LPI 36 Technical Guide - Parr Lumber I-Joists 36 Series.pdfw = uniform load in plf K = shear...

Transcript of LPI 36 Technical Guide - Parr Lumber I-Joists 36 Series.pdfw = uniform load in plf K = shear...

Product Specifications & Design Values 2

Floor Span Tables 3

Uniform Floor Load (PLF) Tables: Simple Spans 4

Uniform Floor Load (PLF) Tables: Continuous Spans 5

Uniform Roof Load (PLF) Tables: Simple Spans 6

Uniform Roof Load (PLF) Tables: Continuous Spans 7

Web Hole Specifications: Circular Holes 8

Web Hole Specifications: Rectangular Holes 9

LP OSB Rim Board 10

Warranty 11

This guide must be used in conjunction with the Engineered Wood Product Guide.

LPI® 36Technical Guide

Floor & Roof Applications

LPEW0037_Mjw_LPI36_US_tguide 2/6/06 4:17 PM Page 1

RIM AND BLOCKING CAPACITY

DESIGN VALUES

NOTES:1. Moment, Shear and Reaction Capacity values are for normal load duration and may be adjusted according to code.2. When calculating deflection, both bending and shear deformation must be determined as follows:

For simple span, uniform load: Δ = + Where: Δ = deflection in inches EI = bending stiffness from tablew = uniform load in plf K = shear stiffness from tableL = design span in feet

3. The Moment capacity shall not be increased by any code-allowed repetitive member use factor.4. These design values are based on the product being used in a dry, well ventilated environment where the moisture content will not exceed

16% - such as in most covered structures. These products are intended to resist the effects of moisture on structural performance fromnormal construction delays but are not intended for permanent exposure to the weather.

22.5wL4 wL2

El K

NOTES:1. Lateral Load Capacity for all series above = 200 plf.2. For LPI Rim or Blocking used for lateral load transfer, nail to bearing

plate with same nail schedule as the deck-to-rim connection.

* Nail Size is for common or box nails.

Weight Moment EI (x 106) K (x 106) ShearReaction Capacity (lbs)

Depth End Bearing Interior Bearing (3-1/2" min.)

(plf) (lb-ft) (lb-in2) (lb-ft/in) (lbs) W/out Stiffeners With Stiffeners Min. Bearing W/out Stiffeners With Stiffeners

11-7/8" 3.10 6445 429 0.468 1615 1200 1510 1-3/4" 2800 3500

14" 3.35 7755 622 0.550 1830 1200 1510 1-3/4" 2800 3500

16" 3.60 8995 836 0.625 2020 1200 1510 1-3/4" 2800 3500

18" 3.85 10135 1082 0.700 2185 1200 1799 2-1/2" 2800 3500

20" 4.10 11270 1360 0.774 2320 1200 1857 2-1/2" 2800 3500

22" 4.35 12390 1669 0.850 2435 1200 1906 2-1/2" 2800 3500

24" 4.60 13505 2010 0.922 2525 1200 1945 2-1/2" 2800 3500

Series

LPI 36

DepthUniform Load

(plf)

11-7/8" 1800

14" 1800

16" 1800

18" 1300

20" 1300

22" 1200

24" 1100

Series

LPI 36

RIM AND BLOCKING NAIL SCHEDULE

Series

LPI 36

Minimum Nail DistanceNail Size

OC End

8d (2-1/2") Box 2-1/2" 4"

10d (3") & 12d (3-1/4") Box 3" 4"

10d (3") & 12d (3-1/4") Common* 3" 4"

16d (3-1/2") Common 4" 4"

Depth Minimum Maximum Nail Size* Nail QtyThickness Height

11-7/8" 23/32" 8-3/4" 8d (2-1/2") 4

14" 23/32" 10-7/8" 8d (2-1/2") 5

16" 23/32" 12-7/8" 8d (2-1/2") 6

18" 23/32" 14-7/8" 8d (2-1/2") 7

20" 23/32" 16-7/8" 8d (2-1/2") 8

22" 23/32" 18-7/8" 8d (2-1/2") 9

24" 23/32" 20-7/8" 8d (2-1/2") 10

Series

LPI 36

2© 2006 Louisiana-Pacific Corporation

Product Specifications & Design Values

LPI 36

2-1/4"

11-7/8",14", 16", 18", 20",22" or 24"

3/8"

1-1/2"

End support min. 1-3/4" bearing

Intermediate support min. 3-1/2" bearing

Nails to be equally spaced, staggered and driven

alternately from each face.Clinch nails where possible.

1/8" min. gap

1/8" min. gap1/8" min. gap1/8" min. gapConcentrated load

WEB STIFFENER REQUIREMENTS NOTES:1. Web stiffeners, when required, must be installed in pairs – one to each side

of the web. Web stiffeners are always required for the “Bird’s Mouth” roofbearing detail.

2. Web stiffeners should be cut to fit between the flanges of the I-Joist, leavinga minimum 1/8" gap (1" maximum). At bearing locations, the stiffenersshould be installed tight to the bottom flange with the gap to the top flange.At locations of concentrated loads, the stiffeners should be installed tight tothe top flange with the gap to the bottom flange.

3. Web stiffeners should be cut from APA-Rated OSB (or equal). 2X lumber ispermissible. Do NOT use 1x lumber as it tends to split.

4. Web stiffeners should be the same width as the bearing surface, with aminimum of 3-1/2".

5. See Web Stiffener Requirements table above for minimum stiffener thickness,maximum stiffener height and required nailing.

WEB STIFFENER REQUIREMENTS

* Includes 16d Sinker (3-1/4”)

LPEW0037_Mjw_LPI36_US_tguide 2/6/06 4:18 PM Page 2

SIMPLE SPAN TABLES

3 © 2006 Louisiana-Pacific Corporation

Floor Span Tables

DESIGN ASSUMPTIONS:1. The spans listed are the clear distance between supports.2. The spans are based on uniform loads only.3. These tables reflect the additional stiffness provided by 23/32” OSB APA-Rated

Sheathing (48/24) or APA-Rated Sturd-I-Floor (24" oc), or equivalent, glued and nailedto the top flange of the joists.

4. Live load deflection has been limited to L /480 or L /360 as indicated in the tablesabove (L /480 only for continuous spans).

5. Total deflection has been limited to L /240. Those spans that exceed 3/4" of totaldeflection are shown in bold.

6. The spans are based on the minimum required bearings as listed on page 2.

ADDITIONAL NOTES:1. Web stiffeners are not required for any of the spans listed in the Simple Span tables. Web stiffeners are only

required for the Continuous Span tables in the “With Web Stiffeners” section. A “-” indicates that there is noincrease in span through the use of web stiffeners. Web fillers are required for joists seated in hangers thatdo not laterally support the top flange.

2. L /360 is the minimum deflection criteria allowed per code, which allows the maximum amount of deflectionin the floor.

3. The design of continuous spans is based on the longest span. The shortest span must not be less than 50%of the longest span.

4. These spans are not evaluated for vibration.5. Bridging, blocking, a direct-applied ceiling and/or bottom-flange bracing, though not required for vertical

load capacity, can improve floor vibration and bounce.6. For conditions not shown, use the Uniform Floor Load (PLF) tables or contact your LP Engineered Wood

Products distributor for assistance.

TO USE:1. Select the appropriate table based on the project design loads.2. For simple spans, select the L /480 or L /360 section of that table, as required.

For continuous spans, select the section with or without web stiffeners, as needed.3. Find a span that meets or exceeds the design span.4. Read the corresponding joist depth and spacing.

Caution: For floor systems that require both simple span and continuous span joists, it is a good idea to check both before selecting a joist. Some conditions are controlledby continuous span strength rather than simple span deflection.

CONTINUOUS SPAN TABLES

Span

Simple (single) Span Application

SpanSpan Span

Continuous (multiple) Span Application

40 psf Live Load, 10 psf Dead LoadSeries Depth L/480 L / 360

12" oc 16" oc 19.2" oc 24" oc 12" oc 16" oc 19.2" oc 24" oc11-7/8" 23'-1" 21'-0" 19'-10" 18'-5" 25'-5" 23'-4" 22'-0" 20'-6"

LPI 36 14" 26'-1" 23'-10" 22'-5" 20'-10" 28'-11" 26'-4" 24'-11" 23'-2"16" 28'-10" 26'-3" 24'-9" 23'-0" 31'-11" 29'-1" 27'-5" 23'-8"

40 psf Live Load, 15 psf Dead LoadSeries Depth L/480 L / 360

12" oc 16" oc 19.2" oc 24" oc 12" oc 16" oc 19.2" oc 24" oc11-7/8" 23'-1" 21'-0" 19'-10" 18'-5" 25'-5" 23'-4" 22'-0" 20'-6"

LPI 36 14" 26'-1" 23'-10" 22'-5" 20'-10" 28'-11" 26'-4" 24'-11" 21'-6"16" 28'-10" 26'-3" 24'-9" 21'-6" 31'-11" 29'-1" 26'-11" 21'-6"

40 psf Live Load, 25 psf Dead LoadSeries Depth L/480 L / 360

12" oc 16" oc 19.2" oc 24" oc 12" oc 16" oc 19.2" oc 24" oc11-7/8" 23'-1" 21'-0" 19'-10" 18'-2" 24'-10" 22'-8" 21'-5" 18'-2"

LPI 36 14" 26'-1" 23'-10" 22'-5" 18'-2" 28'-1" 25'-8" 22'-9" 18'-2"16" 28'-10" 26'-3" 22'-9" 18'-2" 31'-0" 27'-4" 22'-9" 18'-2"

40 psf Live Load, 10 psf Dead Load @ L/480 Series Depth Without Web Stiffeners With Web Stiffeners

12" oc 16" oc 19.2" oc 24" oc 12" oc 16" oc 19.2" oc 24" oc11-7/8" 25'-2" 22'-11" 21'-7" 20'-1" - - - -

LPI 36 14" 29'-2" 25'-11" 24'-5" 22'-1" - - - 22'-9"16" 32'-3" 29'-4" 27'-8" 22'-1" - - - 25'-1"

40 psf Live Load, 15 psf Dead Load @ L/480Series Depth Without Web Stiffeners With Web Stiffeners

12" oc 16" oc 19.2" oc 24" oc 12" oc 16" oc 19.2" oc 24" oc11-7/8" 25'-2" 22'-11" 21'-7" 20'-0" - - - 20'-1"

LPI 36 14" 29'-2" 25'-11" 24'-5" 20'-0" - - - 22'-9"16" 32'-3" 29'-4" 25'-1" 20'-0" - - 27'-8" 25'-1"

40 psf Live Load, 25 psf Dead Load @ L /480Series Depth Without Web Stiffeners With Web Stiffeners

12" oc 16" oc 19.2" oc 24" oc 12" oc 16" oc 19.2" oc 24" oc11-7/8" 25'-2" 22'-11" 21'-2" 16'-11" - - 21'-7" 19'-7"

LPI 36 14" 29'-2" 25'-6" 21'-2" 16'-11" - 25'-11" 24'-2" 21'-2"16" 32'-3" 25'-6" 21'-2" 16'-11" - 28'-7" 26'-1" 21'-2"

LPEW0037_Mjw_LPI36_US_tguide 2/6/06 4:19 PM Page 3

4

Uniform Floor Load (PLF) Tables: Simple Spans

12'13'14'15'16'17'18'19'20'21'22'23'24'25'26'27'28'29'30'31'32'33'34'35'36'37'38'

TO USE:1. Select the span required. 2. Compare the design total load to the Total Load column. Where two numbers are

shown, the first number represents the Total Load capacity without web stiffeners.The second number represents the Total Load capacity with stiffeners. (SeeAdditional Notes below.)

3. Compare the design live load to the appropriate Live Load column.4. Select a product that exceeds both the design total and live loads.5. Specify web stiffeners as dictated by the Total Load column.

EXAMPLE:An I-Joist has the simple clear span of 22'-6", supporting 50 psf Floor Load and 25 psf Dead Load, spaced 24" oc. Select the shallowest joist that satisfies an L /600 live load deflection limit.1. Design Total Load = (50 + 25) * (24 / 12) = 150 plf

Design Live Load = 50 * (24 / 12) = 100 plf2. Select the row corresponding to a 23' span.3. Use the 22" LPI 36: Total Load = 162 plf and the Live Load at L/600 = 102 plf.

NOTE: Web stiffeners required at both end supports. (Exceeds Total Load without stiffeners = 102 plf)

DESIGN ASSUMPTIONS:1. Span is the clear distance between supports and is for simple spans only.2. The values are based on uniform loads of standard duration.3. These tables assume that the joist is NOT a repetitive member, therefore load

sharing has not been applied. Also, the deflection values do not reflect any additional stiffness due to composite action.

4. Total deflection has been limited to L/240. Long term deflection (creep) hasNOT been considered.

5. These tables assume full lateral support of the compression flange. Fullsupport is considered to be a maximum unbraced length of 24".

6. The values are based on the minimum required bearings as listed on page 2.

ADDITIONAL NOTES:1. The values represent the capacity of the joist in pounds per lineal foot (plf) of length. 2. The designer must check both the Total Load and the appropriate Live Load columns. 3. To design for a double I-Joist, the values in these tables can be doubled, or the design loads on the joist may be halved to

verify the capacity of each ply. The capacity is additive.4. Web stiffeners are not required where only one value is shown for Total Load or when the design total load does NOT exceed

the first value in the Total Load column where two values are given. Web stiffeners ARE required at both end supports if thedesign total load exceeds the first value (capacity without stiffeners) but does not exceed the second value (capacity withstiffeners). Web fillers are required for joists seated in hangers that do not laterally support the top flange or for hangers thatrequire nailing into the web.

5. Where the Live Load is blank, the Total Load governs the design.6. Do not use a product where designated “-” without further analysis by a professional engineer.

12'13'14'15'16'17'18'19'20'21'22'23'24'25'26'27'28'29'30'31'32'33'34'35'36'37'38'

Span(ft)

Span(ft)

12'13'14'15'16'17'18'19'20'21'22'23'24'25'26'27'28'29'30'31'32'33'34'35'36'37'38'

12'13'14'15'16'17'18'19'20'21'22'23'24'25'26'27'28'29'30'31'32'33'34'35'36'37'38'

20" LPI 36 22" LPI 36 24" LPI 36Live Load Total Live Load Total Live Load Total

L /600 L /480 L /360 Load L /600 L /480 L /360 Load L /600 L /480 L /360 Load193 / 299 193 / 307 193 / 313178 / 276 178 / 284 178 / 289166 / 257 166 / 264 166 / 269155 / 240 155 / 247 155 / 252

218 146 / 226 146 / 232 146 / 236187 137 / 213 137 / 218 137 / 223162 130 / 201 194 130 / 206 130 / 211140 175 123 / 191 169 123 / 196 199 123 / 200122 153 117 / 181 148 185 117 / 186 174 117 / 190107 134 112 / 173 130 162 112 / 177 154 112 / 18195 119 158 107 / 165 115 143 107 / 170 136 170 107 / 17384 105 140 102 / 158 102 127 102 / 162 121 151 102 / 16675 93 125 98 / 152 91 113 151 98 / 156 108 135 98 / 15967 84 112 94 / 141 81 101 135 94 / 149 96 120 94 / 15360 75 100 90 / 131 73 91 121 90 / 144 86 108 144 90 / 14754 67 90 87 / 121 65 82 109 87 / 133 78 98 130 87 / 14149 61 81 84 / 113 59 74 99 84 / 124 70 88 118 84 / 13544 55 74 81 / 105 54 67 90 81 / 116 64 80 107 81 / 12640 50 67 78 / 98 49 61 81 78 / 108 58 73 97 78 / 11836 46 61 76 / 92 44 55 74 76 / 101 53 66 89 76 / 11033 42 56 74 / 84 40 51 68 74 / 95 48 61 81 74 / 10430 38 51 71 / 77 37 46 62 71 / 89 44 56 74 71 / 9728 35 47 69 / 70 34 43 57 69 / 84 41 51 68 69 / 9226 32 43 65 31 39 52 67 / 79 37 47 63 67 / 8724 30 40 60 29 36 48 65 / 73 35 43 58 65 / 8222 27 37 55 27 33 45 64 / 67 32 40 54 64 / 7820 25 34 51 25 31 41 62 / 62 30 37 50 62 / 74

Span(ft)

Span(ft)

11-7/8" LPI 36 14" LPI 36 16" LPI 36 18" LPI 36Live Load Total Live Load Total Live Load Total Live Load Total

L /600 L /480 L /360 Load L /600 L /480 L /360 Load L /600 L /480 L /360 Load L /600 L /480 L /360 Load 166 208 195 / 245 230 195 / 245 195 / 245 193 / 289135 169 226 180 / 227 188 180 / 227 180 / 227 178 / 268111 139 186 167 / 211 156 195 167 / 211 202 167 / 211 166 / 24993 116 155 156 / 197 130 163 156 / 197 169 156 / 197 210 155 / 23378 97 130 147 / 185 110 137 183 147 / 185 143 179 147 / 185 179 146 / 21966 83 110 138 / 166 93 117 156 138 / 174 122 153 138 / 174 153 191 137 / 20656 70 94 131 / 141 80 100 133 131 / 165 105 131 131 / 165 131 164 130 / 19548 61 81 122 69 86 115 124 / 156 91 113 151 124 / 156 114 142 123 / 18542 52 70 105 60 75 100 118 / 148 79 99 132 118 / 148 99 124 166 117 / 17636 46 61 92 52 65 87 112 / 131 69 86 115 112 / 141 87 109 145 112 / 16832 40 54 81 46 57 76 107 / 115 61 76 101 107 / 135 77 96 128 107 / 16028 35 47 71 40 50 67 101 53 67 89 103 / 129 68 85 113 102 / 15025 31 42 63 36 45 60 90 47 59 79 98 / 119 60 75 101 98 / 13822 28 37 56 32 40 53 80 42 53 71 94 / 106 54 67 90 94 / 127- - - - 28 36 48 72 38 47 63 91 / 95 48 60 80 90 / 118- - - - 25 32 43 64 34 42 57 85 43 54 72 87 / 109- - - - 23 29 38 58 31 38 51 77 39 49 65 84 / 98- - - - 21 26 35 52 28 35 46 70 35 44 59 81 / 89- - - - 19 23 31 47 25 31 42 63 32 40 54 78 / 81- - - - - - - - 23 28 38 57 29 36 49 73- - - - - - - - 21 26 35 52 26 33 44 67- - - - - - - - 19 24 32 48 24 30 41 61- - - - - - - - 17 22 29 44 22 28 37 56- - - - - - - - - - - - 20 26 34 52- - - - - - - - - - - - 19 24 32 48- - - - - - - - - - - - 17 22 29 44- - - - - - - - - - - - 16 20 27 41

© 2006 Louisiana-Pacific Corporation

LPEW0037_Mjw_LPI36_US_tguide 2/6/06 4:19 PM Page 4

5

Uniform Floor Load (PLF) Tables: Continuous Spans

TO USE:1. Select the span required. 2. Compare the design total load to the Total Load column. Where two numbers are

shown, the first number represents the Total Load capacity without web stiffeners. The second number represents the Total Load capacity with stiffeners. (SeeAdditional Notes below.)

3. Compare the design live load to the appropriate Live Load column.4. Select a product that exceeds both the design total and live loads.5. Specify web stiffeners as dictated by the Total Load column.

EXAMPLE:An I-Joist has the continuous clear spans of 20'-8" and 22'-6", supporting 50 psf Floor Loadand 25 psf Dead Load, spaced 24" oc. Select the shallowest joist that satisfies an L /600 liveload deflection limit.1. Design Total Load = (50 + 25) * (24 / 12) = 150 plf

Design Live Load = 50 * (24 / 12) = 100 plf2. Select the row corresponding to a 23' span.3. Cannot use the LPI 36 series: maximum Total Load = 120 plf.

DESIGN ASSUMPTIONS:1. Span is the clear distance between supports and is for continuous spans only.

The design of continuous spans is based on the longest span. The shortestspan must not be less than 50% of the longest span.

2. The values are based on uniform loads of standard duration.3. These tables assume that the joist is NOT a repetitive member, therefore load

sharing has not been applied. Also, the deflection values do not reflect any additional stiffness due to composite action.

4. Total deflection has been limited to L/240. Long term deflection (creep) hasNOT been considered.

5. These tables assume full lateral support of the compression flange. Fullsupport is considered to be a maximum unbraced length of 24".

6. The values are based on the minimum required bearings as listed on page 2.

ADDITIONAL NOTES:1. The values represent the capacity of the joist in pounds per lineal foot (plf) of length. 2. The designer must check both the Total Load and the appropriate Live Load columns. 3. To design for a double I-Joist, the values in these tables can be doubled, or the design loads on the joist may be halved to

verify the capacity of each ply. The capacity is additive.4. Web stiffeners are not required where only one value is shown for Total Load or when the design total load does NOT exceed

the first value in the Total Load column where two values are given. Web stiffeners ARE required at interior supports if thedesign total load exceeds the first value (capacity without stiffeners) but does not exceed the second value (capacity withstiffeners). Additionally, if the second value is marked *, web stiffeners are required at all supports. Web fillers are requiredfor joists seated in hangers that do not laterally support the top flange or for hangers that require nailing into the web.

5. Where the Live Load is blank, the Total Load governs the design.6. Do not use a product where designated “-” without further analysis by a professional engineer.

© 2006 Louisiana-Pacific Corporation

12'13'14'15'16'17'18'19'20'21'22'23'24'25'26'27'28'29'30'31'32'33'34'35'36'37'38'

12'13'14'15'16'17'18'19'20'21'22'23'24'25'26'27'28'29'30'31'32'33'34'35'36'37'38'

Span(ft)

Span(ft)

12'13'14'15'16'17'18'19'20'21'22'23'24'25'26'27'28'29'30'31'32'33'34'35'36'37'38'

12'13'14'15'16'17'18'19'20'21'22'23'24'25'26'27'28'29'30'31'32'33'34'35'36'37'38'

20" LPI 36 22" LPI 36 24" LPI 36Live Load Total Live Load Total Live Load Total

L/ 600 L/480 L/ 360 Load L/ 600 L/480 L/ 360 Load L/ 600 L/480 L/ 360 Load181 / 226* 181 / 226* 181 / 226*167 / 209* 167 / 209* 167 / 209*156 / 195* 156 / 195* 156 / 195*145 / 182* 145 / 182* 145 / 182*136 / 171* 136 / 171* 136 / 171*129 / 161* 129 / 161* 129 / 161*122 / 152* 122 / 152* 122 / 152*115 / 144* 115 / 144* 115 / 144*110 / 137* 110 / 137* 110 / 137*104 / 131* 104 / 131* 104 / 131*

123 100 / 125* 100 / 125* 100 / 125*109 95 / 119* 95 / 119* 95 / 119*97 91 / 114* 91 / 114* 91 / 114*87 109 88 / 110* 105 88 / 110* 88 / 110*78 98 84 / 106* 95 84 / 106* 84 / 106*70 88 81 / 102* 85 81 / 102* 101 81 / 102*63 79 79 / 98* 77 96 79 / 98* 92 79 / 98*57 72 76 / 95* 70 87 76 / 95* 83 76 / 95*52 65 87 73 / 92* 63 79 73 / 92* 76 73 / 92*48 60 80 71 / 89* 58 72 71 / 89* 69 87 71 / 89*43 54 73 69 / 86* 53 66 69 / 86* 63 79 69 / 86*40 50 67 67 / 81* 48 61 81 67 / 83* 58 73 67 / 83*36 46 61 65 / 76 44 56 74 65 / 81* 53 67 65 / 81*34 42 56 63 / 72 41 51 69 63 / 79* 49 61 63 / 79*31 39 52 61 / 68 38 47 63 61 / 75* 45 57 76 61 / 77*29 36 48 59 / 64 35 44 58 59 / 71* 42 52 70 59 / 74*26 33 44 58 / 61 32 40 54 58 / 67 39 49 65 58 / 73*

Span(ft)

Span(ft)

11-7/8" LPI 36 14" LPI 36 16" LPI 36 18" LPI 36Live Load Total Live Load Total Live Load Total Live Load Total

L/ 600 L/480 L/ 360 Load L/ 600 L/480 L/ 360 Load L/ 600 L/480 L/ 360 Load L/ 600 L/480 L/ 360 Load 182 / 211 182 / 227* 182 / 227* 181 / 226*

173 168 / 195 168 / 210* 168 / 210* 167 / 209*143 179 156 / 181 156 / 195* 156 / 195* 156 / 195*119 149 146 / 169 167 146 / 183* 146 / 183* 145 / 182*100 126 137 / 159 141 137 / 171* 137 / 171* 136 / 171*85 107 142 129 / 150 120 150 129 / 161* 157 129 / 161* 129 / 161*73 91 122 122 / 141 103 129 122 / 153* 135 122 / 153* 122 / 152*63 79 105 116 / 134 89 111 116 / 145* 117 116 / 145* 115 / 144*54 68 91 110 / 126 77 97 129 110 / 137* 102 127 110 / 137* 129 110 / 137*47 59 79 105 / 114 68 85 113 105 / 131* 89 112 105 / 131* 113 104 / 131*42 52 70 100 / 104 59 74 99 100 / 125* 78 98 100 / 125* 100 125 100 / 125*37 46 61 92 52 66 88 96 / 115* 69 87 116 96 / 120* 88 110 95 / 119*32 41 54 82 46 58 78 92 / 105 62 77 103 92 / 115* 78 98 91 / 114*29 36 48 73 41 52 69 88 / 97 55 69 92 88 / 110* 70 88 88 / 110*- - - - 37 46 62 85 / 90 49 62 82 85 / 104* 63 79 105 84 / 106*- - - - 33 42 56 82 / 83 44 55 74 82 / 97 56 71 94 81 / 102*- - - - 30 37 50 75 40 50 67 79 / 90 51 64 85 79 / 98*- - - - 27 34 45 68 36 45 60 76 / 84 46 58 77 76 / 94*- - - - 24 31 41 62 33 41 55 73 / 78 42 52 70 73 / 88*- - - - - - - - 30 37 50 71 / 73 38 48 64 71 / 83- - - - - - - - 27 34 45 68 35 44 58 69 / 77- - - - - - - - 25 31 42 63 32 40 53 67 / 73- - - - - - - - 23 28 38 57 29 37 49 65 / 69- - - - - - - - - - - - 27 34 45 63 / 65- - - - - - - - - - - - 25 31 41 61- - - - - - - - - - - - 23 29 38 58- - - - - - - - - - - - 21 26 35 53

LPEW0037_Mjw_LPI36_US_tguide 2/6/06 4:20 PM Page 5

ROOF SLOPE ADJUSTMENT FACTORS

11-7/8" LPI 36 14" LPI 36 16" LPI 36 18" LPI 36Span

Live Load Total Load Live Load Total Load Live Load Total Load Live Load Total LoadSpan

(ft)L/240 Snow 115% Non-Snow 125% L/240 Snow 115% Non-Snow 125% L/240 Snow 115% Non-Snow 125% L/240 Snow 115% Non-Snow 125%

(ft)

12' 224 / 282 244 / 307 224 / 282 244 / 307 224 / 282 244 / 307 222 / 333 241 / 362 12'13' 207 / 261 225 / 284 207 / 261 225 / 284 207 / 261 225 / 284 205 / 308 223 / 335 13'14' 193 / 243 209 / 264 193 / 243 209 / 264 193 / 243 209 / 264 191 / 287 208 / 311 14'15' 233 180 / 227 196 / 246 180 / 227 196 / 246 180 / 227 196 / 246 179 / 268 194 / 291 15'16' 195 169 / 213 184 / 231 169 / 213 184 / 231 169 / 213 184 / 231 168 / 252 182 / 273 16'17' 166 159 / 200 173 159 / 200 173 / 218 159 / 200 173 / 218 158 / 237 172 / 258 17'18' 141 150 164 200 150 / 189 164 / 206 150 / 189 164 / 206 149 / 224 162 / 244 18'19' 122 143 155 173 143 / 180 155 / 195 143 / 180 155 / 195 142 / 213 154 / 231 19'20' 105 136 141 150 136 / 171 147 / 186 136 / 171 147 / 186 135 / 202 146 / 220 20'21' 92 123 123 131 129 / 159 140 173 129 / 163 140 / 177 128 / 193 140 / 210 21'22' 81 108 108 115 123 134 152 123 / 155 134 / 169 192 123 / 184 133 / 200 22'23' 71 95 95 101 118 128 134 118 / 149 128 / 162 170 117 / 173 128 / 188 23'24' 63 84 84 90 113 120 119 113 / 141 123 151 113 / 159 122 / 172 24'25' 56 75 75 80 107 107 106 109 118 135 108 / 146 118 / 159 25'26' 50 67 67 72 96 96 95 104 114 121 104 / 135 113 / 147 26'27' 45 60 60 64 86 86 85 101 109 109 100 / 125 109 / 136 27'28' 40 54 54 58 77 77 77 97 103 98 97 / 117 105 28'29' 36 48 48 52 70 70 70 93 93 89 93 101 29'30' 33 44 44 47 63 63 63 84 84 81 90 98 30'31' 30 40 40 43 57 57 57 77 77 73 87 95 31'32' 27 36 36 39 52 52 52 70 70 67 85 89 32'33' 25 33 33 36 48 48 48 64 64 61 82 82 33'34' 23 30 30 33 44 44 44 59 59 56 75 75 34'35' 21 28 28 30 40 40 40 54 54 52 69 69 35'36' - - - 28 37 37 37 50 50 48 64 64 36'37' - - - 26 34 34 34 46 46 44 59 59 37'38' - - - 24 32 32 32 42 42 41 54 54 38'

6

Uniform Roof Load (PLF) Tables: Simple Spans

DESIGN ASSUMPTIONS:1. Span is the clear distance between

supports, along the length of thejoist, and is for simple spans only.

2. The values are based on uniformloads only.

3. These tables assume that the joistis NOT a repetitive member,therefore load sharing has not beenapplied. Also, the deflection valuesdo not reflect any additionalstiffness due to composite action.

4. Total deflection has been limited toL/180. Long term deflection (creep)has NOT been considered.

5. These tables assume full lateralsupport of the compression flange.Full support is considered to be amaximum unbraced length of 24".

6. The values are based on theminimum required bearings aslisted on page 2.

ADDITIONAL NOTES:1. The values represent the capacity of the joist in pounds per lineal foot (plf) of length. 2. The designer must check the appropriate Total Load column and the Live Load column. 3. For roofs with a slope of 2:12 or greater, the horizontal span must be multiplied by the appropriate slope

adjustment factor from the table at the bottom of this page.4. To design for a double I-Joist, the values in these tables can be doubled, or the design loads on the joist

may be halved to verify the capacity of each ply. The capacity is additive.

TO USE:1. Select the span required. For roofs with a slope of 2:12 or greater, the horizontal

span must be multiplied by the appropriate roof slope adjustment factor from thetable at the bottom of this page.

2. Compare the design total load to the appropriate Total Load column for Snow (115%) or Non-Snow (125%). Where two numbers are shown, the first number represents the Total Load capacity without web stiffeners. The second number represents the TotalLoad capacity with stiffeners. (See Additional Notes below.)

3. Compare the design live load to the Live Load column (L /240).4. Select a product that exceeds both the design total and live loads.5. Specify web stiffeners as dictated by the Total Load column.

EXAMPLE:An I-Joist has the horizontal clear span of 22'-6", supporting 50 psf Snow Load (115%) and 15 psf DeadLoad, spaced 24" oc, with a slope of 4:12. Select a joist that satisfies an L /240 live load deflection limit.1. Sloped Span = (22 + 6/12) * 1.054 = 23.7' ∞ use 24'2. Design Total Load = (50 + 15) * (24 / 12) = 130 plf

Design Live Load = 50 * (24 / 12) = 100 plf3. Select the row corresponding to a 24' span.4. Use the 16" LPI 36: Total Load (115%) = 141 plf and the Live Load at L /240 = 119 plf

NOTE: Web stiffeners required at both end supports. (Exceeds Total Load without stiffeners = 113 plf)ALSO: For an L /360 live load deflection limit, increase to an 18" LPI 36 from page 4 (L /360 = 101 plf).

Slope 2:12 3:12 4:12 5:12 6:12 7:12 8:12 9:12 10:12 11:12 12:12

Factor 1.014 1.031 1.054 1.083 1.118 1.158 1.202 1.250 1.302 1.357 1.414

20" LPI 36 22" LPI 36 24" LPI 36Span

Live Load Total Load Live Load Total Load Live Load Total LoadSpan

(ft)L/240 Snow 115% Non-Snow 125% L/240 Snow 115% Non-Snow 125% L/240 Snow 115% Non-Snow 125%

(ft)

12' 222 / 343 241 / 373 222 / 353 241 / 383 222 / 360 241 / 391 12'13' 205 / 318 223 / 346 205 / 326 223 / 355 205 / 333 223 / 362 13'14' 191 / 296 208 / 322 191 / 304 208 / 330 191 / 310 208 / 337 14'15' 179 / 277 194 / 301 179 / 284 194 / 309 179 / 290 194 / 315 15'16' 168 / 260 182 / 282 168 / 267 182 / 290 168 / 272 182 / 296 16'17' 158 / 245 172 / 266 158 / 251 172 / 273 158 / 256 172 / 279 17'18' 149 / 231 162 / 252 149 / 238 162 / 258 149 / 242 162 / 264 18'19' 142 / 219 154 / 239 142 / 225 154 / 245 142 / 230 154 / 250 19'20' 135 / 209 146 / 227 135 / 214 146 / 233 135 / 219 146 / 238 20'21' 128 / 199 140 / 216 128 / 204 140 / 222 128 / 208 140 / 227 21'22' 123 / 190 133 / 207 123 / 195 133 / 212 123 / 199 133 / 216 22'23' 117 / 182 128 / 198 117 / 187 128 / 203 117 / 191 128 / 207 23'24' 187 113 / 174 122 / 190 113 / 179 122 / 195 113 / 183 122 / 199 24'25' 168 108 / 163 118 / 177 108 / 172 118 / 187 108 / 176 118 / 191 25'26' 150 104 / 150 113 / 164 104 / 165 113 / 180 104 / 169 113 / 184 26'27' 135 100 / 140 109 / 152 164 100 / 153 109 / 167 100 / 163 109 / 177 27'28' 122 97 / 130 105 / 141 148 97 / 143 105 / 155 97 / 156 105 / 169 28'29' 111 93 / 121 101 / 132 135 93 / 133 101 / 145 93 / 145 101 / 158 29'30' 100 90 / 113 98 / 123 122 90 / 124 98 / 135 146 90 / 136 98 / 147 30'31' 92 87 / 106 95 111 87 / 117 95 / 127 133 87 / 127 95 / 138 31'32' 84 85 92 102 85 / 109 92 / 119 122 85 / 119 92 / 130 32'33' 77 82 89 93 82 / 103 89 / 112 112 82 / 112 89 / 122 33'34' 70 80 87 86 80 / 97 87 103 80 / 106 87 / 115 34'35' 65 77 84 79 77 / 91 84 94 77 / 100 84 / 108 35'36' 60 75 80 73 75 82 87 75 / 94 82 / 103 36'37' 55 73 74 67 73 80 81 73 / 89 80 / 97 37'38' 51 68 68 62 71 78 75 71 / 85 78 38'

© 2006 Louisiana-Pacific Corporation

5. Web stiffeners are not required where only one value is shown for Total Load or when the designtotal load does NOT exceed the first value in the Total Load column where two values are given.Web stiffeners ARE required at both end supports if the design total load exceeds the first value(capacity without stiffeners) but does not exceed the second value (capacity with stiffeners).Web fillers are required for joists seated in hangers that do not laterally support the top flangeor for hangers that require nailing into the web.

6. Where the Live Load is blank, the Total Load governs the design.7. To design for a live load limit of L /360, L /480 or L /600, use the Uniform Floor Load tables.8. Do not use a product where designated “-” without further analysis by a professional engineer.

LPEW0037_Mjw_LPI36_US_tguide 2/6/06 4:21 PM Page 6

7

Uniform Roof Load (PLF) Tables: Continuous Spans

DESIGN ASSUMPTIONS:1. Span is the clear distance between

supports, along the length of thejoist, and is for continuous spansonly. The design of continuousspans is based on the longest span.The shortest span must not be lessthan 50% of the longest span.

2. The values are based on uniformloads only.

3. These tables assume that the joistis NOT a repetitive member,therefore load sharing has not beenapplied. Also, the deflection valuesdo not reflect any additionalstiffness due to composite action.

4. Total deflection has been limited toL/180. Long term deflection (creep)has NOT been considered.

5. These tables assume full lateralsupport of the compression flange.Full support is considered to be amaximum unbraced length of 24".

6. The values are based on theminimum required bearings aslisted on page 2.

ADDITIONAL NOTES:1. The values represent the capacity of the joist in pounds per lineal foot (plf) of length. 2. The designer must check the appropriate Total Load column and the Live Load column. 3. For roofs with a slope of 2:12 or greater, the horizontal span must be multiplied by the appropriate slope

adjustment factor from the table at the bottom of this page.4. To design for a double I-Joist, the values in these tables can be doubled, or the design loads on the joist

may be halved to verify the capacity of each ply. The capacity is additive.

TO USE:1. Select the span required. For roofs with a slope of 2:12 or greater, the horizontal span

must be multiplied by the appropriate roof slope adjustment factor from the table atthe bottom of this page.

2. Compare the design total load to the appropriate Total Load column for Snow (115%) or Non-Snow (125%). Where two numbers are shown, the first number represents the Total Load capacity without web stiffeners. The second number represents the TotalLoad capacity with stiffeners. (See Additional Notes below.)

3. Compare the design live load to the Live Load column (L /240).4. Select a product that exceeds both the design total and live loads.5. Specify web stiffeners as dictated by the Total Load column.

EXAMPLE:An I-Joist has the horizontal clear span of 20'-8", supporting 50 psf Snow Load (115%) and 15 psf Dead Load, spaced 24" oc, with a slope of 4:12. Select a joist that satisfies an L /240 live load deflection limit.1. Sloped Span = (22 + 6/12) * 1.054 = 23.7' ∞ use 24'2. Design Total Load = (50 + 15) * (24 / 12) = 130 plf

Design Live Load = 50 * (24 / 12) = 100 plf3. Select the row corresponding to a 24' span.4. Use the 16" LPI 36: Total Load (115%) = 132 plf. Live Load at L /240 does not control.

NOTE: Web stiffeners required at all supports. (Exceeds Total Load without stiffeners = 106 plf, and marked *)

© 2006 Louisiana-Pacific Corporation

11-7/8" LPI 36 14" LPI 36 16" LPI 36 18" LPI 36Span

Live Load Total Load Live Load Total Load Live Load Total Load Live Load Total LoadSpan

(ft)L/240 Snow 115% Non-Snow 125% L/240 Snow 115% Non-Snow 125% L/240 Snow 115% Non-Snow 125% L/240 Snow 115% Non-Snow 125%

(ft)

12' 209 / 243 227 / 264 209 / 261* 227 / 281* 209 / 261* 227 / 281* 208 / 260* 226 / 280* 12'13' 193 / 224 210 / 244 193 / 242* 210 / 260* 193 / 242* 210 / 260* 192 / 241* 209 / 259* 13'14' 180 / 208 195 / 227 180 / 225* 195 / 242* 180 / 225* 195 / 242* 179 / 224* 195 / 241* 14'15' 168 / 195 183 / 212 168 / 210* 183 / 226* 168 / 210* 183 / 226* 167 / 209* 182 / 225* 15'16' 158 / 183 171 / 199 158 / 197* 171 / 212* 158 / 197* 171 / 212* 157 / 196* 171 / 211* 16'17' 148 / 172 161 / 187 148 / 186* 161 / 200* 148 / 186* 161 / 200* 148 / 185* 161 / 199* 17'18' 140 / 163 153 140 / 176* 153 / 189* 140 / 176* 153 / 189* 140 / 175* 152 / 188* 18'19' 158 133 145 133 / 166* 145 / 179* 133 / 166* 145 / 179* 133 / 166* 144 / 179* 19'20' 137 126 137 126 / 158* 137 / 170* 126 / 158* 137 / 170* 126 / 158* 137 / 170* 20'21' 119 120 131 120 / 151* 131 / 162* 120 / 151* 131 / 162* 120 / 150* 131 / 162* 21'22' 105 115 125 149 115 / 144* 125 115 / 144* 125 / 155* 115 / 144* 125 / 155* 22'23' 92 109 119 132 110 120 110 / 138* 120 / 148* 110 / 137* 119 / 148* 23'24' 82 101 109 117 106 115 106 / 132* 115 / 142* 105 / 132* 114 / 142* 24'25' 73 93 97 104 101 110 101 / 127* 110 101 / 127* 110 / 136* 25'26' 65 86 87 93 97 106 124 97 106 97 / 122* 106 / 131* 26'27' 58 78 78 84 94 102 111 94 102 94 / 117* 102 / 126* 27'28' 52 70 70 75 89 97 100 91 98 90 / 113* 98 / 122* 28'29' 47 63 63 68 83 90 91 87 95 116 87 / 108* 95 29'30' 43 57 57 62 78 82 82 85 92 105 84 92 30'31' 39 52 52 56 73 75 75 82 89 96 82 89 31'32' 35 47 47 51 68 68 68 79 86 88 79 86 32'33' 32 43 43 47 63 63 63 74 81 80 77 83 33'34' 30 40 40 43 57 57 57 70 76 74 74 81 34'35' 27 36 36 39 53 53 53 66 70 68 72 79 35'36' - - - 36 49 49 49 63 65 62 70 77 36'37' - - - 33 45 45 45 59 60 58 67 73 37'38' - - - 31 41 41 41 55 55 53 63 69 38'

20" LPI 36 22" LPI 36 24" LPI 36Span

Live Load Total Load Live Load Total Load Live Load Total LoadSpan

(ft)L/240 Snow 115% Non-Snow 125% L/240 Snow 115% Non-Snow 125% L/240 Snow 115% Non-Snow 125%

(ft)

12' 208 / 260* 226 / 280* 208 / 260* 226 / 280* 208 / 260* 226 / 280* 12'13' 192 / 241* 209 / 259* 192 / 241* 209 / 259* 192 / 241* 209 / 259* 13'14' 179 / 224* 195 / 241* 179 / 224* 195 / 241* 179 / 224* 195 / 241* 14'15' 167 / 209* 182 / 225* 167 / 209* 182 / 225* 167 / 209* 182 / 225* 15'16' 157 / 196* 171 / 211* 157 / 196* 171 / 211* 157 / 196* 171 / 211* 16'17' 148 / 185* 161 / 199* 148 / 185* 161 / 199* 148 / 185* 161 / 199* 17'18' 140 / 175* 152 / 188* 140 / 175* 152 / 188* 140 / 175* 152 / 188* 18'19' 133 / 166* 144 / 179* 133 / 166* 144 / 179* 133 / 166* 144 / 179* 19'20' 126 / 158* 137 / 170* 126 / 158* 137 / 170* 126 / 158* 137 / 170* 20'21' 120 / 150* 131 / 162* 120 / 150* 131 / 162* 120 / 150* 131 / 162* 21'22' 115 / 144* 125 / 155* 115 / 144* 125 / 155* 115 / 144* 125 / 155* 22'23' 110 / 137* 119 / 148* 110 / 137* 119 / 148* 110 / 137* 119 / 148* 23'24' 105 / 132* 114 / 142* 105 / 132* 114 / 142* 105 / 132* 114 / 142* 24'25' 101 / 127* 110 / 136* 101 / 127* 110 / 136* 101 / 127* 110 / 136* 25'26' 97 / 122* 106 / 131* 97 / 122* 106 / 131* 97 / 122* 106 / 131* 26'27' 94 / 117* 102 / 126* 94 / 117* 102 / 126* 94 / 117* 102 / 126* 27'28' 90 / 113* 98 / 122* 90 / 113* 98 / 122* 90 / 113* 98 / 122* 28'29' 87 / 109* 95 / 118* 87 / 109* 95 / 118* 87 / 109* 95 / 118* 29'30' 84 / 106* 92 / 114* 84 / 106* 92 / 114* 84 / 106* 92 / 114* 30'31' 82 / 102* 89 / 110* 82 / 102* 89 / 110* 82 / 102* 89 / 110* 31'32' 79 / 99* 86 79 / 99* 86 / 107* 79 / 99* 86 / 107* 32'33' 100 77 / 93* 83 77 / 96* 83 / 103* 77 / 96* 83 / 103* 33'34' 92 74 81 74 / 93* 81 / 100* 74 / 93* 81 / 100* 34'35' 85 72 79 72 / 91* 79 / 98* 72 / 91* 79 / 98* 35'36' 78 70 77 70 / 86* 77 70 / 88* 77 / 95* 36'37' 72 68 74 88 68 74 68 / 86* 74 / 92* 37'38' 67 67 73 81 67 73 67 / 83* 73 / 90* 38'

ROOF SLOPE ADJUSTMENT FACTORSSlope 2:12 3:12 4:12 5:12 6:12 7:12 8:12 9:12 10:12 11:12 12:12

Factor 1.014 1.031 1.054 1.083 1.118 1.158 1.202 1.250 1.302 1.357 1.414

5. Web stiffeners are not required where only one value is shown for Total Load or when the designtotal load does NOT exceed the first value in the Total Load column where two values are given.Web stiffeners ARE required at interior supports if the design total load exceeds the first value(capacity without stiffeners) but does not exceed the second value (capacity with stiffeners).Additionally, if the second value is marked *, web stiffeners are required at all supports. Webfillers are required for joists seated in hangers that do not laterally support the top flange or forhangers that require nailing into the web.

6. Where the Live Load is blank, the Total Load governs the design.7. To design for a live load limit of L /360, L /480 or L /600, use the Uniform Floor Load tables.8. Do not use a product where designated “-” without further analysis by a professional engineer.

LPEW0037_Mjw_LPI36_US_tguide 2/6/06 4:21 PM Page 7

8© 2006 Louisiana-Pacific Corporation

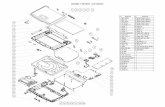

Web Hole Specifications: Circular Holes

6 1'-0" 1'-0" 1'-6" 2'-0" - - - 1'-0" 1'-0" 1'-6" 2'-0" - - -

LPI 36 11-7/8"10 1'-0" 1'-0" 1'-6" 2'-0" - - - 1'-0" 1'-0" 1'-6" 2'-0" - - -14 1'-0" 1'-0" 1'-6" 2'-6" - - - 1'-0" 1'-0" 2'-0" 4'-2" - - -18 1'-0" 1'-0" 2'-4" 4'-7" - - - 1'-0" 2'-2" 4'-11" 7'-2" - - -8 1'-0" 1'-0" 1'-6" 2'-0" 2'-6" - - 1'-0" 1'-0" 1'-6" 2'-0" 2'-6" - -

LPI 36 14"12 1'-0" 1'-0" 1'-6" 2'-0" 2'-6" - - 1'-0" 1'-0" 1'-6" 2'-0" 3'-7" - -16 1'-0" 1'-0" 1'-6" 2'-1" 4'-1" - - 1'-0" 1'-0" 2'-4" 4'-4" 6'-5" - -20 1'-0" 1'-0" 2'-7" 4'-7" 6'-7" - - 1'-0" 2'-11" 4'-11" 7'-6" 10'-0" - -8 1'-0" 1'-0" 1'-6" 2'-0" 2'-6" 3'-0" - 1'-0" 1'-0" 1'-6" 2'-0" 2'-6" 3'-0" -

LPI 36 16"12 1'-0" 1'-0" 1'-6" 2'-0" 2'-6" 3'-0" - 1'-0" 1'-0" 1'-6" 2'-0" 2'-6" 3'-10" -16 1'-0" 1'-0" 1'-6" 2'-0" 2'-10" 4'-11" - 1'-0" 1'-0" 1'-6" 3'-2" 5'-2" 7'-2" -20 1'-0" 1'-0" 1'-7" 3'-7" 5'-1" 7'-7" - 1'-0" 2'-5" 4'-5" 6'-0" 8'-0" - -12 1'-0" 1'-0" 1'-6" 2'-0" 2'-6" 4'-4" - 1'-0" 1'-1" 2'-4" 3'-7" 4'-10" 6'-0" -

LPI 36 18"16 1'-0" 1'-0" 1'-6" 2'-0" 4'-1" 6'-1" - 1'-1" 2'-9" 4'-4" 6'-0" 7'-2" - -20 1'-0" 1'-0" 1'-6" 3'-1" 5'-7" 8'-1" - 2'-11" 4'-5" 6'-6" 8'-0" 9'-6" - -24 1'-0" 1'-0" 2'-6" 4'-3" 7'-4" 10'-4" - 4'-9" 6'-7" 8'-5" 10'-2" 12'-0" - -12 1'-0" 1'-0" 1'-6" 2'-0" 2'-6" 3'-5" 4'-11" 1'-0" 1'-0" 2'-0" 3'-3" 4'-2" 5'-5" -

LPI 36 20"16 1'-0" 1'-0" 1'-6" 2'-0" 2'-11" 4'-11" 6'-11" 1'-0" 2'-4" 3'-11" 5'-2" 6'-5" 7'-7" -20 1'-0" 1'-0" 1'-6" 2'-1" 4'-1" 6'-7" 9'-2" 2'-5" 4'-5" 6'-0" 7'-6" 9'-0" 10'-0" -24 1'-0" 1'-0" 1'-10" 3'-8" 5'-6" 8'-6" 10'-11" 4'-9" 6'-0" 7'-9" 9'-7" 10'-10" - -16 1'-0" 1'-0" 1'-6" 2'-0" 2'-6" 3'-8" 5'-9" 1'-0" 1'-11" 3'-7" 4'-9" 6'-0" 7'-2" -

LPI 36 22"20 1'-0" 1'-0" 1'-6" 2'-0" 3'-1" 5'-1" 7'-7" 2'-5" 3'-11" 5'-6" 7'-0" 8'-0" 9'-6" -24 1'-0" 1'-0" 1'-6" 3'-1" 4'-3" 6'-8" 9'-1" 4'-2" 6'-0" 7'-2" 9'-0" 10'-2" 12'-0" -28 1'-0" 2'-2" 3'-7" 5'-0" 6'-5" 8'-6" 11'-4" 6'-3" 8'-4" 9'-9" 11'-2" 12'-7" 14'-0" -16 1'-0" 1'-0" 1'-6" 2'-0" 2'-6" 3'-0" 4'-6" 1'-0" 1'-11" 3'-2" 4'-4" 5'-7" 6'-5" 7'-7"

LPI 36 24"20 1'-0" 1'-0" 1'-6" 2'-0" 2'-6" 4'-1" 6'-1" 2'-5" 3'-11" 5'-0" 6'-6" 7'-6" 9'-0" 10'-0"24 1'-0" 1'-0" 1'-6" 2'-6" 3'-8" 5'-6" 7'-11" 4'-2" 6'-0" 7'-2" 8'-5" 9'-7" 10'-10" -28 1'-0" 2'-2" 3'-7" 5'-0" 6'-5" 7'-10" 9'-3" 6'-3" 7'-8" 9'-1" 10'-6" 11'-11" 13'-4" -

TO USE:1. Select the required product from the left column.2. Determine the support condition for the nearest bearing: end support or interior support (including end supports with cantilevers).3. Select the row corresponding to the required span. For spans between those listed, use the next largest value.4 Select the column corresponding to the required hole diameter. For diameters between those listed, use the next largest value.5. The intersection of the Span row and Hole Diameter column gives the minimum distance from the inside face of bearing to the center of the circular hole.6. Double check the distance to the other support, using the appropriate support condition.

Series DepthClear Distance from End Support Distance from Interior or Cantilever-End SupportSpan Hole Diameter Hole Diameter(ft) 2" 4" 6" 8" 10" 12" 14" 2" 4" 6" 8" 10" 12" 14"

DESIGN ASSUMPTIONS:1. The hole locations listed above are valid for floor joists supporting only uniform loads as follows:

For joists 16" deep and less, the total uniform load must not exceed 130 plf (e.g., 40 psf Live Loadand a 25 psf Dead Load, spaced up to 24" oc). The uniform dead load must be at least 10 plf.For joists greater than 16" deep, the total uniform load must not exceed 190 plf (e.g., 50 psf LiveLoad, 25 psf Dead Load with a 20 psf Partition Load, spaced up to 24" oc). The uniform dead loadmust be at least 25 plf. An additional concentrated “safe” load of 2000 lbs acting over 6.25 ft2

(2.5' x 2.5') has also been included.2. Hole location is measured from the inside face of bearing to the center of a circular hole, from the

closest support.3. Clear Span has NOT been verified for these joists and is shown for informational purposes only!

Verify that the joist selected will work for the span and loading conditions needed before checkinghole location.

4. Maximum hole depth for circular holes is Joist Depth less 4", not to exceed 14", except themaximum hole depth is 6" for 9-1/2", and 8" for 11-7/8" LP I-Joists.

5. Holes cannot be located in the span where designated “-”, without further analysis by aprofessional engineer.

NOTES:1. CUT HOLES CAREFULLY! DO NOT OVERCUT HOLES! DO NOT CUT JOIST FLANGES!2. Holes may be placed anywhere within the depth of the joist. A minimum 1/4" clear distance is

required between the hole and the flanges.3. Round holes up to 1-1/2" diameter may be placed anywhere in the web.4. Perforated “knockouts” may be neglected when locating web holes.5. Holes larger than 1-1/2" are not permitted in cantilevers without special engineering.6. Multiple holes must have a clear separation along the length of the joist of at least twice the

length of the larger adjacent hole, or a minimum of 12" center-to-center, whichever is greater.7. Multiple holes may be spaced closer provided they fit within the boundary of an acceptable larger

hole. Example: two 3" round holes aligned parallel to the joist length may be spaced 2" apart(clear distance) provided that a 3" high by 8" long rectangle or an 8" diameter round hole areacceptable for the joist depth at that location and completely encompass the holes.

8. Not all series are available in all depths. Check availability with a local LP Engineered Wood Products distributor.

9. Locating holes in joists with spans exceeding those in the tables or larger holes, greater uniformloads or non-uniform loads, and closer proximity to supports and other holes may be possible withanalysis using LP’s design software. Please contact your local LP Engineered Wood Productsdistributor for more information.

Up to a 1-1/2" diameter hole allowedanywhere in the web. Closest spacing 12" oc.

Diameter

Closest distance (x) to center of circular hole

FROM EITHER SUPPORT

Uncut length of web between adjacent holes must be at least twice the length of the larger

hole or 12" center-to-center, whichever is larger.

Closest distance (x) to center of circular hole

FROM EITHER SUPPORT

END SUPPORT INTERIOR OR CANTILEVER-END SUPPORT

LPEW0037_Mjw_LPI36_US_tguide 2/6/06 4:22 PM Page 8

6 1'-0" 1'-0" 1'-6" 2'-0" 2'-6" 3'-0" - - 1'-0" 1'-0" 1'-6" 2'-0" 2'-6" 3'-0" -

LPI 36 11-7/8"10 1'-0" 1'-0" 1'-10" 3'-4" 3'-10" 4'-4" 4'-10" - 1'-0" 1'-11" 3'-3" 4'-9" - - -14 1'-5" 2'-10" 4'-3" 6'-1" 6'-9" - - - 3'-5" 4'-10" 6'-4" - - - -18 3'-8" 5'-6" 6'-10" 8'-8" - - - - 6'-3" 8'-1" - - - - -8 1'-0" 1'-0" 1'-6" 2'-0" 2'-6" 3'-0" 3'-6" 4'-0" 1'-0" 1'-0" 1'-6" 2'-0" 2'-6" 3'-0" 3'-10"

LPI 36 14"12 1'-0" 1'-0" 1'-6" 2'-0" 3'-8" 4'-7" 5'-2" - 1'-0" 1'-0" 1'-6" 3'-3" 5'-5" - -16 1'-0" 1'-0" 2'-1" 4'-1" 6'-6" 7'-4" - - 1'-0" 2'-4" 4'-4" 6'-5" - - -20 1'-0" 2'-7" 4'-7" 6'-7" 9'-1" - - - 2'-11" 4'-11" 7'-0" 9'-6" - - -8 1'-0" 1'-0" 1'-6" 2'-0" 2'-6" 3'-0" 3'-6" 4'-0" 1'-0" 1'-0" 1'-6" 2'-0" 2'-6" 3'-5" -

LPI 36 16"12 1'-0" 1'-0" 1'-6" 2'-0" 2'-9" 4'-11" 5'-10" - 1'-0" 1'-0" 1'-6" 2'-8" 4'-6" - -16 1'-0" 1'-0" 1'-8" 3'-3" 5'-3" 7'-9" - - 1'-0" 1'-11" 3'-7" 5'-7" 7'-7" - -20 1'-0" 2'-1" 3'-7" 5'-7" 8'-1" - - - 2'-11" 4'-11" 6'-6" 8'-6" - - -12 1'-0" 1'-3" 2'-6" 4'-0" 5'-3" - - - 1'-0" 2'-4" 3'-11" 5'-1" - - -

LPI 36 18"16 1'-0" 2'-6" 4'-1" 5'-9" 7'-4" - - - 2'-9" 4'-4" 6'-0" 7'-7" - - -20 2'-7" 4'-1" 6'-1" 7'-7" 9'-8" - - - 4'-5" 6'-6" 8'-0" 10'-0" - - -24 3'-8" 6'-1" 7'-11" 9'-9" 11'-6" - - - 6'-7" 8'-5" 10'-2" 12'-0" - - -12 1'-0" 1'-0" 2'-2" 3'-5" 4'-11" - - - 1'-0" 2'-4" 3'-7" 4'-10" 6'-0" - -

LPI 36 20"16 1'-0" 2'-6" 3'-8" 5'-4" 6'-11" - - - 2'-9" 3'-11" 5'-7" 7'-2" - - -20 2'-1" 4'-1" 5'-7" 7'-1" 8'-8" - - - 4'-5" 6'-0" 8'-0" 9'-6" - - -24 3'-8" 5'-6" 7'-4" 9'-1" 10'-11" - - - 6'-7" 8'-5" 10'-2" 12'-0" - - -16 1'-0" 2'-1" 3'-8" 4'-11" 6'-6" 7'-9" - - 2'-4" 3'-11" 5'-7" 6'-10" 8'-0" - -

LPI 36 22"20 2'-1" 3'-7" 5'-1" 6'-7" 8'-8" - - - 4'-5" 6'-0" 7'-6" 9'-0" - - -24 3'-8" 5'-6" 7'-4" 8'-6" 10'-4" - - - 6'-7" 7'-9" 9'-7" 11'-5" - - -28 5'-0" 7'-1" 8'-6" 10'-7" 12'-9" - - - 8'-4" 10'-6" 11'-11" 14'-0" - - -16 1'-0" 2'-1" 3'-3" 4'-11" 6'-1" 7'-4" - - 2'-4" 3'-11" 5'-2" 6'-5" 7'-7" - -

LPI 36 24"20 2'-1" 3'-7" 5'-1" 6'-7" 8'-1" 9'-8" - - 4'-5" 6'-0" 7'-6" 8'-6" 10'-0" - -24 3'-8" 5'-6" 6'-8" 8'-6" 9'-9" 11'-6" - - 6'-0" 7'-9" 9'-7" 10'-10" - - -28 5'-0" 7'-1" 8'-6" 9'-11" 12'-0" 13'-5" - - 8'-4" 9'-9" 11'-11" 13'-4" - - -

© 2006 Louisiana-Pacific Corporation

Web Hole Specifications: Rectangular Holes

9

TO USE:1. Select the required product from the left column.2. Determine the support condition for the nearest bearing: end support or interior support (includes end supports with cantilevers).3. Select the row corresponding to the required span. For spans between those listed, use the next largest value.4. Select the column corresponding to the required hole dimension. For dimensions between those listed, use the next largest value.5. The intersection of the Span row and Hole Dimension column gives the minimum distance from the inside face of bearing to the nearest edge of the rectangular hole.6. Double check the distance to the other support, using the appropriate support condition.

Series DepthClear Distance from End Support Distance from Interior or Cantilever-End SupportSpan Maximum Hole Dimension: Depth or Width Maximum Hole Dimension: Depth or Width(ft) 2" 4" 6" 8" 10" 12" 14" 16" 2" 4" 6" 8" 10" 12" 14"

DESIGN ASSUMPTIONS:1. The hole locations listed above are valid for floor joists supporting only uniform loads as follows:

For joists 16" deep and less, the total uniform load must not exceed 130 plf (e.g., 40 psf Live Loadand a 25 psf Dead Load, spaced up to 24" oc). The uniform dead load must be at least 10 plf.For joists greater than 16" deep, the total uniform load must not exceed 190 plf (e.g., 50 psf LiveLoad, 25 psf Dead Load with a 20 psf Partition Load, spaced up to 24" oc). The uniform dead loadmust be at least 25 plf. An additional concentrated “safe” load of 2000 lbs acting over 6.25 ft2

(2.5' x 2.5') has also been included.2. Hole location is measured from the inside face of bearing to the nearest edge of a rectangular hole,

from the closest support.3. Clear Span has NOT been verified for these joists and is shown for informational purposes only!

Verify that the joist selected will work for the span and loading conditions needed before checkinghole location.

4. Maximum hole depth for rectangular holes is Joist Depth less 4", not to exceed 14", except themaximum hole depth is 6" for 9-1/2", and 8" for 11-7/8" LP I-Joists. Maximum hole width forrectangular holes is 18". Where the Maximum Hole Dimension for rectangular holes exceeds themaximum hole depth, the dimension refers to hole width, and the hole depth is assumed to be themaximum for that joist depth.

5. Holes cannot be located in the span where designated “-”, without further analysis by aprofessional engineer.

NOTES:1. CUT HOLES CAREFULLY! DO NOT OVERCUT HOLES! DO NOT CUT JOIST FLANGES!2. Holes may be placed anywhere within the depth of the joist. A minimum 1/4" clear distance is

required between the hole and the flanges.3. Round holes up to 1-1/2" diameter may be placed anywhere in the web.4. Perforated “knockouts” may be neglected when locating web holes.5. Holes larger than 1-1/2" are not permitted in cantilevers without special engineering.6. Multiple holes must have a clear separation along the length of the joist of at least twice the

length of the larger adjacent hole, or a minimum of 12" center-to-center, whichever is greater.7. Multiple holes may be spaced closer provided they fit within the boundary of an acceptable larger

hole. Example: two 3" round holes aligned parallel to the joist length may be spaced 2" apart(clear distance) provided that a 3" high by 8" long rectangle or an 8" diameter round hole areacceptable for the joist depth at that location and completely encompass the holes.

8. Not all series are available in all depths. Check availability with a local LP Engineered Wood Products distributor.

9. Locating holes in joists with spans exceeding those in the tables or larger holes, greater uniformloads or non-uniform loads, and closer proximity to supports and other holes may be possible withanalysis using LP’s design software. Please contact your local LP Engineered Wood Productsdistributor for more information.

Depth

Closest distance (x) toedge of rectangular hole

FROM EITHER SUPPORT

Closest distance (x) toedge of rectangular hole

FROM EITHER SUPPORT

END SUPPORT INTERIOR OR CANTILEVER-END SUPPORT

Width

Uncut length of web between adjacent holes must be at least twice the length of the larger

hole or 12" center-to-center, whichever is larger.

LPEW0037_Mjw_LPI36_US_tguide 2/6/06 4:22 PM Page 9

© 2006 Louisiana-Pacific Corporation

LP OSB Rim Board

10

RIM BOARD WEIGHTS BY THICKNESS (PLF)

INSTALLATION

An Exact Match To Our LP I-Joist Depths

LP OSB Rim Board is a strong, cost-effective complement to LP’s engineered

floor system. LP I-Joists and LP LVL beams offer many advantages over

conventional framing. Now LP OSB Rim Board completes LP’s floor system

package with an easy, reliable way to finish off floor and roof installations.

• Quick and convenient, LP OSB Rim Board is precision cut to match our 9 -1/2", 11-7/8", 14" and 16" LP I-Joist depths.

• 12'- 0" and 16'- 0" lengths mean your LP engineered floor system goes together even faster.

• Eliminates inaccuracies and time involved in ripping plywood rim.

• High load capacity means squash blocks are unnecessary on most multi-story applications.

• Flat surface means easy fastening for siding.

• LP OSB Rim Board is manufactured using predominantly fast growingtrees, a renewable resource that leaves our old-growth forests for future generations to enjoy.

Fastener Values

(1) Nail Values: For nails installed into the wide face of LP OSB Rim Board,

use the values for Douglas Fir lumber (Specific Gravity, SG=0.50) per

the National Design Specification™ for Wood Construction. To allow for the

16d nails from the sole plate above into the top edge of the rim, the deck

nailing must be at least 6" oc and the 16d nails must be spaced in

accordance with the prescriptive requirements of the code.

(2) Bolt & Lag Screw Values: For 1/2" diameter through-bolts and lag

screws installed in the wide face and loaded in single shear,

perpendicular-to-grain, the allowable capacity is:

∞ 300 lbs. for 1" rim board

∞ 350 lbs. for 1-1/8" rim board

Lag screws must be at least 4" long.

NOTE: Rim board must be connected to wall plate and floor deck.See detail below.

8d (box or common) or 10dbox nails, one at top, oneat bottom of each I-Joist

NOTE: Rim board must be connected to I-Joist. See detail above.

• Floor deck to rim board: Use 8d or 10d nails (box or common) at 6" oc

• Rim board to wall plate: Toe-nail using 8d (box or common) at 6" oc, or l6d (box or common) at 12" oc

RIM TO DECK/PLATE CONNECTION

RIM TO JOIST CONNECTION

Design value for horizontalshear for APA rim board: 180plf. This value is applicableto wind or seismic loads andshall not be adjusted forload duration.

d≤16" 16"<d≤24"1" 3300 plf 1650 plf

1-1/8" 4400 plf 3000 plf

ThicknessJoist Depth

9-1/2" 11-7/8" 14" 16"

1" 2.6 3.2 3.8 4.3

1-1/8" 2.9 3.6 4.3 4.8

NOTES:1. 1" and 1-1/8" LP OSB Rim Board is manufactured to meet APA standard

PRR-401 Performance Standard for APA EWS Rim Boards, effective.2. LP OSB Rim Board must be supported by continuous structural bearing.3. For additional details about LP OSB Rim Board, which is an APA-Rated rim

board, refer to APA literature.

MAXIMUM LOAD

LPEW0037_Mjw_LPI36_US_tguide 2/6/06 4:23 PM Page 10

LP I-Joists, LP LVL, LP Rim Board &

LP TopNotch® T&G Flooring Products

Limited Lifetime Warranty

LP Structural Products

FOR FURTHER INFORMATION, CONTACT:

888.820.0325

Visit our Web site at www.lpcorp.com.

1.Warranty Coverage

This warranty applies to the original purchaser

(“Purchaser”) of LP I-Joists, LP LVL and LP Rim

Board (the “Products”) and to any owner of a building

in which the Products are originally installed

(“Owner”). LP warrants that the Products will,

at the time of delivery, meet or exceed LP

manufacturing standards and when installed in

accordance with LP current published specifications

will, for the life of the structure, (a) perform as

reasonably required of I-Joists, laminated veneer

lumber and rim board, and (b) exhibit no defects

which are defined as delaminations or glue failures.

LP further warrants that its LP TopNotch® tongue-

and-groove flooring products, when used in a

flooring system application with LP I-Joists and/or

LP LVL and LP Rim Board, is free from defects in

materials and workmanship when installed and

finished according to LP published installation

instructions, and will perform in accordance with

LP current published specifications for the lifetime

of the structure. IN THE EVENT THE PRODUCTS

DO NOT COMPLY WITH THIS WARRANTY,THE

LIABILITY OF LP IS LIMITED TO THE REPAIR

AND REPLACEMENT, OR PAYMENT PROVISIONS

SET FORTH IN PARAGRAPH 4 BELOW.

Delamination is defined as a visible separation

which results in the reduction of structural strength

within the I-Joist web or the laminated veneer

lumber or the rim board. Glue failure is defined as

visible separation of glued joints which results in

reduction of structural strength within the web to

web section joints or flange to web joints in I-Joists.

Minor surface characteristics such as loose or folded

surface flakes or minor edge swelling in OSB rim

board or I-Joist webs and minor surface checking

in laminated veneer lumber or I-Joist flanges and

minor swelling or cupping in laminated veneer

lumber do not qualify as defects.

2.Exclusions from Warranty Coverage

THIS EXPRESS WARRANTY PROVIDES A REMEDY

ONLY FOR NON-CONFORMITIES REPORTED IN

ACCORDANCE WITH PARAGRAPH 6(a) BELOW.

IN ADDITION,THIS WARRANTY DOES NOT

PROVIDE A REMEDY FOR:

a. NON-CONFORMITIES CAUSED BY: (1) MISUSE

OR IMPROPER HANDLING, INSTALLATION

OR MAINTENANCE; (2) ALTERATIONS TO

THE STRUCTURE AFTER THE ORIGINAL

INSTALLATION OF THE PRODUCTS; (3) ACTS

OF GOD, SUCH AS EARTHQUAKE,TORNADO,

FLOOD OR OTHER SIMILAR SEVERE WEATHER

OR SIMILAR NATURAL PHENOMENA; (4)

TRANSPORT, STORAGE OR HANDLING OF

THE PRODUCTS PRIOR TO INSTALLATION.

b. PRODUCTS THAT ARE NOT INSTALLED

IN COMPLIANCE WITH ALL APPLICABLE

BUILDING CODES AND INSTALLED AND

MAINTAINED ACCORDING TO LP PRINTED

INSTALLATION AND MAINTENANCE

INSTRUCTIONS; OR

c. WORKMANSHIP OF THE INSTALLATION OF

THE PRODUCTS.

3.Exclusion of Implied Warranties;

No Other Express Warranties

THIS WARRANTY IS THE ONLY WARRANTY

APPLICABLE TO THESE PRODUCTS AND

EXCLUDES ALL OTHER EXPRESSED OR

IMPLIED WARRANTIES, INCLUDING ANY

IMPLIED WARRANTY OF MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE,

OR ANY WARRANTIES OTHERWISE ARISING

FROM A COURSE OF DEALING OR A USAGE OF

TRADE OR ADVERTISING, EXCEPT WHERE

SUCH WARRANTIES ARISE UNDER APPLICABLE

CONSUMER PRODUCT WARRANTY LAWS AND

CANNOT LAWFULLY BE DISCLAIMED, IN WHICH

EVENT SUCH WARRANTIES ARE LIMITED TO

THE SHORTEST PERIOD PERMITTED OR

REQUIRED UNDER APPLICABLE LAW.

Some states or provinces may not allow limitations

on how long an implied warranty lasts, so the above

limitations may not apply to you.

NO OTHER WARRANTY HAS BEEN MADE OR

WILL BE MADE ON BEHALF OF LP WITH

RESPECT TO THESE PRODUCTS.

4.Remedies

THIS SECTION PROVIDES FOR THE SOLE

REMEDY AVAILABLE TO THE OWNER FROM LP

FOR ANY NONCONFORMITY IN THE PRODUCTS.

In the event of any nonconformity covered by

this, or any implied warranty, LP at its option will

repair or replace the nonconforming Products

including the cost of labor which will be based upon

labor estimates established by an independent,

nationally-recognized construction cost estimator

or construction cost estimating publication.

5.Exclusion of Other Remedies

IN NO EVENT WILL LP BE LIABLE FOR

ANY INCIDENTAL, SPECIAL, INDIRECT OR

CONSEQUENTIAL DAMAGES RESULTING

FROM ANY DEFECT IN THE PRODUCTS

SUPPLIED INCLUDING, BUT NOT LIMITED TO,

DAMAGE TO PROPERTY OR LOST PROFITS.

Some states or provinces do not allow the exclusion

or limitation of incidental or consequential damages,

so the above limitation or exclusion may not apply

to you.

6.Responsibility of Owner

a. Any Owner seeking remedies under this warranty

must notify LP in writing within 30 days after

discovering a possible non-conformity of the

Products, and before beginning any permanent

repair.This written notice should include the date

the Products were installed, and if known, the

mill identity number imprinted on the Products.

b. It is the Owner’s responsibility to establish the

date of installation. The Owner should do this

by retaining any records which would tend to

prove when the product was installed including,

but not limited to: purchase invoices and

receipts, contractor’s billings, service contracts

and building permits.

c. Upon reasonable notice, the Owner must allow

LP agents to enter the property and building

on which the Products are installed to inspect

such Products.

This warranty gives you specific legal rights,

and you may also have other rights which vary

in each state or province.

LP is a registered trademark of Louisiana-Pacific Corporation.

© 2006 Louisiana-Pacific Corporation. All rights reserved.

Specifications (details) subject to change without notice. PT I5M

EW6100IN-C 2/06

© 2006 Louisiana-Pacific Corporation

Warranty

11

For a copy of the LP Structural Products Limited Lifetime Warranty,call 1.888.820.0325 or visit our Web site at www.lpcorp.com.

LPEW0037_Mjw_LPI36_US_tguide 2/6/06 4:23 PM Page 11

LP is a registered trademark of Louisiana-Pacific Corporation. © 2006 Louisiana-Pacific Corporation. All rights reserved. Printed in USA. MW 5MSpecifications (details) subject to change without notice.

LPEW0008 2/06

For more information on the full line of LP Engineered Wood Products or the nearest distributor, please contact 1.888.820.0325or e-mail [email protected]. Visit our Web site at www.lpcorp.com.

LP Engineered Wood Products are manufactured at different locationsin the United States and Canada. Please verify availability with the LPEngineered Wood Products distributor in your area before specifyingthese products.

36493_Lapacific 9/28/06 12:24 PM Page 12

![Plf Fi e 30d [PDF Library]](https://static.fdocuments.us/doc/165x107/5478ddcbb479596d098b45e0/plf-fi-e-30d-pdf-library.jpg)