Alignment Procedure Plf

-

Upload

papathsheila -

Category

Documents

-

view

222 -

download

0

Transcript of Alignment Procedure Plf

-

8/16/2019 Alignment Procedure Plf

1/22

…making flui d energy work for you copyright © Fluid Equipment Development Company 1

Alignment Procedure for MSS Pumps

Thank you for purchasing a FEDCO MSS Pump. FEDCOequipment is designed for ease of use and operation. Thefollowing procedure will provide detailed instructions for properalignment of the pump and motor. This will ensure years of

trouble-free service.

Once again, thank you for choosing FEDCO!!!!!!!!!

-

8/16/2019 Alignment Procedure Plf

2/22

-

8/16/2019 Alignment Procedure Plf

3/22

…making flui d energy work for you copyright © Fluid Equipment Development Company 3

Alignment Procedure for MSS Pumps

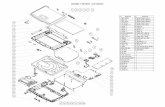

Parts and Tools

Precision level*

Alignmentpins (2)

Feelergauge*

Shaftcoupling

Motorshaft key

Pumpshaft key

Couplingset screws

(2)

Motor adapterbolt , lock washer,

flat washer

Coupling guardscreen (2)

Coupling guardscreen bolts (8)

Shims*

* Indicates tools that canbe provided by FEDCO atadditional charge

Anti-Seize

-

8/16/2019 Alignment Procedure Plf

4/22

-

8/16/2019 Alignment Procedure Plf

5/22

…making flui d energy work for you copyright © Fluid Equipment Development Company 5

Alignment Procedure for MSS Pumps

Coupling End Assembly Animation

The animation above shows the assembly of thecoupling end of the MSS Pump.

-

8/16/2019 Alignment Procedure Plf

6/22

-

8/16/2019 Alignment Procedure Plf

7/22

…making flui d energy work for you copyright © Fluid Equipment Development Company 7

Alignment Procedure for MSS Pumps

Pump Leveling Foot Assembly Animation

The animation above shows the assembly of theleveling foot of the MSS Pump.

-

8/16/2019 Alignment Procedure Plf

8/22

…making flui d energy work for you copyright © Fluid Equipment Development Company 8

Alignment Procedure for MSS Pumps

STEP 1: General PreparationIf pump and motor are mounted on a skid,•Skid must be leveled and shimmed to support:

•Weight of motor and pump.•Weight of membrane housings, process piping, and all other equipment

installed on the skid when filled with water.

If pump and motor are mounted on concrete foundation,•Foundation must be leveled.• Anchor bolts must be properly installed and tightened.

Skid Shim

Foundation

Anchor bolt

NOTE: If your pump has a rotated inlet, rotate the inlet to the verticalposition prior to alignment. Once alignment is complete, rotate the inletback to it required location.

-

8/16/2019 Alignment Procedure Plf

9/22

…making flui d energy work for you copyright © Fluid Equipment Development Company 9

Alignment Procedure for MSS Pumps

STEP 2: Level the Motor

1. Pump end and motor should not becoupled at this time.

2. Verify motor feet sit flat on mountingsurface (no “ soft foot” ).3. Place level on motor shaft.4. Adjust motor shims until

motor shaft is level.

3. Tighten motor foot bolts to mountingsurface.4. Verify shaft remains level.

NOTE: Motor must be placed at final installation location prior tostarting alignment procedure

-

8/16/2019 Alignment Procedure Plf

10/22

…making flui d energy work for you copyright © Fluid Equipment Development Company 10

Alignment Procedure for MSS Pumps

STEP 3: Prepare for Alignment1. Install the two (2) alignment pins2. Discharge cradle halves should not

be bolted together at this t ime.

3. Pump end should rest on the bottomhalf of the discharge cradle to allowthe pump to slide axially duringalignment.

4. Sl ide pump onto motor face.• Coupling NOT installed• Ensure motor adapter is fully

engaged with motor face5. Place level across inlet .6. Adjust bottom half of pump leveling

foot discharge cradle until levelusing adjusting nuts.

7. Do NOT tighten down top half ofdischarge cradle at this time.

-

8/16/2019 Alignment Procedure Plf

11/22

…making flui d energy work for you copyright © Fluid Equipment Development Company 11

Alignment Procedure for MSS Pumps

STEP 4: Ensure Mounting Flanges are Parallel

1. Check for uniform gap between motoradapter and motor face throughout theentire interface.• If there is no gap, or gap is

uniform, proceed to Step 5.•

If gap is not uniform, proceed to #2below.

2. Using feeler gauge, measure clearanceon one side of gap.

3. Measure clearance on other side.4. Move pump discharge end sidewise

until clearance is uniform.

Make clearanceuniform

Feeler gauge

-

8/16/2019 Alignment Procedure Plf

12/22

…making flui d energy work for you copyright © Fluid Equipment Development Company 12

Alignment Procedure for MSS Pumps

STEP 5: Check Shaft Gap

1. Install two motor adapter bolts to drawpump to motor.

2. Measure gap between motor andpump shafts.• Gap should be between 1/8” (3

mm) and 1/4” (6 mm).

Shaft gap between 1/8 and 1/4inches (3 to 6 mm)

-

8/16/2019 Alignment Procedure Plf

13/22

…making flui d energy work for you copyright © Fluid Equipment Development Company 13

Alignment Procedure for MSS Pumps

STEP 6: Lubricate Shafts

1. Remove the two bolts installed inprevious step.2. Separate pump and motor.3. Liberally apply anti-seize to pump and

motor shafts and coupling bores.•

Use anti-seize provided in smallpouch.

Apply anti-seize to these areas

-

8/16/2019 Alignment Procedure Plf

14/22

…making flui d energy work for you copyright © Fluid Equipment Development Company 14

Alignment Procedure for MSS Pumps

STEP 7: Install Coupling

1. Instal l key on motor shaft.2. Sl ide coupling on motor shaft.

• Push until firmly seated.3. Install both set screws and firmly

tighten.• Note that there are NO set screws onthe pump side of the coupling.

Tighten both set screws

-

8/16/2019 Alignment Procedure Plf

15/22

…making flui d energy work for you copyright © Fluid Equipment Development Company 15

Alignment Procedure for MSS Pumps

STEP 8: Insert Pump Shaft into Coupling

1. Slide pump onto alignment pins.2. Instal l key onto pump shaft.3. Line up pump key with pump keyway

in coupling.

Line up pump key withcoupling keyway

Alignment pins

-

8/16/2019 Alignment Procedure Plf

16/22

-

8/16/2019 Alignment Procedure Plf

17/22

…making flui d energy work for you copyright © Fluid Equipment Development Company 17

Alignment Procedure for MSS Pumps

STEP 10: Final Installation – Motor Adapter

1. Install two (2) motor adapter boltsand tighten *.

2. Remove two (2) alignment pins.

3. Install remaining adapter bolts andtighten *.

Install and tighten all motoradapter bolts

*For 1/2” bolts, tighten to 30 ft-lbs*For 5/8” bolts, tighten to 60 ft-lbs

-

8/16/2019 Alignment Procedure Plf

18/22

…making flui d energy work for you copyright © Fluid Equipment Development Company 18

Alignment Procedure for MSS Pumps

STEP 11: Final Installation – Leveling Foot

1. Place level on inlet .2. Bring top half of discharge cradle

down to meet bottom half.3. Begin to tighten down top half ofdischarge cradle.

4. During tightening, the cradle maydraw the pump downward.

5. Verify that pump remains levelduring tightening.• If pump comes out of level, raise

the bottom half of the cradle untilpump is again level.

•

Repeat this process until cradleis fully secured and pumpremains level.

6. Tighten down cradle jamb nuts.

-

8/16/2019 Alignment Procedure Plf

19/22

-

8/16/2019 Alignment Procedure Plf

20/22

…making flui d energy work for you copyright © Fluid Equipment Development Company 20

Alignment Procedure for MSS Pumps

STEP 13: Coupling Guard InstallationCoupling guard

Coupling guard screw

Install both coupling guards andtighten the screws.

-

8/16/2019 Alignment Procedure Plf

21/22

…making flui d energy work for you copyright © Fluid Equipment Development Company 21

Alignment Procedure for MSS Pumps

STEP 14: Piping Alignment CheckPump and pipe

connections are aligned

Proper gap

A good pump-motor alignment can beruined by improper alignment of thepiping.

Please make sure that suction anddischarge piping are concentric with thepump connections and have the propergap prior to installation of the Victauliccouplings.

DO NOT FORCE THE CONNECTINGPIPES INTO POSITION!

BADBAD

-

8/16/2019 Alignment Procedure Plf

22/22

…making flui d energy work for you copyright © Fluid Equipment Development Company 22

Alignment Procedure for MSS Pumps

Alignment Completed

YOUR ALIGNMENT IS COMPLETE!!!

Please refer to the O&M manual for pipe connections and startupprocedures.

If there are ANY questions, please contact FEDCO:

+734.241.3935 (telephone)+734.241.5173 (fax)William Byrne : wbyrne @fedco-usa.comCasey Bly: [email protected]

Thank you for using FEDCO equipment!