5.plastering

-

Upload

amynaah-amye -

Category

Engineering

-

view

17 -

download

0

Transcript of 5.plastering

PLASTERING

Plastering

• Process of covering rough walls and uneven

surfaces of a building with a plastic material to

form a durable surface.

• Additives are added to improve the

adhesiveness, water proof, termite resistance

Objectives of plastering

• Provide an even,smooth,regular, clean and durable

finished surface

• Protect the surface from the effects of atmospheric

agencies

• Conceals the defective workmanship

• Covers up the use of inferior quality materials and

joints

• Provides satisfactory base for white washing, color

washing

Characteristic of good plastering

• Should be fire resistant and sound proof

• Should provide a smooth, non-absorbent and

washable surface

• Should adhere to the surface firmly

• Should be weather proof

• Should be free from volumetric changes while

setting and drying

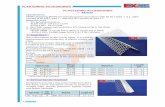

Types of Plastering

Depending upon the binding material

• Cement Plastering

• Mud Plastering

• Lime Plastering

• Lime cement plaster

• Cement plastering

• Mud plastering

Lime plastering

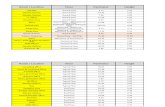

Procedure for cement plastering

• Average thickness of cement plastering is 12-

15mm

• Clean the surface with water and is kept wet till

applying plaster

• Preliminary coat is applied on the surface to fill up

hollow portion of masonry

• First coat is applied with a thickness of 9-10mm

• Second coat is applied after 6hrs and thickness of

second coat is 10mm.

• Surface is polished with a trowel

• Third coat if required is applied with maximum

thickness 3mm

• Completed plaster is allowed to rest for 24hrs and

well watered for at least one week

• Slow setting under higher humidity improves the

strength of plaster

Defects in Plastering• Cracks-appears on the

plastered surface in the form

of thin lines or wider cracks

• Due to shrinkage of thick

plaster or poor workmanship

• Prevented by proper curing -

10 days and keeping

thickness of plaster uniform

(<15mm)

• Efflorescence- due to soluble salts present in the brick or mortar

• Avoided by washing the surface with zinc sulphate solution and water

• Falling out of plaster- due to inadequate water

bondage, water absorption by dry wall

• Avoided by proper cleaning of joints and proper

washing of surface of wall

THANK YOU