California Petroleum Refinery Hazardous Waste Source Reduction 2002 Assessment Report

WASTE REFINERY & GENCOAL · 2018. 11. 28. · 3 SUMMARY WASTE REFINERY & GENCOAL is a new and...

Transcript of WASTE REFINERY & GENCOAL · 2018. 11. 28. · 3 SUMMARY WASTE REFINERY & GENCOAL is a new and...

WASTE REFINERY & GENCOAL®The sustainable way to valorise waste

concept & references

2

Table of Contents

Summary 3

1. The concept 5

2. WASTEREFINERYprocessflow 6

3. ACompilationofproventechnologies 7

4. ComponentsfromtheportfolioofIPAS 8

CoalWashing 9

CoalSludgeRecovery 10

BottomAshTreatment 11

SoilWashing/Remediation/Sanitation 12

GlassRecycling 13

WaterPurification&Treatmentoforganicsinthefoodindustry 14

Sludge&WaterTreatmentintheconcreteindustry&brickworks 15

5. Advantagesofthetechnology 16

6. Equipment 17

Annex1 Exampleofabusinesscase 19

Annex2 Detailedresultsofwasteseparationatlaboratory,2013 20

Annex3 LaboratorytestresultsonGENCOAL 22

Annex3.1.Summaryofseparationresults 22

Annex3.2.Resultsfromthe‘ashtest’atTechnicalUniversityOstrava 24

Annex3.3.CertificationtestasalternativefuelatVVUÚOstrava 26

Annex 4 Impressionsofsemi-industrialtestin2018 28

Annex5 ProjectteamforWASTEREFINERY&GENCOAL 30

3

SUMMARY

WASTE REFINERY & GENCOAL is a new and straightforward approach of the solid waste challenge that meets both the need for high ecological standards and economic realism. Moreover this new concept for valorising waste streams leans on vast industrial experience with proven technologies. There certainly is a worldwide market potential. WASTE REFINERY & GENCOAL is the result of a thorough analysis of existing practices and of fresh industrial thinking, based on many years of hands on experience in the sector of separation technologies.

WASTEREFINERY&GENCOALisanewpracticalconceptforturningwaste1into‘instantrecoverablematerials’forenergygenerationandin‘instantrecyclablematerials’formaterialsrecycling.Thesolutionisbasedonanewcombinationofexistingtechnologies,allowingto:

• buildandoperatea‘WASTE REFINERY’,using‘wettechnology’;• producea‘coalequivalent’combustible:Bio Generated Coal,inshortGENCOAL.

WASTEREFINERY&GENCOAListhebestandmostrealisticalternativeforwasteincineration,asitismuchcheaperininvestmentandoperationalcost.Moreover, itreachesthemaximumpossiblerecyclingofmaterials2 and it produces a biomass combustible that can be valorized in existing installations. ’WASTE REFINERY & GENCOAL’ is the mostcontemporarysolutionasitmeetssocietalchallenges,bothinthefieldofenergyandofmaterials.

WASTEREFINERY&GENCOALisaconceptdevelopedandpromotedbytransit_LAB,togetherwiththeBelgiancompanyIPAS,aninternationallyrenownedspecialistinseparationtechnology.

Transit_LAB, isaBelgiumbasedcooperative innovationanddevelopmentcompany, founded in2012,specialising intransitiontechnologiesandregionaldevelopmentprograms.Transit_LABpromotescreativesolutionsforsocietyandindustryandoperatesasa‘platform for co-creation’.

Knowledge and technology partner IPAS, Industrial Processes – Active Services, designs and builds ‘tailor made’installationsasanindependentandhighlyexperiencedpartnerforallrefiningandseparationchallenges.IPAShasover 30 years of international experience inoptimizing industrialprocesses,refiningrawmaterialsandwaste,separatingcoal,rawmaterialsandwaste,applyingwetanddrytechnologies.

1 Wastehereis:MSW:municipalsolidwasteandlikewiseclassifiedcompanywaste.ButWASTEREFINERYcanalsobeappliedinLandfill

Mining,recoveringexisting/historicalwastedumpsites.MoreoverWASTEREFINERYcandealwithaverywiderangeincompositionofwaste

streams.

2 Maximumpossiblerecyclingofmaterials:tobeseeninthelightofanequilibrium-basedonpermanentprogressiveinsight–between

economicviability,industrialdoabilityandthehighestpossibleenvironmentalgain.

4

‘‘I am convinced that the classical waste incineration as it still is promoted throughout Europe has had its days of glory. It was a wonderful technological breakthrough towards a better care for environment and public health. But it is high time now that we start taking seriously initiatives like WASTE REFINERY & GENCOAL. The reason: this combines the best possible practice towards recycling at large scale of materials with the best possible use of the calorific fraction in waste streams. Building classical incinerators is no longer a socially responsible answer to the contemporary challenges. That is why I joined the WASTE REFINERY & GENCOAL team with com-plete conviction and commitment.’’Wilfried De Nijs

WilfriedDeNijs,honorary Inspector General at OVAM, the public WasteAgency of Flanders was responsible in Belgium for theintroduction of contemporary waste legislation. In thatposition he closed dozens of badly managed public andprivatelandfillsandintroducedinthe1980’sthefirstWASTEINCINERATORSinthecountry.

5

1. The conceptIngeneral,MSWiscomposedof1/3water,1/3inertmaterialsand1/3organicsandplastics.The‘WASTEREFINERY’,theinstallationfortreatmentofwaste,usesthe1/3ofinherentwaterintheprocessingplantandtherestisseparatedand‘washed’untiltheinertmaterialsarerecyclableandtheorganicandplasticsareupgradedintoaperformantfuelforexistingelectricityorheatingplants.IfcarefullymanagedthisBio Generated Coal or new fuel is a biomass combustible.

Instant recyclable materials for RAW MATERIALS:Out of our own laboratory findings, confirmed by international literature on the composition of municipal wastestreams,weseethat,evenincountrieswherewasteisalreadysortedinthehouseholds,aportionofupto1/3ofthetotalmassor½ofthetotaldrymassofMSWiscomposedofinertmaterialsthatarerecyclable.TheWASTEREFINERYistheaccurateanswertotheworldwideneedformaterialsrecycling.Thematerialschallengeisrealasnaturalresourcesaredecliningandgettingmoreandmorecostly.Thecleanrecycledmaterialscanbesoldontheopenmarket:ferrousmetals,non-ferrousmetals,stainlesssteel,sandandgravel/stones.

Instant recoverable materials for ENERGY:BioGeneratedCoal,orGENCOAL,isacombustiblethathasthesamecalorificvalueascoalandthatcanbeprocessedintopellets,soitalsohasthephysicalcharacteristicsofcoal(fortransportandstorageandharshweatherconditions).GENCOALcanbeusedforco-firingincoalfiredpowerandheatingstationsorinbiomassinstallations.Ifneeded,thecalorificvalueoftheGENCOALcanbeadjustedbymixingwithadditives,sothatGENCOALcanbemadesuitableforallexistingcombustioninstallations.ThetestsconductedattheTechnicalUniversityofOstrava(CZ)inDecember2013confirmedthatthecalorificvalueofGENCOALisadequateforuseatindustrialscale.Thecalorificfractioncanalsobefurtherprocessedintosyngasorotherenergeticsolutions.

GENCOALorBioGeneratedCoalisaflexiblefuel,meetingtheclimatechallenge:TheuseonabigscaleofGENCOAL,giventhefactthatmanyoftheworldspowersupplyisbasedondifferentkindsofcombustioninstallations,canbringaneconomicandanecologicalbenefittosociety.BioGeneratedCoalisaflexiblebiomass.GENCOALcanbecontrolledandsteeredbyusingadditives:

• Thecalorificandthereforeeconomicvaluecanbeadjustedtothetypeofincinerationprocess.• TheenvironmentalimpactoftheuseofGENCOALasfuelcanbesteered.Theemissionsofsulphurand

chlorideswillbeinfluencedinapositiveway,probablyevenneutralised.Ofcourse,thecombustionofGENCOALwillhavetomeettheenvironmentalcriteria,alsobyuseinovensequippedwithgaswashinginstallations.

Wet technology as innovative approach:TheheartofthetechnologicalprocessconsistsmainlyofaWETseparationline.Wettechnologyhasthefollowingmainadvantages:• theendproductsarecleanandthereforehaveahighermarketvalueandgivelessleaching;• theenergyneedislow:noenergyiswastedbyevaporationofunnecessarywaterorheatingofinertmaterials;• amaximumamountofmetalscanberecycledaslittleoxidationoccurs;• theproblemofdustandfineparticleswillbetackledinherentlybythewetprocess;• thecapacityoftheinstallationcanbescaledasdesired.Unlikedryseparationprocessesforwaste,wetseparation

lineshavethepotentialtohandlebigvolumesatconstanthighqualityoutputs.IPASisspecialistatinternationallevelforwetseparationandupgradingprocesses.

WASTEREFINERY&GENCOAL is a sustainableway of treatingMSWand is aTRANSITION TECHNOLOGY, especially designedforthetimewelivein,atimeofchanginginsightsanddevelopmentsinthematerialsandenergymarket,worldwide.

The main advantage of WASTE REFINERY & GENCOAL is that investments in classic (and expensive) waste incinerators are no longer needed and that a viable and sustainable alternative for landfill is available. In addition GENCOAL can combine the treatment of actual MSW with ‘landfill mining3’ whereby historical waste is recycled or (energy) recovered. For this reason WASTE REFINERY & GENCOAL can also offer a solution in land reclamation policies.

3 Landfillminingisaprocesswherebymaterialsandenergyisrecuperatedwhilediggingupexistinglandfillsites.Theunderlyingideais

thatalandfillsitemightcontainmoreusefulmaterialsthanactualminesorquarriesfornewrawmaterials.

6

2. WASTE REFINERY process flow

DexF

RDF

Clean water

F FeedDEX Screening for explosivesFe IronRDF Refused Derived FuelR RejectEp End productT TemperatureSa SandN.Fre Non-ferroO OrganicGr GravelAd AdditiveA SandB Gravel

Legende

Clean water

Fe

FeRDF

RDF

Ad

x2

A

N.Fe N.Fe

INOX

Sa Fe Fe Gr

B

R

Ep

T

O

GreenCoal Pellets

© transit_Lab / IPAS

simplifiedschematicdiagramoftheWASTEREFINERY

7

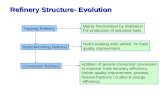

3. A compilation of proven technologies

IPAS,thetechnicalpartnerinWASTEREFINERY&GENCOAL,hasover30yearsofhandsonexperienceinseparationandupgradingtechnologies.

Theinstallation‘WASTEREFINERY’isinfacta balanced compilation / synthesis of existing technologies,thatallofthemhavebeendesignedandbuiltbyIPASitselfindifferentpartsoftheworld.

It is in a laboratory test project in 2013, performedon actualwaste streams from the Karvina region in the CzechRepublicthatthisnewconceptwascreated.Inannex2and3thewasteseparationprojectforKarvinaispresented.AlsothetestresultsofGENCOALatlaboratories.

In2018anindustrialtestwasdoneinKarvina:30tonsoffreshwastewasprocessed.Thetestconfirmedthelaboratoryresultsandapositivebusinesscaseisdrafted.

MATERIALS ENERGY GENCOAL

WASTE REFINERY

COALWASHING

COALSLUDGE

RECOVERY

BOTTOMASH

TREATMENTSOIL

WASHINGGLASS

RECYCLING

WATERTREATMENT

IN FOODINDUSTRY

SLUDGE WATERTREATMENT

IN CONCRETEINDUSTRY

8

4. Components from the portfolio of IPAS.

AlltheessentialcomponentsarenotonlyproventechnologyandevenBestAvailableTechnique,buttheyhavealsoallbeenbuiltseveraltimesinrecenthistorybyIPAS,theknowhowandtechnologypartneroftransit_LAB.

In this paragraph is described, the international portfolio of relevant IPAS projects. WASTE REFINERY & GENCOALis the combinationof technologies fromCoalwashing,Coal sludge recovery,bottomash treatment, soilwashing&remediation,glassrecycling,watertreatmentinthefoodindustry,sludgeandwatertreatmentintheconcreteindustryandbrickworks.

w COAL WASHING

w COAL SLUDGE RECOVERY

w BOTTOM ASH TREATMENT

w SOIL WASHING / REMEDIATION / SANITATION

w GLASS RECYCLING

w WATER PURIFICATION & TREATMENT OF ORGANICS IN THE FOOD INDUSTRY

w SLUDGE & WATER TREATMENT IN THE CONCRETE INDUSTRY & BRICKWORKS

“Waste Refinery & Gencoal

is the smart compilation

synthesis of all these

technologies and installations.

That is the only secret behind it all.”

Etienne Schouterden - IPAS

9

COAL WASHING

IPAShasbuiltseveral‘totalseparationconcepts’forthecoalminingindustry.• ‘RunofMine’COAL:designandbuildofinstallationsofallpossiblecapacities.• ‘TIPwashing’:designandbuildofprofitableinstallationsfromacoalcontentof10%.

References:SSMTerneuzen(1990/Netherlands/TSC-totalseparationconcept4);Anscoalnv(1991,Belgium/TSC);Terval(1991/Belgium/PWT-processwater treatment 5);StadtwerkeSaarbrücken (1993/Germany/TSC– research);Knurow(1995/Poland/machinery);Slask(1995/Poland/machinery);Czechcoalmines(1996/CzechRepublik/chemicals);TechnoAgrar(1996/Germany/chemicals);Jankowice(1997/Poland/machinery);TrInternationalLtd(1998/USA/TSC–research);Donbasscoalmines(1998/Ukraine/chemicals);APM(2000/Indonesia/TSCresearch);Mekol(2000/Belgium/processwatertreatment);ChinaCoalmines(2000/China/chemicals);Dzerdzhinsko–Energosurs(2001/Ukraine/TSC);Gorenenrgo(2002/Ukraine/TSC);ROA/Adcoal(2003/Belgium/TSC);SEEcotekh(2003/Ukraine/TSC);ABT(2005/Belgium/processwatertreatment);CoalminesMarcel,Jankowice,Anna,Jasmos,Knurow(1991–2007/Poland/chemicals);Techexpertise(2010/Ukraine/separationplantinpartnership);

4 TSCor‘TotalSeparationConcepts’means:completeanalysis,designandbuildofindustrialsolutiontoseparateandupgrade

materials.

5 PWTor‘ProcessWaterTreatment’means:analysis,designandbuildofindustrialtreatmentinstallationforwater/processwater.

flowsheetofcoalwashingplantatKrasnoarmeyskaya-Zapadnaya

10

COAL SLUDGE RECOVERY

IntheenvironmentofworkingandclosedcoalminesmostoftenexistPONDS,thatcanbeverybig.TheyareusedtostoreinatemporaryorpermanentwaytheSLUDGEfromthecoalwashingprocess.Veryoftenthesepondsarestillrichinfinecoaltoveryfinefractionsofusablecoal.IPASisatopspecialistinrecoveryofcoalfromtheseponds,asIPASmastersthewetprocesstechnology.IPAShasdesignedandbuildseveralPONDWASHINGINSTALLATIONStorecovercoalfromsludgemass.IPASinstallationsrunprofitableforcoalpondsfrom40%coalcontent.Therecoveryandsanitationofcoalpondsis,ofcoursealsoanecessitywhentheminingactivitystops.

References:IPAS references in coalmine sludge recovery. The projects are situated in run ofmine environment or in sanitationcontextsorpitrecoveryoperations.Fechner(1988/Germany/TotalSeparationConcept-TSC-);Sewater(1989/Belgium/TSC);Solichar(1989/Belgium/TSC);Haisy(1990/USA/TSC);HansenCoalGmbh(1990/Germany/TSC); Issabel(1990/USA/TSC);KempenseSteenkoolmijnen(1990/Belgium/TSC);IPASPolska(2010–2013/Poland/contaminatedCoalTipsandSludgePonds–studies).

• Coalcrushing• ScreeningWET/DRYtill350mm• Separating:

o Dens mediumo Jiggingo Cycloningo Spiralso Flotation

• Thickening:o Deepconeo Normalthickener

• Dewatering:o Centrifuges

-Decanter -Shubcentrifuges -Pushercentrifuge

o Vacuumfiltration -Drum -Disc -Belt

o Multirollfiltero Chamberfilterpress

• Drying:mechanicalandthermaldrying

Available techniques @ IPAS

DzerzinskCoalSludgeRecovery

11

BOTTOM ASH TREATMENT

IPASdesignedandbuilda world premier installationintheyear2000tocleanandseparatethebottomashfromtheINDAVERwasteincineratorsinAntwerp,Belgium.ThisinstallationrunseversincewithoutanytechnicaldefectsandstillisareferenceinthesectorofWasteManagement.

Intheashtreatmentunit,ashesfromthehousehold incinerationfacilitiesarewashed,sievedandpurified.Theendproductisavaluablesecondarymaterialthatcanbeusedforseveralapplications.Ferrousandnon-ferrousmetalsarecarefullyremovedinvariouscut,sieveandwashunits.Someofthoserecuperatedmetalswillbere-usedinindustry.Inertashesremainingafterincinerationareconvertedintogranulates.Thesecanbeusedassecondarymaterialsintheconstructionindustry,inaccordancewiththerelevantenvironmentalregulations.

Top reference:ReferenceofaworldpremierinstallationINDAVER(2000/Belgium):totalrealisationforseparatingandupgradingofrestmaterialsafterwasteincinerator.Afterburningofwasteremains25to30%ofthetotalmass.This30%isreducedto3%ofrestmaterial.27%oftheashmassisrevalorisedthroughtheIPASprocess.Seealso:http://www.indaver.be/en/installations-processes/material-recovery/ash-treatment/

Other references:AZN(2005/theNetherlands/TSC);Machiels(2005/Belgium/TSC)

Ash treatment

> 50 mm

incineratorashes

rotary sieve coarse material> 50 mm

extraction of ferrous metals

ferrous metals(> 50 mm)

to land�ll

< 50 mm washer barrel

light organic materialto grate

incinerators

screening &washing

installation6 -50 mm

extraction offerrous metals

extraction ofnon - ferrous metals

6 - 50 mmgranulates

2 - 6 mmgranulates

ferrous metals non-ferrous metals

< 2 mmtot water puri�cation plant

2 - 6 mm

extraction offerrous metals

extraction ofnon-ferrous metals

sand �lter cakes

flowsheetofbottomashtreatmentatINDAVER,builtin2000

INDAVERBottomAshTreatment INDAVERBottomAshTreatment

12

SOIL WASHING / REMEDIATION / SANITATION

InIPASdevelopedinstallationsforSOILWASHING,highlycontaminatedsoilsarecleanedinhighvolumesanduntila100% recyclabilityofthematerials.

www.carmans.be

Top reference:GrondreinigingscentrumLimburg/CarmansNV(2007to2015,Belgium/TSC).Thisinstallationruns90t/hourofhighlycontaminatedsoil.IPASiscurrentlypreparingansimilarinstallationtoprocess250t/hour.Moreoverthewholeplantrunsonrenewableenergy.Asfinalstep,IPASisdevelopinganaddedoninstallationtovalorisethelast20%fractionofthecontaminatedsludge:17%offinematerialswillbeturnedintoanewproduct,capturingandstabilizingthecontaminantsand3%organicswillgotoenergeticvalorisation.Sothisplantwillsoonreacha100%recyclingofcontaminatedsoils.

Other references:NMB(1991/theNetherlands/TSCforroadconstruction);Gyprocnv(1991/Poland/combustionplant inGypsumindustry);BasseSambre(1991/Belgium/TSCsandrecovery);SETnv(1991/Belgium/TSC);HogeschoolDelft(1996/theNetherlands/TSC);WatcoRSWnv(1999/Belgium/TSC);Rens(2000/Belgium/TSC);

13

GLASS RECYCLING

Thecollectionofusedglass (bottles, jars,…) fromhouseholds isa commonpractise inEurope.Glass representsanimportantinertfractionintheMunicipalWastestream.IPAShasdevelopedafullyautomaticrecyclinglinethatprocessesup to 25 tons per hour.

Differentstepsintheglassrecyclingprocess:

• Separationofthecoursefractiontopreparecolourseparationoncompletebottles• Separationofgranulates• Separationofnon-ferrousfraction• Separationofstonesandporcelain.

References:GRV(1992/Belgium/TSC);VLAR(1994/Belgium/Engineering);GRL(1997:Belgium/TSC);GRL(2009/Belgium/CHPinstallation)

14

WATER PURIFICATION & TREATMENT OF ORGANICS IN THE FOOD INDUSTRY

References:Clareboutnv(1991/Belgium/PWT);OrganicWasteSystem(1992/Belgium/TSC);NolikoVegetables(1992/Belgium/PWT);VanReuselSnacks(1993/Belgium/BAKreactor);VanlommelSlachthuisnv(1994/Belgium/PWTresearchmeatindustry);Krikro(1994/Belgium/PWT–potatoindustry);Decosterbvba(1996/Belgium/PWTpotatoindustry);VanReuselSnacks(1996/Belgium/consultancyonprocess);VanReuselSnacks(1998/Belgium/processoptimisation);VanReuselSnacks(2000/Belgium/PWT);Equinox(2000/Belgium/consulting);Bravinv(2002/Belgium:PWTpotatoindustry);

DAF-unit

InthefoodindustryIPAShasbuiltseveralprojectsbasedonDAFtechnologies(Dissolved air flotation). This is a water treatment process that clarifieswastewaters by the removal of suspendedmatter such as oil or solids. Theremoval is achieved by dissolving air in thewastewater under pressure andthenreleasingtheairatatmosphericpressureinaflotationtankorbasin.Thereleasedairformstinybubbleswhichadheretothesuspendedmattercausingthe suspendedmatter to float to the surface of the water where it then isremovedbyskimming.

15

SLUDGE & WATER TREATMENT IN THE CONCRETE INDUSTRY & BRICKWORKS

IPASdevelopedandimplementedintheconcretesectoraveryperformantsystemforrecuperationofprocesswater.Thepaybacktimefortheseinvestmentswaseverywherelessthan6months,becauseofthereuseofwaterstreamsandthefactthatnolongercontaminatedwaterneedstobedischargedintotheenvironmentorinthepublicwastewatersystemsorthatnolongersludgeneedstobeputinthelandfills.

References:DeNieuwe Zandegroeven (1992 L/ Belgium / TSC); ECHO (1994 / Belgium / PWT– development of new concept);Varenbergnv (1994/Belgium/PWT– researchgravel recovery);Winters (1994/Belgium/PWT– researchgravelrecovery);Goudezeune(1996&1997&1998&1999/Belgium/PWT4 installations);Ropabvba (1996/Belgium/PWTmeatindustry);VosVleeswaren(1996/Belgium/PWTmeatindustry);Heylen(1997/Belgium/PWT–ceramics);Betonson (Kampen) (1997 / Belgium / PWT); Trilco (1997 / Belgium / PWT); Vasco (1997 / Belgium / PWTprocessoptimizationinheatingsystem);Ergon(1998/Belgium/PWT);Kerkstoel(1998/Belgium/PWT);CarrièresduHainaut(1998/Belgium/PWTstonequarry);Dammannv(1999/Belgium/TSC–brickworks);MartensBetonnv(1999/Belgium/PWT);CarrièresduBoulonnais(1999/France/PWTresearch–stonequarry);Agref(2000/Belgium/PWT);Ebema(2000/Belgium/PWT);Marlux(2000/Belgium/PWT);Sander-Pebüso(2000/Belgium/PWT);Tripan(2000/Belgium/PWT);CarrièresduHainaut(1998/Belgium/PWTstonequarry);Boskalis(2001/theNetherlands/TSCresearchsievesand);DeVijfhoek(2001/theNetherlands/TSCresearchsievesand);SVK(2001/Belgium/PWT);DeMeteoor(2001/theNetherlands/PWTresearch);Heembeton(2001/theNetherlands/PWT);KlapsBeton(2001/Belgium/PWT);Sevetonnv(2001/Belgium/PWTresearch);EWInv(2001/Belgium/PWT);Mostone(2001/Poland/PWTresearchstonequarry);Marlux(2001/Belgium/chemicals);Seveton(2002/Belgium/PWT–adjustment);BDIAmbés(2002/France/PWT);BDIGrigny(2002/France/PWT);DenBoerBeton(2002/Belgium/PWTadjustment);MBI(2002/Belgium/PWT);Heembeton(2002/theNetherlands/chemicals);BMI(2003/France/PWT);Lithobeton(2003/Belgium/PWT);C&G(2003/UK/PWT);C&G(2004/UK/PWT);BDIPujaut(2004/France/PWT);DenBoerBeton(2005/theNetherlands/PWT)

IPAShasmorerelevantreferencesinsectors,usefullforthenewconceptWASTEREFINERY&GENCOAL.

Other relevant references of IPAS:BooyCleanBelgium(1994/Belgium/TSCschredderinwastemanagement);Mathysnv(1994/Belgium/PWT/research–paintindustry);Mireille(1996/Belgium/PWTdrycleaningindustry);DSM(1996/Belgium/PWTplasticsindustry);Watco(1998/Belgium/TSCwastemanagement);SK-Eng&Const(2001/Korea/TSCresearchwastemanagement);Londonwaste(2002/UK/TSCresearchwastemanagement);Galloometal(2007/Belgium/Metal–NonFerroseparationstudy).

16

5. Advantages of the technology

Thekeyof thetechnology inWASTEREFINERY&GENCOAL isawettechnologyallowingtoseparatenon-selectivelycollected municipal waste, as well as the rest-fraction from selective collection into combustible materials (RDF)6,stainlesssteel,ferrousmetals,non-ferrousmetals,inertsof<0.25–1mm,of1–12.5mmandof>12mm,andsludge.TheRDFcanbeusedasfuel(ifneededafteradjustingthecalorificvalue)e.g.incoalcombustioninstallationsinordertorecoverenergy.Themetalfractionscanberecycledassuch.Theinertfractionshaveapplicationsinconstruction.ThistechnologyisfullyinlinewiththewastetreatmenthierarchyoftheEU,whichplaces(material)recyclinghigherthan(energy)recovery,whichisplacedhigherthandisposal(landfill).

Themainadvantagesofwettechnologyare:• amaximumamountofmetalscanberecycledaslittleoxidationoccurs(comparedtolandfillandincineration);• thecapacityoftheinstallationcanbeadjustedasdesired;• thepossibleproblematicparticlesoftheMSW,suchasfinedust,canbelocalisedinthewastewaterstreamsand

arethereforecontrollableandtreatable.

Advantagesofthepresenttechnologycomparedtocombustionare:• intheincineratorsthewastehasfirsttodrybyevaporationofthewater,whichnecessitatesalotofenergybefore

thewasteignites,whereasinthepresenttechnologynounnecessarywaterevaporationisneeded.Thereforemoreenergycanberecovered;

• theGENCOALisacleanfuelthatcaninprinciplebe(co)incineratedinacoalfuelledpowerplant.Theseusuallyhaveahigherenergyconversionyieldthanwasteincinerators;

• sincenocombustionofthematerialtakesplace,onlylittleoxidationofe.g.metalpartsandmetalfoilsoccurs.Thishas2consequences:(1)ahigherfractionofthemetalsintheMSWcanberecycledasmetal(withmuchhighervaluethanmetaloxides);(2)somemetalsdissolvelessthantheiroxidesorsalts,sothatlowermetalleachingoftheresultingproductsoccursthanforcombustionashes.

Asaconclusionbetterenergyrecoveryandbetterrecyclingofmetals(themostvaluablefractionintheMSW)andnon-metalsisexpectedthanwithwasteincineration.

Compared to dry technology (egMBT) to separate and recycle/recoverMSW, the presentwet technology has thefollowingadvantages:• theendproductsarecleaner,aswetcleaningdissolvesallsortsof impuritiesthatsticktothematerialwithdry

technology. Therefore, themarket valueof theproducts is higher (metals) and thematerials (inerts)will showreducedleachingandwillthereforemoreeasilycomplywiththeregulationsforrecyclingasconstructionmaterials;

• wettechnologyusesthewater(=30%)oftheMSWintheprocess,ratherthanhavingtoevaporateit,whichisaccompaniedbylossofenergy;

• thecapacityofawetinstallationcaneasilybeadjustedincapacity,comparedtoadryinstallation;• inawettechnologytherearemuchlessproblemswithdust.

Of courseawet technology requiresanexcellentwater treatmentplant (biological andphysicochemical treatment)allowingrecyclingofthewater.TheWASTEREFINERYwillhaveaclosedwatercircuit.

6 RDF:RefusedDerivedFuel

17

6. Equipment

Dependingon localcircumstances, localenvironmental regulationsandothervariable factorsanddependingonthenecessarycapacity(amountoftonsofMSWtobeprocessed),themachinerywillbebiggerorsmaller.Butasanindicationofinvestmentcostwecansay:

• AWASTEREFINERYprocessing10tons/hour,costsbetween4and7millioneuro.• AWASTEREFINERYprocessing20ton/hourintwoshiftsperworkingdayor80.000tons/year,costsbetween

7and14millioneuro.

ThelayoutfortheWASTEREFINERYhastoconsistofthefollowingcomponents:

• Feederwitho bunker,o bag–opener,o dosingline,o weighingunit

• Screen• Magnets:4• Non-Ferrous:2• Conveyors:10• Screens:5• Blowers:2• Shredders:3• Stainlesssteelseparators:2• Sandwashingfine:1• Sandwashingheavy:1• Gravelwasher:1• Mechanicaldryer:1• ThermaldryerwithCHP(combinedheatandpower):1• Blender:2• Thickener:1• Clarifier:1• Flocculantsstation:1• Dewateringfilter:1• Press(pellets):1• Watercyclewith10pumps• Measurementandcontrol• Electricalequipment• Steelworks• Wastewatertreatment

Thefootprintforthiswashinstallation(asmallinstallationof10t/h)canbelimitedto1.000m²,i.e.50X20mwithaheightof20m.

ANNEX

Annex 1 Example of a business case

Annex 2 Detailed results of waste separation at laboratory, 2013

Annex 3 Laboratory test results on GENCOAL

Annex 3.1. Summary of separation results

Annex 3.2. Results from the ‘ash test’ at Technical University Ostrava

Annex 3.3. Certification test as alternative fuel at VVUÚ Ostrava

Annex 4 Impressions of semi-industrial test in 2018

Annex 5 Project team for WASTE REFINERY & GENCOAL

19

Annex 1– Example of a business case

Althoughbeingsubjecttoallpossiblereservations,wepresentahypotheticalbusinesscasetaking intoaccount(asexampleonly):

• Acapacityof20tons/hourintwoworkingshifts/dayor80.000tonsyearoftobeprocessedMSW.• AcompleteinstallationtakingItoaccountthehigheststandardsinenvironmentalcriteria,withamongother

things,acompletewaterpurificationsystem(biologicalandfysicochemicaltreatment)

Cost / ton

ASSUMPTIONS

Capacity 20 t/h2shifts/day 4,000 h/a

total capacity 100,000 t/a

INVESTMENT

Plant 15,600,000.00

Building 1,000,000.00 dependsoflocality

Varia(study&unforeseen)

700,000.00

TOTAL: €17,300,000.00

CAPITALCOST

depreciation 10% 1,730,000.00intrest 4% 692,000.00TOTAL: 2,422,000.00 €/a

WORKINGCOSTBased upon European standards(seebelow)8

2,500,000.00 €/a

TOTALCOST/ANNUM: 4,500,000.00 €/a

cost/ton@80000t= 56.25 €/t

Totalcost/ton=€56.25 9

This is the pre calculated cost per ton without the sale of the recuperated materials and the sale / use of the GENCOAL. If sold on the open marker, the revenue of the sale of materials and GENCOAL will probably cut the cost by half: between € 25 and 30. To compare: Total cost in waste - incinerator = 110 €/ton (accepted average cost in Europe)

Thesecalculationsdonottakeintoaccountthepossiblepositiveeffectofcombinationswithlocalopportunities,likebiogasstationsorcombustioninstallationsthatcanprovideelectricalenergyandheatfortheWASTEREFINERY.

8Workingcostinthishypotheticalbusinessprojectionisbasedupon:energycostofabout€730.000/annum,manpoweratabout€200.000/

annum;maintenanceat7%ofinvestment;overhead,chemicalproductsandinsuranceat€600.000/annum.Theseareverycautiousandnon-

optimisedestimates.Mostprobablythenumberswilldecreaseinarealtimeproject,certainlyinnon-European/Americancontext.

9Thisnumberof€56,25/tonascostoftheseparationprocesshastobeinterpretedwithcare.Thisisapre-calculationfortheEmirates(sept

2015).IncomparablequantitiesofMSW,thenumberfortheCzechRepublicIn2014was€35,30.Thecalculationcanonlybeseenasguiding

principle.Everyprojectorlocationshallhaveitsowncalculation,baseduponconcretelocaldata.Thiscalculationsarewithoutlocaltaxes.

20

Annex 2 – Detailed results of waste separation at laboratory, 2013

Thefollowingpages,showpicturesofthedifferentfractionsfroma20kgsamplefromtheDEPOSlandfillsiteinHornySucha,CzechRepublic,takenonJuly3,2013andtreatedinthelaboratoryattransit_LABandIPASinBelgium.

InBelgiumthefollowingstepsweretaken:• screening;• handpicking;• densityseparationinwaterofdifferentfractions;• dryingfirstinopenair(summerconditions),theninacoveredspace;• millingindifferentsteps:cuttingbyhand,millinginthelaboratoryusingablender,millinginanindustrialtest

installation

SEPARATION RESULTS:

RDF to be processed to pellets Possibly enriched

21

To be sold on market:Ferrous, Non-Ferrous & Stainless steel

> 12,5 mm

< 12,5 mm

22

Annex 3: laboratory test results on GENCOAL

InthisannexispresentedtheresultsoftheWASTEREFINERYseparationtestatlaboratoryscale1) theresultsofthelaboratorytestattransit_LAB&IPASonMSWfromtheKarvinaRegion2) TheresultsoflaboratorytestingatTechnicalUniversityofOstrava,LaboratoryoftheGeologicalInstitute,Prof.

HelenaRaclavska.3) ThetestresultsatVVUU,Vitkovice,testingcenterinOstrava.

Thelasttestwasaprestudytogetaclassificationas‘alternativefuel’tohavetheGANCOALallowedinexistingcombustioninstallationsintheCzechRepublic,moreconcreteintheCentralHeatingStationsofthecityofOstrava

Annex 3.1. summary of sepatarion results

DRY + MOISTDate July 31, 2013

Weight, g % of totalMoist 6,370.50 31.65%RDF 6,155.00 30.58%SS 105.00 0.52%Fe 714.20 3.55%Non Fe 85.70 0.43%Inert>12.50mm/stone 2,310.00 11.48%Inert1.00mm–12.50mm/gravel 3,348.00 16.63%Inert0.25mm–1.00mm/sand 577.00 2.87%<0,25mm 464.00 2.31%

TOTAL 20,129.40 100.00%

Conclusion:theresultiscomparabletoanalysesobtainedinotherregionsinternationally:• 1/3ofMSW=moistorwater.• 1/3ofMSW=organic&RDF• 1/3ofMSW=inertmaterial

DRY + MOIST

<0,25mm

Inert 1 - 0,25 mm

Inert 12,50mm - 1,00 mm

Moist31,65%

RDF30,58%

Inox0,52%

Non Fe0,43%

Inert > 12,50 mm

Fe3,55%

23

Afterlaboratorytreatmentthestatusofthematerialsisassummarizedinthenextfigure.

Preliminary conclusion

Thematerial(MSW)takenfromtheDEPOSlandfillsiteinHornySucha,Karvinacanbeprocessedinto:

• RDFas‘pellets’withca10%moist• SS/Ferrous/Non–ferrouswith1–3%moist• Sandwith12–15%moist• Gravelwith6–10%moist• Sludgewith50%moist.Thismaterialcanbereusedinceramics,butinanticipationitisputinatemporarylandfill

Thisscenarioallows100%recycling/recovery.

WeexpectthatthiswillleadtoMSWprocessingatacostofabout.€35/t,completelyoratleastpartlyrecoverablebythesalesofthematerialstoberecycledandoftheGENCOALproducttobeusedasfuel.

24

Annex 3.2. results from the ‘ash test’ at Technical University Ostrava

Mainconclusion:calorificvalueofGENCOALiscomparabletocoal.

VŠB–TechnickáuniverzitaOstravaLaboratořeInstitutugeologickéhoinženýrství [email protected],tel:596995460

ANALYSIS OF THE GENCOAL (RDF)

Protocol No.1/01/2013 dated on 11.12.2013

RDF – Depos Mr.Ceslav ValosekUsed method

Mixed sample

Waterdryup(Wex) % ČSN441377Tuhápaliva–Stanoveníobsahuvody

Waterrest(Wh) % ČSN441377Tuhápaliva–Stanoveníobsahuvody

Warerintotal(Wt) % ČSN441377Tuhápaliva–Stanoveníobsahuvody

Water at the sample % 3,24 ČSNISO11722Tuhápaliva–Černáuhlí–StanovenívodyvanalytickémvzorkusušenímvN2

Humidity % ČSNISO562Černáuhlíakoks–Stanoveníprchavéhořlaviny

Ashindrymatter % 20,87 ČSNISO602Stanoveníobsahupopelovin

Volatileflammableindrymatter % 74,27 ČSNISO562Černáuhlíakoks–StanoveníprchavéhořlavinyČSNISO5071-1Hnědáuhlíalignity-StanoveníprchavéhořlavinyvanalytickémvzorkuFixedCarbon % 4,86

Heatofcombustionindrymatter J/g 23013

ČSN ISO 1928 Stanovení spalného tepla kalorimetrickoumetodouvtlakovénádoběavýpočetvýhřevnosti

Caloricvalueindrymatter J/g 19835

Caloricvalueinthesample J/g 18985

Cindrymatter % 47,526

ČSNPISOTS/12902Tuhápaliva–Stanoveníveškeréhouhlíku,vodíkuadusíku–Instrumentálnímetody

Hindrymatter % 15,426

Nindrymatter % 0,769

0indrymatter(calculation) % 15,409

Sindrymatter % <0,010

Valuescalculatedasaveragefrom6samplesRightnessdueby

Mrs.Prof.Ing.H.Raclavská,CSc.

25

ASH MEASUREMENT

Temperature for ash melting ČSN ISO 540 DT(deformationtemperature):1093-1132ST(spheretemperature):1198-1211HT(hemispheretemperature):1209-1230FT(flowtemperature):1222-1257

X-RAY FLUORESCENCE ANALYSIS

IndicativeresultsfrommobileX-rayunit(X-rayfluorescenceanalysis).Ag,Ba,Cd,Co,Hg,Se,Snwereunderdetectionlimit

Element mg/kg dry matter

Ca 38457

V 31

Cr 101

Mn 221

Ti 2690

Fe 5421

Ni 51

Cu 16

Zn 677

As 11

Rb 10

Sr 119

Zr 43

Mo 31

Sb 112

Pb 38

Bi 7

26

Annex 3.3. Laboratory test at VVUÚ in Ostrava, CZ to get certificate as alternative fuel

27

ASSESSMENTREPORTN°VUÙ-017216/2014

28

Annex 4: Impressions of semi-industrial test in 2018

30 TONS OF FRESH MSW

ROUGH SHREDDING

WASHING & SEPARATING

29

FINE SHREDDING

DELIVERY OF GENCOAL AT CITY HEATING PLANT

GENCOAL

30

Annex 5: project team for WASTE REFINERY & GENCOAL

ETIENNE SCHOUTERDEN

Etienne Schouterden (1947) has 45 years of experience in business and process organisation. After his training inindustrialchemistry,hespent13yearsasheadofthelaboratorydepartmentandthepersoninchargeofnewseparationtechniquesinthecoalpreparationplantofKSWaterschei.HeleftKSin1984andhassinceworkedworldwideonprojectsfor thedesignand realisationof installations for theprocessingof rawmaterialsandcoal.Since2007,hehasbeensupervisingtheindustrialprocessofseveralSMEs(smallandmedium-sizedbusinesses) inLimburg,andinparticularprojectsonsoilremediationandrenewableenergywiththegroupCarmansNV.HehasalsobeeninvolvedinprojectswithGRL,Galloo,etc.

EtienneSchouterden’sspecialityistheintegrationofinnovativeprocessesintoexistingproductionenvironments,prac-ticalsupportfortheplacementandexploitationofcomplexinstallationsforrenewableenergy(solar,wind,CHP).HealsodoesconcreteresearchintonewpossibilitiesforPPOandotherbiomasssources.Furthermore,heholdsarecentcertificatefromtheInnovationSchool,SustainabilityinChemistryandtheNanoschoolinMaastricht.

Achievements:• Designingandbuildingwaterpurificationinstallationsinthefollowingsectors:Precastconcreteindustry,Foodin-

dustry,Coalindustry,Brickworks,Municipalwasteincineration,Soilremediation,Spoiltiptreatment,Sludgebasintreatment,Metalrecycling

• Designingandbuildingturn-keyprocessinginstallationsinthefollowingsectors:Waste-to-energy,Glassrecycling,Coal sludgetreatment,Spoiltipwashing,Coalpreparationplants,Rubbleanddemolitionwaste,Screenedsandpurification,Soilremediation,Municipalwasteincinerationslags.

• Designingandbuildingturn-keyrenewableenergyinstallations:largesolarprojects,windproject,CHPproject.

Relevantassignmentsfromhiscareer:

• R&DGevaertAgfaMortsel(1966–1971)• HeadoflaboratoryandnewseparationtechniquesKSWaterschei(1971–1984)• WorldwideflotationresponsibleforHoechstAGFrankfurt(D)(1984–1986)• Designerworldpremierecoal–sludgeprocessinginstallationfromwasteforFechnerGmbhBottrop(D)(1986–

1988)• Founderandmanagerof IPASnv,processingof rawmaterialsandwastematerialswithworldwide realisations.

(1988–2007),managingdirectorIPAS2008–now.• FreelanceprojectdesignandprocesssupervisionforLimburgSMEsCarmans,GRL,Galloo,…• Inspirerandco-founderofSCRLtransit_LAB.

EtienneSchouterden,WilfriedDeNijs&PaulBoutsen

31

PAUL BOUTSEN

PaulBoutsen(1962)has30yearsofexperienceinparticipatoryprocesssupervision,policypreparationandregionaleconomicdevelopment.Hehasahistoryinthesupervisionofrestructuringandproductadviceinthepublicandprivatesector.Hehasworkedaroundurban regeneration inMechelen,neighbourhood communitywork and regional eco-nomicplanningintheLimburgminingregion,conversionofindustrialpremisesonbehalfoftheFlemishgovernment,restructuringofaproducerofgreenenergyandvariouslarge-scaleculturalproductions.Boutsenisalsoactiveinaninternationalnetworkofminingregions.Between2009and2012,hesupervisedthetrajectorytotheCleantechCampusinHouthalen-Helchteren,aswellastheconversionofitsformerminingsite.Since2013,hehasbeenactiveintheSCRLtransit_LAB,acooperativecompanyininnovationanddevelopment;

Relevantassignmentsfromhiscareerare:• Urbanregeneration,welfareplanningandhousingprojectsinMechelenbetween1984and1990.• Neighbourhoodcommunitywork intheMiningregionascommunityworker inZwartberg(1991–1992)andas

directorofthenon-profitSTEBO(1993–1995)• RegionalPlatformMiningRegionandMiddleLimburgasmemberofstaffwithsubstantivefocusonlocaleconomic

andspatialdevelopment,conversionofminingsites,touristandsocialdevelopmentoftheminingmunicipalities(1995–2000)

• InthecompanyEcowatt(hydropowerplants),hewasinchargeofacorporaterestructuringandwithaself-assem-bledtechnicalteam,hebuilt4hydropowerplants(2000–2001)

• IndependentconsultantinregionaldevelopmentforFlemishGovernment(2001–2003)ascommissionerminingpatrimony.

• IndependentconsultantinregionaldevelopmentforTourismLimburg(2003–2004)ascommissionertouristdeve-lopmentplanMiningRegion.

• IndependentconsultantforthecityofGenkregardingtouristdevelopmentminingpatrimony(2004–2005):deve-lopmentofpartsofC-Mine.

• IndependentconsultantforthetownofHouthalen-Helchteren(2009–2012):supervisionofthepreparatoryproc-ess to theCleantechCampus, the foundingof theFlemishCleantech–management structure (vzw I-CleantechVlaanderen)andCleantechacquisitionsforLimburg.

• BelgianRepresentativeinEURACOM,Europeannetworkofminingregions.• FounderandmanagerofADACTPLC,consultingandmanagementassignmentsinregionaldevelopment.• Founder(1990)andManagingDirectorofnon-profitHetVervolg,projectcentreoftheMiningRegionandofCOAL-

FACE,internationalprojectonconceptualisationofminingregions(2006–now)• FounderandManagingDirectoroftheSCRLtransit_LAB,acooperativecompanyintransitionandregionaldevelop-

ment,promoterofWASTEREFINERY&GENCOAL.

WILFRIED DE NIJS

IR.LIC.JUR.WilfriedDeNijs(1945)isHonoraryInspectorGeneralofOVAM,thePublicWasteAgencyofFlanders,andhasbuiltacareerasmanager,directorandexecutorinvariousBelgianandFlemishgovernmentalbodies,projectsandcompanies.HeisaCivilEngineer(IR)ChemistryandAgriculturalIndustry(KULeuven),IREnvironmentalRemediation(RUGhent),Lic.Law(UIAntwerp)andAppliedEconomicSciences(KULeuven).Ascabinetadvisorundervariousmini-sters,hewasthefounderoftheFlemishenvironmentallegislation.HeistheauthoroftheWasteDecree1981andtheSoilDecontaminationDecree1995,andthefounderofOVAMandcreator-founderofINDAVER.Hehasfilledalonglistofmandates,amongwhichintheFlandersParticipationSociety(PMV),theWorldBank,andnumerousinnovativeprojectsandcompaniesintheenvironmentalsector.HisforeignexperienceisbuiltonvariousmissionstoCentralandEasternEuroperegardingwasteprocessingandenvironmentalandsoilremediation.

Relevantassignmentsandachievementsfromhiscareer:• CabinetadvisorfortheministersServaisandDeSaeger(1971–1978)• HeadEngineer–DirectorfortheMinistryofHealth,SanitaryEngineering(1974–1981)• InspectorGeneralforOVAM,ManagementRealisationandRemediation(1981–2010)• SpecialCommissionerbrownfieldsforFlandersParticipationSociety(PMV)(2004–2010)• Authorof29publicationsintheenvironmentalandwastesectors.

Asexecutiveanddirectiveofficer:• Theclosingandremediationofdozensofpublic,semi-publicandprivateandnon-controlledlandfills• thefoundingofOVAM,thePublicWasteAgencyofFlanders• theintroductionoftheinnovativeprocessesforwasteincinerationinFlandersinthe1980s• therealizationofanenvironmentallyresponsiblewastetreatmentpracticeforthechemicalindustriesinAntwerp• thefoundingofINDAVERaspublic–privatecompanyforwasteprocessingintheportofAntwerp.

The concept WASTE REFINERY & GENCOAL was reviewedby Professor Carlo Vandecasteele of the Department ofChemicalEngineeringoftheUniversityofLeuven,Belgium.

TheconceptofWASTEREFINERY&GENCOALwassignedandlaiddownattheBENELUXofficeforintellectualpropertyin2014and2015asheldbycvbatransit_LAB.

transit_LAB

CONTACT

PaulBoutsenmail:[email protected]:0032477632920CEOtransit_LABcvbathroughADACTbvba

Adress:Transit_LABscrl/cvbaRondPunt73550Heusden-ZolderBelgium

CompanyID:BE0844324325www.transit-lab.be

industrial processes & active serviceswww.ipas.world