Valve data sheet: BCXS302T

description

Transcript of Valve data sheet: BCXS302T

12/5/13 tr2000.statoil.com/TR2000/complete_issue/dataSheet4.xsql?opn=84&issue=6.1&4=BCXS302T&DScompany=1&DSarea=1&setcustomrev=0

tr2000.statoil.com/TR2000/complete_issue/dataSheet4.xsql?opn=84&issue=6.1&4=BCXS302T&DScompany=1&DSarea=1&setcustomrev=0 1/2

Close Window

Piping and valve specification

Doc.no. TR2000

Sec.no. 4

Valve data sheet: BCXS302T Area Europe

Rev.no. B

Rev.date 09.09.2011

Status: R

Page: 1

Of: 1

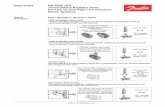

VALVETYPE : Ball Floating, Soft SeatsCODE : ASME B16.34SIZE RANGE : 0.25" - 1"RATING : 6000 PSI

Maximum design pressure : Barg 414.0 414.0 414.0

At temperature : oC -46 50 60

| Minimum operating temperature: -46 Maximum operating temperature: 60

PORT DESIGN : Full bore

END CONNECTION : NPT female threads to ANSI B1.20.1

END TO END DIM : Manufacture standard

HOUSING DESIGN : Bar stock body

TRIM DESIGN : Floating ball

: Bi directional sealing

: The resilient seat shall be secured in a pocket in the valve body or a metal seat ring for valve sizes 6"and above

STEM SEAL DESIGN : Packed gland, stuffing box or lip seal

STATIC SEALS : Manufacturer standard

O-RINGS : Not allowed

SPECIAL DESIGN REQ. : Firesafe to API 6FA or ISO 10497

MATERIALS

ITEM SUBITEM MATERIAL MDS

HOUSING Body/bonnet ASTM A182 F316 SF305

Body/bonnet ASTM A351 CF8M SC301

Body/bonnet ASTM A479 TP316 SB301

INSIDE TRIM Stem AISI 316 SV301

Ball AISI 316 SV301

Ball ASTM A351 CF8M SC302

Seat PTFE

Other materials AISI 316 SV301

SEALS Packed gland PTFE based rings PG102

Lip seals PTFE PG101

| PRESSURE RETAININGBOLTING

Bolting Bolt material shall be selected according to MDS XN501

AUXILIARYCONNECTION

Plugs ASTM A182 F316 SF306

OUTSIDE TRIM Bolting Min SS316 for bolts 10mm and smaller, min hot dip galvanized carbon steelfor larger

VN105

Wrench/handweel SS304/316 or HDG and painted CS/nodular iron

SPECIAL MAT.REQ. Wetted parts suitable for sour service to NACE MR0175/ISO 15156

MISCELLANEOUS REQUIREMENTS

ITEM VSK DESCRIPTION

Reference

GENERAL V 761

TESTING V 741

EXTERNAL COAT V 732 If not otherwise specified in order, this valve shall be supplied without any external valvecoating

MARKING V 718

OPERATOR V 719

SHIPMENT V 715

DOCUMENTATION V 743