A Presentation on PRYJ-SFG AUTOMATIC SIGNALLING WORK …

Transcript of A Presentation on PRYJ-SFG AUTOMATIC SIGNALLING WORK …

A Presentation on

PRYJ-SFG AUTOMATIC SIGNALLING WORK USING MSDAC & UFSBI

Automatic Block Signalling using MSDAC & UFSBI on Quad/OFC

➢The scheme, utilizes the MSDAC for track detections, with detection points spread over the entire auto section (3.2 Km). There are 6 track sections in UP line, 6 in Down line & 4 in 3rd Line. Total 32 DP’s are installed. Out of total 16 track sections 6 track sections have DCTC + Axle counters & remaining 10 track section have Dual Axle counters of Frauscher make.

➢Quad cable is used for connection the each Detection Points to the respective redundant Evaluators.

➢UFSBI were planned (separate for UP +3rd Line & DN line) in lieu of Quad or signaling cable. Separate OFC via different path is used for A & B system.

➢This not only reduces project expenditure, it also mitigates the possibility of service disruption owing to cable theft.

➢At PRYJ, total 17 nos. output bits for RH are sent & 32 nos. input bits are received. At SFG, total 17 nos. output bits for RH are sent & 26 nos. input bits are received.

Hardware used

Deltron UFSBI MUX

➢ Universal Fail-Safe Block Interface (UFSBI) is a fail-safe digital triple modular redundant (TMR) multiplexer capable of transmitting 16 & receiving 16 On-Off relay states between locations physically separated by a distance but connected through a voice/data channel over OFC/Microwave or Quad cable.

Advantages

➢ Provides high level of reliability and fail-safety.➢ Avoids additional block section cable laying, maintenance time and cost.➢ Can work over very long Block Sections using OFC Mux.➢ High level of noise and electro-magnetic immunity

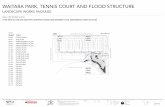

SFG PRYJ

RH

A/B

C/D

A/B

C/D

A/B A/B

C/D C/D

THIRD LINE

DN LINE

UP LINE

OFC cable (Q) OFC cable (Q)

(Q) Quad cableQuad cable

UFSBI

UFSBI CABLE LAYOUT (OFC/QUAD)

A/BA/B

A/BA/B

C/DC/D

C/DC/D

UFSBI Hardware architecture

UFSBI A

UFSBI B

UFSBI A BIPR 1 & 2

UFSBI A FUSE TERMINALS

UFSBI-A SPD & MCB

DC DC CONVERTER

Version display, secondary modem, auto changeover, modem, reset box

6 nos. Input, 2 nos. output card, 3 nos. CPU card & CCC Card

DC DC CONVERTER

6 nos. Input, 2 nos. output card, 3 nos. CPU card & CCC Card

Version display, secondary modem, auto changeover, modem, reset box

UFSBI B BIPR 1 & 2

UFSBI B FUSE TERMINALS

UFSBI-B SPD & MCB

PARTS OF USFBI

DC DC CONVERTER

➢ DC-DC Converter is provided to derive the necessary voltages to operate the UFSBI from the external 24V source provided. The features of the power supply are:

▪ Separate IPS Modules for main & Standby system (A & B)▪ Input to UFSBI is 24 V (+/-20%), 5 Amps.▪ DC DC converter generates 24V, 5V, +12V & -12V output.▪ 24VDC is used for sensing input, output feedback, BIP R1, BIP R2

Relay contacts through Input card. It also drives output relays.▪ 5VDC is used for power and working of Electronics IC’s.▪ +12VDC, -12VDC is used for modem power & communication.

UFSBI DS (Dual Standby)

UFSBI-DS consisting of the following parts1) Input card (6 Nos.)

➢ It is responsible for complementary sensing of the relay status of UFSBI. i.e. for sensing one pick up and one drop contact of each input relays, feedback contact of each output relays and health checking relays (BIPR1 & BIPR2).

2) CPU card

➢ The UFSBI system works on a 2 out of 3 majority voting logic i.e. ifone CPU card or its corresponding Input cards goes bad then also system canwork. CPU – “A” reads the Inputs through Input Card 1&2, CPU – “B” readsthe Inputs through Input Card 3&4 and CPU – “C” reads the Inputs throughInput Card 5&6.

3) Control cum communication (CCC) Card

The CCC Card mainly performs two important functions :a) It drives health check relays (BIP R1 & BIP R2).

(BIP stands for Block Interface Proving Relay)b) It converts the data provided by the CPU card as per RS 232

protocol and sends it to the Modem.

4) OUTPUT CARD

➢ 2 numbers of such cards are provided for driving Output relays. ➢ 1st Output card drives Output relays 1 - 8 and rest 9 - 16 number output

relays are driven by Output card number 2.

5) RESET BOX

➢ Perform resetting so that CPU resets itself to show 0db on all CPUs.➢ Keep track of number of reset operation.➢ Monitors UFSBI if it is in working condition or failure mode.➢ BI-ON Button is required for starting the system.➢ BZ-ACK Button is required for acknowledging the buzzer when it sounds

due to dropping of Shut down relays (BIP R1 & BIP R2).➢ BI-OK indication glows (green) when UFSBI is in working condition.➢ BI-Fail indication glows (red) when UFSBI is in failure mode.

Reset Box & I/O card Layout

6) MODEM

➢ The fiber optic modem converts Electrical Asynchronous Serial RS232signals into optical signals and transmitted over Single-Mode fiberoptic cable.

➢ Separate modem card for communication on quad cable is alsoprovided with auto changeover facility. Indication for availability ofboth the mediums and media on load indication provided on mediachangeover card.

7) UFSBI ALARM PANEL

➢ The UFSBI alarm panel provided at SM room to give preventive alarm for single CPU failure, Redundant DC-DC converter failure and System total failure.

➢ All the alarms are being monitored through Datalogger control 24*7 basis.

Failure with error codes

* Error code no.33 - Link Fail (SSB Mode)

* Error code no.37 - CPU A Bad

* Error code no.38 - CPU B Bad

* Error code no.39 - CPU C Bad

FRAUSCHER ADVANCED AXLE COUNTER

The Frauscher Advanced Counter FAdC is a Multi Section Digital Axle counter which is modular in design and have following advantages:

➢ Flexible architecture.

➢ No trackside electronics thus reduced interference.

➢ Track access for routine maintenance is less since the sensor currents are monitored in the station equipment room itself.

➢ Requirement of less space & extensive diagnostics features.

➢ Easy and Quick to remove and reinstall during engineering activities like machine working .

Trackside equipment

➢ Wheel sensor RSR180 with moulded cable and protection tube

➢ Rail claw Sk140 with clamping bolts

➢ Track side connection box

The system comprises the following components/boards:

RSR180

SK140

BBK

SK140 RAIL CLAW

➢ The wheel sensor RSR180 consists of 2 sensor systems.

➢ During installation of a sensor, care should be taken that coil is fitted at the permissible height of 40-45 mm below with respect to top of the rail. Also torque of tightening the bolt should be done with adjustable torque wrench on 40mm.

➢ Sensor system A is fitted on the left hand side and sensor system B is on the right hand side.

➢ On the wheel sensor there is a moulded 4-wire cable with standard length of 5m.

➢ One wire is assigned to each sensor system in which the sensor system signal is transmitted to evaluation board.

➢ The rail claw SK140 is used to fix the wheel sensor RSR180 to the rail.

INDOOR INSTALLATION

1) OVERVOLTAGE PROTECTION BOARD BSI

➢ The overvoltage protection board BSI protects the indoor equipment from interference voltages in the event of a lightning strike or overhead contact line short circuit.

➢ The overvoltage protection board BSI is connected between the evaluation board and the wheel sensor RSR180.

2) POWER SUPPLY BOARD PSC

➢ Power Supply Board PSC supplies the power for the components of the system and protects the components from overvoltage.

➢ The power supply range is +19 V DC to +72 V DC.

3) ADVANCED EVALUATION BOARD (AEB)

➢ One AEB Supplies and evaluates one wheel sensor

➢ It counts the no. of axles and gives the data to I/O card.

➢ AEB can also count axles and generate failsafe clear and occupied indication.

➢ PWR green indication lit means 24 v supply is available at AEB card.

4) INPUT/OUTPUT BOARD IO-EXB

➢ The Input/Output Board IO-EXB can only be used in combination with an AEB.

➢ Outputs clear/occupied status of upto 2 track sections .

➢ Outputs counting head information (direction & system).

➢ Status LED red means track sections is occupied.

➢ Display LED yellow means which track section information is being displayed.

5) COMMUNICATION BOARD COM

➢ It consists of 2 Ethernet connectors (configurable).

➢ Forwards vital counting head data in between AEBs via Ethernet.

➢ Forwards non-failsafe diagnostics data (FDS).

➢ The CF card available in the COM board provides configuration data for AEB and COM.

Cabling Scheme – Block Diagram

TROUBLESHOOTING

LOCAL DIAGNOSTICS AEB FOR TROUBLESHOOTING

Sys1 / Sys2 red LED

Slow blinking➢ Wrong / broken connection of wheel

sensor cable.➢ AEB not yet adjusted.

B1 /B2- LED off➢ CAN bus error free communication.LED lit➢ Faulty communication on CAN bus due

to defective PSC or defective AEB or CAN bus cabling not correct.

A1 / A2 – LED off➢ Track section clear.

LED lit➢ Track section occupied

LED flashing➢ Track section faulty requiring reset.

LED Diagnostics – IO-EXB for troubleshooting

P. 1“P” - Partial Traversing i.e. wheel not travel over both the sys1 & sys2.

“E” – Error - DP disconnected/cable fault.

“F” – preparatory RESET

Fault Analysis through Datalogger

Fault logic of Axle counter and UFSBI MUX are prepared and monitored through data logger & concerned alarms are generated in data logger control. The kind of alarms generated are as follows:

❖ Axle counter failure alarms (like 2XT1R fail)

❖ System failure alarms (like DC DC converter fail, A system fail alarm)

❖ Link failure alarms (like RH-SFG system A Link fail)

Data logger control staff acknowledges these faults alarms and immediately informs to concerned staff and officers.