Vernier Calipper ExperimentS

-

Upload

maylaleiborday -

Category

Documents

-

view

24 -

download

1

description

Transcript of Vernier Calipper ExperimentS

QUIZON,ELMER M.

A-102

TITLE :MEASUREMENT

Vernier caliperMain article: Vernier scale

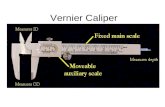

Parts of a vernier caliper:

1. Outside jaws: used to measure external diameter or width of an object2. Inside jaws: used to measure internal diameter of an object3. Depth probe: used to measure depths of an object or a hole4. Main scale: scale marked every mm5. Main scale: scale marked in inches and fractions6. Vernier scale gives interpolated measurements to 0.1 mm or better7. Vernier scale gives interpolated measurements in fractions of an inch8. Retainer: used to block movable part to allow the easy transferring of a measurement

The vernier, dial, and digital calipers give a direct reading of the distance measured with high accuracy and precision. They are functionally identical, with different ways of reading the result. These calipers comprise a calibrated scale with a fixed jaw, and another jaw, with a pointer, that slides along the scale. The distance between the jaws is then read in different ways for the three types.

The simplest method is to read the position of the pointer directly on the scale. When the pointer is between two markings, the user can mentally interpolate to improve the precision of the reading. This would be a simple calibrated caliper; but the addition of a vernier scale allows more accurate interpolation, and is the universal practice; this is the vernier caliper.

Vernier, dial, and digital calipers can measure internal dimensions (using the uppermost jaws in the picture at right), external dimensions using the pictured lower jaws, and in many cases depth by the use of a probe that is attached to the movable head and slides along the centre of the body. This probe is slender and can get into deep grooves that may prove difficult for other measuring tools.

The vernier scales may include metric measurements on the lower part of the scale and inch measurements on the upper, or vice versa, in countries that use inches. Vernier calipers commonly used in industry provide a precision to 0.01 mm (10 micrometres), or one thousandth of an inch. They are available in sizes that can measure up to 1,829 mm (72 in).[8]

Dial caliper

Mitutoyo dial caliper

Instead of using a vernier mechanism, which requires some practice to use, the dial caliper reads the final fraction of a millimeter or inch on a simple dial.

In this instrument, a small, precise gear rack drives a pointer on a circular dial, allowing direct reading without the need to read a vernier scale. Typically, the pointer rotates once every inch, tenth of an inch, or 1 millimeter. This measurement must be added to the coarse whole inches or centimeters read from the slide. The dial is usually arranged to be rotatable beneath the pointer, allowing for "differential" measurements (the measuring of the difference in size between two objects, or the setting of the dial using a master object and subsequently being able to read directly the plus-or-minus variance in size of subsequent objects relative to the master object).

The slide of a dial caliper can usually be locked at a setting using a small lever or screw; this allows simple go/no-go checks of part sizes.

Digital caliper

Digital caliper

A refinement now popular is the replacement of the analog dial with an electronic digital display on which the reading is displayed as a single value. Some digital calipers can be switched between centimeters or millimeters, and inches. All provide for zeroing the display at any point along the slide, allowing the same sort of differential measurements as with the dial caliper.

Digital calipers may contain some sort of "reading hold" feature, allowing the reading of dimensions even in awkward locations where the display cannot be seen. Ordinary 6-in/150-mm digital calipers are made of stainless steel, have a rated accuracy of 0.001 in (0.02mm) and resolution of 0.0005 in (0.01 mm). [9] The same technology is used to make longer 8-in and 12-in calipers; the accuracy for bigger measurements declines to 0.001 in (0.03 mm) for 100–200 mm and 0.0015 in (0.04 mm) for 200–300 mm. [10]

Many Chinese-made digital calipers are inexpensive and perform reasonably well. One point worth noting is battery current when they are turned off. Many calipers do not stop drawing power when the switch is in the off position; they shut down the display but continue drawing nearly as much current. The current may be as much as 20 microamperes,[11] which is much higher than many established brands. Sometimes calipers may not work properly when the battery voltage has dropped relatively little; silver cells, preferably selected from a datasheet to have a constant voltage for most of their life, may give a much longer usable life than alkaline button cells (e.g., SR44 instead of LR44).[11][12]

Increasingly, digital calipers offer a serial data output to allow them to be interfaced with a dedicated recorder or a personal computer. The digital interface significantly decreases the time to make and record a series of measurements, and it also improves the reliability of the records. A suitable device to convert the serial data output to common computer interfaces such as RS-232, Universal Serial Bus, or wireless can be built or purchased. With such a converter, measurements can be directly entered into a spreadsheet, a statistical process control program, or similar software.

The serial digital output varies among manufacturers. Common options are

Mitutoyo's Digimatic interface. This is the dominant name brand interface. Format is 52-bits arranged as 13 nibbles.[13][14][15][16]

Sylvac interface. This is the common protocol for inexpensive, non-name brand, calipers. Format is 24 bit 90 kHz synchronous.[17][18]

Starrett[19]

Brown & Sharpe[19]

Federal Mahr (appears to offer Digimatic, RS232, and USB) Tesa[19]

Aldi. Format is 7 BCD digits.[18]

Like dial calipers, the slide of a digital caliper can usually be locked using a lever or thumb-screw.

Some digital calipers contain a capacitive linear encoder. A pattern of bars is etched directly on the printed circuit board in the slider. Under the scale of the caliper another printed circuit board also contains an etched pattern of lines. The combination of these printed circuit boards forms two variable capacitors. The two capacitances are out of phase. As the slider moves the capacitance changes in a linear fashion and in a repeating pattern. The circuitry built into the slider counts the bars as the slider moves and does a linear interpolation based on the magnitudes

of the capacitors to find the precise position of the slider. Other digital calipers contain an inductive linear encoder, which allows robust performance in the presence of contamination such as coolants [1]. Magnetic linear encoders are used in yet other digital calipers.

Micrometer caliper

Main article: Micrometer

A caliper using a calibrated screw for measurement, rather than a slide, is called a micrometer caliper or, more often, simply a micrometer. (Sometimes the term caliper, referring to any other type in this article, is held in contradistinction to micrometer.)

Comparison

Each of the above types of calipers have their relative merits and faults.

Vernier calipers are rugged and have long lasting accuracy, are coolant proof, are not affected by magnetic fields, and are largely shock proof. They may have both centimeter and inch scales. However, vernier calipers require good eyesight or a magnifying glass to read and can be difficult to read from a distance or from awkward angles. It is relatively easy to misread the last digit. In production environments, reading vernier calipers all day long is error-prone and is annoying to the workers.

Dial calipers are comparatively easy to read, especially when seeking exact center by rocking and observing the needle movement. They can be set to 0 at any point for comparisons. They are usually fairly susceptible to shock damage. They are also very prone to getting dirt in the gears, which can cause accuracy problems.

Digital calipers switch easily between centimeter and inch systems.They can be set to 0 easily at any point with full count in either direction, and can take measurements even if the display is completely hidden, either by using a "hold" key, or by zeroing the display and closing the jaws, showing the correct measurement, but negative. They can be mechanically and electronically fragile. Most also require batteries, and do not resist coolant well. They are also only moderately shockproof, and can be vulnerable to dirt.

Calipers may read to a resolution of 0.01 mm or 0.0005 in, but accuracy may not be better than about ±0.02 mm or 0.001 in for 150 mm (6 in) calipers, and worse for longer ones.[20]

Use

Using the vernier caliper

A caliper must be properly applied against the part in order to take the desired measurement. For example, when measuring the thickness of a plate a vernier caliper must be held at right angles to the piece. Some practice may be needed to measure round or irregular objects correctly.

Accuracy of measurement when using a caliper is highly dependent on the skill of the operator. Regardless of type, a caliper's jaws must be forced into contact with the part being measured. As both part and caliper are always to some extent elastic, the amount of force used affects the indication. A consistent, firm touch is correct. Too much force results in an underindication as part and tool distort; too little force gives insufficient contact and an overindication. This is a greater problem with a caliper incorporating a wheel, which lends mechanical advantage. This is especially the case with digital calipers, calipers out of adjustment, or calipers with a poor quality beam.

Simple calipers are uncalibrated; the measurement taken must be compared against a scale. Whether the scale is part of the caliper or not, all analog calipers—verniers and dials—require good eyesight in order to achieve the highest precision. Digital calipers have the advantage in this area.

Calibrated calipers may be mishandled, leading to loss of zero. When a calipers' jaws are fully closed, it should of course indicate zero. If it does not, it must be recalibrated or repaired. It might seem that a vernier caliper cannot get out of calibration but a drop or knock can be enough. Digital calipers have zero set buttons.

Vernier, dial and digital calipers can be used with accessories that extend their usefulness. Examples are a base that extends their usefulness as a depth gauge and a jaw attachment that allows measuring the center distance between holes. Since the 1970s a clever modification of the moveable jaw on the back side of any caliper allows for step or depth measurements in addition to external caliper measurements, in similar fashion to a universal micrometer (e.g., Starrett Mul-T-Anvil or Mitutoyo Uni-Mike).

Zero error

The method to use a vernier scale or caliper with zero error is to use the formula 'actual reading = main scale + vernier scale - (zero error)'. Zero error may arise due to knocks that cause the calibration at the 0.00 mm when the jaws are perfectly closed or just touching each other.

when the jaws are closed and if the reading is 0.10mm, the zero error is referred to as +0.10mm.The method to use a vernier scale or caliper with zero error is to use the formula 'actual reading = main scale + vernier scale - (zero error)' thus the actual reading is 19.00 + 0.54 - (0.10) = 19.44 mm

Positive zero error refers to the fact that when the jaws of the vernier caliper are just closed, the reading is a positive reading away from the actual reading of 0.00mm. If the reading is 0.10mm, the zero error is referred to as +0.10mm.

when the jaws are closed and if the reading is -0.08mm, the zero error is referred to as -0.08mm..The method to use a vernier scale or caliper with zero error is to use the formula 'actual reading = main scale + vernier scale - (zero error)' thus the actual reading is 19.00 + 0.36 - (-0.08) = 19.44 mm

Negative zero error refers to the fact that when the jaws of the vernier caliper are just closed, the reading is a negative reading away from the actual reading of 0.00mm. If the reading is -0.08mm, the zero error is referred to as -0.08mm.

Experimentation:

Experiments based on vernier calipers

A meter scale can measure accurately up to one–tenth part of one cm. Its least measurement 0.1 cm, is called least count of scale. There is limitation of meter scale that the meter scale cannot measure the value less than 0.1 cm. For greater accuracy measurement we have devices such as, Vernier Callipers A vernier callipers provides with an auxiliary (or vernier) scale in addition to the main scale. Thevernier scale can slide along the main scale. The vernier scale is so graduated (or marked) that the length of total number of divisions on it is smaller by length of one division on main scale. The least count of vernier scale is calculated by using the following formula

Least count of vernier scale (or vernier constant) = orLeast count (vernier constant) = 1 M.S.D.(Main scale division) – 1 V.S.D.(vernier scale division).

Solved Example 1:

If N division of vernier coincides with (N – 1) division of main scale. Given one main scale division is equal to ‘a unit’, find the least count of the vernier.

Solution:

Vernier constant = 1MSD – 1VSD = MSD = a/N,

Generally, the value of 1 main scale division on vernier callipers is 0.1 cm and there are 10 divisions on the vernier scale, i.e., x = 0.1 cm and n = 10. Least count of vernier callipers = 0.1cm/10 = 0.01 cm. Zero error of vernier callipers: If the zero marking of main scale and vernier callipers does not coincide, necessary correction has to be made for this error which is known as zero error of the instrument. If the zero error of the vernier scale is to the right of the zero of the main scale the zero error is said to be positive & the correction will be negative otherwise vice versa.

Solved Example 2:

What will be measurement of following vernier callipers gauge position?

Coinciding division

Solution:

Reading = main scale reading + vernier scale position´least count

= 0.1cm + 4 (due to fourth line of vernier matches with main scale) ´ .01cm = 0.1+ 0.04= 0.14cm

Solved Example 3:

Find the absolute error in density of a sphere of radius 10.01 cm and mass 4.692kg. Least count of vernier callipers and balance is 0.01cm and 0.001kg respectively.

Solution:

Email Based Homework Assignment Help in Vernier Calipers

Transtutors is the best place to get answers to all your doubts regarding vernier calipers, vernier scale, vernier constant, experiments based on vernier calipers and zero error of vernier calipers with solved examples. You can submit your school, college or university level homework or assignment to us and we will make sure that you get the answers you need which are timely and also cost effective. Our tutors are available round the clock to help you out in any way with Physics.

Live Online Tutor Help for Vernier Calipers

Transtutors has a vast panel of experienced physics tutors who specialize in vernier calipers and can explain the different concepts to you effectively. You can also interact directly with our physics tutors for a one to one session and get answers to all your problems in your school, college or university levelPhysics homework. Our tutors will make sure that you achieve the highest grades for your physics assignments.