Gpa 254l Ahts Series

-

Upload

erwin-paulian-sihombing -

Category

Documents

-

view

224 -

download

0

Transcript of Gpa 254l Ahts Series

-

8/8/2019 Gpa 254l Ahts Series

1/6

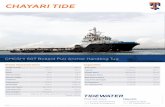

Anc hor Handling a nd Tow ing 30% Grea ter Ca rgo Capac ityFuel Savings Reliab ility in Ad verse Weathe r Cond itions

Exc eptiona l Ma neuverab ility Ma in Systems Redundanc y

GPA 254L AHTS SeriesReliab ility in Ad verse Wea ther Cond itions

Excep tiona l Ma neuvrab ilityEnvironmentally Friendly Operations

BOURBON

LIBERTY 200SERIES

A Modern Diesel-Elec tric

Anc hor Hand ling Tug Supp ly

Vessel Equipped withSta te-of-the-Art Tec hno logy.

-

8/8/2019 Gpa 254l Ahts Series

2/6

GPA 254L AHTS SeriesReliab ility in Ad verse Wea ther Cond itions

Excep tiona l Ma neuvrab ilityEnvironmentally Friendly Operations

To m ee t the inc rea sing demand for oil worldwide, the rap id build ing of ves-sels, capab le of deepwater offshore operations, is req uired to rep lac e exist-

ing , obsolete offshore vessels. GPA s vessel designs are b ased on efficiencyand constructability:

Effic ienc y HullsDevelopab le Hull Surfac es (Sing le Curvature Hulls)Transverse FramingFlanged Pla te Construc tionModular Elec tric Propulsion System by Elec tronic Power Design (EPD)

-

8/8/2019 Gpa 254l Ahts Series

3/6

GPA 254L AHTS SeriesReliab ility in Ad verse Wea ther Cond itions

Excep tiona l Ma neuvrab ilityEnvironmentally Friendly Operations

GPA 254L AHTSA State-of-the-Art Anchor Handling Tug Supply Vessel.

Anc hor Hand ling and TowingThe GPA 254L AHTS is eq uipp ed with a Ma c -Gregor-Plimsoll doub le d rum winc h rate d a t150 mt line p ull on eac h d rum for towing a nd anc hor hand ling op erations respec tively. Thevessel is eq uipped with a 250mt Ste rn Roller, Sha rk Jaw s for the safe stopp ing o f cha ins andwires during anc hor hand ling op erat ions, Ret rac tab le Tow ing Pins for centering , controllingand guiding to wing line a nd cables tow ing o pe ra tions.

+30% Grea ter Cargo Capac ityThe engine room has bee n moved to a bo ve ma in deck, a c oncep t pioneered by GPAseveral yea rs ago. This unique p ropulsion c onfiguration creates greater cargo capacitiesbelow dec k as the d rive sha ft has been e liminated . Com pared to trad itional AHTS vesselsof simila r size, the GPA 254L AHTS c an therefore c arry 30% more c argo.

Fuel Savings

The Diesel-Elec tric Propulsion system is environmenta lly friend ly by dec reasing CO 2 em is-sions by 30% and also offers improved fuel effic ienc y. Clients benefit from considerablecost savings, as the insta lla tion of d iesel generators of d ifferent o utp ut ratings can p rovidesma ller inc rem ents of pow er to best suit a g iven op erationa l mode. Add itional elec tricconsumers can be a dded to the design, suc h as add itiona l thrusters or Fi-Fi pumps withoutad ding ded ica ted d iesel engines to d rive them .

Reliab ility and Excep tiona l Maneuverab ility in Ad verse ConditionsThe GPA 254L AHTS is equipped with two azimuthing ste rn thruste rs, one fixed ste rn thrusterand two bo w thrusters, whic h a llow excep tiona l maneuverab ility and sta tion-keep ing ca-pab ilities. The Dynam ic Positioning system Class II c rea tes dua l red und anc y on a ll eq uip-

ment a nd ena b les the vessel to ma inta in p rec ise position when a long side rigs or plat formsto offloa d c argo , if and when req uired , even in adverse w ea ther cond itions. The sta tion-keeping capability also improves the Anchor Handling process due to less tension on wire,inc rea sed safety fo r the d ec k crew , prec ise sta tion-keep ing and a lso a llow s the vessel tomaintain forward p osition in sea wa y. This unique p rop ulsion configuration permits the ves-sel to c a rry out op erations sa fely and makes vessel mo re reliab le.

Main Systems Redundanc yThree main generators, two azimuthing ste rn thrusters, one fixed stern thruster, two bowthruste rs and Dyna mic Positioning C lass II.

-

8/8/2019 Gpa 254l Ahts Series

4/6

MAIN CHARACTERISTICSLengt h Ove rall 59.78 m (196.13 ft)

Length BP 57.34 m (188.12 ft)

Bea m 15.00 m (49.21 ft)Dep th 5.50 m (18.04 ft)

Design Draf t 4.30 m (14.11 ft)Ma ximum Draft 4.88 m (16.01 ft)

Ligh t Draf t 2.90 m (9.51 ft)

Ope rating Displac eme nt2,700 mt (2,657 lt)

Ma ximum Displac eme nt3,150 mt (3,100 lt)

Gross Reg istered Tonna ge Under 1,800

CAPACITIES

Dead weight at Ma x Draft1,670 mt (1,841 st)

Ca rgo Dec k Area24.4m x 12.4m...302.56 m 2

(80.05ft x 40.68ft ... 3,256.43ft2)

Dec k Ca rgo 830 mt (915 st)Fuel O il Ca rgo

544 m3 (143,710 ga l) (3,422 bb l)Fue l Oil Day Tank

33 m3

(8,718 ga l) (208 bb l)Bulk Mud157 m3 (41,475 ga l) (988 bb l)

Liquid Mud632 m3 (166,957 ga l) (3,975 bb l)

Drill Water

357 m3 (94,309 ga l) (2,245 bb l)Ba llast Wa ter

117 m3 (30,908 ga l) (736 bb l)Fresh Water

355 m3 (93,781 ga l) (2,233 bb l)Foa m Tank

14 m3 (3,698 ga l) (88 bb l)

DYNAMIC POSITIONING SYSTEM (CLASS II)

ABS c lassed DPS-2 Red und ant Position -ing System Co mp rising:

2 Operating Consoles

1 Com pu ter with Printer2 Anemometers

2 Gyrocompasses1 Laser Referenc e System

2 DGPS

2 Vertic al Referenc e Units1 Independent Joysticks

PERFORMANCESpee d (@ Design Draft) 12 knots

Fuel Co nsump tion a t 4.3 m Draft

Cruising Speed TBDEc onom ica l Spee d TBD

PROPULSION - MACHINERY

Tota l Insta lled Pow er

5,475kW (7,340 Hp)Ma in Diesel Generato rs

3 x 1,825 kW (2,447 Hp )QSK60 -D(M)

Emergenc y Generator

1 x 170 kW (228 HP)Ma in Propulsion

2 x 1,685 kW (2,259 Hp )Azimuthing Z-Drives

Steerp rop SP 2001 x 1,685 kW (2,259 Hp )

Fixed Z-Drive

Bow Tunnel Thrusters2x 560 kW (751 Hp)

Berg BFTT-316

CARGO DISCHARGEFue l Oil 150 m3/hr (660 gp m)Rig Fresh Wa te r 150 m3/hr (660 gp m)

Liquid M ud (LM) 150 m3/hr (660 gp m)LM Tank C lea ning System TBD

Bulk Materia l (BM) 50 mt/ hr (55 st / hr)

DECK EQUIPMENT

Rescue Boa t 1 x SOLASDeck Cargo Crane

2 mt @ 6.5 m (2.2 st @ 21.3 ft)Tow Winch:

Doub le Drum 150 mt Line Pull

Ste rn Roller 250 mt SWLStorag e Ree l:

1,500 m x 57 mm (4,921 ft x 0.18 ft)Diameter Wire

Sha rk Jaw 250 mt (276 st) SWL

Anc hor Windlass 1Fire Fighting System Class I

2 pumps @6,600 ga l/min (1,500 m3/hr) eac h2 monitors @ 5,283 ga l/min(1,200 m3/hr) eac h

CONTROL & SAFETYFully integrate d DP / c ontrol dua l re-

dundan t system

Alarm, mo nitoring and c ontrol systemfor pe riod ically unattende d m ac hinery

spaceRemo te c ontrol and mo nitoring o f bulk

mud c argo system

ELECTRONICS

1 Joystic k System fo r DPS-2 system2 Rada rs with ARPA

3 Navigation Gyro Compasses

1 Dep th Sound er1 Autopilot

1 Spee d Log1 Imm arsat B or F77 providing phone ,

fax, E-ma il1 Iridium

1 mini M

1 EPIRB (2 rada r transponders)1 GPS

1 UHF, 2 VHF (b ridge t o b ridge)1 Rad io System c om pliant w ith GMDSS

A3 rules

ACCOMMODATION

Fully air-conditionedAcc omod ations for 22 peo ple com -

po sed o f:

4 x 1 man c ab ins5 x 2 man c ab ins

2 x 4 man c ab insGa lley, 1 Day Roo m, 1 Smo king Day

Room, Mess Room1 Client O ffic e, Sto res

REGISTRATIONType:

Anc hor Hand ling Tug Sup p ly VesselDesigner:

Guido Perla & Associates, Inc.

Classific a tio ns: ABS, DPS-2, SOLASFFV1 AMS AH

Tow ing VesselOffshore Support Ve ssel

GPA 254L AHTS Spec ifications

NOTICE: The d at a c ont ained he rein is provid ed to a llow users to d ete rmine the suitab ility ofthe subject e quipment. Data m ay vary from the c urrent c ondition of eq uipme nt which ca nonly be determined by physical inspection. Company has exercised due diligence to en-sure that the data contained herein is reasonably accurate. However, Company does notwa rrant the ac curacy o r comp leteness of the d ata . In no e vent shall Comp any b e liab le forany d am ag es wha tsoeve r arising out of the use of the d ata co ntained herein.

GPA 254L AHTS SeriesReliab ility in Ad verse Wea ther Cond itions

Excep tiona l Ma neuvrab ilityEnvironmentally Friendly Operations

-

8/8/2019 Gpa 254l Ahts Series

5/6

GPA 254L AHTS54 Vessels

for Bourbon Offshore

In 2008, the first of 54

GPA 254L AHTS ves-sels was delivered atDayang Shipyard for

Bourbon Offshore.

GPA 254L AHTS SeriesReliab ility in Ad verse Wea ther Cond itions

Excep tiona l Ma neuvrab ilityEnvironmentally Friendly Operations

-

8/8/2019 Gpa 254l Ahts Series

6/6

GPA 254L AHTS SeriesReliab ility in Ad verse Wea ther Cond itions

Excep tiona l Ma neuvrab ilityEnvironmentally Friendly Operations

![Barahipath, jif{ @@ c° ^$ @)&$ c;f/ g] 19 k[ ^±^≠!@ dNo ...apeksha thapa gpa: 3.70 kajal rai gpa: 3.70 rohan dahal gpa: 3.70 deewakar dahal gpa: 3.70 ishwor poudel gpa: 3.65 sonam](https://static.fdocuments.us/doc/165x107/5e9ce50a88852d7f7d5df312/barahipath-jif-c-cf-g-19-k-a-dno-apeksha-thapa.jpg)