Container Terminal NCB Container Terminal Tobishima Pier North

Transcript of Container Terminal NCB Container Terminal Tobishima Pier North

23

23

247

302

全日検一般社団法人

日本貨物検数協会一般社団法人

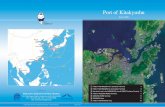

NUTS Terminal Map

Gate procedural work conventionally conducted at each terminal is consolidated to the integrated control gate installed outside the terminal premises

Start of service: 1970 at Nagoya Container PierPier length: 900 mNo. of gantry cranes: 6Cargo handling style: Straddle careerContainer Yard: 289,000 m2

Start of service: 1984Pier length: 620 mNo. of gantry cranes: 3Cargo handling style: Straddle careerContainer Yard: 170,000 m2

Tobishima Pier North Container Terminal

Association Pro�le

NCB Container Terminal

Start of service: 1991Pier length: 700 mNo. of gantry cranes: 6Cargo handling style: Straddle careerContainer Yard: 225,000 m2

Start of service: 2005 at Tobishima Container PierPier length: 750 mNo. of gantry cranes: 6Cargo handling style: Transfer craneContainer Yard: 354,500 m2

Integrated Control Gate

Start of service: 2001 at Nagoya United Container TerminalPier length: 985 mNo. of gantry cranes: 8Cargo handling style: Transfer craneContainer Yard: 548,500 m2

Nabeta Pier Container terminal

Tobishima Pier South Side Container TerminalTobishima Pier South Container Terminal

Organization Chart of Container Terminal Department of Nagoya Harbor Transportation Association

NagoyaHarbor Transportation

AssociationNagoya Container Committee Container Terminal Department Nabeta Container

Terminal Section

Tobishima East SideTerminal Section

TCB Terminal SectionNUTS System Development& System Engineering Team

Isewangan Expressway

InaeiPier

ShiomiPier

Obu ICTokai ICShiomi ICChuo ICTobishimaIC

Yatomi IC

Garden Pier

YatomiTown

TobishimaVillage

TokaiCity

TokaiMotohama

Pier

Port Island

Nikko River

Shonai R

iver

NabetaPier

NorthIntegratedControl

GateSouth

South Side

Nabeta

NCB

Container terminal departmental meeting member involved in NUTS development

Photo by Nagoya Port Authority

TobishimaPier Nagoya to the World,

a Bridge of Logistics

Nagoya United Terminal System

Nagoya R

ing Road

No.2

Nagoya City

Nagoya

Exp

ressway

KasaderaIC

Chitahanto R

oad

OdakaIC

Odaka

Nagoyaminami

IC

ASAHI UNYU KAISHA, LTD.

NIPPON EXPRESS CO.,LTD. FUJITRANS CORPORATION

ISEWAN TERMINAL SERVICE CO.,LTD.

MITSUI-SOKO CO.,LTD.

KAMIGUMI Co., Ltd.

MITSUBISHI LOGISTICS CORPORATION MEIKO TRANS CO.,LTD.

TOKAI KYOWA CO.,LTD. TOYO LOGISTICS CO.,LTD.

ALL NIPPON CHECKERS CORPORATION

JAPAN CARGO TALLY CORPORATION

CSControl System

Nagoya United Terminal System

YPYard

Planning System

VPVessel Planning System

YOYard

Operation System DGPS

PDS

We hereby express our deep appreciation for your continuing support for the operation of Nagoya Port Container Terminal.

In 2017, the Port of Nagoya handled 2.69 million TEU of cargo, making it the third largest in Japan. The Port will be

improved further as some of the 13 container berths installed in Tobishima and Nabeta Piers are upgraded to handle larger

vessels with deepening projects and anti-seismic designs, as well as replacement of existing gantry cranes.

“NUTS” is a terminal operation system utilized by all container terminals in the Port of Nagoya. It has grown to be an

indispensable system for shipping companies, shipper, forwarder and port operators to bene�t from high quality services

available at the container terminals.

In 1997, Container Terminal Department of Nagoya Harbor Transportation Association resolved to establish “Nagoya

United Terminal System (NUTS)” and realized the uni�cation of all terminal systems in the Port of Nagoya in August 1999.

The participating members continued holding development meetings to share their experience and ideas and thus

upgraded the System to “New NUTS” in 2007 and “Next-generation NUTS” in 2014 realizing a more ef�cient terminal

operation. Various improvements have been implemented by systemizing the container logistics, such as an expanded

NUTS-Web function to provide better services to the terminal users and the operation of integrated control gate to resolve

the traf�c congestion in the piers.

We the staff members are determined to continue to improve and develop this System for enhancing the global

competitiveness of the Port of Nagoya for the bene�t of our customers, while focusing on the working condition of the

container logistics in the Port and keeping in mind the “heart of NUTS” which we shared in the beginning. We therefore ask

for your continuing support and cooperation.

We would like to take this opportunity to express our heartfelt gratitude for Nagoya Customs, Nagoya Port Authority,

Nagoya Port Terminal Corporation, Nagoya-Yokkaichi International Port Corporation, Nagoya Terminal Service Center,

Nagoya Kaiun Kyokai, Tobishima Container Berth Co., Ltd., Aichi Trucking Association Kaijo Container Bukai and other

partners for their consistent support and guidance for the operation of NUTS.

Nagoya Harbor Transportation AssociationNagoya Container Committee Container Terminal Department

June 2018

Greeting

NUTS stands for Nagoya United Terminal System, a united terminal system operated at the Port of Nagoya.

An ef�cient and functional terminal operation has been realized by four sub-systems mentioned below that

carry out, through a mutual linkage, such tasks as container loading/unloading, planning, container storage

management, container carry-in/out management, yard operation management, bonded management, etc.

NUTS also has realized an unmatched network environment which connects all users with cargo handling

equipment and various communication devices in the terminals, all �ve container terminals and integrated

control gate in the Port, Sea-NACCS with the customs and NUTS-Web with the terminal users.

After its establishment in 1999, NUTS has been enhanced continuously with

new container terminals and integrated control gate for more functional

operation with improved ef�ciency, whereby it was upgraded to “New NUTS”

in 2007 and “Next-generation NUTS” in 2014. The Next-generation NUTS is

equipped with disaster response functions including the “emergency simulta-

neous noti�cation” delivered to all terminal work equipment and devices, as

well as cooperation with duplicated data centers for distant area.

We are currently working on a new project “NUTS second” with the introduc-

tion of a further advanced terminal operation system, as part of our continu-

ing evolution into the future.

Schematic

NUTS consists of 4 systems

Control System

Ever Advancing NUTS

YardPlanning

SystemYard management,

yard simulation

Vessel Planning SystemVessel planning operation

YardOperation

System

Ef�cient and functional terminal operation system operated at all container terminals in the Port of Nagoya.

Job execution management of DGPS, radio, in-vehicle

communication devices, status monitoring inside the yard

Bonds management, gate management, vanpool management, Sea-Naccs operation, EDI service, etc.

CSControl System

Nagoya United Terminal System

YPYard

Planning System

VPVessel Planning System

YOYard

Operation System DGPS

PDS

We hereby express our deep appreciation for your continuing support for the operation of Nagoya Port Container Terminal.

In 2017, the Port of Nagoya handled 2.69 million TEU of cargo, making it the third largest in Japan. The Port will be

improved further as some of the 13 container berths installed in Tobishima and Nabeta Piers are upgraded to handle larger

vessels with deepening projects and anti-seismic designs, as well as replacement of existing gantry cranes.

“NUTS” is a terminal operation system utilized by all container terminals in the Port of Nagoya. It has grown to be an

indispensable system for shipping companies, shipper, forwarder and port operators to bene�t from high quality services

available at the container terminals.

In 1997, Container Terminal Department of Nagoya Harbor Transportation Association resolved to establish “Nagoya

United Terminal System (NUTS)” and realized the uni�cation of all terminal systems in the Port of Nagoya in August 1999.

The participating members continued holding development meetings to share their experience and ideas and thus

upgraded the System to “New NUTS” in 2007 and “Next-generation NUTS” in 2014 realizing a more ef�cient terminal

operation. Various improvements have been implemented by systemizing the container logistics, such as an expanded

NUTS-Web function to provide better services to the terminal users and the operation of integrated control gate to resolve

the traf�c congestion in the piers.

We the staff members are determined to continue to improve and develop this System for enhancing the global

competitiveness of the Port of Nagoya for the bene�t of our customers, while focusing on the working condition of the

container logistics in the Port and keeping in mind the “heart of NUTS” which we shared in the beginning. We therefore ask

for your continuing support and cooperation.

We would like to take this opportunity to express our heartfelt gratitude for Nagoya Customs, Nagoya Port Authority,

Nagoya Port Terminal Corporation, Nagoya-Yokkaichi International Port Corporation, Nagoya Terminal Service Center,

Nagoya Kaiun Kyokai, Tobishima Container Berth Co., Ltd., Aichi Trucking Association Kaijo Container Bukai and other

partners for their consistent support and guidance for the operation of NUTS.

Nagoya Harbor Transportation AssociationNagoya Container Committee Container Terminal Department

June 2018

Greeting

NUTS stands for Nagoya United Terminal System, a united terminal system operated at the Port of Nagoya.

An ef�cient and functional terminal operation has been realized by four sub-systems mentioned below that

carry out, through a mutual linkage, such tasks as container loading/unloading, planning, container storage

management, container carry-in/out management, yard operation management, bonded management, etc.

NUTS also has realized an unmatched network environment which connects all users with cargo handling

equipment and various communication devices in the terminals, all �ve container terminals and integrated

control gate in the Port, Sea-NACCS with the customs and NUTS-Web with the terminal users.

After its establishment in 1999, NUTS has been enhanced continuously with

new container terminals and integrated control gate for more functional

operation with improved ef�ciency, whereby it was upgraded to “New NUTS”

in 2007 and “Next-generation NUTS” in 2014. The Next-generation NUTS is

equipped with disaster response functions including the “emergency simulta-

neous noti�cation” delivered to all terminal work equipment and devices, as

well as cooperation with duplicated data centers for distant area.

We are currently working on a new project “NUTS second” with the introduc-

tion of a further advanced terminal operation system, as part of our continu-

ing evolution into the future.

Schematic

NUTS consists of 4 systems

Control System

Ever Advancing NUTS

YardPlanning

SystemYard management,

yard simulation

Vessel Planning SystemVessel planning operation

YardOperation

System

Ef�cient and functional terminal operation system operated at all container terminals in the Port of Nagoya.

Job execution management of DGPS, radio, in-vehicle

communication devices, status monitoring inside the yard

Bonds management, gate management, vanpool management, Sea-Naccs operation, EDI service, etc.

P8

P9

P10

54

Operation Flow

NUTS Assists Terminal Operation in All Processes from Loading/Unloading to Carry in/out

Stock Control

Operation Management

Process Directive

Unloading

Planning

Yard Management

Damage check at check bridge (handy terminals)

Instructions on storage yard (In-vehicle terminals for trailer)

Updating the stock status of CY real-time (Yard planning)

Loading

Container number con�rmation at ship side (Vessel tablet)

Providing support for planning (Vessel planning) by an excellent GUI (Graphical User Interface) function

Real-time monitoring of work progress onboard, immediately responding to work interruptions or alternations (Job control)

Total support is given to complicated container terminal work operations such as instructions to cargo handling equipment, container information maintenance from loading/unloading to carry-in/out of ship cargo, vessel planning, yard planning, etc.Vessel tablet, handy terminals used for container check onboard or at the gate and other in-vehicle terminals mounted in cargo handling equipment can provide accurate work instructions and realize a substantial paperless work environment, thus improving safety and eco-friendliness.

Carry Out

Gate Management

Carrying Out Processing

Process Directive

Carrying In Processing

Damage check and carry-out processing (handy terminals)

Integrated Control Gate

Instructions on carry-in/out operation and transmission of work completion (In-vehicle terminals for straddle carrier/RTG)

Controlling congestion in the yard (Delivery control program)

Handling carry-in/out for stay-in drivers (using RFID)

Carry In

Vessel Tab

let

RF

ID

Integrated Control Gate

P8

P9

P10

54

Operation Flow

NUTS Assists Terminal Operation in All Processes from Loading/Unloading to Carry in/out

Stock Control

Operation Management

Process Directive

Unloading

Planning

Yard Management

Damage check at check bridge (handy terminals)

Instructions on storage yard (In-vehicle terminals for trailer)

Updating the stock status of CY real-time (Yard planning)

Loading

Container number con�rmation at ship side (Vessel tablet)

Providing support for planning (Vessel planning) by an excellent GUI (Graphical User Interface) function

Real-time monitoring of work progress onboard, immediately responding to work interruptions or alternations (Job control)

Total support is given to complicated container terminal work operations such as instructions to cargo handling equipment, container information maintenance from loading/unloading to carry-in/out of ship cargo, vessel planning, yard planning, etc.Vessel tablet, handy terminals used for container check onboard or at the gate and other in-vehicle terminals mounted in cargo handling equipment can provide accurate work instructions and realize a substantial paperless work environment, thus improving safety and eco-friendliness.

Carry Out

Gate Management

Carrying Out Processing

Process Directive

Carrying In Processing

Damage check and carry-out processing (handy terminals)

Integrated Control Gate

Instructions on carry-in/out operation and transmission of work completion (In-vehicle terminals for straddle carrier/RTG)

Controlling congestion in the yard (Delivery control program)

Handling carry-in/out for stay-in drivers (using RFID)

Carry In

Vessel Tab

let

RF

ID

Integrated Control Gate

NUTS-Websystem

www.nutsweb.com

76 76

NUTS-Web

Ever Advancing NUTS-WebNUTS-Web system uni�es and networks all terminal systems of the Port of Nagoya.

This system has enabled widely transmitting information from the terminal to the outside via Internet.

Advance examination application submission

Advance examination application cancellation

Dispatch order issuance notice

Dispatch order status reference

Dispatch order directive division

Dispatch order batch division

Carry-out permission check

Carry-out progress check

Inspection application submission

Inspection application maintenance/reference

Advance examination batch application

Check vessel entry schedule

Vessel schedule reference

Notice menu

Main Menu

Status change notice request

Empty carry-out reservation (screen)

Empty carry-out reservation (�le)

Pick-up status reference

Booking information reference

Carry-in ledger advance examination

Weekday gate outside-hours ticket reservation

Weekday gate outside-hours history output

Holiday carry-in request

Holiday carry-out request

Holiday carry-in/out history output

Progress inside yard (Tobishima Area)

Progress inside yard (Nabeta Area)

DispatchCenter

Dispatch Order

Application

Advance ExaminationApplication

This system issues dispatch orders on the Internet based on advance document examination.By taking in information on clearance from Sea-Naccs and D/O release from shipping companies, the man-hours required for accepting imported cargo have been reduced, and logistics ef�ciency has been improved.

Advance Examination Application for Import

Advance examination application

Check/ Issuance

Reference of application status

Order division

Carry-out status check

Carry-out permission check

Dispatchorders presented

Terminal

Users

Dispatch orders issuing process by web users

NACCS participated, DOR01 unexecuted,

D/O presentedNACCS not participated,

D/O and clearance document presented

Application for various inspection processes in the terminal can be made on the Web, and the inspection status and details of the target container can be browsed.

Ledger entries can be input on the Website in advance before arriving at the carry-in gate for advance document check, shortening the time required for the gate check.

Customs inspection

Inspection of animals/plants

Scene of Inspection(plants)

Inspection applicationreference

Users

Application

Booking information

Advance examinationinformation

Reporting differences

NUTS-Web Inspection Application System

Carry-in Ledger Advance Check

Bookinginformation

Inspection ApplicationSystem

Forwarder

ShippingCompany

Shipper

CY

Creating carry-in information,Entry data check

For reduction of checking time

Containers to priority lane after advance examination

Arrival at weigh bridge <lane distribution instruction>

Integrated Control Gate,Weigh Bridge

Arrival at priority lane<container physical check>

Checking difference between carry-in ledger and physical container

<Inspections for Application/Reference>

Gate Lane

Users (Forwarder)(Shipper)

ECDoperators

Trailercompany

This function accepts booking of empty containers for export on the Web. By inputting the required items, the applicant receives Pickup Order No., and RFID enables smooth pickup by trailers.

Pickup Order No. input into RFID

Pickup Order No. checked or sent by email

Booking information registered

Pickup Order No. issued

CS(NUTS)

Accessing with Booking No., ship company name

Empty Container Booking

NUTS-Websystem

NUTS-Websystem

Empty ContainerBooking

NUTS-Websystem

Sea-NACCS

Clearanceinformation,

DOR

◎ Inspection on animals and plants

◎Customs onsite inspection SamplingX-ray inspection (including BL containing inspection targets/non-targets) Total de vanning inspection

◎ Inspection by the Ministry of Health, Labour and Welfareon

NUTS-Websystem

www.nutsweb.com

76 76

NUTS-Web

Ever Advancing NUTS-WebNUTS-Web system uni�es and networks all terminal systems of the Port of Nagoya.

This system has enabled widely transmitting information from the terminal to the outside via Internet.

Advance examination application submission

Advance examination application cancellation

Dispatch order issuance notice

Dispatch order status reference

Dispatch order directive division

Dispatch order batch division

Carry-out permission check

Carry-out progress check

Inspection application submission

Inspection application maintenance/reference

Advance examination batch application

Check vessel entry schedule

Vessel schedule reference

Notice menu

Main Menu

Status change notice request

Empty carry-out reservation (screen)

Empty carry-out reservation (�le)

Pick-up status reference

Booking information reference

Carry-in ledger advance examination

Weekday gate outside-hours ticket reservation

Weekday gate outside-hours history output

Holiday carry-in request

Holiday carry-out request

Holiday carry-in/out history output

Progress inside yard (Tobishima Area)

Progress inside yard (Nabeta Area)

DispatchCenter

Dispatch Order

Application

Advance ExaminationApplication

This system issues dispatch orders on the Internet based on advance document examination.By taking in information on clearance from Sea-Naccs and D/O release from shipping companies, the man-hours required for accepting imported cargo have been reduced, and logistics ef�ciency has been improved.

Advance Examination Application for Import

Advance examination application

Check/ Issuance

Reference of application status

Order division

Carry-out status check

Carry-out permission check

Dispatchorders presented

Terminal

Users

Dispatch orders issuing process by web users

NACCS participated, DOR01 unexecuted,

D/O presentedNACCS not participated,

D/O and clearance document presented

Application for various inspection processes in the terminal can be made on the Web, and the inspection status and details of the target container can be browsed.

Ledger entries can be input on the Website in advance before arriving at the carry-in gate for advance document check, shortening the time required for the gate check.

Customs inspection

Inspection of animals/plants

Scene of Inspection(plants)

Inspection applicationreference

Users

Application

Booking information

Advance examinationinformation

Reporting differences

NUTS-Web Inspection Application System

Carry-in Ledger Advance Check

Bookinginformation

Inspection ApplicationSystem

Forwarder

ShippingCompany

Shipper

CY

Creating carry-in information,Entry data check

For reduction of checking time

Containers to priority lane after advance examination

Arrival at weigh bridge <lane distribution instruction>

Integrated Control Gate,Weigh Bridge

Arrival at priority lane<container physical check>

Checking difference between carry-in ledger and physical container

<Inspections for Application/Reference>

Gate Lane

Users (Forwarder)(Shipper)

ECDoperators

Trailercompany

This function accepts booking of empty containers for export on the Web. By inputting the required items, the applicant receives Pickup Order No., and RFID enables smooth pickup by trailers.

Pickup Order No. input into RFID

Pickup Order No. checked or sent by email

Booking information registered

Pickup Order No. issued

CS(NUTS)

Accessing with Booking No., ship company name

Empty Container Booking

NUTS-Websystem

NUTS-Websystem

Empty ContainerBooking

NUTS-Websystem

Sea-NACCS

Clearanceinformation,

DOR

◎ Inspection on animals and plants

◎Customs onsite inspection SamplingX-ray inspection (including BL containing inspection targets/non-targets) Total de vanning inspection

◎ Inspection by the Ministry of Health, Labour and Welfareon

98

Vessel Tablet

Paperless vessel planningImproved ef�ciency for cargo operation

Introduction of vessel tablet improves ef�ciency by eliminating bay planning and entry on paper.

Conventional check method

Vessel tablet introduced for highly ef�cient, eco-friendly paperless cargo operation is cable of checking loading/unloading container numbers, cargo loading positions, plug-in/out control and temperature control for freezer containers.It also enables to browse all operation conducted for the target vessel, greatly contributing to the manage-ment of cargo handling progress.

●Vessel operation schedule screen ●Vessel tablet planning screen & entry screen

Cargo Unloading

Cargo Loading

Container number con�rmation Input / Send Select / Store

Check / Select Chassis delivery Loading position / Container number con�rmation

South Exit

Waiting Space

WeightBridge

Chassis Pool

West Exit/Entrance

West Exit/Entrance

EastEntrance

EastExit

Approximately 300 m

Integrated Control Gate

Expert facility for consolidated gate controlOptimization of processing lanes

Features

Gate control and management conventionally conducted at each terminal has been consoli-dated to the integrated control gate installed outside the terminal premises. By changing the processing lanes �exibly according to carry-in/out workload, processing ef�ciency is improved, and labor cost is reduced with optimal workforce.In the carry-in process, NUTS automatically assign the processing lanes according to the accuracy of information from the shipping companies. Those providing highly accurate information are led to priority processing lanes, which thus shortens the lead time.

Road congestions at the gate during busy hours and seasons are resolved by installing integrated control gate.

●Control Building●Gate (22 Lane)

●Weight Bridge●Gate Lane

Integrated Control Gate

Control Building

Elimination of congestion by shorter processing time at Terminal Main Gate

Fluctuations in processing times at the terminal main gate caused by changing congestion levels are mitigated by increasing available lanes, processing in advance and simplifying work procedures, thus improving the overall work ef�ciency.

Improvement in transporting ef�ciency by absorbing �uctuations

Container storage locations are optimized, and cargo is handled more quickly by communicating the cargo information obtained at the integrated control gate to the container terminal in advance.

Upgrading of container terminal processing capacity by advance information communication

98

Vessel Tablet

Paperless vessel planningImproved ef�ciency for cargo operation

Introduction of vessel tablet improves ef�ciency by eliminating bay planning and entry on paper.

Conventional check method

Vessel tablet introduced for highly ef�cient, eco-friendly paperless cargo operation is cable of checking loading/unloading container numbers, cargo loading positions, plug-in/out control and temperature control for freezer containers.It also enables to browse all operation conducted for the target vessel, greatly contributing to the manage-ment of cargo handling progress.

●Vessel operation schedule screen ●Vessel tablet planning screen & entry screen

Cargo Unloading

Cargo Loading

Container number con�rmation Input / Send Select / Store

Check / Select Chassis delivery Loading position / Container number con�rmation

South Exit

Waiting Space

WeightBridge

Chassis Pool

West Exit/Entrance

West Exit/Entrance

EastEntrance

EastExit

Approximately 300 m

Integrated Control Gate

Expert facility for consolidated gate controlOptimization of processing lanes

Features

Gate control and management conventionally conducted at each terminal has been consoli-dated to the integrated control gate installed outside the terminal premises. By changing the processing lanes �exibly according to carry-in/out workload, processing ef�ciency is improved, and labor cost is reduced with optimal workforce.In the carry-in process, NUTS automatically assign the processing lanes according to the accuracy of information from the shipping companies. Those providing highly accurate information are led to priority processing lanes, which thus shortens the lead time.

Road congestions at the gate during busy hours and seasons are resolved by installing integrated control gate.

●Control Building●Gate (22 Lane)

●Weight Bridge●Gate Lane

Integrated Control Gate

Control Building

Elimination of congestion by shorter processing time at Terminal Main Gate

Fluctuations in processing times at the terminal main gate caused by changing congestion levels are mitigated by increasing available lanes, processing in advance and simplifying work procedures, thus improving the overall work ef�ciency.

Improvement in transporting ef�ciency by absorbing �uctuations

Container storage locations are optimized, and cargo is handled more quickly by communicating the cargo information obtained at the integrated control gate to the container terminal in advance.

Upgrading of container terminal processing capacity by advance information communication

1996.07

1997.02

1997.03

1999.07

2001.05

2001.10

2004.04

2004.12

2006.06

2007.01

2007.05

2007.05

2009.04

2011.04

2012. 01

2012. 05

2012. 12

2013. 03

2014. 04

2014. 06

2015. 05

2015. 06

2016. 01

2017. 04

2017. 05

2017. 05

1110

Marine container trailers play the role of

connecting the warehouses, cargo ships,

and cargo terminals. NUTS has been

promoting effective logistics in various

collaborations with Aichi Trucking

Association.

RFID non-contact IC tag

Collaboration with Aichi Trucking Association

Radio Frequency IDentificationRFID (multi-function ID tag) is a portable terminal that provides the trailer driver with delivery point information after data exchange of Trailer ID* or other necessary information with RFID Reader installed at the terminal gate. This device substantially reduced the gate processing time and related work procedure. As of April 2018, about 3,050 trailers are using the RFID tag.

*Trailer ID: ID given to the trailers entering the Port of Nagoya with cooperation from Aichi Truck Corporation. Management of ID numbers by NUTS facilitated the expedient identi�cation of incoming trailers in the yard, while improving the accuracy of related work operations.

Advantages of Adopting RFID

No need to drop off at the gate

Application processing handled by types ofcarry-in/out cargo

Reduction ofapplication

processing time

Promotion ofpaperless

Multi-Function ID Tag

The trailer driver sends all the required information on a single transmission from RFID to the Reader at the gate stop line, and the location of delivering and receiving containers (delivery point) is given immediately.

After completion of RFID process at the gate, the trailer heads for the delivery point instructed via RFID. At the delivery point, the cargo handling machines (RTG, straddle carriers, etc.) receives instruction from NUTS and accordingly delivers container.

After receiving the container, the (carry-out) trailer checks external damage, conducts the carry-out procedure with the handy terminal, and completes the terminal work process. The terminal carry-in procedure is completed when the container is delivered at the delivery point. The introduction of RFID considerably reduced the application time of carry-in/out process, and the gate work ef�ciency has been remarkably improved.

RFID reader Substantial reduction of application processing

Gate Delivery Point Completion of Carry-in/out Process

A Revolution for Gate Processing

— History of NUTS —

Challenge taken up for establishing a latest terminal operation system!

NU

TS

I-IV —

Develo

pm

ent Perio

d—

NE

W N

UT

S —

Develo

pm

ent Perio

d—

Next-generation N

UTS —

Developm

ent Period—

NU

TS second —

Developm

ent Concept—

Resolution by West Area Executing Committee on establishment of a uni�ed system

Approval of development of the uni�ed system (former NUTS) by Container Terminal Department

Commencement of system development by System Development & System Engineering Team selected from each member company

Completion of installation of NUTS at Kinjo, Tobishima North, South, and NCB Terminals

Reinstallation of revised NUTS with new additional functions, completion of system release to Nabeta Terminal

Opening of Port of Nagoya Dispatch Center, subsequent installation of advance examination/inspection application systems

Commencement of discussion at Nuts System Development Committee on replacement of OS and installation of a new system with additional functions

Approval of development of a new uni�ed system (New NUTS) by Container Terminal Department

Completion of spec de�nition after holding 300 meetings with Mitsui Engineering & Shipbuilding Co., Ltd.

Uni�cation of system servers in connection with consolidation of control buildings of three Tobishima Terminals

Completion of installation of new NUTS in Kinjo, Tobishima North, South, NCB and Nabeta Terminals

Commencement of operation of multi-function RFID tags in terminal carry-in/out operation

Incorporation of Web Booking System of empty container pickup as part of extended functions of NUTS-Web

Stepwise implementation of demonstration of integrated control gate

Approval of development of Next-generation NUTS by Container Terminal Department

Coordinated with the Bonded Area Code in Tobishima East Side Container Terminal

Commencement of development mainly by NUTS System Development & System Engineering Team

Completion of transfer of serves to Data Center

Commencement of operation of new type RFID

Commencement of co-operation with SOLAS entry/exit management system

Introduction of Twin / Dual Operation System

NUTS Website redesigned (to include Vessel Schedule browsing function)

Commencement of carry-in ledger advance examination system

Upgrading of NUTS-Web to accept applications for cargo handling on holidays

Approval of upgrading to “NUTS Second” by Container Terminal Department

Launch of development project of “NUTS Second” mainly by NUTS System Development & System Engineering Team

1996.07

1997.02

1997.03

1999.07

2001.05

2001.10

2004.04

2004.12

2006.06

2007.01

2007.05

2007.05

2009.04

2011.04

2012. 01

2012. 05

2012. 12

2013. 03

2014. 04

2014. 06

2015. 05

2015. 06

2016. 01

2017. 04

2017. 05

2017. 05

1110

Marine container trailers play the role of

connecting the warehouses, cargo ships,

and cargo terminals. NUTS has been

promoting effective logistics in various

collaborations with Aichi Trucking

Association.

RFID non-contact IC tag

Collaboration with Aichi Trucking Association

Radio Frequency IDentificationRFID (multi-function ID tag) is a portable terminal that provides the trailer driver with delivery point information after data exchange of Trailer ID* or other necessary information with RFID Reader installed at the terminal gate. This device substantially reduced the gate processing time and related work procedure. As of April 2018, about 3,050 trailers are using the RFID tag.

*Trailer ID: ID given to the trailers entering the Port of Nagoya with cooperation from Aichi Truck Corporation. Management of ID numbers by NUTS facilitated the expedient identi�cation of incoming trailers in the yard, while improving the accuracy of related work operations.

Advantages of Adopting RFID

No need to drop off at the gate

Application processing handled by types ofcarry-in/out cargo

Reduction ofapplication

processing time

Promotion ofpaperless

Multi-Function ID Tag

The trailer driver sends all the required information on a single transmission from RFID to the Reader at the gate stop line, and the location of delivering and receiving containers (delivery point) is given immediately.

After completion of RFID process at the gate, the trailer heads for the delivery point instructed via RFID. At the delivery point, the cargo handling machines (RTG, straddle carriers, etc.) receives instruction from NUTS and accordingly delivers container.

After receiving the container, the (carry-out) trailer checks external damage, conducts the carry-out procedure with the handy terminal, and completes the terminal work process. The terminal carry-in procedure is completed when the container is delivered at the delivery point. The introduction of RFID considerably reduced the application time of carry-in/out process, and the gate work ef�ciency has been remarkably improved.

RFID reader Substantial reduction of application processing

Gate Delivery Point Completion of Carry-in/out Process

A Revolution for Gate Processing

— History of NUTS —

Challenge taken up for establishing a latest terminal operation system!

NU

TS

I-IV —

Develo

pm

ent Perio

d—

NE

W N

UT

S —

Develo

pm

ent Perio

d—

Next-generation N

UTS —

Developm

ent Period—

NU

TS second —

Developm

ent Concept—

Resolution by West Area Executing Committee on establishment of a uni�ed system

Approval of development of the uni�ed system (former NUTS) by Container Terminal Department

Commencement of system development by System Development & System Engineering Team selected from each member company

Completion of installation of NUTS at Kinjo, Tobishima North, South, and NCB Terminals

Reinstallation of revised NUTS with new additional functions, completion of system release to Nabeta Terminal

Opening of Port of Nagoya Dispatch Center, subsequent installation of advance examination/inspection application systems

Commencement of discussion at Nuts System Development Committee on replacement of OS and installation of a new system with additional functions

Approval of development of a new uni�ed system (New NUTS) by Container Terminal Department

Completion of spec de�nition after holding 300 meetings with Mitsui Engineering & Shipbuilding Co., Ltd.

Uni�cation of system servers in connection with consolidation of control buildings of three Tobishima Terminals

Completion of installation of new NUTS in Kinjo, Tobishima North, South, NCB and Nabeta Terminals

Commencement of operation of multi-function RFID tags in terminal carry-in/out operation

Incorporation of Web Booking System of empty container pickup as part of extended functions of NUTS-Web

Stepwise implementation of demonstration of integrated control gate

Approval of development of Next-generation NUTS by Container Terminal Department

Coordinated with the Bonded Area Code in Tobishima East Side Container Terminal

Commencement of development mainly by NUTS System Development & System Engineering Team

Completion of transfer of serves to Data Center

Commencement of operation of new type RFID

Commencement of co-operation with SOLAS entry/exit management system

Introduction of Twin / Dual Operation System

NUTS Website redesigned (to include Vessel Schedule browsing function)

Commencement of carry-in ledger advance examination system

Upgrading of NUTS-Web to accept applications for cargo handling on holidays

Approval of upgrading to “NUTS Second” by Container Terminal Department

Launch of development project of “NUTS Second” mainly by NUTS System Development & System Engineering Team

23

23

247

302

全日検一般社団法人

日本貨物検数協会一般社団法人

NUTS Terminal Map

Gate procedural work conventionally conducted at each terminal is consolidated to the integrated control gate installed outside the terminal premises

Start of service: 1970 at Nagoya Container PierPier length: 900 mNo. of gantry cranes: 6Cargo handling style: Straddle careerContainer Yard: 289,000 m2

Start of service: 1984Pier length: 620 mNo. of gantry cranes: 3Cargo handling style: Straddle careerContainer Yard: 170,000 m2

Tobishima Pier North Container Terminal

Association Pro�le

NCB Container Terminal

Start of service: 1991Pier length: 700 mNo. of gantry cranes: 6Cargo handling style: Straddle careerContainer Yard: 225,000 m2

Start of service: 2005 at Tobishima Container PierPier length: 750 mNo. of gantry cranes: 6Cargo handling style: Transfer craneContainer Yard: 354,500 m2

Integrated Control Gate

Start of service: 2001 at Nagoya United Container TerminalPier length: 985 mNo. of gantry cranes: 8Cargo handling style: Transfer craneContainer Yard: 548,500 m2

Nabeta Pier Container terminal

Tobishima Pier South Side Container TerminalTobishima Pier South Container Terminal

Organization Chart of Container Terminal Department of Nagoya Harbor Transportation Association

NagoyaHarbor Transportation

AssociationNagoya Container Committee Container Terminal Department Nabeta Container

Terminal Section

Tobishima East SideTerminal Section

TCB Terminal SectionNUTS System Development& System Engineering Team

Isewangan Expressway

InaeiPier

ShiomiPier

Obu ICTokai ICShiomi ICChuo ICTobishimaIC

Yatomi IC

Garden Pier

YatomiTown

TobishimaVillage

TokaiCity

TokaiMotohama

Pier

Port Island

Nikko River

Shonai R

iver

NabetaPier

NorthIntegratedControl

GateSouth

South Side

Nabeta

NCB

Container terminal departmental meeting member involved in NUTS development

Photo by Nagoya Port Authority

TobishimaPier Nagoya to the World,

a Bridge of Logistics

Nagoya United Terminal System

Nagoya R

ing Road

No.2

Nagoya City

Nagoya

Exp

ressway

KasaderaIC

Chitahanto R

oad

OdakaIC

Odaka

Nagoyaminami

IC

ASAHI UNYU KAISHA, LTD.

NIPPON EXPRESS CO.,LTD. FUJITRANS CORPORATION

ISEWAN TERMINAL SERVICE CO.,LTD.

MITSUI-SOKO CO.,LTD.

KAMIGUMI Co., Ltd.

MITSUBISHI LOGISTICS CORPORATION MEIKO TRANS CO.,LTD.

TOKAI KYOWA CO.,LTD. TOYO LOGISTICS CO.,LTD.

ALL NIPPON CHECKERS CORPORATION

JAPAN CARGO TALLY CORPORATION