9.8 Terminal Operation - BPsubsites.bp.com/caspian/ACG/Eng/Phase3_v2_nov_04/09 Ch09_09-04/… · G...

Transcript of 9.8 Terminal Operation - BPsubsites.bp.com/caspian/ACG/Eng/Phase3_v2_nov_04/09 Ch09_09-04/… · G...

Azeri, Chirag & Gunashli Full Field Development Phase 3 Environmental & Socio-economic Impact Assessment Final Report

9.8 Terminal Operation Once constructed and commissioned, the Phase 3 terminal facilities will receive commingled partially stabilised crude oil from the DWG and Azeri (Phases 1 and 2) fields (Section 5.3) and process it to remove any remaining associated gas (stabilisation), separate any residual produced water. The terminal will also receive separated gas for conditioning and export. The stabilised oil product is routed to storage tanks before being pumped to the Baku-Tbilisi-Ceyhan (BTC) pipeline for export to markets. The majority of the gas will be treated to meet the export specification and supplied to SOCAR for input into the national grid, although some of the gas will be diverted to support power generation and other utilities at the terminal. 9.8.1 Environmental Impacts The results of the environmental impact assessment are summarised in Table 9.27. The assessment of routine and planned non-routine activities associated with the operation of ACG terminal facilities predicted that no residual impacts or impacts of only low residual significance would result from these activities. A number of activities do however, have implications for consideration in respect to the contribution to wider impacts from Phase 3 in the context of other BP projects in the region.

31648-046 ACG Phase 3 ESIA Chapter 9 9/69 October 2004

Azeri, Chirag & Gunashli Full Field Development Phase 3 Environmental & Socio-economic Impact Assessment Final Report

Table 9.27 Summary of Environmental Impact Assessment for Terminal Operation

ID Activity Environmental Aspects Environmental Mitigation

Cum

ulat

ive

Con

tribu

tion

Envi

ronm

enta

l Im

pact

Si

gnifi

canc

e

Justification / Comments Residual Environmental Issues to be Addressed

G Terminal Operation and Maintenance

G1.

Transportation of goods, materials and personnel

Atmospheric emissions; dust Vehicle and plant maintenance as per pollution prevention procedures;

Dust suppression through watering down.

Transport management plan

▲ L Low contribution to overall air emissions from the project and within international standards.

Atmospheric emissions raised during consultation as a concern affecting air quality on local inhabitants.

None.

G2.

Process crude oil heating and fin fan cooling.

Atmospheric emissions, wastes Temperature regulation;

Regular maintenance;

Dry Low (low NOx) Emission fired heaters as standard.

▲ L Low residual impact when considered as a single activity but a cumulative contribution to ACG Phase 3 emissions as well as to the wider ACG FFD.

Atmospheric emissions raised during consultation as a concern affecting air quality on local inhabitants.

Issue of waste management raised during consultation.

None.

G3. Oil storage and export Atmospheric emissions, landscape. Floating roof tanks with low loss fittings and secondary seals. L Low as minimal fugitive emissions.

Atmospheric emissions raised during consultation as a concern affecting air quality on local inhabitants.

None.

G4.

Gas compression and cooling/Dew point control using propane refrigeration.

Atmospheric emissions, gas supply. Common compressor suction manifold/header. ▲ L Low residual impact when considered as a single activity but a cumulative contribution to ACG Phase 3 emissions as well as to the wider ACG FFD.

Atmospheric emissions raised during consultation as a concern affecting air quality on local inhabitants.

None required

G5.

Flaring Atmospheric emissions, light, heat, noise No routine flaring to produce, only lit pilot

Flare gas recovery and nitrogen purge;

Flare gas metering;

Smokeless Flare.

▲ L Low as flaring due to process upsets only. Cumulative contribution to wider ACG FFD.

Atmospheric emissions raised during consultation as a concern affecting air quality on local inhabitants.

Flaring policy

See section 9.8.1.1

G6. Drainage, sewage, firewater

Liquid and solid wastes; No discharge of sewage waters or hazardous drains;

Charcoal filters on storm water drains.

L Low due to use of existing system and no discharges of hazardous effluents.

None

31648-046 ACG Phase 3 ESIA Chapter 9 9/70 October 2004

Azeri, Chirag & Gunashli Full Field Development Phase 3 Environmental & Socio-economic Impact Assessment Final Report

ID Activity Environmental Aspects Environmental Mitigation

Cum

ulat

ive

Con

tribu

tion

Envi

ronm

enta

l Im

pact

Si

gnifi

canc

e

Justification / Comments Residual Environmental Issues to be Addressed

G7.

Power generation Atmospheric emissions, noise Regular maintenance of turbines;

Optimisation of operating range;

Dry Low (low NOx) Emission as standard on gas turbines;

Power Management System.

▲ L Low residual impact when considered as a single activity but a cumulative contribution to ACG Phase 3 emissions as well as to the wider ACG FFD.

Atmospheric emissions raised during consultation as a concern affecting air quality on local inhabitants.

None.

G8. Produced water generation and disposal

Liquid waste Subject to separate evaluation. ▲ L No residual impacts but cumulative produced water generation issue across AzBU activities.

Issue of waste management raised during consultation.

Subject to separate evaluation.

G9. Produced sand generation and disposal

Solid waste No uncontrolled discharge of produced sand. Sand jetting/cleaning to reduce contamination.

▲ L No residual impacts but cumulative waste generation issue across AzBU activities if CRI fails.

Issue of waste management raised during consultation.

Waste management

Refer to Section 10.2

G10. Hydrogen Sulphide (H2S) Subject to separate evaluation. - - Subject to separate evaluation. Subject to separate evaluation.

31648-046 ACG Phase 3 ESIA Chapter 9 9/71 October 2004

Azeri, Chirag & Gunashli Full Field Development Phase 3 Environmental & Socio-economic Impact Assessment Final Report The operation of the Phase 3 terminal facilities incorporates a number of activities ranging from logistical tasks, such as the mobilisation of personnel, equipment and resources, to operational requirements such as oil processing and gas compression. As discussed in Section 9.7, a number of facilities are already present at Sangachal Terminal that will meet the demands of the Phase 3 project, for example the CWAA, toilet, mess, accommodation, warehouses, and storage area. Furthermore, operational wastes, such as sewage effluents, clean water drainage and hazardous drainage can be collected, treated and disposed of in line with current operational practices at the terminal. Readers are referred to Section 9.2 Onshore Fabrication of Offshore Facilities for summary details of the existing management and mitigation of any potential environmental impacts for construction. Some of these apply to operations, such as:

The approach and measure for the reduction and management of wastes generated onsite. As with the onshore fabrication and construction sites, the terminal has developed a CWAA, which will be used for all construction stages and operations (Section 9.8) at the site.

•

•

•

•

Transportation management measures to control the movement of materials, equipment and personnel to and from the terminal site.

Maintenance of plant and equipment to minimise atmospheric emissions to the extent practicable.

Storage of bulk fuels and chemicals within bunded areas.

The new ACG Phase 3 terminal process trains will operate in parallel with EOP, ACG Phase 1 and 2. Operations at the Shah Deniz gas processing plant will also be underway. As such, terminal operations cannot be considered in isolation but as cumulative to all projects. Processing and export operations will result in the cumulative contribution to atmospheric emissions and waste generation onsite. As discussed in Section 8, local scientists and the community have raised both of these issues during consultation. These are discussed in the following subsections. Health concerns raised by local residents relating to atmospheric emissions are discussed in Section 9.8.3 Socio-economic Impacts. Details of the key mitigation measures considered in the impact assessment are summarised in the following subsections together with procedures/standards/comments specific to some of the proposed activities.

31648-046 ACG Phase 3 ESIA Chapter 9 9/72 October 2004

Azeri, Chirag & Gunashli Full Field Development Phase 3 Environmental & Socio-economic Impact Assessment Final Report 9.8.1.1 Atmospheric Emission Sources and Modelling The main sources of air emissions at the terminal are the exhaust gases from the gas turbine generators, with diesel back up generators, and the fired heaters. Both the gas turbine generators, and the fired heaters will have Dry Low-NOX Emission burners (DLE) to minimise NOX emissions. Non-routine operational flaring during plant upsets will also contribute to emissions from the terminal. Under normal operating conditions however, the flare will only burn a small amount of gas to sustain the safety pilot, and the requirement to routinely flare gases from the process system will be avoided through the application of flare gas recovery. Table 9.28 presents the total estimated atmospheric emissions by species and source from Phase 3 terminal operations between 2008 and 2024. At present, it is uncertain as to the exact souring mechanism in the ACG reservoirs, whether from Sulphur reducing bacteria or through a naturally sour aquifer, consequently absolute prediction of concentrations is not available. Historically, for the Azeri Project, 500ppm H2S has been used as the blended gas concentration as a worst-case scenario for design. ACG FFD Air Dispersion Modelling was carried out for Phase 2 ESIA based on this assumption and this showed that there were no exceedences in air quality standards for SO2 at nearby receptors. Full results of this can be accessed in the ACG Phase 2 ESIA. Recent studies show 45ppm to 200ppm as a more realistic concentration. Current reservoir information indicates that H2S is shown around the oil water contact layer, however the Chirag field currently remains sweet. Further data is now becoming available and will result in a full field review of the design requirements for potential H2S handling. A strategy will be developed and best choice of technology made considering the future souring potential, environmental impact and end product disposal. Souring of the reservoir that could occur due to the injection of seawater into the reservoir may be mitigated offshore by the use of liquid scavenger injection. However this will be subject to a separate evaluation when more information is available on amount of H2S likely to present and timing that this will occur. The fuel gas that will be used in the power generators and fired heaters will be derived from the produced gas delivered to the terminal by the 28” gas subsea export pipeline. Emissions per year are shown in Figures 9.3 and 9.4. As the level of H2S in the DWG reservoir remains uncertain SO2 emissions are not currently predicted for Phase 3. Table 9.28 Forecast Atmospheric Emissions by Species and Source from Phase 3

Terminal Operations (2008 – 2024) (tonnes)

CO2 CO NOX CH4 VOC

Combustion: 2,744,302 1,567 4,516 410 370

Flaring: 238,398 511 65 589 589

Total: 2,982,700 4,581 2,078 999 959

31648-046 ACG Phase 3 ESIA Chapter 9 9/73 October 2004

Azeri, Chirag & Gunashli Full Field Development Phase 3 Environmental & Socio-economic Impact Assessment Final Report Figure 9.3: Estimated Total Emissions by Species, Onshore Operations (tonnes)

0

100

200

300

400

500

600

700

2008

2009

2010

2011

2012

2013

2014

2015

2016

2017

2018

2019

2020

2021

2022

2023

2024

Year

Tonn

es

VOC

CH4

NOx

CO

Figure 9.4: Estimated Total CO2 Emissions, Onshore Operations (tonnes)

0

50000

100000

150000

200000

250000

300000

2008

2009

2010

2011

2012

2013

2014

2015

2016

2017

2018

2019

2020

2021

2022

2023

2024

Year

Tonn

es

As discussed, flaring (excluding purge gas and the pilot light flare) will only be undertaken during operational upsets and emergency situations. Under these scenarios, the majority (estimated at 86%) of flaring will be undertaken preferentially offshore with the balance (estimated at 14%) being undertaken at the onshore terminal. Emissions resulting from operational upset flaring including start-up years (first two years), when availability of plant will be less, have been accounted for in the above estimates. The onshore environment around the terminal site includes sensitive human receptors (Section 6 Environmental Description). As such, air dispersion modelling was carried out for future developments including ACG Phase 1, 2 and 3 and Shah Deniz Gas Export Stage 1 to ensure that the proposed developments would not exceed the internationally recognised air quality standards and guidelines. The full modelling report, ACG FFD Phase 3 and Shah Deniz Air Dispersion Modelling is presented at Appendix 11 to this ESIA report.

31648-046 ACG Phase 3 ESIA Chapter 9 9/74 October 2004

Azeri, Chirag & Gunashli Full Field Development Phase 3 Environmental & Socio-economic Impact Assessment Final Report Scenarios were designed to model a number of aspects for planned routine operations at Sangachal terminal from EOP operation through to the operation of EOP, ACG phase 1, 2 and 3, and Shah Deniz. Emissions of nitrogen dioxide (NO2) and carbon monoxide (CO) were modelled to give a forecast of air quality in the area. Sulphur dioxide (SO2) was not modelled because of the reasons noted above.

Combustion of fuel gas at the terminal will result in the emission of principally carbon dioxide (CO2) and water vapour, together with carbon monoxide (CO) and oxides of nitrogen (NOX) in smaller quantities. These latter emissions have the potential to affect human health and vegetation in the vicinity of the plant. The modelling study therefore focused on the potential to impact local air quality as a result of emission of the NOX and CO species. NOX emitted from the combustion source comprises a mixture of the relatively low toxicity nitric oxide (NO) and the more toxic nitrogen dioxide (NO2). The majority of NOX produced from a combustion process is in the form of NO. The NO is converted to NO2 by oxidation in the presence of ozone and sunlight in the atmosphere. In accordance with standard practice (DETR, 20001), the dispersion modelling conservatively assumed that 50% of the NOX would be present in the form of NO2, and it is the NO2 concentration that has been modelled.

At the terminal ACG Phase 1 requires dual fuel turbines for start up capabilities, with the option is to retrofit DLE NOX at a later date. ACG Phase 2 has DLE low-NOx turbines and ACG Phase 3 will fit DLE NOX turbines as standard. For purposes of the modelling it has been assumed that after the start up of ACG Phase 2, the DLE gas turbines will be used preferentially. The number of gas turbines used in the model reflects the power requirements for the period modelled.

Scenarios modelled were those when emissions are likely to be highest, ie. during start up and at peak production:

EOP, ACG Phase 1, 2, Shah Deniz in normal operation plus ACC Phase 3 start up (2008);

•

•

•

•

EOP, ACG Phase 1, 2, 3 and Shah Deniz in normal operation (2010), at peak production.

In addition, emergency shutdown (ESD) scenarios were modelled. The ACG and Shah Deniz facilities do not share a common flare system and are independent processing operations and therefore, the chance of both facilities going into an ESD is extremely unlikely. As such, the modelling has taken into account the possibility of emergency flaring from ACG FFD Phase 1, 2 and 3 and EOP only or from Shah Deniz only. The following worst case scenarios were modelled:

EOP, ACG Phase 1, 2, 3 and Shah Deniz operation with the addition of Emergency Shut Down (ESD) of ACG FFD via elevated flare at a rate of 100 MMscfd for 1 hour;2

ACG Phase 1, 2, 3 EOP and Shah Deniz operation with the addition of ESD of Shah Deniz via ground flare at a rate of 990 MMscfd.1

The scenarios listed above were modelled and the resulting NO2 and CO emission species’ concentrations were compared to internationally accepted air quality standards and guidelines as presented in Table 9.29 below.

Table 9.29 International Standards and Guidelines of Air Quality

Air Quality Objectives Pollutant Concentration (µg/m3) Averaging Period International Standard/Guideline

200 1 hour mean (99.8%ile) WHO, EC, UK 150 24 hour average WHO, World Bank

Nitrogen Dioxide

40 Annual mean WHO, EC, UK 30,000 I hour mean WHO, EU, UK Carbon Monoxide 10,000 8 hour rolling average WHO

NB 99.8%ile = standard not to be exceeded more than 18 times per year.

1 DETR 2000, Review and Assessment of Pollutants. Specification Guidance TG4 (00). 2 The design rate for both flares are for emergency shut downs. This rate will only last for a few minutes and will decay

exponentially. For modelling purposes the full blow down rate was assumed to last for one hour.

31648-046 ACG Phase 3 ESIA Chapter 9 9/75 October 2004

Azeri, Chirag & Gunashli Full Field Development Phase 3 Environmental & Socio-economic Impact Assessment Final Report The model calculated hourly, daily and annual averages. CO standards include an 8-hour averaging period but the hourly average was selected as the critical standard for comparison. Modelling results for the above four scenarios (two routine and two unplanned) are presented in Tables 9.30 through 9.34 below. The tables and figures are arranged as follows:

ACG Phases 1, 2, EOP and Shah Deniz in Normal Operation and Phase 3 in Start-Up (2008); Table (a) NO2 with isopleths and (b) CO;

•

•

•

•

ACG Phases 1, 2 and 3, EOP and Shah Deniz in Normal Operation (2010); Table (a) NO2 with isopleths and (b) CO;

ACG Phase 1, 2, 3 EOP and Shah Deniz Operation with the Addition of Emergency Shut Down of ACG FFD via Elevated Flare at a Rate of 100 MMscfd for 1 Hour; Table (a) NO2 with isopleths and (b) CO;

ACG Phase 1, 2, 3 EOP and Shah Deniz Operation with the Addition of Emergency Shut Down of Shah Deniz via Ground Flare at a rate of 900 MMscfd; Table (a) NO2 with isopleths and (b) CO .

The spatial distribution of the predicted concentrations of NO2 and CO is presented as a series of isopleths in corresponding diagrams to the tables (Figures 9.5 through 9.8). The plots present the results for hourly mean predictions of NO2 for the scenarios modelled. The background concentration in the area was added to the predicted Process Contribution (PC) from the terminal to give a Predicted Environmental Concentration (PEC), which was then compared to the relevant Air Quality Standard (AQS) for NO2 and CO concentrations. The full results of the modelling are presented in Appendix 9 to this report. Table 9.30 below presents the measured background (ambient) levels of NO2 at nearby sensitive receptors. It is noted that no measurements were taken for CO. Table 9.30 Baseline Data for Nitrogen Dioxide (NO2) at Nearby Sensitive Receptors

Background concentrations Hourly µgm-3 Annual µgm-3 Terminal 6 3

Sangachal Town 8 4 Pipeline Landfall 4 2 Cement Camp 6 4

31648-046 ACG Phase 3 ESIA Chapter 9 9/76 October 2004

Azeri, Chirag & Gunashli Full Field Development Phase 3 Environmental & Socio-economic Impact Assessment Final Report Table 9.31(a) ACG Phases 1, 2, EOP and Shah Deniz in Normal Operation and Phase 3

in Start-Up (2008) – Concentrations of NO2

Air Quality Std.

Back ground

Process Contribution

Total Concentration

Compliant Receptor

ugm-3 ugm-3 ugm-3 ugm-3 yes/no

Maximum hourly average Cement camp 200 6.0 81.9 87.9 yes Sangachal Town 200 8.0 65.7 73.7 yes West Hill herders 200 6.0 34.9 40.9 yes

Cheyildag 200 6.0 65.9 71.9 yes Peak 200 8.0 91.2 99.2 yes

Maximum 24 hr Average Cement camp 150 na 23.0 na na Sangachal Town na na 26.0 na na West Hill herders na na 18.6 na na

Cheyildag na na 26.0 na na Peak na na 33.5 na na

Forecast Annual Average Cement camp 40 4.0 0.7 4.7 yes Sangachal Town 40 3.0 1.4 4.4 yes West Hill herders 40 3.0 1.4 4.4 yes

Cheyildag 40 3.0 1.1 4.1 yes Peak 40 4.0 2.3 6.3 yes

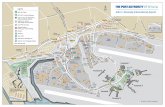

Figure 9.5(a) Isopleths for ACG Phases 1, 2, EOP and Shah Deniz in Normal Operation

and Phase 3 in Start-Up (2008) – Hourly Concentrations of NO2

31648-046 ACG Phase 3 ESIA Chapter 9 9/77 October 2004

Azeri, Chirag & Gunashli Full Field Development Phase 3 Environmental & Socio-economic Impact Assessment Final Report Figure 9.5(b) Isopleths for ACG Phases 1, 2, EOP and Shah Deniz in Normal Operation

and Phase 3 in Start-Up (2008) – Hourly Concentrations of CO

Table 9.32(a) ACG Phases 1, 2 and 3, EOP and Shah Deniz in Normal Operation (2010)

– Concentrations of NO2

Air Quality Std.

Back ground

Process Contribution

Total Concentration

Compliant Receptor

ugm-3 ugm-3 ugm-3 ugm-3 yes/no Maximum hourly average

Cement camp 200 6.0 83.6 93.6 yes Sangachal Town 200 8.0 67.7 71.7 yes West Hill herders 200 6.0 34.9 40.9 yes

Cheyildag 200 6.0 66.1 72.1 yes Peak 200 8.0 93.9 101.9 yes

Maximum 24 hr Average Cement camp 150 na 24.2 na na Sangachal Town na na 26.2 na na West Hill herders na na 18.6 na na

Cheyildag na na 26.6 na na Peak na na 34.6 na na

Forecast Annual Average Cement camp 40 4.0 0.8 4.8 yes Sangachal Town 40 3.0 1.5 4.5 yes West Hill herders 40 3.0 1.5 4.5 yes

Cheyildag 40 3.0 1.2 4.2 yes Peak 40 4.0 2.4 6.4 yes

31648-046 ACG Phase 3 ESIA Chapter 9 9/78 October 2004

Azeri, Chirag & Gunashli Full Field Development Phase 3 Environmental & Socio-economic Impact Assessment Final Report Figure 9.6(a) Isopleths for ACG Phases 1, 2 and 3, EOP and Shah Deniz in Normal

Operation (2010) – Hourly Concentrations of NO2

Figure 9.6(b) Isopleths for ACG Phases 1, 2 and 3, EOP and Shah Deniz in Normal Operation (2010) – Hourly Concentrations of CO

31648-046 ACG Phase 3 ESIA Chapter 9 9/79 October 2004

Azeri, Chirag & Gunashli Full Field Development Phase 3 Environmental & Socio-economic Impact Assessment Final Report Table 9.33(a) ACG Phase 1, 2, 3 EOP and Shah Deniz Operation with the Addition of

Emergency Shut Down of ACG FFD via Elevated Flare at a Rate of 100 MMscfd for 1 Hour – Concentrations of NO2

Air Quality

Std. Back

ground Process

Contribution Total

Concentration Compliant Receptor

ugm-3 ugm-3 ugm-3 ugm-3 yes/no

Maximum hourly average Cement camp 200 6.0 83.7 93.7 yes Sangachal Town 200 8.0 67.7 71.7 yes West Hill herders 200 6.0 34.0 40.0 yes

Cheyildag 200 6.0 66.1 72.1 yes Peak 200 8.0 93.9 101.9 yes

Maximum 24 hr Average Cement camp 150 na 24.2 na na Sangachal Town na na 26.2 na na West Hill herders na na 18.6 na na

Cheyildag na na 26.7 na na Peak na na 34.6 na na

Forecast Annual Average Cement camp 40 4.0 0.8 4.8 yes Sangachal Town 40 3.0 1.5 4.5 yes West Hill herders 40 3.0 1.5 4.5 yes

Cheyildag 40 3.0 1.2 4.2 yes Peak 40 4.0 2.4 6.4 yes

Figure 9.7(a) Isopleths for ACG Phase 1, 2, 3 EOP and Shah Deniz Operation with the

Addition of Emergency Shut Down of ACG FFD via Elevated Flare at a Rate of 100 MMscfd for 1 Hour – Hourly Concentrations of NO2

31648-046 ACG Phase 3 ESIA Chapter 9 9/80 October 2004

Azeri, Chirag & Gunashli Full Field Development Phase 3 Environmental & Socio-economic Impact Assessment Final Report Figure 9.7(b) Isopleths for ACG Phase 1, 2, 3 EOP and Shah Deniz Operation with the

Addition of Emergency Shut Down of ACG FFD via Elevated Flare at a Rate of 100 MMscfd for 1 Hour – Hourly Concentrations of CO

Table 9.34(a) ACG Phase 1, 2, 3 EOP and Shah Deniz Operation with the Addition of Emergency Shut Down of Shah Deniz via Ground Flare at a rate of

900 MMscfd –Concentrations of NO2

Air Quality Std.

Back ground

Process Contribution

Total Concentration

Compliant Receptor

ugm-3 ugm-3 ugm-3 ugm-3 yes/no

Maximum hourly average Cement camp 200 6.0 83.7 93.7 yes Sangachal Town 200 8.0 67.7 71.7 yes West Hill herders 200 6.0 34.9 40.9 yes

Cheyildag 200 6.0 66.1 72.1 yes Peak 200 8.0 94.0 102.0 yes

Maximum 24 hr Average Cement camp 150 na 24.2 na na Sangachal Town na na 26.2 na na West Hill herders na na 18.6 na na

Cheyildag na na 26.7 na na Peak na na 34.7 na na

Forecast Annual Average Cement camp 40 4.0 0.8 4.8 yes Sangachal Town 40 3.0 1.5 4.5 yes West Hill herders 40 3.0 1.5 4.5 yes

Cheyildag 40 3.0 1.2 4.2 yes Peak 40 4.0 2.4 6.4 yes

31648-046 ACG Phase 3 ESIA Chapter 9 9/81 October 2004

Azeri, Chirag & Gunashli Full Field Development Phase 3 Environmental & Socio-economic Impact Assessment Final Report Figure 9.8(a) Isopleths for ACG Phase 1, 2, 3 EOP and Shah Deniz Operation with the

Addition of Emergency Shut Down of Shah Deniz via Ground Flare at a rate of 900 MMscfd – Hourly Concentrations of NO2

Figure 9.8(b) Isopleths for ACG Phase 1, 2, 3 EOP and Shah Deniz Operation with the Addition of Emergency Shut Down of Shah Deniz via Ground Flare at a rate of 900 MMscfd – Hourly Concentrations of CO

31648-046 ACG Phase 3 ESIA Chapter 9 9/82 October 2004

Azeri, Chirag & Gunashli Full Field Development Phase 3 Environmental & Socio-economic Impact Assessment Final Report Table 9.31(b) ACG Phase 1, 2, EOP and Shah Deniz in Normal Operation with ACG

Phase 3 Start-Up (2008) – Concentrations of CO

Air Quality Std.

Back ground

Process Contribution

Compliant Receptor

ugm-3 ugm-3 ugm-3 yes/no

Maximum hourly average Cement camp 30,000 na 11.9 yes Sangachal Town 30,000 na 9.1 yes West Hill herders 30,000 na 11.3 yes

Cheyildag 30,000 na 14.7 yes Peak 30,000 na 17.0 yes

Maximum 24 hr Average Cement camp na na 3.3 na Sangachal Town na na 3.3 na West Hill herders na na 5.6 na

Cheyildag na na 5.4 na Peak na na 7.0 na

Table 9.32(b) ACG Phase 1, 2, 3 EOP and Shah Deniz in Normal Operation (2010) –

Concentrations of CO

Air Quality Std.

Back ground

Process Contribution

Compliant Receptor

ugm-3 ugm-3 ugm-3 yes/no

Maximum hourly average Cement camp 30,000 na 12.0 yes Sangachal Town 30,000 na 9.1 yes West Hill herders 30,000 na 11.3 yes

Cheyildag 30,000 na 14.7 yes Peak 30,000 na 17.0 yes

Maximum 24 hr Average Cement camp na na 3.4 na Sangachal Town na na 3.3 na West Hill herders na na 5.6 na

Cheyildag na na 5.4 na Peak na na 7.0 na

31648-046 ACG Phase 3 ESIA Chapter 9 9/83 October 2004

Azeri, Chirag & Gunashli Full Field Development Phase 3 Environmental & Socio-economic Impact Assessment Final Report Table 9.33(b) ACG Phase 1, 2, 3 EOP and Shah Deniz in Normal Operation with

Addition of Emergency Shut Down of ACG FFD via Elevated Flare at a rate of 100MMscfd for 1 hour – Concentrations of CO

Air Quality

Std. Back

ground Process

Contribution Compliant Receptor

ugm-3 ugm-3 ugm-3 yes/no

Maximum hourly average Cement camp 30,000 na 12.1 yes Sangachal Town 30,000 na 9.1 yes West Hill herders 30,000 na 11.3 yes

Cheyildag 30,000 na 14.8 yes Peak 30,000 na 17.0 yes

Maximum 24 hr Average Cement camp na na 3.6 na Sangachal Town na na 3.3 na West Hill herders na na 5.6 na

Cheyildag na na 5.5 na Peak na na 7.1 na

Table 9.34(b) ACG Phase 1, 2, 3 EOP and Shah Deniz in Normal Operation with

Addition of Emergency Shut Down of Shah Deniz via Ground Flare at a Rate of 990 MMscfd – Concentrations of CO

Air Quality

Std. Back

ground Process

Contribution Compliant Receptor

ugm-3 ugm-3 ugm-3 yes/no

Maximum hourly average Cement camp 30,000 na 12.4 yes Sangachal Town 30,000 na 9.1 yes West Hill herders 30,000 na 11.3 yes

Cheyildag 30,000 na 14.9 yes Peak 30,000 na 17.4 yes

Maximum 24 hr Average Cement camp na na 3.7 na Sangachal Town na na 3.3 na West Hill herders na na 5.6 na

Cheyildag na na 5.5 na Peak na na 7.3 na

The modelling of onshore air emissions determined that, while considerable in terms of volume, local air currents would ensure that dispersion of the emission plumes would be such that under all plant conditions (i.e. normal operation and emergency/upset worst case flaring conditions) air quality, including NO2 and CO, would be within the cited air quality standards. As such, impacts on human health would not be expected. On this basis, the operation of the terminal is not considered to constitute a significant environmental impact in regards deteriorating local air quality. BP is currently conducting a one-year atmospheric monitoring programme within the terminal boundary and at various external sites surrounding the facility. At the completion of this monitoring programme monitoring will continue as appropriate under the IMP. The data obtained from the monitoring will be used to support modelling results and assist in facility management at the terminal.

31648-046 ACG Phase 3 ESIA Chapter 9 9/84 October 2004

Azeri, Chirag & Gunashli Full Field Development Phase 3 Environmental & Socio-economic Impact Assessment Final Report Phase 3 onshore terminal operations will also result in considerable emissions of CO2 being released to the atmosphere and these would also be in addition to the Phase 1 and 2, EOP and Shah Deniz emissions from both onshore and offshore operations. The CO2 contribution from the combined operations is considered to represent an appreciable GHG contribution and hence is considered to be of significance. CO2 emissions are further discussed in Section 9.9. 9.8.1.2 Wastes As with the onshore fabrication and construction sites, the terminal has developed a CWAA, which will be used for all construction stages and operations (Section 9.2.1) at the site. The cumulative contribution to waste generation and the final disposal of these wastes in Azerbaijan is an AzBU managed issue and is discussed in more detail in Section 10. A key waste issue is onshore produced water. The management of onshore produced water has been an area of considerable investigation by AIOC. As this issue relates to all phases of the ACG FFD it is discussed more fully in Section 10. The ACG Phase 3 project has taken steps to minimise the volume of produced water that will be transferred with oil to the terminal reception facilities. This includes an enhanced offshore water separation process (i.e. addition of electrostatic coalescers) that will minimise the water cut of the oil transported to shore to 0.5%1. The volumes of Phase 3 produced water that require ultimate disposal onshore are thus significantly minimised. This reduction in water cut also brings with it other associated benefits such as reduction in chemicals required offshore to aid the separation and export process, and more room in the export pipelines to shore for oil during peak production periods. Figure 9.9 illustrates the predicted volumes of produced water that will be transferred to the terminal with the Phase 3 crude oil, which shows that volumes will peak at approximately 14.5 Mbpd in 2015. Figure 9.9 Predicted Phase 3 Produced Water Volumes Onshore (Mbpd)

0

2

4

6

8

10

12

14

16

2008

2009

2010

2011

2012

2013

2014

2015

2016

2017

2018

2019

2020

2021

2022

2023

2024

Year

Mbp

d

The disposal of any produced water at the terminal from Phase 3 operations will align with the disposal solution defined for the ACG FFD. Produced water volumes associated with the

1 It should be noted that the inclusion of coalescers into the offshore design for previous ACG project phases was evaluated but could not be included due to weight and space constraints for these topsides. As such oil transported from the ACG Phase 1 and 2 offshore facilities will contain a maximum water cut of 5%.

31648-046 ACG Phase 3 ESIA Chapter 9 9/85 October 2004

Azeri, Chirag & Gunashli Full Field Development Phase 3 Environmental & Socio-economic Impact Assessment Final Report Chirag-1 platform (EOP) are currently being transferred to the Garadagh Cement Plant north of the terminal site for use in the cement manufacture process. This solution however will handle limited volumes only, and as such a produced water management strategy is being formulated to address the higher volumes of produced water that are predicted from the ACG and Shah Deniz fields in 2007. Currently there are three long-term disposal options under evaluation by AIOC and AzBU:

Disposal to a dedicated injection well at the Lokbatan onshore oilfield; • • •

Subsea pipeline back to ACG Field and re-injection via existing offshore facilities; Treatment and disposal to the marine environment at a suitable distance offshore.

Evaluation of the above options is continuing to assess the equipment, design, cost and potential environmental impacts to determine a preferred final option to pursue. The final decision will be subject to a separate Environmental and Social Impact Assessment, and will require review and approval by the Ministry of Ecology and Natural Resources.

31648-046 ACG Phase 3 ESIA Chapter 9 9/86 October 2004