XT Service Manual Pro2V080 Rev 5.6B5 5-15-07

Transcript of XT Service Manual Pro2V080 Rev 5.6B5 5-15-07

Service Manual Rev 5.6B5 with software Pro2V080

and Pro2V081

XT SERIES

Service Manual

820 Lakeside Drive – Gurnee, IL 60031

Phone: 1-800- 374-8266 Fax: (847) 855-9650

www.drivecon.com

This document and the information contained herein, is the exclusive property of

Drivecon, Inc. and represents a non-public, confidential and proprietary trade secret

that may not be reproduced, disclosed to third parties, altered or otherwise employed

in any manner whatsoever without the express written consent of Drivecon, Inc.

Copyright © 2006 Drivecon, Inc. All rights reserved.

Page 1

Service Manual Pro2V080 Pro2V081

Drivecon reserves the right to al ter or amend the above information wi thout notice12/18/06 • rev 5.6B5 for Pro2V080 or Pro2V081 software

CAUTION

1. Before starting, read the instructions carefully.

2. Verify all of the connections are in done in accordance to the drawings.

3. Verify the motor supply is connected correctly; faulty connections will damage the drive.

4. Check to make sure that the drive’s cover is properly installed.

5. High voltages are present in the drive. Switch the power off and wait 5 minutes before opening the cover.

6. Insulation resistance test with a megger requires special precautions.

7. Do not make any measurements inside the device when it is connected to the 3-phase power supply.

8. Do not touch the components on the circuit boards. Static voltage discharge may cause damage to the IC-circuits.

9. Check to make sure that all ventilation holes are clear and uncovered.

10. Check to make sure that hot air coming from the dynamic braking resistors cannot cause any damage.

11. Do not make any inspections unless the supply has been disconnected at the main disconnect switch.

12. It is forbidden to use radiophones or portable phones near this device with the doors open.

13. All the doors and covers must be closed during crane operation.

Page 2

Service Manual Pro2V080 Pro2V081

Drivecon reserves the right to al ter or amend the above information wi thout notice12/18/06 • rev 5.6B5 for Pro2V080 or Pro2V081 software

CONTENTS

1 GENERAL....................................................................................................................... 4 1.1 Technical data ...................................................................................................... 4 1.2 Type mark coding.................................................................................................. 5 1.3 Basic description ................................................................................................... 6 1.4 Functional description............................................................................................ 7 1.5 Control methods.................................................................................................... 8 1.6 Mechanical brake control ..................................................................................... 10 1.7 Motor control modes................................................................................... ......... 10 1.8 EMC................................................................................................................... 11

1.8.1 Fulfilled EMC-standards ............................................................................ 12

2 INSTALLATION ............................................................................................................. 13 2.1 Cooling............................................................................................................... 13 2.2 Power cabling ..................................................................................................... 13 2.3 Control wiring...................................................................................................... 15 2.4 EMC compatible grounding .................................................................................. 16

3 START-UP PROCEDURE .............................................................................................. 17 3.1 Visual checks...................................................................................................... 17 3.2 Checks before the f irst test run ............................................................................ 17 3.3 Test run without load ........................................................................................... 18 3.4 Test run with load................................................................................................ 18 3.5 After the test run and autotuning .......................................................................... 18

4 PARAMETER ADJUSTMENTS ....................................................................................... 19 4.1 Control keypad operation ..................................................................................... 19

4.1.1 Navigation on the control keypad ............................................................... 20 4.1.2 Value line editing...................................................................................... 20 4.1.3 Passwords................................................................................................ 21 4.1.4 Special button functions and shortcuts ....................................................... 21 4.1.5 Monitoring................................................................................................ 22

4.2 Input selections................................................................................................... 23 4.3 Speed superv ision settings .................................................................................. 24

4.3.1 Functional test run for SSU ....................................................................... 26 4.4 Open Loop motor parameter adjustments.............................................................. 27

4.4.1 Open Loop speed control for hoisting ......................................................... 27 4.4.2 Open Loop motor parameters for traveling ................................................. 27 4.4.3 Open Loop autotuning for traveling, frequency control................................. 28 4.4.4 Open Loop manual tuning for traveling....................................................... 28 4.4.5 Open Loop manual tuning for traveling, frequency control ........................... 29 4.4.6 Open Loop manual tuning for traveling, current control ............................... 29

4.5 Closed Loop motor parameter adjustments............................................................ 30 4.5.1 Closed Loop rated motor parameters ......................................................... 30 4.5.2 Closed Loop autotuning, speed control ....................................................... 31 4.5.3 Closed Loop manual tuning for hoisting, speed control ................................ 34

4.6 Brake Slip Feature……………………………………………………………………………….37 4.6.1 Description of brake slip feature………………………………………...…………..37 4.6.2 Activation of brake slip feature……………………………..……………..………..38 4.6.3 Brake Slip Feature Field Testing Procedure…………………………..……….….38 4.6.4 What to do in case of brake slip……………………………………………………..39 4.6.5 Service on hoist motor/encoder/brake with Brake Slip feature active………...40

5 PARAMETER DESCRIPTIONS....................................................................................... 41

Page 3

Service Manual Pro2V080 Pro2V081

Drivecon reserves the right to al ter or amend the above information wi thout notice12/18/06 • rev 5.6B5 for Pro2V080 or Pro2V081 software

6 COMPONENTS ............................................................................................................. 54 6.1 Inverter .............................................................................................................. 54

6.1.1 Power supply unit (PSU) ........................................................................... 56 6.1.2 Control unit (CSU) .................................................................................... 56 6.1.3 Basic I/O board (Slot A) ............................................................................ 57 6.1.4 Relay / Thermistor board (Slot B) .............................................................. 58 6.1.5 SSU Speed Superv ision board (Slot C) ...................................................... 58 6.1.6 I/O Extension board (Slot D)...................................................................... 59 6.1.7 Relay Extension board (Slot E) .................................................................. 59 6.1.8 Prof ibus board (Slot E) ............................................................................. 60

6.2 Reference potentiometer...................................................................................... 61 6.3 Speed sensors .................................................................................................... 62

6.3.1 Encoder ................................................................................................... 62 6.3.2 Bearing Sensor......................................................................................... 63 6.3.3 Proximity switch ....................................................................................... 64 6.3.4 Buffer amplifier KAE234 ........................................................................... 65

6.4 Brake controllers ................................................................................................. 66 6.4.1 REC12-690+DC ........................................................................................ 66 6.4.2 ESD141 ................................................................................................ ... 66

7 TROUBLESHOOTING.................................................................................................... 67 7.1 Field repair actions.............................................................................................. 67 7.2 Inverter fault codes ............................................................................................. 68

7.2.1 Fault time data record............................................................................... 73 7.2.2 Fault Counter ......................................................................................... .. 73

7.3 Inverter Alarm codes .................................................................................. ......... 74

8 SERVICE...................................................................................................................... 75 8.1 DC-bus electrolytic capacitors .............................................................................. 75

8.1.1 Re-forming after a long storage period ....................................................... 75

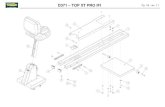

9 DRAWINGS ........................................... ....................................................................... 76

Page 4

Service Manual Pro2V080 Pro2V081

Drivecon reserves the right to al ter or amend the above information wi thout notice12/18/06 • rev 5.6B5 for Pro2V080 or Pro2V081 software

1 GENERAL

1.1 Technical data

Overloadabi li ty 1.5 x In, 1min/10min; 2.0 x In, 2s/20s Max. output voltage Equal to supply vol tage Supply Supply voltage 460-ser ies 380-500VAC, 575-series 525-690VAC Al lowable vol tage f luctuation +/- 10% Nominal supply frequency 50/60Hz +/- 5% Signal Input Levels Digi tal controls S1, S2, DIA3, DIA4, DIA5, DID1, DID2, DID3, DID4, DID5: 42 … 240VAC; 15mA Analog references AIN1: 0 … +10V and AIN2: -10 … +10V; 200kΩ load; accuracy 0.5% Encoder feedback EA+/- and EB+/-; 0/24V; 3kΩ load; f loating dif ferential inputs Control features Control method Open loop or closed loop vector control Frequency control range 0 ... 250Hz Frequency command Potentiometer, motor potentiometer , 2-4-step controller or 0 ... 10V analog signal Limi t switch functions Slowdown and stop limit inputs for both directions Speed control range Open loop vector control sN . .. 100% (sN= motor nominal slip) Closed loop vector control 0 ... 100% Speed accuracy Open loop vector control

1% of nominal speed at speed range 10 .. . 100% 1/3 of motor nominal slip at speed below 10%

Closed loop vector control 0.01% of nominal speed Extended speed range 100 ... 200% programmable Braking torque 150% Protect ions Stal l prevention During acceleration and constant speed Motor overload protection Thermistor /Klixon based temperature measurement Overload protection Fault is detected if the current momentarily exceeds 280% of RMS rated current Undervol tage / blown fuse Fault is detected if DC voltage drops below 333V (460-series), 460V (575-ser ies) Overvol tage protection Fault is detected if DC voltage exceeds 911V (460-series), 1200V (575-series) Momentary power loss Immediate fault stop Inverter overtemperature Temperature sensor on the heat sink Mechanical brake Brake contactor control relay Braking transistor Electronic supervision for the braking chopper and for the braking resistor Brake slip protection Only in closed loop and if protection function enabled, also a programmable relay output Ground fault Provided by electronic circuitry Overspeed, stall , speed difference supervision

Independent measurement using SSU board and a pulse wheel or encoder

Ambient conditions Ambient temperature -10°C ... +55°C (14°F ... 131°F) for ED≤60% Storage temperature -40°C ... +60°C (-31°F ... 140°F) dry. Power on >1h per year. Humidity <95%RH (no condensation) Al titude Maximum 1000m at In. Above 1000m: In reduces 1% per each 100m. Above 3000m: consult factory. Vibration Operation: maximum displacement ampl itude 1mm at 3-15.8Hz. Maximum acceleration ampl itude 1G (9.81m/s²) at 15.8-150Hz Conforms to LV and EMC directives (optional).

Power Class (460-series) 4004 4005 4009 4012 4016 4022 4031 4038 4045 4061 4072 4087 4105 4140 4168 4210 4245 4300 4385 4460 4590 4650

Frame Size Fr4 Fr4 Fr4 Fr4 Fr5 Fr5 Fr6 Fr6 Fr6 Fr7 Fr7 Fr7 Fr8 Fr8 Fr8 Fr9 Fr9 Fr10 Fr10 Fr10 Fr11 Fr11

Horsepower (Hp) at 460V 2 3 5 7.5 10 15 20 25 30 40 50 60 75 100 125 150 200 250 300 350 500 550

Output Current In (A) 4.5 5.6 9 12 16 22 31 38 45 61 72 87 105 140 168 210 245 300 385 460 590 650

Max. Current 1min (A) 10 10 15 20 27 36 48 63 72 90 113 135 165 225 270 315 368 450 578 690 885 975

Max. Current 2s/20s (A) 11 11 18 24 32 46 62 76 92 122 144 174 210 280 336 349 444 545 697 832 1068 1177

Power Class (575-series) 5005 5007 5010 5013 5018 5022 5027 5034 5041 5052 5062 5080 5100 5125 5144 5170

Frame Size Fr6 Fr6 Fr6 Fr6 Fr6 Fr6 Fr6 Fr7 Fr7 Fr8 Fr8 Fr8 Fr9 Fr9 Fr9 Fr9

Horsepower (Hp) at 575V 3 5 7.5 10 15 20 25 30 40 50 60 75 100 125 150 175

Output Current In (A) 5.5 7.5 10 13.5 18 22 27 34 41 52 62 80 100 125 144 170

Max Current 1min (A) 9 12 15 21 27 33 41 51 62 78 93 120 150 188 216 255

Max. Current 2s/20s (A) 11 15 20 27 36 44 54 68 82 104 124 160 200 213 245 289

Page 5

Service Manual Pro2V080 Pro2V081

Drivecon reserves the right to al ter or amend the above information wi thout notice12/18/06 • rev 5.6B5 for Pro2V080 or Pro2V081 software

1.2 Type mark coding XT Series drives can be summarized as "crane motor control systems, which controls the speed by changing the frequency of the supply voltage of a squirrel cage motor". A stepless speed adjustment can be achieved by this method. Type marking is shown below.

Device name 000 - Base Drive (430,440) or Pre-engineered Panel (488,489,etc…) XT - Series name x - d (Base drive vector), e (base drive vector with SSU board), s (open loop vector panel), v (closed loop vector panel)

Supply voltage 4 380 - 500VAC, 50/60Hz 5 525 - 690VAC, 50/60Hz

Power class current handling type code See technical specifications

Panel Motion and Duty Class XX=Base Drive only TC=Traverse class C TD=Traverse class D HC=Hoist class C HD=Hoist class D

000 XTx

4

009

TC

56 Software Revision code The latest rev ision may differ

000 XTx 4 009 TC 56 0 0 0 4

Construction 0 Basic wall mounted 1 Through panel

EMC-compatibility 0 IT Network (Americas) N IEC 61800-3 Second Environment (Europe) Option board configuration 0 Standard A, B, D 1 Standard with speed supervision A, B, C, D 2 Profibus A, B, D, E 3 Profibus with speed supervision A, B, C, D, E 8 Relay A, B, D, E 9 Relay with speed supervision A, B, C, D, E

Special

1. NXP and normal boards 2. NXP and lacquered boards 3. NXP and fiber optic link and lacquered boards 4. NXP2 and normal boards 5. NXP2 and lacquered boards 6. NXP2 and fiber optic link and lacquered boards

Page 6

Service Manual Pro2V080 Pro2V081

Drivecon reserves the right to al ter or amend the above information wi thout notice12/18/06 • rev 5.6B5 for Pro2V080 or Pro2V081 software

1.3 Basic description XT Series drives have many advantages and offer many new features, when compared to other inverter based systems, which might be used in crane applications. Inverter The XT Series drive is a crane specific inverter. The specific crane

features for the inverter hardware and the special software are achieved by combining the experience and know-how of crane applications with the latest technology. The inverter uses vector calculations for several different motor control modes in both open and closed loop.

Crane user interface All XT Series drives have exactly the same interface with pre-designed locations for all typical crane functions. The main part of this interface is carried out by a terminal strip, which has separated sections for signals with main, control and electronics voltage levels.

Brake control XT Series drive panels include a relay for brake contactor control. The brake contactor then controls the “parking” brake on the motor whether it is 3-phase AC, 1-phase AC, or a DC brake coil.

Electrical braking XT Series drives include an internal dynamic braking transistor, which is dimensioned for all crane applications. The braking transistor will dissipate regenerative energy through an external braking resistor. This resistor is sized according to the drive voltage, power, and duty cycle.

Control methods XT Series drives can be controlled by the electronic potentiometer control with 2-step pushbuttons (2 speed infinitely variable), the potentiometer control with analog joystick-type control, the automation control with PLC and radio controls, and by the multistep control with 2-5 step controllers. Any two of these control methods is programmable and available with every drive.

Limit switch functions

XT Series drives will come preprogrammed for slowdown and stop limit switch functions for both operating directions. If slowdown and/or stop limit switches are not used, their inputs may be programmed to other functions or to not used.

Speed supervision In a non-loadbrake hoisting application the drive must include a overspeed detection device. In XT Series drives this is called a speed superv ision unit (SSU) and is separate from the drive and is not dependent on software. This safety circuitry is used to monitor the speed of the motor. In case of speed difference, overspeed or stall, the speed supervision unit stops the motion immediately. A SSU board is standard with any non-load brake hoist however can also be supplied for this application or any traveling application if requested.

Protections XT Series drives include motor thermal protection that is based on motor temperature measurement by thermistors or kl ixons placed in the motor windings. If this protection is not desired, it may be turned off in the programming. All other protection functions are listed in the technical data.

Page 7

Service Manual Pro2V080 Pro2V081

Drivecon reserves the right to al ter or amend the above information wi thout notice12/18/06 • rev 5.6B5 for Pro2V080 or Pro2V081 software

1.4 Functional description See circuit diagrams for following descriptions of operation. Operation when power is switched on

- Slow down limit switches S11 and S21, and stop limit switches S12 and S22 are assumed to be normally closed, as well as the emergency stop button ES.

- The control voltage is supplied to the drive’s control inputs (externally supplied 42VAC…230VAC control voltage). When the supply voltage is connected to the drive’s power supply and inverter wil l power up. If the control voltage ok and the ready circuit has all of its contacts closed, drive will be ready to operate in about 1-2 seconds.

- If either one of the direction signals S1 or S2 is on, the display shows F6 and running can begin only after the direction signals have been turned off for 300ms.

Normal operation – For the description of the speed reference setting options see

chapter 1.5 "Control methods". – Operation starts when one of the directional inputs is given to the

drive. The drive will then close the ROB2 relay and energize the K7 brake contactor, which will cause the “parking” brake to open. The drive will then accelerate according to the acceleration ramp settings to the requested speed.

– When the directional input is removed from the drive, it wil l stop according to the deceleration ramp settings and finish by controlling the “parking” brake to set and hold the motor.

– The dynamic braking resistor will dissipate the regenerative energy during deceleration and hoisting in the down direction. The power supplied to the resistor is controlled by the drive. If the braking resistor fan(s) are included in an external resistor unit, they will start to operate when power is supplied to the braking resistors. The fan cooling will continue for about 4-5 minutes after electrical regenerative braking to ensure that the temperature of the dynamic braking resistors drops below 150°C (302°F).

Other features – Slowdown limit switches S11 and S21 provide position dependent

f requency l imiting. – Any reason that causes the ready circuit to open wil l stop the

operation of drive and sets the mechanical “parking” brake. – In case of an overload (motor overheating, etc.), the hoisting can be

disabled by removing the direction signal. – Thermistor or Klixon interface function can be used when required. – When the stop limit switch S12 or S22 opens, the brake contactor K7

de-energizes and the mechanical “parking” brake will stop the motion.

– Independent speed superv ision unit (SSU) for applications with speed feedback.

– The speed measurement and supervision can be done either using an encoder, bearing encoder, or pulse sensor. The measured signals are square wave pulses. The frequency of the pulses is proportional to the speed of the motor and if the frequency is too high, overspeed is detected. If there are no pulses a stall situation is detected. If the actual speed differs too much from the supply frequency to the motor, the speed difference supervision stops the motion.

– When using a proximity switch or bearing sensor a buffer amplif ier should be used to amplify the sensor pulses and fi lter out disturbances. This amplifier should be located as close to the motor as possible.

Page 8

Service Manual Pro2V080 Pro2V081

Drivecon reserves the right to al ter or amend the above information wi thout notice12/18/06 • rev 5.6B5 for Pro2V080 or Pro2V081 software

1.5 Control methods There are four different control methods (command modes) available. At any given time 2 different control modes may be used. A selector switch and programming of the drive is required to select the desired control method when using 2 different control modes. Instructions on how to program the drive for each different type of control can be found below. EP Electronic motor potentiometer function.

- Stepless control using a 2-step pushbutton controller (2 speed infinitely variable).

- EP3 stepless control using a 3-step controller (3 speed infinitely variable).

PO Potentiometer control using a joystick type controller.

- Requires a single 15V power supply (supplied by the drive). - Additional amplifier is not required.

AU Automation control - For any control dev ice with an output in the range of 0-10V. - E.g. radio-controls, process computers.

MS Multistep control (2-5 steps as standard). - Requires programmable digital inputs for each speed

reference step.

Command mode selection

The command mode (EP, PO or AU) is selected by the CMS and AP inputs to the drive. Normally the selection can be done only when the motion is stopped (not when running), but in special applications it may be possible.

PO- and AU-modes PO and AU modes select either of the analog inputs for speed reference. Both analog inputs can be adjusted from 0V to 10V (radio or PLC-reference) or from 10V to 6.7V (potentiometer). As default, Ain1 is used in PO-mode and Ain2 is used in AU-mode.

Ain1 / PO Ain1 / PO Ain2 / AU Ain2 / AU Ain1 / PO

DIA3 AP not used AP not used AP not used AP = 0 AP = 1

DIA4 CMS not used

CMS = 0 CMS = 1 CMS = 1 CMS = 1

EP-mode EP-mode selects the AP-button for speed reference. EP step 1 is

command for minimum speed or hold speed. EP step 2 is the acceleration command.

EP step 1 EP step 2 EP step 1 EP step 2

DIA3 AP = 0 AP = 1 AP = 0 AP = 1

DIA4 CMS not used

CMS not used

CMS = 0 CMS = 0

Synchronization If required, two or more XT Series drives can be run in precise digital

synchronization. A separate synchronization controller is needed for this. The same speed reference (in EP- or PO-mode) and the correction signal are connected to each drive. The speed reference signal of each drive can also be modified separately by a PLC. Parameter selection and proper tuning activate the synchronization functionality.

Page 9

Service Manual Pro2V080 Pro2V081

Drivecon reserves the right to al ter or amend the above information wi thout notice12/18/06 • rev 5.6B5 for Pro2V080 or Pro2V081 software

Description of the control methods

EP2-control requires two 2-step pushbuttons, one for each direction. The operation is as follows: - the rest position means standstil l (0-position) - while running the rest position means deceleration - when starting, step one means acceleration up to

the minimum speed - when running step one (switch S1 or S2) means

hold speed - step two (switch AP) means acceleration (up to

the maximum speed if desired) - at the maximum speed step two does nothing

because the maximum speed cannot be exceeded

Pushbutton positionrest = decelerationstep 1 = hold speedstep 2 = acceleration

speed

pushbuttonposition

up / fwd

down / rev

time

EP-mode

EP3-control requires a 3-step controller. The operation is as follows: - the rest position means standstil l (0-position) - step one (switch S1 or S2) is the minimum speed

command - step two (EP hold command) means hold speed - step three (switch AP) means acceleration (up to

the maximum speed if desired) - when releasing the controller, step one means

deceleration down to the minimum speed

speed

Pushbutton positionrest = stopstep 1 = minimum speedstep 2 = hold speedstep 3 = acceleration

pushbuttonposition

up / fwd

down / rev

time

EP3-mode

PO-control requires a controller with potentiometer. The operation is as follows: - when the controller is at the rest position the

potentiometer is at the middle position causing zero speed

- run commands are controlled separately by closing the direction switches (S1 and S2)

- when the operator turns the controller to any direction the speed increases

- the same turning angle of the controller causes a smaller change in speed, the closer the speed is to the minimum speed

AU-control requires an analog reference from radio or PLC. The operation is as follows: - the speed linearly follows the input signal. 0V

means zero speed and the higher the voltage, the higher the speed

- run commands are controlled separately by closing the direction switches (S1 and S2)

up / fwd

down / rev

speedspeed

controllerposition

time

potentiometer reference (controller position)or auxiliary reference

PO- and AU-modes

MS-control requires a 2-5-step controller. The operation is as follows: - each step has its own frequency - the frequencies are freely selectable - when controller is set to a certain step, the drive

will either accelerate or decelerate to match the requested speed

speed

controllerposition

up / fwd

down / rev

time

speed

controller position

MS-mode

Page 10

Service Manual Pro2V080 Pro2V081

Drivecon reserves the right to al ter or amend the above information wi thout notice12/18/06 • rev 5.6B5 for Pro2V080 or Pro2V081 software

1.6 Mechanical brake control The brake is controlled so that while starting the motor generates torque f irst and then the brake is opened. The same applies for stopping; while the brake is being closed, the motor still generates torque. During a direction change, the brake is held open. The drive wil l decelerate the motor to a stop according to the set deceleration time when the run command is removed, so the brake is used only as a holding brake. This way brake wear is minimized. Only if a fault occurs or the emergency stop button is pushed will cause the brake to close immediately stopping the motor and the load. All motors used on cranes should use some type of electromechanical brake. Different applications may require a different type of brake. Also, different applications may require this brake to be used differently. As a default, XT Series drive panels are wired to control a single-phase AC brake. If a 3-phase brake is to be used, some wiring changes will be required. If a DC brake is being used, a brake rectifier will need to be used. The type brake rectifier that is required wil l depend upon the size and voltage of the brake coil.

1.7 Motor control modes Open loop XT Series drives have a built-in motor model, which calculates - one thousand times per second - the values of the motor. The input data needed for the calculation is the instantaneous value of the motor voltage from the ASIC and the measured motor current. Motor magnetic flux and shaft torque are calculated in the motor model based on the nameplate data parameters taken from motor. Open loop vector control

Speedref

InverterAsic

CurrentVectorcalculation

SpeedControl

Torque

Flux

ref

M3~

Frequency control Open loop (mode 0)

In Open Loop Frequency Control, the frequency supplied to the motor follows the frequency reference signal given to the drive. The actual rotating speed depends on load and is equal to the slip below or above the output frequency. Even with frequency control, the vector calculation is used to keep the magnetization at a correct level for optimized torque.

Current control Open Loop (mode 1)

In Open Loop Current Control, the frequency supplied to the motor fol lows the frequency reference signal given to the drive. The motor is current control led in smaller frequencies (typically <10Hz) and in higher frequencies the motor is voltage controlled. The current control ensures that in small frequencies the speed of the motor is almost independent of the load.

Closed loop The closed loop vector control also includes a motor model, which has simpler configuration than the open loop vector control. This is because an additional input data from the incremental encoder is available, thus eliminating additional calculations inside the drive. This measurement of the rotation of the motor is used as feedback to the motor model calculation and allows possibil ities for additional checking and fine adjustments of the motor control. This is how 1000:1 speed control is achieved.

Page 11

Service Manual Pro2V080 Pro2V081

Drivecon reserves the right to al ter or amend the above information wi thout notice12/18/06 • rev 5.6B5 for Pro2V080 or Pro2V081 software

Closed loop vector control

Speedref

InverterAsic

CurrentVectorcalculation

SpeedControl

Torque

Flux

ref

Speed

G

M3~

Speed control Closed loop (mode 3)

In Closed Loop Speed Control, the frequency supplied to the motor fol lows the frequency reference signal given to the drive. The drive adjusts the motor frequency and with this function compensates the load-dependent sl ip. The slip compensation keeps the actual shaft speed constant and independent of loading conditions. With closed loop speed control it is even possible to reach zero speed with ful l torque.

Torque control Closed loop (mode 4)

In Torque Control, the shaft torque is kept equal to the reference signal provided to the drive. The motor speed depends very much on loading conditions - for example, an unloaded motor would run at full speed all the time. For safety reasons, the speed is limited between adjustable minimum and maximum speeds.

1.8 EMC The abbreviation "EMC" stands for the Electro Magnetic Compatibility. The XT Series drives contain EMC input fil tering that reduces the voltage and current harmonics that are produced by the drive and generated back into the power supply. The XT Series drives used in North America have this fi ltering capacity modif ied to allow for the varying types and fluctuations in the power network. If the European Union EMC standards are necessary, the power supply must meet minimum requirements and the drive configuration for this must be specif ied when ordering. According to the European Union EMC directive "the apparatus shall be so constructed that: a) The electromagnetic disturbance it generates does not exceed a level allowing other

apparatus to operate as intended b) The apparatus has an adequate level of intrinsic immunity of electromagnetic disturbance to

enable it to operate as intended." Technical construction file

The technical construction file describes how the frequency converters have been constructed to comply with the directive and standard requirements.

Declaration of conformity

With the declaration of conformity the manufacturer informs that device is manufactured to fulfil l required EMC standards.

CE-mark The CE marking is a declaration by a manufacturer or importer located in the European Economic Area that a product complies with the safety and health requirements of the directive in question. The manufacturer demonstrates for the authorities that the product complies with the safety requirements within the EU.

EMC Plan EMC Plan for inverters is intend to use as a guide in cases when disturbance problems appear in crane installations, in the crane itself or in other devices in the installation environment.

Page 12

Service Manual Pro2V080 Pro2V081

Drivecon reserves the right to al ter or amend the above information wi thout notice12/18/06 • rev 5.6B5 for Pro2V080 or Pro2V081 software

Environments Immunity and emission requirements are div ided in two levels in the product standard according to the environments.

PDS

PDS

First environment means an environment that includes domestic premises and also establishments directly connected to a low-voltage power supply network. The first environment is div ided in to categories C1 and C2. XT Series drives are not intended to be used on a low-voltage public network, which supplies domestic premises. The drive may cause radio frequency interference to other devices if used on such a network. Second environment means environment that includes all establishments other than those directly connected a low-voltage power supply network. The second environment is divided in to categories C3 and C4. If rated current of the crane supply is less than 400 A, the inverters belong to the category C3, otherwise they belong to the category C4. Power drive system (PDS) means a system consisting of power and control equipment, including the XT Series drive.

1.8.1 Fulfilled EMC-standards Immunity The XT Series drive fulfills the immunity requirements defined in the

EN/IEC 61800-3: 2004 for the second environment, EN 61000-6-1 (residential, commercial and light industry) and EN 61000-6-2 (industrial environment).

Emissions The XT Series drive fulfills the emission requirements of the EN/IEC 61800-3: 2004 for the second environment. If a disturbance causes problems the EMC Plan can be used as the guide to solve those.

Page 13

Service Manual Pro2V080 Pro2V081

Drivecon reserves the right to al ter or amend the above information wi thout notice12/18/06 • rev 5.6B5 for Pro2V080 or Pro2V081 software

2 INSTALLATION

2.1 Cooling The cooling requirements for XT Series drives vary by application. The actual thermal loading of the enclosure has to be estimated based on the environmental conditions and duty cycles. The power losses of the drive are listed in the below table for each power rating in units of Watts [W]. Cooling for models, which are installed in totally closed cubicles should be checked case by case with ambient temperatures above 110 degrees Fahrenheit.

Through panel mounted

Totally enclosed cubicle

Through panel mounted

Totally enclosed cubicle

Model ED40 ED60 ED100 ED40 ED60 ED100 Model ED40 ED60 ED100 ED40 ED60 ED100

4004 21 24 29 67 92 141 5003 18 19 21 56 64 80 4005 21 24 29 67 92 141 5004 19 21 23 67 81 108 4009 21 23 28 64 87 132 5005 20 22 26 76 94 130 4012 24 28 36 96 134 211 5007 22 25 30 93 120 174 4016 25 30 39 116 160 248 5010 24 28 35 115 153 229 4022 31 39 54 176 250 398 5013 27 32 43 146 199 305 4031 30 37 51 177 246 383 5018 31 38 53 185 258 403 4038 38 49 71 256 364 581 5022 35 44 62 220 310 491 4045 41 54 79 289 413 662 5027 39 50 73 264 376 600 4061 34 43 60 230 318 493 5034 44 58 86 332 471 748 4072 43 57 83 322 456 724 5041 50 67 101 392 561 899 4087 53 71 107 415 596 957 5052 57 76 114 598 791 1176 4105 54 72 108 570 749 1108 5062 65 89 136 684 920 1392 4140 73 101 156 763 1039 1591 5080 81 112 175 840 1153 1781 4168 89 125 197 927 1284 1999 5100 50 66 98 781 942 1264 4210 73 101 157 1013 1291 1845 5125 62 84 127 896 1114 1551 4245 89 125 196 1170 1526 2237 5144 70 97 149 983 1245 1769

5170 82 115 179 1103 1424 2068 Note! The power losses given above do not include t he power fed to the dynamic

braking resistors. Check each application that requ ires the dynamic braking resistor to be installed in the same enclosure as t he drive.

2.2 Power cabling Shielded motor cable

In crane applications the drive fulfills EN/IEC 61800-3: 2004 second environment radiated emission requirements without a shielded motor cable. However, shielded motor cable is recommended to be used in fixed installations, especially in buildings. In the second environment, shielded motor cable is recommended to be used in fixed installations, especially in buildings. However motor cables in crane and festoon power supplies are normally not shielded due to the practicality of it. Shielded motor cable is essential to use if the installation is requested to fulfi ll the first env ironment emission requirements.

Double collectors

If the power is supplied to the crane via conductor rails, double collectors are required. This ensures a reliable contact with the rail in all circumstances. Short interruptions and sparks between the conductor rail and the collector may cause nuisance tripping, other undesired operation, and in some cases even cause permanent damage to the drive components.

Page 14

Service Manual Pro2V080 Pro2V081

Drivecon reserves the right to al ter or amend the above information wi thout notice12/18/06 • rev 5.6B5 for Pro2V080 or Pro2V081 software

Cable selection

Cabling for the drive can be done using normal crane cables. All the cables must be dimensioned according to local regulations. Ambient temperature, cabling method (size of bunches etc.) and allowable current for the cable in use must be taken into consideration. If there are no other regulations, following values can be used (three phase 480V/575V supply).

The table below is based on ED less than or equal to 60% and ambient temperature +40C (104F). A higher ambient temperature may require increased cable sizes. The input current does not exceed the continuous current (Icont) of the drive, so it can be used as the dimensioning current. If the actual load current is below the drive’s rated continuous current, then the fuses and the supply cable may be dimensioned according to the load current.

Power class 4004 4005 4009 4012 4016 4022 4031 4038 Continuous current ICONT A 4.5 5.5 9 12 16 22 31 38 Motor cable 104oF AWG 14 14 14 14 14 14 12 10 Braking resistor cable for hoist CMAA Class D SRML Cable

104oF AWG 14 14 14 14 14 14 14 14

Braking resistor cable for travel CMAA Class D SRML Cable

104oF AWG 14 14 14 14 14 14 14 14

Power class 4045 4061 4072 4087 4105 4140 4168 4210 Continuous current ICONT A 45 61 72 87 105 140 168 210 Motor cable 104oF AWG 8 6 6 4 2 1 1/0 2/0 Braking resistor cable for hoist CMAA Class D SRML Cable

104oF AWG 10 8 6 6 4 1/0 1/0 1/0

Braking resistor cable for travel CMAA Class D SRML Cable

104oF AWG 10 8 6 6 4 2 2 2

Power class 5005 5007 5010 5013 5018 5022 5027 5034 Continuous current ICONT A 5.5 7.5 10 13.5 18 22 27 34 Motor cable 104oF AWG 14 14 14 14 14 10 10 8 Braking resistor cable for hoist CMAA Class D SRML Cable

104oF AWG 14 14 14 14 14 14 14 10

Braking resistor cable for travel CMAA Class D SRML Cable

104oF AWG 14 14 14 14 14 14 14 12

Power class 5041 5052 5062 5080 5100 5125 5144 5170 Continuous current ICONT A 41 52 62 80 100 125 144 170 Motor cable 104oF AWG 8 4 4 2 2 2/0 2/0 3/0 Braking resistor cable for hoist CMAA Class D SRML Cable

104oF AWG 8 6 6 4 2 1 1/0 2/0

Braking resistor cable for travel CMAA Class D SRML Cable

104oF AWG 10 10 8 6 4 4 1 1/0

**For wire sizing information for higher duty cycles and/or drives larger than listed above, please contact Drivecon.

Page 15

Service Manual Pro2V080 Pro2V081

Drivecon reserves the right to al ter or amend the above information wi thout notice12/18/06 • rev 5.6B5 for Pro2V080 or Pro2V081 software

Cable protection

To protect the supply cables from a short circuit there must be fuses or motor circuit breakers (MCCBs) installed at the supply end of the power cable. Sizing of the fuses or MCCBs depends on the cable used and on the type of primary fuses or MCCBs. If there are no other regulations, the values given in this section can be used to size the fuses (three phase 480V/575V supply). The overload protection of the XT drive protects both the supply and the motor cables. The fuses on the power supply provide short circuit protection.

Cable length

The maximum motor cable length is based on 150% of inverter rated current (=current during acceleration) and a 2.5 % voltage drop in the cable. For longer cables, the required conductor cross sectional area A (mm2) is given by the following formula: A = 2.43*[( l * 1.5 * IF) / (p * U)] where l is the cable length (m) IF is the motor current (A) at shaf t power PF p is the allowed voltage drop in % U is the nominal motor voltage

Note! All control wires must be placed as far away from the motor and braking resistor

wires as possible.

2.3 Control wiring Shielded signal cable It's recommended to use twisted pair and braided shielded signal

cables. Foil shields are not sufficient enough in crane applications because of its poor mechanical durability. The cable insulation material ef fects the cable capacitance. The recommended cable capacitance between signal-signal and signal-ground is equal or less than 100pF/m (31pF/ft). It is not recommended to use shielded flat cable, because its capacitance is extremely high and thus may cause high frequency interference.

Reference signals Shielded round cables must be used for analog reference signals. The shield is to be grounded only at the drive (not at the other end of the cable).

Bearing sensor/Pulse sensor

The cable for bearing sensors or pulse sensors must be shielded round cable and should be 360° grounded at both ends.

Encoder The encoder connections may be split into two cables. The signal conductors (4pcs) should go together in one cable and the supply and common (+24V/0V) together in another cable. The encoder cable(s) must be shielded round cable(s) and should be 360 degree grounded at both ends.

Note! All shielded cables must be placed as far fro m the motor cables as possible

(>20cm). Shielding must be continuous. The "pigtail " (= the end to be connected) of the shield should not be used. Instea d, 360 degree grounding should be used to minimize disturbances to the low voltage signals.

Page 16

Service Manual Pro2V080 Pro2V081

Drivecon reserves the right to al ter or amend the above information wi thout notice12/18/06 • rev 5.6B5 for Pro2V080 or Pro2V081 software

2.4 EMC compatible grounding Construction connections

All metal construction parts of the cubicle must be electrically connected to each other using largest possible surface area. Paint to paint connection must not be used.

Cable connections Control cables and power cables should be separated and routed separately for eliminating noise coupling. The distance between braking resistor cables and the other cables should be kept as long as possible. The distance between the resistor cables should be kept as low as possible to prevent the antenna behavior. Cable lengths should be kept as short as possible to minimize the noise effects that can come from coupling capacitances and inductances between the wires.

Shielded control cables

Shielded control cables should be grounded in both ends. The shield must be connected to the ground using the largest possible surface area. Extra intermediary terminators cutting the shield are not allowed. Spare conductors should be grounded in both ends to avoid antenna behavior. All shielded cable shields should be 360° grounded.

Page 17

Service Manual Pro2V080 Pro2V081

Drivecon reserves the right to al ter or amend the above information wi thout notice12/18/06 • rev 5.6B5 for Pro2V080 or Pro2V081 software

3 START-UP PROCEDURE If any problems or malfunctions occur during the start-up, refer to the “Troubleshooting” chapter to find hints on correcting the problem. All problems must be solved before continuing.

- Do not connect any voltage to the output terminals (U, V, W). This will cause damage to the drive. - The overload protection protects both the supply and the motor cables. The fuses in the power supply prov ide short circuit protection.

3.1 Visual checks - Record all checks and results. - Check condition of the enclosures. - Make sure that the drive serial number is the same as in the delivery documents. - Check the rotary dial and dip switch settings on the SSU board (see chapter "SSU").

- If necessary, open the control box cover and adjust the SSU settings. - Check the wiring to the motor, brake, thermistors and speed sensor. - Check the motor type and motor parameters - Check the wire terminations in the motor connection box

- Check connections for motor, thermistors, heaters, brake wear and speed sensor circuits. - Disconnect motor (U, V, W) and brake cables to prevent damage of the inverter. Measure the

isolation resistance (using a megger) of the brake coil and the motor windings (each phase to ground).

- Re-connect motor and brake cables. - Check braking resistor(s) and resistor enclosure air venti lation.

- The temperature of hot air coming from braking resistors may rise over 200C (400F). Make sure that hot air does not cause any danger.

- A board terminals A1-A10 and C board terminals C1-C6 are for electronics level signals. - Normally only shielded wires are connected to these terminals. Make sure that no control

or line voltage level wires are connected there.

3.2 Checks before the first test run

Warning! High voltages inside the device.

- Make sure that the power supply voltage is sufficient (nominal voltage +/- 10%). - Make sure that run commands are off (pushbuttons / controller (master switch) at zero position). - Turn on the power from the main switch and the control voltage switch. - Within about 1 second the keypad should display "AC on", and then in about 1 second the

display should change to the multimonitor parameter 4.23.1 and the green READY status indicator should also turn on. - In a fault situation, the red FAULT status indicator blinks and the display shows a fault code

instead of the multimonitor. - Make sure that the green RUN status indicator is off. - Make sure that the external connections and programming of the digital and analog inputs are

done according to the application requirements.

Warning! High voltages inside the device. Wait for at least five minutes after the supply voltage has been switched off before performing any service actions. The display in the operating condition (lights on) indi cates a dangerous voltage on the DC-bus. When display turns off, the DC-bus volt age is approximately 100V. Note also that there is always a dangerous voltage in the braking resistor when the DC-bus is charged.

Page 18

Service Manual Pro2V080 Pro2V081

Drivecon reserves the right to al ter or amend the above information wi thout notice12/18/06 • rev 5.6B5 for Pro2V080 or Pro2V081 software

- Check to make sure the parameters are properly set. Take notes of all of the parameter adjustments that were necessary on the parameter list supplied with the drive; write down in the parameter l ist all the values that have been changed.

3.3 Test run without load - Reference chapter 4.4 Open Loop motor parameter adjustments and chapter 4.5 Closed Loop

motor parameter adjustments. - Make sure that movement will not cause any danger to the environment or to the crane itself.

Avoid running close to the l imit areas. - Check the l imit switches manually if possible. - Check the run commands on the keypad display and correct the motor rotating direction. The

arrow rotates clockwise if S1 (fwd/up) is applied, and counter-clockwise if S2 (rev/down) is applied.

- Check the function of the speed sensor, see chapter “Speed sensors” - Check the function of the speed supervision circuit. See "Functional test run for SSU". - Run forward (upwards) at minimum speed for 5 to 10 seconds. Accelerate to full speed. Run 5

to 10 seconds. Stop. Repeat the same in the reverse (down) direction. Check the f requency display to make sure that the frequency changes through the whole operational f requency range from the minimum to the nominal speed.

- Check the motor operation (acceleration, deceleration and braking): accelerate to full speed forward (up), change to full speed reverse (down) and full speed forward (up) again and stop.

- Check the limit switch functions: run forward (up) slowly and check the slowdown and the stop l imit switch operations. Re-check using full speed. Repeat the same check for the reverse (down) direction.

- If the optional ESR is used, check the maximum frequency. - When all functionality is verified to be correct, autotuning needs to be performed.

- See chapter 4.4.3 for open loop autotuning instructions for Traverse motions. - See chapter 4.5.2 for closed loop autotuning instructions for Hoist motions with an encoder.

3.4 Test run with load - See also chapter 4.4 Open Loop motor parameter adjustments and chapter 4.5 Closed Loop

motor parameter adjustments - Note, three loads are required:

- Nominal load (100%) for normal operation. - Limited load for ESR (optional). - An adequate extra load for dynamic overload testing and to test the ESR load limit.

- Make sure that movement will not cause any danger to the environment or to the crane itself. - If the optional extended speed range (ESR) is used, check that the load limit is correctly set

and hoisting with bigger loads is prevented. - Run in both directions at minimum and maximum speeds. - If the fan tube resistor unit is included, check that the fan(s) starts to blow when running down

with nominal load and continues to blow for about 4-5 minutes after stopping.

3.5 After the test run and autotuning - Record all the parameter value changes in the parameter l ist. - Make sure all remarks and setting values are recorded. - Copy all parameters up to keypad memory at parameter 6.3.2. - Save user parameters in Control Unit at parameter 4.1.2.

Page 19

Service Manual Pro2V080 Pro2V081

Drivecon reserves the right to al ter or amend the above information wi thout notice12/18/06 • rev 5.6B5 for Pro2V080 or Pro2V081 software

4 PARAMETER ADJUSTMENTS

4.1 Control keypad operation

Drive status indications : RUN Motor is running

Motor rotation direction STOP Inverter is not running READY OK circuit is active ALARM Active warning FAULT Active fault

Control place indications :

I/O term Terminals are the selected control place Keypad Control keypad is the selected control place Bus/Comm Control through Profibus is selected Text lines : Line 1 Location indication (parameter number) Line 2 Description line (parameter name) Line 3 Value line (parameter value) Status LEDs : ready green Il luminates the AC-supply is on run green Il luminates during run

KeypadI/O term

READY FAULTSTOPRUN ALARM

Bus/CommP3.4.1.1.

Motor Nom Volt 400 V

START

STOP

enterselect

reset

ready run fault

fault red Il luminates due to a fault

Button descriptions – also see section 4.1.4 for ke ypad shortcuts:

reset

Reset active faults START

Starts the motor if the keypad is the active control location

select

Switch between two latest displays STOP

Stops the motor if the keypad is the active control location

enter Confirmation of selections

Browse up the menus Increase values

Move to prev ious menu level Move cursor left Exit edit mode

Browse down the menus Decrease values

Move to next menu level Move cursor right Enter edit mode

Warning! Running via keypad can cause a hazardous s ituation. Keypad control must not

be used.

Page 20

Service Manual Pro2V080 Pro2V081

Drivecon reserves the right to al ter or amend the above information wi thout notice12/18/06 • rev 5.6B5 for Pro2V080 or Pro2V081 software

4.1.1 Navigation on the control keypad The letters listed below will appear as the first character in the parameter address. This letter only describes the type of parameter you are viewing. It has no relationship as to where you are in the parameters. Parameter navigation is actually completely determined by the numbers and is not dependent upon the letter.

Letter front of the code number describes variable type B = Button G = Group N = Multimonitor T = Trip Counter C = Counter H = Fault History P = Parameter V = Value D = Data I = Info R = Reference E = Expander M = Menu Group S = System

READYSTOP

G3.

Parameters G1G9

READYSTOP

G4.

Monitoring G1G23

READYSTOP

G5.

Panel Control B1R2

READYSTOP

M6.

System Menu S1S8

READYSTOP

M7.

Active Faults F0

READYSTOP

M8.

Fault History H1Hxx

READYSTOP

G3.4.

Motor Parameters G1G7

READYSTOP

G3.4.1.

Motor Set 1 P1G23

READYSTOP

P3.4.1.1.

Motor Nom Volt 400 V

READYSTOP

V4.22.

Output Frequency 0.00 Hz

READYSTOP

B5.1.

Panel ControlOff

READYSTOP

S6.2.

ApplicationCrane

READYSTOP

H8.1.

57 ThermistorF T1T16

READYSTOP

Operation days 0

I/O term I/O term I/O term

I/O term

I/O term I/O term

I/O term I/O term

I/O term I/O term

I/O term I/O term I/O te rm I/O term

T8.1.1.

4.1.2 Value line editing

enter

Modechange

Acceptvalue

Editvalue

READYSTOP

P3.4.1.1.

Motor Nom Volt 400 V

I/O te rm

Warning! Changing parameter settings during running may cause a hazardous situation.

Parameter settings must not be changed during opera tion.

Page 21

Service Manual Pro2V080 Pro2V081

Drivecon reserves the right to al ter or amend the above information wi thout notice12/18/06 • rev 5.6B5 for Pro2V080 or Pro2V081 software

4.1.3 Passwords Parameter Name Description

Following passwords release the parameter locks. Level 1 Locked 0 Level 2 Start-up 26

P3.1.1 Password

Level 3 Engineering 768

4.1.4 Special button functions and shortcuts

Button Time delay Description

START

> 2 seconds Password level changes to Level 3 Engineering.

> 2 seconds Displays the sof tware version.

> 2 seconds Display changes straight to adequate autotuning parameter.

select

> 2 seconds Changes display straight to V4.22 Output Frequency.

reset

> 3 seconds Resets whole H8 Fault History when display in any level of H8 menu.

enter > 1 second Resets whole H8 Fault History when display in sublevel of H8 menu.

Page 22

Service Manual Pro2V080 Pro2V081

Drivecon reserves the right to al ter or amend the above information wi thout notice12/18/06 • rev 5.6B5 for Pro2V080 or Pro2V081 software

4.1.5 Monitoring Below is a l ist of the group 4 Monitoring parameters. For example, operation of analog and digital inputs can be verified with monitoring parameters. After power off and on the display returns to its default display at 4.23.1 which is the Multimonitor. G4 Monitoring Unit PW 1

G4.1 Parameter Backup Unit PW 1B4.1.1 Load Default Par 1B4.1.2 Save User Par 1B4.1.3 Load User Par 1

G4.1.4 Factory Default Unit PW 4B4.1.4.1 Save Default Par 4

G4.2 Analog I/O Unit PW 1V4.2.1 Ain1 Value V 1V4.2.2 Ain2 Value V 1V4.2.3 Aout1 Value mA 1V4.2.4 Aout2 Value V 1

G4.3 Relay Output Unit PW 1V4.3.1 ROB1 State 1V4.3.2 ROB2 State K7 1V4.3.3 ROC1 State 1V4.3.4 ROD1 State 1V4.3.5 ROE1 State 1V4.3.6 ROE2 State 1V4.3.7 ROE3 State 1

G4.4 Operate Counters Unit PW 2V4.4.1 Motor MWh MWh 2V4.4.2 Generator MWh MWh 2V4.4.3 Start Counter x 1k 2V4.4.4 MotorRuntime (h) h 2

G4.5 Fault Counter Unit PW 2V4.5.1 F1 Overcurrent 2V4.5.2 F2 Overvoltage 2V4.5.3 F3 Earth Fault 2V4.5.4 F7 Saturation 2V4.5.5 F9 Undervoltage 2V4.5.6 F10 Input Phase 2V4.5.7 F11 Output Phase 2V4.5.8 F12 BrakeChopper 2V4.5.9 F13 Undertemp 2V4.5.10 F14 Overtemp 2V4.5.12 F31 IGBT Temp HW 2V4.5.13 F41 IGBT Temp 2V4.5.14 F43 Encoder 2V4.5.15 F53 Profibus 2V4.5.16 F56 Gen Curr Lim 2V4.5.11 F57 Thermistor 2V4.5.17 F61 SSU Overspd 2V4.5.18 F62 SSU Spd Diff 2V4.5.19 F63 SSU Stall 2V4.5.20 F74 Sway Control 2V4.5.21 F76 Input Signal 2V4.5.22 A81 Brake Slip 2V4.5.23 A82 Overweight 2V4.5.24 Other faults 2V4.5.25 Total Faults 2

G4.6 Bus Control Unit PW 1V4.6.1 S1 Fieldbus 1V4.6.2 S2 Fieldbus 1V4.6.3 Motor Set 2 1V4.6.4 Second Speed Lim 1V4.6.5 Field Weakening 1V4.6.6 Alt Control Mode 1V4.6.7 Brake Feedback 1V4.6.8 Ramp 2 1V4.6.9 Torque Limit 1V4.6.10 AP 1V4.6.11 Slow Limit S11 1V4.6.12 Slow Limit S21 1V4.6.13 End Limit S12 1V4.6.14 End Limit S22 1V4.6.15 Brake Pedal 1V4.6.16 S-Curve Inhibit 1V4.6.17 Tare 1V4.6.18 Inching 1V4.6.19 SlackCableBypass 1V4.6.20 Brake Pedal 2 1V4.6.21 Synchronizing 1V4.6.22 Speed Reference Hz 1V4.6.23 Torque Reference % 1V4.6.24 Speed Correction Hz 1V4.6.25 Ramp Reference 1V4.6.26 Torgue Limit Ref % 1V4.6.27 Speed Limit Ref 1V4.6.28 Load Feedback 1V4.6.29 Sway Ctrl Height 1V4.6.30 Calibration Pos 1V4.6.31 Profibus Status 1V4.6.32 Bus Cycle Time ms 1

G4.7 Digital Input Unit PW 1G4.7.1 DI Status Unit PW 1

V4.7.1.1 S1 1V4.7.1.2 S2 1V4.7.1.3 DIA3 1V4.7.1.4 DIA4 1V4.7.1.5 DIA5 1V4.7.1.6 OK 1V4.7.1.7 DID1 1V4.7.1.8 DID2 1V4.7.1.9 DID3 1V4.7.1.10 DID4 1V4.7.1.11 DID5 1

G4.7.2 DI Functions Unit PW 1V4.7.2.1 DIA3 Function 1V4.7.2.2 DIA4 Function 1V4.7.2.3 DIA5 Function 1V4.7.2.4 DID1 Function 1V4.7.2.5 DID2 Function 1V4.7.2.6 DID3 Function 1V4.7.2.7 DID4 Function 1V4.7.2.8 DID5 Function 1

V4.7.3 Basic Board 1V4.7.4 Extension Board 1

G4.8 SSU Unit PW 1V4.8.1 Overspd Lim 1 % 1V4.8.2 Overspd Lim 2 % 1

G4.9 Service Unit PW 3V4.9.1 Phase U Curr A 3V4.9.2 Phase V Curr A 3V4.9.3 Phase W Curr A 3V4.9.4 Encoder Speed Hz 3V4.9.5 HeatSinkTempMax °C 3V4.9.6 HeatSinkTempMin °C 3V4.9.7 IGBT Temp Max °C 3V4.9.8 IGBT Temperature °C 3V4.9.9 SlipAdjustChange % 3

G4.9.10 Max Current Unit PW 3V4.9.10.1 Max Current 3V4.9.10.2 Max Current Freq 3V4.9.10.3 Max Current Torq 3

G4.10 Sway Control Unit PW 3V4.10.1 Swing Time s 3V4.10.2 Pendulum Length m 3V4.10.3 StoppingDistance m 3V4.10.4 Sway Ctrl Status 3V4.10.5 License Status 3V4.10.6 DemoLicenseTime 3

V4.11 Freq Ref Hz 1V4.12 Speed Req Hz 1V4.13 Distance Counter m 1V4.14 DC-link Voltage V 1V4.15 Heat Sink Temp °C 1V4.16 MotorTemperature % 1V4.17 Motor Power % 1V4.18 Motor Voltage V 1V4.19 Motor Torque % 1V4.20 Motor Current A 1V4.21 Motor Speed rpm 1V4.22 Output Frequency Hz 1

G4.23 Multimonitor Unit PW 1V4.23.1 Multimonitor 1

Page 23

Service Manual Pro2V080 Pro2V081

Drivecon reserves the right to al ter or amend the above information wi thout notice12/18/06 • rev 5.6B5 for Pro2V080 or Pro2V081 software

4.2 Input selections Digital inputs are programmed based on function. Each function can be set to one of the 8 programmable digital inputs. The programmable digital inputs are DIA3, DIA4, DIA5, DID1, DID2, DID3, DID4 or DID5. Some functions can be set always ON or always OFF to activate certain functions permanently. There are also 3 other inputs, which functions can not be changed by parameters. These non-programmable inputs are OK-input and the direction signals S1 (up or forward) and S2 (down or reverse). In basic applications one function is set to each input. For special applications it is also possible to set many functions to same input. For example the Torque limit and Ramp2 should be activated with DIA5. Select the value 3=DIA5 in both parameters P3.2.1.7 and P3.2.1.8. Note! Impossible function combinations may be selec ted. The following table lists the possible inputs for each function. Parameter Name / Function DIA3 DIA4 DIA5 DID1 DID2 DID3 DID4 DID5 ON OFF P3.2.1.1 Motor Set 2 X X X X X X X X X X P3.2.1.2 SSL X X X X X X X X X X P3.2.1.3 ESR X X X X X X X X X X P3.2.1.4 Micro Speed Sel X X X X X X X X X X P3.2.1.5 Alt Control Sel X X X X X X X X X X P3.2.1.6 Profibus Control - - X - - - - - - - P3.2.1.7 Ramp2 X X X X X X X X X X P3.2.1.8 Trq Limit X X X X X X X X X X P3.2.1.9 AP X - - - - - - - X X P3.2.1.10 CMS - X - - - - - - X X P3.2.1.11 EP-Hold X X X X X X X X - - P3.2.1.12 Mult istep2 X X - - - - - - - - P3.2.1.13 Mult istep3 - X X - - - - - - - P3.2.1.14 Mult istep4 - - X X - - - - - - P3.2.1.15 Mult istep5 - - - X X - - - - - P3.2.1.16 PO/MS X X X X X X X X - - P3.2.1.17 S11 - - X - X - - - X X P3.2.1.18 S21 - - - X - X - - X X P3.2.1.19 S11 & S21 X X X X X X X X - - P3.2.1.20 S12 - - - - X - X - - - P3.2.1.21 S22 - - - - - X - X - - P3.2.1.22 MF1 Input X X X X X X X X - - P3.2.1.24 MF2 Input X X X X X X X X - -

Page 24

Service Manual Pro2V080 Pro2V081

Drivecon reserves the right to al ter or amend the above information wi thout notice12/18/06 • rev 5.6B5 for Pro2V080 or Pro2V081 software

4.3 Speed supervision settings SSU is a hoist motion speed supervision unit, which reads the pulse frequency from the hoist motor bearing sensor, encoder, or pulse sensor. This pulse frequency is compared with a fixed oscil lator frequency and drive frequency reference. As a result of the frequency comparison, there are three different speed supervision functions available:

- overspeed superv ision (rush control) - stall superv ision - speed difference supervision

Overspeed supervision (F61) is totally implemented by hardware. Switches S2-2 and S2-3 div ide the full frequency range to four frequency areas.

- Selected frequency area is the same for normal and ESR speeds. The four frequency areas are each div ided to lower and upper frequency ranges

- Switch S2-1 selects the frequency range at normal speed. - Switch S2-4 selects the frequency range at ESR speed (Extended Speed

Range). The exact tripping frequency level is selected with rotary switches.

- Switch S1 sets the tripping level at normal speed (value shown in V4.8.1). - Switch S3 sets the tripping level at ESR speed (value shown in V4.8.2).

Overspeed tripping levels are shown at display as % of the motor nominal speed. The overspeed setting should be 15-25% above the nominal speed. Speed difference supervision (F62) compares the motor actual speed (= pulse frequency) with frequency reference. In practice this means that the motor slip is measured and if that exceeds a preset l imit, supervision stops the motion. Allowed speed difference (%) is adjusted with parameter P3.3.10.1. The use of ESR has no effect on this parameter setting. Stall supervision (F63) stops the motion if there are no pulses coming from the sensor when the brake is open (K7 energized). Allowed time (s) without pulses before a fault is detected is adjusted with parameter P3.3.10.2. SSU relay test (F64): SSU relay is tested each time the drive powers up. Operation is prevented if a fault has been detected. SSU Watchdog fault (F65): Communication between SSU board and control board is tested once every 50ms. A fault will be detected if there is communication error. When a fault is detected operation is prevented. SSU Overspeed Limit (F66): Maximum setting of the overspeed limit is 1.4*nominal speed of direction S2 (normal and ESR). Fault will be detected if the overspeed l imit is set higher than that value. When a fault is detected, operation is prevented. Brake Slip (A84): Active only when the parameters have been programmed for this detection. See section 4.6 of this manual for further information about this feature.

1 2 3 4

ON OFF

S1

S2

S3

Page 25

Service Manual Pro2V080 Pro2V081

Drivecon reserves the right to al ter or amend the above information wi thout notice12/18/06 • rev 5.6B5 for Pro2V080 or Pro2V081 software

Standard settings As an aid to determine proper settings, these tables indicate the pulse frequencies and the correct switch settings for standard cases with certain combinations of motor speed and pulses per revolution. Open loop Proximity switch Bearing sensor

Motor RPM 3600 3000 1800 1500 3600 3000 3600 3000 3600 3000 Pulse number 24 24 24 24 32 32 64 64 80 80 Pulse frequency 1440 1200 720 600 1920 1600 3840 3200 4800 4000 Rotary switch S1, S3 7 4 E B 1 F A 8 D B Switch S2-1, S2-4 ON ON OFF OFF ON OFF ON ON ON ON Switch S2-2 ON ON ON ON OFF OFF OFF OFF OFF OFF Switch S2-3 OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF Closed loop Encoder

Motor RPM 3600 3000 1800 1500 1200 1000 Pulse number 600 600 600 600 600 600 Pulse frequency 36000 30000 18000 15000 12000 10000 Rotary switch S1, S3 4 1 B 8 5 3 Switch S2-1, S2-4 ON ON OFF OFF OFF OFF Switch S2-2 ON ON ON ON ON ON Switch S2-3 ON ON ON ON ON ON

Overspeed tripping frequency levels Area selection 300 – 3234 Hz 600 – 6467Hz 1200 – 12 935Hz 9600 – 70722Hz S2:2 ON OFF OFF ON S2:3 OFF OFF ON ON Range selection Normal S2:1 OFF ON OFF ON OFF ON OFF ON

0 300 1027 600 2055 1200 4110 9600 32878 1 324 1109 647 2218 1295 4436 10359 35489 2 350 1195 700 2391 1400 4781 11196 38251 3 378 1291 756 2582 1511 5163 12092 41304 4 408 1396 816 2793 1632 5585 13055 44684 5 441 1506 881 3012 1763 6024 14104 48188 6 476 1625 951 3251 1902 6502 15217 52013 7 514 1755 1027 3511 2055 7022 16439 56174 8 555 1896 1109 3793 2218 7585 17744 60681 9 599 2048 1198 4096 2395 8192 19163 65536 A 647 2210 1296 4420 2587 8840 20696 70722 B 698 2381 1396 4763 2793 9526 22342 -- C 755 2586 1510 5163 3019 10326 24153 -- D 815 2793 1630 5585 3259 11171 26075 -- E 880 3012 1760 6024 3521 12047 28167 --

S1/Normal

Tripping level

selection

S3/ESR

F 951 3234 1902 6467 3804 12935 30435 ESR S2:4 Range selection

OFF ON OFF ON OFF ON OFF ON

S2:1 together with S1 is used for setting the tripping frequency level at normal speed. S2:4 together with S3 is used for setting the tripping frequency level at ESR speed. If ESR is not used, set S2:4 + S3 equal to S2:1 and S1.

Page 26

Service Manual Pro2V080 Pro2V081

Drivecon reserves the right to al ter or amend the above information wi thout notice12/18/06 • rev 5.6B5 for Pro2V080 or Pro2V081 software

Example

Normal use A 3000 rpm motor with 32 pulses per revolution has a full speed pulse frequency of 1600 Hz.

Suitable maximum overspeed detection level is 1600Hz + 25% = 2000Hz.

On the table the highest value under 2000Hz is 1902Hz. Suitable switch settings are

S2-2=OFF and S2-3=OFF

S2-1=OFF and S2-4=OFF

S1=F and S3=F

Check from V4.8.1 that the detection level is 1902Hz/1600Hz =118.9% of nominal speed.

ESR use If ESR is applied for 150% of nominal speed, then the full ESR pulse frequency is 1.5 * 1600Hz = 2400Hz.

Suitable maximum over-speed detection level is 2400Hz + 25% = 3000Hz.

S2-2=OFF and S2-3=OFF are according to normal speed settings.

On the table the highest value under 3000Hz is 2793Hz.

Correct switch settings are S2-4=ON and S3=4.

Check from V4.8.2 that the detection level is 2793Hz/2400Hz =116.4% of ESR speed.

Settings for non-standard cases In nonstandard situations the pulse frequency can be calculated. With these results the SSU settings can be def ined l ike ESR setting above. Pulse frequency calculation

Pulse frequency (Hz) = [(Motor RPM * Pulses Per Revolution) / 60]

4.3.1 Functional test run for SSU

Note! Test run must be made without load. This test is completely applicable for hoisting motions. In traveling motions the only overspeed superv ision can be tested by following steps 5 - 7. All of the SSU faults wil l be reset automatically after one second without pulses.

1. Disconnect the +24V wire going to the pulse generator at the terminal strip. 2. Run with the minimum speed. The motion must stop within the set time.

- Fault F63 (Stall superv ision) should be detected 3. Run with maximum speed, the motion must stop at once.

- Fault F62 (Speed dif ference) should be detected 4. Reconnect the disconnected +24V wire to the terminal strip. 5. Set rotary switch S1/S3 value 2 steps smaller 6. Run with maximum speed. The motion must stop after full speed is reached.

- Fault F61 (Overspeed) should be detected 7. Set rotary switch S1/S3 back to its original value.

Note! The test makes the crane stop suddenly that m ay cause a dangerous situation.

Page 27

Service Manual Pro2V080 Pro2V081

Drivecon reserves the right to al ter or amend the above information wi thout notice12/18/06 • rev 5.6B5 for Pro2V080 or Pro2V081 software

4.4 Open Loop motor parameter adjustments In hoisting motions the open loop control is available. In hoisting motions the open loop is only available for specific motors that use bearing sensors or pulse sensors, or load brake hoists. The purpose of this is that there must be some overspeed detection device when using a hoist with an inverter. In traveling motions the open loop control is suitable for most applications. The applicable minimum speed is 1/3 of the motor rated slip.

4.4.1 Open Loop speed control for hoisting Note! Non-loadbrake hoisting open loop motor parame ters must not be changed. In open loop speed control when using a motor with a bearing sensor, the parameters are factory tested for the specif ic motor type. The motor parameters are set at the factory and must not be modified.

P3.4.1.9 Control Mode Preset value is 1 (OL Current Control). Factory preset value must not be changed.

4.4.2 Open Loop motor parameters for traveling Note! If motor type is marked on the parameter list , the calculated motor parameters

have been set at the factory. However, in some case s these factory set parameters do not give the best result and the adju stment should be done according to this instruction.

In traveling motion the most commonly used motor control mode is Frequency control, however current control is also available. The following parameter adjustments must be done before these modes can be used.

1. P3.4.1.1 Motor Nominal Voltage Set equal to nominal voltage on motor rating plate.

P3.4.1.2 Motor Nominal Frequency

Set equal to nominal frequency on motor rating plate.

P3.4.1.3 Motor Nominal Speed Set equal to nominal speed on motor rating plate.

2. P3.4.1.4 Motor Nominal Current Set equal to nominal current on motor rating plate.

P3.4.1.5 Nominal Flux Current Set equal to no load current on motor rating plate (if not available, set value to 50% of P3.4.1.4).

- If there are several motors connected in parallel, the correct value of P3.4.1.4 and P3.4.1.5 is the current of one motor multipl ied by the number of motors.

3. P3.4.1.6 Motor Cosine Phi Set equal to cosine phi value on motor rating plate (if not available, do not change the default setting).

4. P3.4.1.7 Start Current Set to 0.8 x P3.4.1.4.

- The value of P3.4.1.7 must be limited to 0.8 x drive's nominal output current (In).

P3.4.1.8 Current Limit Set to 1.2 x P3.1.1.4. Different applications may require a different multiplier to be used.

- The value of P3.4.1.8 must be limited to the drive's maximum output current (1 minute value).

5. P3.4.1.15 P3.4.1.16

Maximum Frequency S1 Maximum Frequency S2

Set equal to desired maximum frequency (usually the nominal f requency on motor rating plate).

Page 28

Service Manual Pro2V080 Pro2V081

Drivecon reserves the right to al ter or amend the above information wi thout notice12/18/06 • rev 5.6B5 for Pro2V080 or Pro2V081 software

4.4.3 Open Loop autotuning for traveling, frequency control The purpose of autotuning is to allow for an adequate motor magnetizing level throughout the entire frequency range. By performing autotuning the drive will automatically calculate and set the motor specific tuning parameters in Frequency control. Note! Motor rating plate value parameters must to b e set correctly before autotuning.

Any changes to the motor parameters will require au totuning to be reperformed.

1. P3.4.1.9 Control mode Set to 0 (OL Frequency Control).

P3.4.1.19 Drive selection Set to 1 (Travel).

2. P3.4.2.3 OL Autotuning 1 Default value is Not Done.

- Push Enter >2 s to start autotuning.

- The value changes to Tuning. The brake is not opened during autotuning. Tuning may be aborted by pushing Reset or Stop.

- If autotuning fails, the value changes to Failed, Output Phase or Store Failure. Check connections, motor rating plate values and motor set selection.

- After successful procedure, the value is Done. After successful autotuning there is no need for other motor parameter changes or manual adjustment of U/f-curve parameters. Any manual change of motor parameters will change the value of P3.4.2.3 to Modified. The adjusted autotuning parameters are:

P3.4.2.1.1 Zero Freq Volt P3.4.1.13 Min Freq S1

P3.4.2.1.2 U/f Mid Volt P3.4.1.14 Min Freq S2

P3.4.2.1.3 U/f Mid Freq P3.4.2.2.6 Start Freq S1

P3.4.2.1.7 Rs Voltage Drop P3.4.2.2.7 Start Freq S2 The drive is ready to operate after a successful completion of this procedure.

4.4.4 Open Loop manual tuning for traveling If autotuning did not give a proper result, calculate Rs Voltage Drop and go through chapter Open Loop manual tuning for traveling. Check also the values of parameters P3.4.2.2.6 and P3.4.2.2.7.

P3.4.2.1.7 Rs Voltage Drop Set equal to calculated relative motor phase impedance.

A. Switch the power off and disconnect the motor cables on motor output terminals.

B. Measure the stator phase impedance (R) of cold motor on disconnected cable ends.

- If there are several motors connected in parallel, the correct value is approximately the stator impedance of one motor div ided by the number of motors.

- A simple multimeter might not be good enough to measure low resistances.

C. Connect the motor and switch power on.

D. Calculate relative value of motor phase impedance.

Rs Voltage Drop = [(2217 * Resistance * P3.4.1.4) / P3.4.1.1]

Page 29

Service Manual Pro2V080 Pro2V081

Drivecon reserves the right to al ter or amend the above information wi thout notice12/18/06 • rev 5.6B5 for Pro2V080 or Pro2V081 software

4.4.5 Open Loop manual tuning for traveling, freque ncy control The default motor control mode is Frequency control. Frequency control is used to get optimal magnetizing current to the motor by util izing U/f-curve tuning. When using Frequency control this guarantees good low and middle speed characteristics. The following table shows the formulas to calculate the values f rom where to start the tuning.

P3.4.2.1.1

Zero Frequency Voltage (%)

P3.4.2.1.2

U/f Midpoint Voltage (%)

P3.4.2.1.3

U/f Midpoint Frequency (Hz)

[(100 * Resistance * P3.4.1.5) / P3.4.1.1] 1.41 * P3.4.2.1.1 (P3.4.2.1.1 * P3.4.1.2) / 100

1. P3.4.1.9 Control Mode Set to 0 (OL Frequency Control).

2. P3.4.1.13 P3.4.1.14

Minimum Frequency S1 Minimum Frequency S2

Set equal to P3.4.2.1.3 (U/f Midpoint Frequency).

A. Run at maximum speed and check the motor current value (V4.20).

B. Try to run at minimum speed and check the motor current value. Motor current at minimum speed should be approximately average of the prev iously measured maximum speed current and the rated current.

P3.4.2.1.2 C. Increase or decrease value to increase or decrease motor current. Run again minimum speed and check motor current. Repeat step B unti l current value is within the desired range.

3. P3.4.1.13 P3.4.1.14

Minimum Frequency S1 Minimum Frequency S2

Set equal to P3.4.2.1.3 div ided by 2.

A. Try to run at minimum speed and check the motor current value. It must be approximately average of the previously measured maximum speed current and rated current.