – current transformer extension

f – 50/60Hz

If all the connection pads are not occupied, the current could be limited, since the neighbour conductor will also influence the thermal behavior of the bushing.

—Condenser cores with a max. length of 9m can be produced.

—Current curve RTXF 36–200/7000, drawing no. 1ZCD061816, diagram no. 1ZCD063650

—Current curve RTXF 36–200/15500, drawing no. 1ZCD061820, diagram no. 1ZCD063648

—Current curve RTXF 36–200/11 000, drawing no. 1ZCD061556, diagram no. 1ZCD063649

—Current curve RTXF 36–200/22000, drawing no. 1ZCD061826, diagram no. 1ZCD063655

Fig. 100 Fig. 106

Fig. 103 Fig. 109

Fig. 101 Fig. 107

Fig. 104 Fig. 110

Fig. 102 Fig. 108

Fig. 105 Fig. 111

Bus temperature (daily mean)

Bus duct air temperature (daily mean), Tair

Transformer oil temperature (daily mean), Toil

Transformer lead temperature (daily mean)

12 M I C A F I L H I G H CU R R E NT TR A N S FO R M E R B U S H I N G S H I R I P/RT X F 3 6 K V U P TO 4 0 K A 1311

70

70

60

80

80 90 100

30.0

28.0

26.0

24.0

22.0

32.0

30.0

32.0

30.0

32.0

28.0

26.0

24.0

22.0

20.0

18.0

16.0

20.0

18.0

16.0

28.0

26.0

24.0

22.0

20.0

18.0

16.0

Toil (°C)

L6 = 0

I r (kA

)

Tair (°C)

70

70

60

80

80 90 100

Toil (°C)

L6 = 100

I r (kA

)

Tair (°C)

70

70

60

80

80 90 100

Toil (°C)

L6 = 300

I r (kA

)

Tair (°C)

70

70

60

80

80 90 100

24.0

26.0

28.0

30.0

32.0

34.0

36.0

38.0

40.0

42.0

24.0

26.0

28.0

30.0

32.0

34.0

36.0

38.0

40.0

42.0

24.0

26.0

22.022.022.0

28.0

30.0

32.0

34.0

36.0

38.0

40.0

42.0

Toil (°C)

L6 = 0

I r (kA

)

Tair (°C)

70

70

70

60

60

80

80

80 90 100

Toil (°C)

L6 = 100

I r (kA

)

Tair (°C)

70 80 90 100

Toil (°C)

L6 = 300

I r (kA

)

Tair (°C)

—Ordering information

—Other MICAFIL RIP and RIS bushings

RIP transformer bushings, oil-air

Series: AirRIP / RTKF KSISilicone composite insulator available with straight or helical shedsVoltage range: from 24 to 550 kVCurrent range: up to 5000 A

Series: AirRIP / RTKFPorcelain insulatorVoltage range: from 24 to 550 kVCurrent range: up to 5000 A

Series: SeismicRIP® / RTKF KSISilicone composite insulatorVoltage range: from 69 to 550 kVCurrent range: up to 5000 AStandard: IEEE 693 (2005) and IEC 61263 (2016)High seismic performance level

Series: HIRIP high-current RTXFPorcelain insulatorVoltage range: up to 36 kVCurrent range: up to 40 000 A

RIP transformer bushings, oil-SF6

Series: GARIP / RTKGVoltage range: from 36 to 550 kVCurrent range: up to 4000 A

RIP transformer bushings, oil-oil

Series: OilRIP / RTKKVoltage range: from 72.5 to 550 kVCurrent range: up to 4000 A

RIP outdoor-SF6 bushings for GIS

Series: RAKF Porcelain or silicone composite insulatorVoltage range: from 245 to 550 kVCurrent range: up to 4000 A

RIP wall bushings

Series: RMI indoor-indoor RMF outdoor-indoor RMFF outdoor-outdoor

Porcelain or silicone composite insulatorVoltage range: from 24 to 300 kVCurrent range: up to 5000 A

RIP railway bushings

Series: RMF / RTAK porcelain insulatorVoltage range: from 15 to 36 kVCurrent range: up to 2000 A

RIS transformer bushings, oil-air

Series: EasyDry / DMB-OASilicone composite insulator with straight shedsVoltage range: from 24 to 140 kVCurrent range: up to 2500 A

In addition to the transformer high current bushings described here, ABB Switzerland Ltd Insulation and Components offers other transformer bushings, GIS bushings, wall bushings and railway bushings, as well as customer tailored bushings.

Type designation

The type designation for high-current bushings is made up as follows:

Ordering number

The ordering number comprises two parts:

Part 1 – Ordering type number, which specifies the bushing type

Part 2 – Ordering modifications number, which specifies the bushing options

Current transformer extension (L6) [mm]

Porcelain insulator color

Terminal geometry*

Ordering modification number

0 brown version 1 R0011

0 brown version 2 R0012

0 grey version 1 R0021

0 grey version 2 R0022

100 brown version 1 R0111

100 brown version 2 R0112

100 grey version 1 R0121

100 grey version 2 R0122

300 brown version 1 R0311

300 brown version 2 R0312

300 grey version 1 R0321

300 grey version 2 R0322

Designation Ordering type number

HIRIP RTXF 36–200/7000 1ZCD061816

HIRIP RTXF 36–200/11000 1ZCD061556

HIRIP RTXF 36–200/15500 1ZCD061820

HIRIP RTXF 36–200/22000 1ZCD061826

HIRIP RTXF 36–200/26000 1ZCD061855

HIRIP RTXF 36–200/37000 1ZCD061892

Example

Part 1: RTXF 36–200/11000 - 1ZCD061556

Part 2:

Current transformer extension porcelain insulator color terminal geometry

0 brown version 1

- R0011

The complete ordering number is: 1ZCD061556R0011

—Current curve RTXF 36–200/26000, drawing no. 1ZCD061855, diagram no. 1ZCD063656

—Current curve RTXF 36–200/37000, drawing no. 1ZCD061892, diagram no. 1ZCD063657

Fig. 112

Fig. 115

Fig. 113

Fig. 116

Fig. 114

Fig. 117

HiRIP RTXF 36–200/11000

Reference current with current transformer extension = 0 mm, maximum daily mean oil temperature = 90 °C and maximum daily mean air temperature = 70 °C in bus duct, frequency = 50Hz

Rated lightning impulse withstand voltage (BIL) [kV]

Rated voltage [kV]

R = RIP insulation | T = transformer application | X = length of oil side | F = air side

HIgh current Resin Impregnated Paper bushing

Ordering type number (part 1)

Ordering type number (part 2)

* See table on page 7

1ZC

D0

823

28P

00

02

AA

EN

10

/20

18. S

ub

ject

to

ch

ang

e.

We reserve the right to make technical changes or modify the contents of this document without prior notice. With regard to purchase orders, the agreed particulars shall prevail. ABB Ltd. does not accept any responsibility what-soever for potential errors or possible lack of information in this document. We reserve all rights in this document and in the subject matter and illustrations contained therein. Any reproduction, disclosure to third parties or utilization of its contents – in whole or in parts – is forbid-den without prior written consent of ABB Ltd. Copyright© 2018 ABBAll rights reserved

—ABB Switzerland Ltd Insulation and Components MICAFIL Bushings Badenerstrasse 780CH-8048 ZurichSwitzerlandPhone: +41 (0)58 586 03 33E-mail: [email protected]

abb.com/transformercomponents 24/7 Service hotline for technical issues Phone: +41 (0)58 586 07 70