e Div 9 Recycling

-

Upload

jojee-catap-yabut -

Category

Documents

-

view

221 -

download

0

description

Transcript of e Div 9 Recycling

DIVISION 9 RECYCLING 273

9.1 Scope 273 9.2 Hot-Mix Recycling 273

9.2.1 Description 273 9.2.2 Materials 273 9.2.3 Recycled Asphaltic Concrete Mixes 274

9.2.3.1 Job Mix Formula 274 9.2.3.2 Acceptance Of Job Mix Formula 275

9.2.4 Equipment 276 9.2.4.1 Cold Milling Machine 276 9.2.4.2 Heater And Scarifier 276 9.2.4.3 Crushers 276 9.2.4.4 Mixing Plants 276 9.2.4.5 Spreaders 277 9.2.4.6 Rollers 277

9.2.5 Weather Limitations 277 9.2.6 Construction 277

9.2.6.1 Central Plant Mixing 277 9.2.6.2 In-Site Mixing 278 9.2.6.3 Surface Smoothness 278 9.2.6.4 Determining Aggregate Gradation And Asphalt Content In

Recycled Mixes 278

9.2.7 Traffic Control 279 9.2.8 Work Acceptance 279

9.2.8.1 Quality Control Procedures 279 9.2.8.2 Quality Assurance Procedures 280

9.2.9 Measurements 280 9.2.10 Payment 280

9.3 Cold-Mix Recycling 282 9.3.1 Description 282 9.3.2 Materials 282 9.3.3 Job Mix Formula 282

9.3.3.1 Proposing Job Mix Formula 282 9.3.3.2 Acceptance Of Job Mix Formula 283

9.3.4 Equipment 283 9.3.5 Weather Limitations 283 9.3.6 Construction 283

9.3.6.1 Pulverization 283 9.3.6.2 Mixing 283 9.3.6.3 Placing And Compaction 284 9.3.6.4 Surface Leveling 284

9.3.7 Traffic Control 284 9.3.8 Work Acceptance 284

9.3.8.1 Quality Control 285 9.3.8.2 Quality Assurance 285

9.3.9 Measurements 285 9.3.10 Payment 285

General Specifications of Urban Roads Construction Division 9 - Recycling

Ministry of Municipal & Rural Affairs – Kingdom of Saudi Arabia 273

DIVISION 9

RECYCLING 9.1 Scope:

The asphalt pavement recycling means producing new asphaltic mixes that comprise aggregate obtained from an old asphalt pavement and from new added aggregate, the asphalt binder from an old asphalt pavement and fresh asphalt, and recycling agent for the old asphalt if needed. This technology is used to preserve the natural resources and pavement construction and maintenance funds saving. It helps also in environment protection. Asphalt pavement recycling has several advantages such as: upgrading the structural capacity of the existing pavement by adding small thickness, correcting some pavement distresses such as rutting, shoving, and cracking, treatment of some asphalt mixes, and providing economical solution for reconstruction.

Asphalt recycled mixes are divided into two types: hot-mix recycling (asphaltic

concrete) and cold-mix recycling. Based on production, they are divided into central plant mixing and on-road mixing using mobile mixing plant; and based on depth; they are divided into surface recycling up to fifty (50) millimeters and deep recycling for more than fifty (50) millimeters.

9.2 Hot-Mix Recycling: 9.2.1 Description:

This Section consist of furnishing and mixing new aggregate, pulverized asphaltic concrete pavement, asphaltic material and asphaltic recycling agent, heating and mixing these components, hauling, spreading, and compacting the mixture on a prepared surface, all as shown on the plans, specified in these General Specifications or the Special Specifications.

This Section is applied only when the reclaimed asphalt pavement (RAP)

exceeds twenty (20) percent of the total aggregate weight. The recycled asphaltic concrete containing RAP shall conform to the gradation and quality requirements specified in Section 8.5 in these General Specifications wherever it is used in pavement layers. The recycled asphalt concrete mixes shall be produced in suitable mixing plants which raises the RAP's temperature without damaging it or affecting the environment and controlling the basic prosperities of the final product.

9.2.2 Materials: Added Asphalt Materials: It shall be asphalt cement material conforming to the quality requirements specified in Tables (7.2.1) in these General Specifications. New Aggregate: It shall conform to the quality requirements specified in Table (7.3.1) (types 1, 2, and 3) in these General Specifications. Mineral Filler: Mineral filler shall conform to the requirements specified in Tables (7.3.2) and (7.3.3) in these General Specifications.

General Specifications of Urban Roads Construction Division 9 - Recycling

Ministry of Municipal & Rural Affairs – Kingdom of Saudi Arabia 274

RAP: RAP for hot-mix recycled Asphaltic Concrete shall consist of asphaltic concrete pavement, which has been pulverized or crushed (without being ground), and reduced, in size to the requirements shown in table (9.2.1).

Table 9.2.1: Gradation requirement of aggregate in RAP

Sieve Size Percent Passing 37.5 mm (1.5 inch) 100

25 mm (1 inch) 90-100 Asphalt-Recycling Agent: Hot-mix recycling agent shall be from asphaltic origin and shall conform to the requirements listed in Table (9.2.2) or as specified in the Special Specifications. Chemical Admixtures and Asphalt Modifiers: The types and amounts of chemical admixtures/asphalt modifiers used shall be limited to those listed in the Special Specifications or proposed by the Contractor and approved by the Ministry. They shall conform to the requirements specified in Item 7.2.4 in these General Specifications.

Table 9.2.2: Recycling agent requirements according to ASTM D 4522

Requirements

Property Test Low Grade (RA5)

High Grade (RA25)

Viscosity @ 60 °C, (cSt) AASHTO T-202 200-800 1000-4000 Flash Point, C.O.C., (°C) minimum AASHTO T-48 219 219 Saturates by weight (%), Maximum ASTM D 2007 30 Max. 30 Max.

Tests on Residue From Rolling Thin Film Oven (RTFO) @ 60°C according to AASHTO T-240, OR

Tests on Residue from Thin Film Oven (TFO) Oven @ 163 °C according to AASHTO T-179

Weight change, (%), Maximum - 4.0 3.0 Viscosity Ratio, Maximum (See Note) - 3.0 3.0 Note: Viscosity Ratio = RTFO Residue Viscosity @ 60 °C, cSt) / (Viscosity of the Original Material @

60°C). 9.2.3 Recycled Asphaltic Concrete Mixes: 9.2.3.1 Job Mix Formula: Unless stated in the Special Specifications or Contract Documents, the asphaltic concrete type shall be prepared according to Item 8.5.3 in these General Specifications and according to hot-mix recycling Asphalt Institute Series Manual (MS-20), with the following considerations: RAP: One test for the asphalt content, gradation, and reclaimed asphalt penetration shall be done for every one thousand (1000) cubic meter of RAP, with minimum of five (5) tests in all cases.

General Specifications of Urban Roads Construction Division 9 - Recycling

Ministry of Municipal & Rural Affairs – Kingdom of Saudi Arabia 275

Added Aggregate: The added aggregate, when blended with the RAP, shall conform to all quality requirements specified in Table (7.3.1) (types 1, 2, 3) in these General Specifications. The gradation shall be determined with the RAP according to the targeted gradation. Asphalt Materials: Type, grade, and quantity of asphaltic material, and recycling agent (when used), shall be determined according to the following criteria: • It must help to conform the specific requirements of Asphaltic mixture. • The combined asphaltic material in the final mixture shall have a penetration not

less than forty-five (45) and not greater than fifty-five (55). The variation in penetration, at production, shall be within plus or minus five (5) units.

The Contractor shall furnish and submit a technical report including the JMF prepared by an skilled agency approved by the Ministry. The report shall include, but not limited to, the following:

• The originals of the laboratory test results on the mix. • The originals of the laboratory test results on the RAP and added

materials. • The percentage of RAP to be used, by total weight of mix. • The percentage of added aggregate to be used, by total weight of mix. • The gradation of added aggregate to be blended with the RAP and the

gradation of the final aggregate. • The type, penetration, or viscosity, and percent of asphaltic material to be

added, by total weight of mix. • The type, penetration, or viscosity, and percent of recycling agent to be

added, by total weight of mix. • The penetration or viscosity of the final asphaltic material to be used in

the mix. • The type and amount of mineral filler, chemical admixture, and asphalt

modifier to be added by total weight of mix. • The type and location of plants to be used for mixing each mix to be

furnished. • Construction method. • The proposed beginning date for producing hot-mix recycled asphaltic

concrete mixtures. The Engineer shall be provided access to the materials sampling and testing operations at all times. 9.2.3.2 Acceptance of Job Mix Formula: The Ministry shall review the JMF and all related matters, shown in previous Sub item, submitted by the Contractor according to the following steps: 1. Assure that the report contains all requirements. If it does not contain all required

information, it shall be returned within seven (7) days to the Contractor for further action and resubmission by the Contractor.

2. If the proposed JMF contains all required information but fails to meet all of the requirements specified, it shall not be accepted by the Engineer and will be returned to the Contractor within fourteen (14) days. The Contractor shall prepare and submit to the Engineer a revised JMF conforming to the requirements specified.

3. The fist-day work shall be considered as a field control strip. It shall be assured that mix is constructible in terms of spreading, compaction, and smoothness level.

General Specifications of Urban Roads Construction Division 9 - Recycling

Ministry of Municipal & Rural Affairs – Kingdom of Saudi Arabia 276

The Contractor shall not alter the methods of manufacturing, screening, mixing, stockpiling of aggregate, or production of asphalt mixtures since this alteration will mandate evaluation of JMF. Changing JMF shall not be permitted without retesting and resubmission of a proposed (revised) JMF in accordance with all the steps in Sub-item 9.2.3.1. 9.2.4 Equipment: The Contractor shall furnish suitable equipment to execute the recycling work. The number and the production capacity of this equipment shall be within the Contract time in accordance with his Program of Work as approved by the Engineer. This equipment shall be, but not limited to, the following: 9.2.4.1 Cold Milling Machine: The cold milling equipment shall be self-propelled, equipped with a rotating cutting cylinder and replaceable cutting teeth and be of such size and capacity as may be required to perform the milling work in accordance with required depth. The equipment shall have a water tank, pump and spray bar for applying cooling water to the teeth during cutting and for control of dust. The cold milling machine shall be equipped with an electronically controlled leveling device which will produce the grade and cross-slope specified, and it shall be able to ride-over obstacles such as manhole covers. 9.2.4.2 Heater and Scarifier:

The equipment used to heat and scarify the asphaltic surface shall be self-propelled, equipped to burn liquid petroleum gas (LPG) or natural gas. Diesel fuel shall not be allowed. The combustion chamber shall be insulated to avoid the flame to contact the asphalt rear wheel positioned, and equipped with calibrated burners which is capable of heating the asphaltic surface to a temperature of one hundred and fifty (150) degrees Celsius plus or minus ten (±10) degrees Celsius to a depth between twenty and thirty (20-30) millimeters. The machine shall be equipped with two (2) rows of spring-equalized scarifier-leveling rakes which will automatically ride over obstructions in the surface such as man-hole covers. Additional heater units, without scarifier rakes, shall be operated in advance for preliminary heating. Heater-scarifying equipment shall be capable of being adjusted to heat widths between two and four (2-4) meters.

9.2.4.3 Crushers: Big lumps RAP shall be crushed, using special crushers to obtain the required gradation. 9.2.4.4 Mixing Plants: Mixing plants shall conform to the requirements specified in Section 8.5 in these General Specifications. The plants shall be equipped with devices to raise the RAP temperature by induction with the added aggregates without contacting the flame. These plants may be a batch plant, continuous mix pugmill, or dryer-drum mixing plant. Plants shall be equipped with controls to feed the RAP to pugmill or drum directly within the allowable limits. 9.2.4.5 Spreaders:

General Specifications of Urban Roads Construction Division 9 - Recycling

Ministry of Municipal & Rural Affairs – Kingdom of Saudi Arabia 277

Asphalt spreader, whether independent or attached to heating and scarifier unit, shall conform to all requirements specified in Section 8.5 in these General Specifications, and shall be self-propelled and capable to control the levels and slopes. 9.2.4.6 Rollers: All used pneumatic or steel wheels rollers shall conform to all requirements specified in Section 8.5 in these General Specifications, and shall be capable to compact the pavement to the required density in a fast and easy manner. It shall be self-propelled and equipped with scraper to clean the tires from any adherent materials and steering mechanism shall operate readily and permit the roller to be directed on the alignment desired.

Roller shall have a capacity and weight compatible with the thickness of the layers to be constructed.

Hand-operated rollers may be used provided they have adequate weight to compact the pavement sides to the same level of the pavement body. 9.2.5 Weather Limitations: Weather limitations specified in Item 8.5.5 in these General Specifications shall be applied. 9.2.6 Construction: 9.2.6.1 Central Plant Mixing: When the central plant mixing is used, the following considerations shall be applied:

1. The exact locations of the areas to be recycled along with the respective thicknesses thereof shall be determined and delineated by the Engineer immediately prior to the start of the Work.

2. Surface to be recycled shall be cleaned from untreated base soils and other deleterious materials.

3. The existing asphaltic pavement layer shall be removed in such a manner as to prevent the mixing of the asphalt-bound materials with soils and other deleterious materials, or damage the remaining pavement course or sublayers (base, subbase, or subgrade). The surface shall be smooth conforming to the required levels and slopes.

4. The surface shall be thoroughly checked before placing the asphaltic concrete. If the Contractor finds and defect on the surface or in the sub layers, he shall inform the Engineer, in writing, detailing the extent of the problem, it possible causes, and the remedy method. Defect found due to the Contractor’s removal operations, as determined by the Engineer, shall be repaired by the Contractor at his own expense and prior to the placement of the recycled layer. Deficient parts of base course or subgrade that are to be restored, as shown on the plans or directed by the Engineer prior to start of the removal operations, shall be repaired and paid for separately as specified in the pertinent sections of the Contract documents and Bill of Quantities.

5. RAP materials shall be reduced, without grinding the aggregates, to a size smaller than thirty seven and one half (37.5) millimeters as specified in Item 9.2.1 in this Section.

General Specifications of Urban Roads Construction Division 9 - Recycling

Ministry of Municipal & Rural Affairs – Kingdom of Saudi Arabia 278

6. RAP materials shall not be exposed to flame for heating or mixing purpose at any time.

7. Reclaimed aggregate, after being reduced to the required size and prior to their use in the recycled mixture, shall be segregated into two sizes: course retained on No. 4 sieve (4.75 millimeter), and fine passing a No. 4 sieve (4.75 mm), when using central plant mixing.

8. The used mixing plant shall be suitable to feed all mix components at their proportions in the JMF, and heating the RAP to the required temperature by heat transfer with the added aggregates so as not to damage the asphalt binder, and be capable to produce uniform asphaltic concrete conforming to the specifications

9.2.6.2 In-Site Mixing: When the recycling construction is-site mixing is selected, the asphaltic concrete shall be done in layers suitable to the maximum size aggregate as specified in Table (8.5.5) in these General Specifications. When the work requires construction in layers, the top layers shall be removed and properly stored, then the bottom layer is scarified or milled, heated, and mixed with other components specified in the JMF, then the top layer shall be brought, heated, mixed, spread, and compacted. This process is repeated for other layers. If approved by field trail to obtain asphaltic concrete conforming to the specifications, the added aggregates and asphalt cement may be mixed in central plant, then hauled the mixture and mix it with RAP by a mobile mixing plant after heating and adding the recycling agent. It may also be applicable to spread the aggregate, cold or hot, coated or uncoated, before the scarifier, so that it collects it and mixes it with RAP and conveys it to mobile mixing plant. The recycling agent may be sprayed, at the predetermined amount, before or after pavement removal, while stockpiling, or while mixing provided it serves the purpose of its utilization. 9.2.6.3 Surface Smoothness: The recycled asphaltic concrete wearing course shall conform to the requirements specified in Sub item 8.5.6.10 in these General Specifications. 9.2.6.4 Determining Aggregate Gradation and Asphalt Content in Recycled Mixes: The asphaltic concrete aggregate gradation and asphaltic content will be sampled, tested and evaluated in accordance AASHTO T-164. The asphalt penetration or viscosity is determined by Abson method according to AASHTO T-170. The limit for payment purposes are as follows:

1. Aggregate gradation: The upper and lower specification limits are the approved JMF target values plus or minus the allowable deviations shown in Table (8.5.1) multiplied by one plus the ratio of reclaimed asphalt pavement (RAP) material to the total mixture. Round to the nearest percent except for the 0.075 mm (No. 200) sieve that is rounded to the nearest 0.10%.

Example: If thirty percent (30%) of the mixture is reclaimed asphalt pavement material, then all allowable deviation from target value for percent of aggregate passing the 0.075 mm (No. 200) sieve is 2x (1.30) = 2.6%. Use plus 0.3% and minus 0.3% from the approved JMF target value for percent passing the 0.075 mm (No. 200) sieve.

General Specifications of Urban Roads Construction Division 9 - Recycling

Ministry of Municipal & Rural Affairs – Kingdom of Saudi Arabia 279

2. Asphaltic material content. The upper and lower specification limits are

the approved job-mix formula target value ±0.4 x (1 + the ratio of the reclaimed asphalt pavement material to the total mixture rounded to the nearest 0.10%). Example: If thirty percent (30%) of the mixture is reclaimed asphalt pavement material, then the allowable deviation from target value for percent asphalt content is 0.4x(1.30) = 0.52%. Use plus 0.5% and minus 0.5% from approved JMF target value for asphaltic material content.

3. Asphaltic penetration. The minimum allowable limits are equal to the

approval JMF plus or minus fifteen (15) units. 9.2.7 Traffic Control:

The Contractor shall take effective action to allow safe traffic operations when using the recycling work as specified by Item 8.5.7 in these General Specifications. 9.2.8 Work Acceptance:

The Contractor shall apply quality control procedures for all recycled asphaltic concrete works to ensure that the materials used and the executed work conform to these General Specifications and other Contract’s Documents.

The Ministry shall assure the quality of production by checking that the

Contractor is performing the quality control procedures in correct manners. The Ministry may have a direct supervision on the quality control system or by applying quality assurance procedures in an independent unbiased way, on adequate number of samples to judge the execution level and decide whether to accept or reject the work. Division 17 in these General Specifications shall be used for this purpose, unless stated otherwise in the Special Specifications or Contract’s Documents.

9.2.8.1 Quality Control Procedures:

The Contractor shall perform all required tests and measurements, and shall collect, document, and draw the critical property diagrams to ensure that the raw materials at source, materials while work execution, recycled asphaltic concrete produced, and the executed work are within acceptable limits. The tests may be performed at The Contractor’s laboratory or at an independent laboratory, approved by the Ministry. The Contractor shall submit copies of all test results to the Engineer. Table (9.2.3) shows the tests that the Contractor shall perform on raw materials and mixes, the frequency of these tests, and the allowance limits. The Contractor shall submit copies of all tests to the Engineers and shall apply all requirements detailed in Item 17.1.1 in these General Specifications. 9.2.8.2 Quality Assurance Procedures:

The Ministry reserves the right, at any time, to assure the quality of materials and executed work by performing or ordering the Contractor to perform, under its direct supervision, some or all quality control tests that are shown previous Sub item 9.2.8.1. The Ministry has also the right to inspect all Contractors' quality control test records and compare them with its quality assurance test done according to Division 17 in these

General Specifications of Urban Roads Construction Division 9 - Recycling

Ministry of Municipal & Rural Affairs – Kingdom of Saudi Arabia 280

General Specifications. Ministry may inspect Contractor's laboratory, devices, technical staff, and testing methods to assure the full adequacy and capability of the Contractor to execute the work according to standard approved methods.

9.2.9 Measurements:

The quantity of each lot and course of hot-mix recycled asphaltic concrete pavement shall be measured by the cubic meter or as stated in Special Specifications, as placed and compacted to the required density, within the lines and grades, and thickness shown on the plans or directed by the Engineer. No measurement will be made for extra thickness or areas of pavement placed outside authorized limits.

Asphalt cement and modified asphalt cement shall be considered subsidiary to

the construction of each lot of asphaltic concrete pavement unless specifically stated in the Special Specifications and listed in the Bill of Quantities. When they are listed separately they shall be measured in liters.

Hot-mix asphaltic recycling agent shall not be measured separately unless

specifically stated in the Special Specifications and the item is listed in the Bill of Quantities, in which case it will be measured in liters.

Mineral fillers, chemical admixtures and asphalt modifiers used by the

Contractor to meet the Job Mix Formula (JMF) requirements will be considered subsidiary to the construction of the asphaltic concrete layers and will not be measured separately unless specifically stated in the Special Specifications and listed in the Bill of Quantities. When they are listed separately they shall be measured as in the specific specifications Section 8.3.

Prime coat shall be measured as specified in Section 8.2, in these General Specifications. Tack coat shall not be measured for payment purposes. 9.2.10 Payment:

Payment shall be made at the contract unit price, or adjusted contract unit price, per cubic meter measured as described in the pervious Item for each grading and class of recycled asphaltic concrete listed in the Bill of Quantities.

The above prices and payment shall cover and be full compensation for

furnishing labor, materials, equipment, tools and incidentals necessary for completing all work involved in construction of asphaltic concrete pavement, payment will be made according to Table (9.2.4).

General Specifications of Urban Roads Construction Division 9 - Recycling

Ministry of Municipal & Rural Affairs – Kingdom of Saudi Arabia 281

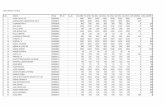

Table 9.2.3: Quality control requirements for hot-mix recycling

Work Properties Test Method Sample location Sampling frequency Requirement

s

Asphaltic material

Quality requirements

tests

Certification of compliance and supply

and source change Table 7.2.1

New Aggregates Quality

requirements tests

Three (3) tests at start of work or source change Table 7.3.1

Recycling agents

Quality requirements

tests

Certification of compliance at start of work or source change

Table 9.2.1

RAP AASHTO T-27

Three (3) tests at start of work or source change

Item 9.2.2 (RAP)

Mineral Filler

Quality requirements

tests

Certification of compliance and supply

and source change

Contract documents

Raw materials

Chemical admixture and

modifiers

Quality requirements

tests

Source

Certification of compliance and supply

and source change Table 7.3.2

Aggregate gradation

AASHTO T-164/T-27

Asphalt content AASHTO T-164/T-170

One (1) test every five hundred (500) ton

produced or for each working day whichever

the minimum

JMF

Viscosity of the asphalt materials

AASHTO T-201

Material at use

Penetration of the asphalt materials

AASHTO T-49

project site One (1) test every five

thousand (5000) ton produced or for each

working day whichever the minimum

JMF

Compaction AASHTO T-2726

Minimum one (1) test every 1000 cubic square meters from each layer

Sub item 8.5.6.8

Thickness ASTM D 3549

Minimum one (1) test every 1000 cubic square meters from each layer

Sub item 8.5.6.6 Road

Surface roughness

Approved device

Project site

Five (5) measuring per day or thousand (1000)

meter whichever the minimum for each lane.

Sub item 8.5.6.10

Finishing

Level, dimensions, slopes, and smoothness

Contract documents

Project site

Transverse segments every 25 meters or five segments every 1000 meters, whichever the

maximum

Contract documents

Table 9.2.4: Hot-mix recycling pay items

No. Pay Item Pay units

9.2.1 Hot-mix recycling type __________ gradation ___________ Cubic meter

General Specifications of Urban Roads Construction Division 9 - Recycling

Ministry of Municipal & Rural Affairs – Kingdom of Saudi Arabia 282

9.3 Cold-Mix Recycling:

9.3.1 Description: This Section consist of furnishing and mixing new aggregate, pulverized

asphaltic concrete pavement, asphaltic material (emulsified and non-emulsified) and/or asphaltic recycling agent, mixing these components, hauling, spreading, and compacting the mixture on a prepared surface, all as shown on the plans, specified in these General Specifications or the Special Specifications. The recycled pavement, by this method, is used in asphaltic concrete base course in the same site or different sites. These base layers shall be covered by a surface treatment or an asphaltic wearing course. There are two construction methods:

1. In-place cold-mix recycling: it is used at roads with low traffic volumes or in

remote areas away form central mixing plants. 2. Cold-mixing in central mixing plant: it is used when high production rates and

precise control are required. 9.3.2 Materials:

The cold-mix containing RAP shall conform to the materials requirements for cold mixes specified in Section 7.2 and Section 7.3 in these General Specifications, unless otherwise specified in Contract Documents. These requirements shall include the following:

RAP: RAP shall be pulverized or crushed (without being ground), and reduced, in size so that all particles pass one hundred (100) percent from sieve size thirty-seven and one half (37.5) millimeters. New Aggregate: When specified in the Special Specifications or required by the Job Mix Formula, new aggregate shall be blended with RAP. The new aggregate, when combined with the RAP materials, shall conform to the fracture, gradation and quality requirements as necessary to produce the specified base course Asphalt Materials: The types and grades of asphaltic materials shall conform to the grade listed in the Special Specifications and requirements specified in the Tables (7.2.2) through (7.2.5) in these General Specifications. Asphalt-Recycling Agent: Recycling agent shall conform to the requirements listed in Table (9.2.2) or as specified in the Special Specifications. Test results and Certificate of Compliance shall be submitted with each shipment of the recycling agent. 9.3.3 Job Mix Formula: 9.3.3.1 Proposing Job Mix Formula: The procedure outlined in Sub item 9.2.3.1 shall be followed for proposing the JMF. The Contractor shall submit to the Engineer his proposed method of operation and test data confirming that the aggregate will conform to all specified fracture, gradation and quality requirements.

General Specifications of Urban Roads Construction Division 9 - Recycling

Ministry of Municipal & Rural Affairs – Kingdom of Saudi Arabia 283

9.3.3.2 Acceptance of Job Mix Formula: The revision and acceptance of the cold-mix recycled asphaltic mixture job mix

formula shall be in accordance with Sub item 9.2.3.2.

9.3.4 Equipment: The Contractor shall furnish suitable equipment to execute the recycling work.

The number and the production capacity of this equipment shall be within the Contract time in accordance with his Program of Work as approved by the Engineer, and shall include equipment detailed in Item 9.2.4 in this Division.

9.3.5 Weather Limitations: Cold mix recycled asphaltic materials shall not be mixed or placed during rainfall, dust or sand storms, when the ambient temperature is less than five (5) degrees Celsius or when weather conditions prevent specified mixing and compaction requirements. 9.3.6 Construction:

The exact locations of the areas to be recycled along with the respective thicknesses thereof shall be determined and delineated by the Engineer immediately prior to the start of the Work. The construction process shall involve pulverization, mixing, and compaction.

9.3.6.1 Pulverization:

The Contractor shall submit to the Engineer prior to the start of the work the proposed pulverization method for the existing pavement and the addition and mixing in place of any required new aggregate and new asphalt or recycling agent. The resultant mixture shall be spread, compacted, and finished.

The Contractor shall pulverize the existing pavement to the required size and

shall add any amount of new aggregate and asphalt required by JMF. Undesirable contamination of the reclaimed materials with underlying untreated

base course or subgrade materials, clay, silt, or other deleterious matter shall not be accepted. Should such undesirable contamination occur, as determined by the Engineer, the materials shall be discarded as directed and shall be replaced with new approved materials, all at the Contractor’s expense.

9.3.6.2 Mixing :

Mixing asphaltic materials and/or recycling agent with RAP shall be uniform using any of the following methods:

1. The asphaltic material and/or recycling agent may be applied through the machine used to cold mill the asphaltic surface as a part of the liquid used to cool the cutter teeth, provided it is applied uniformly across the width of cut and results in a complete and uniform blending of all materials.

2. The asphaltic material and/or recycling agent may be applied through a mixing machine capable of mixing a windrow of RAP and other materials on the road side.

3. The asphaltic material and/or recycling agent may be added through a paving machine that is capable of mixing and placing the recycled asphaltic base in its final position for compacting.

General Specifications of Urban Roads Construction Division 9 - Recycling

Ministry of Municipal & Rural Affairs – Kingdom of Saudi Arabia 284

4. The cold mix recycled asphaltic base may be produced using a continuous operation consisting of an interconnected cold milling device, portable crusher mounted on a trailer, cold mixing pugmill mounted on a trailer, paving machine, materials transfer belts for moving the materials from milling equipment through to the paving machine and compaction equipment. When new aggregates are required they shall be spread uniformly at the approved quantity on the road surface in advance of the cold milling machine.

Regardless of which method is used, mixing equipment shall have accurately meter

the planned amount of asphaltic material and/or recycling agent into the RAP and aggregate.

When directed by the Engineer, water shall be added to the RAP to facilitate

uniform mixing with asphaltic materials. Water may be added prior to or concurrently with adding the asphaltic materials, as approved by the Engineer.

9.3.6.3 Placing and Compaction:

The recycled mixture shall be compacted using pneumatic or steel-drum tandem roller (vibratory or normal) until the compacted density of recycled mixture is at least ninety-six (96) percent from the Marshall laboratory compacted specimen determined from ASTM D 2726.

After the recycled mixture has been spread and compacted, it shall be allowed to

cure for at least three (3) days to reduce the moisture content prior to placing a wearing surface. Additional curing time may be required by the Engineer in the event that the recycled mixture becomes wet during rainfall. Any damage to the recycled mixture shall be repaired by and at the Contractor's expense and to the satisfaction of the Engineer. 9.3.6.4 Surface leveling: After each working day, the final surface after completion of compaction shall tested for leveling, and shall have no depressions under a four (4) meter straightedge greater than three (6) millimeters when laid parallel or transverse to the centerline. 9.3.7 Traffic Control:

The Contractor shall take effective action to allow safe traffic operations when using the recycling work as specified by Item 8.5.7 in these General Specifications.

9.3.8 Work Acceptance:

The Contractor shall apply quality control procedures for all cold-mix recycled asphaltic concrete works to assure that the materials used and the executed work conform to these General Specifications and other Contract’s Documents.

The Ministry shall assure the quality of production by checking that the

Contractor is performing the quality control procedures in correct manners. The Ministry may have a direct supervision on the quality control system or by applying quality assurance procedures in an independent unbiased way, on adequate number of samples to judge the execution level and decide whether to accept or reject the work.

General Specifications of Urban Roads Construction Division 9 - Recycling

Ministry of Municipal & Rural Affairs – Kingdom of Saudi Arabia 285

Division 17 in these General Specifications shall be used for this purpose, unless stated otherwise in the Special Specifications or Contract’s Documents. 9.3.8.1 Quality Control :

The Contractor shall perform all required tests and measurements, and shall collect, document, and draw the critical property diagrams to ensure that the raw materials at source, materials while work execution, cold-mix recycled asphaltic concrete produced, and the executed work are within acceptable limits. The tests may be performed at The Contractor’s laboratory or at an independent laboratory, approved by the Ministry. The Contractor shall submit copies of all test results to the Engineer. Table (9.3.1) shows the tests that the Contractor shall perform on raw materials and mixes, the frequency of these tests, and the allowance limits. The Contractor shall submit copies of all tests to the Engineers and shall apply all requirements detailed in Item 17.1.1 in these General Specifications.

9.3.8.2 Quality Assurance :

The Ministry reserves the right, at any time, to assure the quality of materials and executed work by performing or ordering the Contractor to perform, under its direct supervision, some or all quality control tests that are shown previous Sub item. The Ministry has also the right to inspect all Contractors' quality control test records and compare them with its quality assurance test done according to Division 17 in these General Specifications. Ministry may inspect Contractor's laboratory, devices, technical staff, and testing methods to assure the full adequacy and capability of the Contractor to execute the work according to standard approved methods.

9.3.9 Measurements:

The quantity of each lot and course of cold-mix recycled asphaltic pavement shall be measured by the cubic meter, as placed and compacted to the required density, within the lines and grades, and thickness shown on the plans or directed by the Engineer. No measurement will be made for extra thickness or areas of pavement placed outside authorized limits.

Cold-mix asphaltic recycling agent shall not be measured separately unless

specifically stated in the Special Specifications and the item is listed in the Bill of Quantities, in which case it will be measured in liters. 9.3.10 Payment:

Payment shall be made at the contract unit price, or adjusted contract unit price, per cubic meter measured as described in the pervious Item for each grading and class of recycled asphaltic concrete listed in the Bill of Quantities.

The above prices and payment shall cover and be full compensation for

furnishing labor, materials, equipment, tools and incidentals necessary for completing all work involved in construction of asphaltic concrete pavement. Payment will be made according to Table (9.3.2).

General Specifications of Urban Roads Construction Division 9 - Recycling

Ministry of Municipal & Rural Affairs – Kingdom of Saudi Arabia 286

Table 9.3.1: Quality control requirements for cold-mix asphaltic concrete mixes

Work Properties Test Method

Sample location Sampling frequency Requirements

Asphaltic material

Quality requirements

tests

Certification of compliance and supply and source

change

Tables 7.2.2.A to 7.2.5

New Aggregates

Quality requirements

tests

Three (3) tests at start of work or source change Table 7.3.1

Recycling agents

Quality requirements

tests

Certification of compliance and supply and source

change Table 9.2.1

Raw materials

RAP AASHTO T-27

Source

Three (3) tests at start of work or source change

Item 9.3.2 (RAP)

Aggregate gradation

AASHTO T-164/T-27 Material

at use Asphalt content

AASHTO T-164/T-170

Project site

two (2) tests every 2000 square meters from each

layer or each working day JMF

Compaction

ASTM D 2726

Minimum one (1) test every 1000 cubic square meters

from each layer

Sub item 9.3.6.3

Thickness ASTM D 3549

Minimum one (1) test every 1000 cubic square meters

from each layer

Contract documents

Road

Surface roughness -

Project site

Straight edge for each working day

Sub item 9.3.6.4

Finishing

Level, dimensions, slopes, and smoothness

Contract documents

Project site

Transverse segments every 25 meters or five segments

every 1000 meters, whichever the maximum

Contract documents

Table 9.3.2: Cold-mix recycling pay items

No. Pay Item Pay units

9.3.1 Cold-mix recycling type __________ gradation ___________ Cubic meter