V5A51 Application Chart

Click here to load reader

-

Upload

leeroyhill -

Category

Documents

-

view

224 -

download

0

Transcript of V5A51 Application Chart

8/12/2019 V5A51 Application Chart

http://slidepdf.com/reader/full/v5a51-application-chart 1/3

INTRODUCTIONR/V4A51 AND V5A51

AUTOMATIC TRANSMISSION SERVICE GROUP18635 S.W. 107 AVENUEMIAMI, FLORIDA 33157

(305) 670-4161 1

No part of any ATSG publication may be reproduced, stored in any retrieval system or transmitted in any form or by any means, including but not limited to electronic, mechanical, photocopying, recording or otherwise,without written permission of Automatic Transmission Service Group. This includes all text illustrations,tables and charts.

The information and part numbers contained in this booklet havebeen carefully compiled from industry sources known for their

reliability, but ATSG does not guarantee its accuracy.

Copyright © ATSG 2008

1st Printing November, 2008

DALE ENGLANDFIELD SERVICE CONSULTANT

ED KRUSETECHNICAL CONSULTANT

WAYNE COLONNAPRESIDENT

PETER LUBANTECHNICAL CONSULTANT

JIM DIALTECHNICAL CONSULTANT

GREGORY LIPNICK TECHNICAL CONSULTANT

RICHARD GRAHAMTECHNICAL CONSULTANT

JON GLATSTEINTECHNICAL CONSULTANT

DAVID CHALKER TECHNICAL CONSULTANT

ROLAND ALVAREZTECHNICAL CONSULTANT

GREG CATANZAROTECHNICAL CONSULTANT

GERALD CAMPBELLTECHNICAL CONSULTANT

This is a four speed, Rear Wheel Drive transmission, with fully electronic controls for the upshifts anddownshifts, with 4th gear being overdrive. The individual gear ratios are achieved through two planetary gearsets connected one behind the other. The components of the planetary gear sets are driven or held by means offive multiple plate clutch packs, and a low sprag. To minimize fuel consumption, the torque converter clutch is applied by the PCM, depending on throttle

position and vehicle speed. These units are currently found in Mitsubishi Montero 1999-2002 models,equipped with 3.0L and 3.5L engines.

This is a five speed, Rear Wheel Drive transmission, with fully electronic controls for the upshifts anddownshifts, with 5th gear being overdrive. The individual gear ratios are achieved through 3 planetary gear setsconnected one behind the other. The components of the planetary gear sets are driven or held by means of sixmultiple plate clutch packs, 1 band, and two sprags. To minimize fuel consumption, the torque converter clutch is applied by the PCM, depending on throttle

position and vehicle speed. These units are currently found in Mitsubishi Montero 2001-Up models, equippedwith 3.5L and 3.8L engines.

We wish to thank Mitsubishi Motor Company for the information and illustrationsthat have made this booklet possible. A special thanks also to Bob Nuttall for

information and suggestions that has made this a very accurate booklet.

R/V4A51 R=2WD, V=4WD

V5A51 V=4WD

8/12/2019 V5A51 Application Chart

http://slidepdf.com/reader/full/v5a51-application-chart 2/3

INDEX

Copyright © ATSG 2008

MITSUBISHI MONTEROR/V4 A51 AND V5A51

(4 Sp eed ) (5 Sp eed )

2

AUTOMATIC TRANSMISSION SERVICE GROUP18635 S.W. 107 AVENUEMIAMI, FLORIDA 33157

(305) 670-4161

QUICK EXTERNAL IDENTIFICATION ....................................................................................................................... IDENTIFICATION CODE STAMPING LOCATION ....................................................................................................4 SPEED COMPONENT APPLICATION CHART ........................................................................................................5 SPEED COMPONENT APPLICATION CHART ........................................................................................................

ELECTRONIC COMPONENT DESCRIPTION ............................................................................................................. SOLENOID CONNECTOR IDENTIFICATION AND RESISTANCE CHART ...........................................................4 SPEED WIRE SCHEMATIC ........................................................................................................................................4 SPEED CONNECTOR IDENTIFICATION .................................................................................................................5 SPEED WIRE SCHEMATIC ........................................................................................................................................5 SPEED CONNECTOR IDENTIFICATION .................................................................................................................

DIAGNOSTIC TROUBLE CODE DESCRIPTION ........................................................................................................ AIR CHECKS ....................................................................................................................................................................

LINE PRESSURE TEST SPECS, PRESSURE TAP LOCATIONS, FLUID SPECIFICATION .................................TRANSMISSION DISASSEMBLY ..................................................................................................................................COMPONENT REBUILD SECTION TRANSMISSION CASE ASSEMBLY ..................................................................................................................... EXTENSION HOUSING OR 4WD ADAPTER HOUSING ................................................................................... 2WD SPEEDOMETER GEAR ASSEMBLY .......................................................................................................... OIL PUMP ASSEMBLY ........................................................................................................................................... OVERDRIVE AND REVERSE CLUTCH HOUSING ASSEMBLY ...................................................................... PLANETARY GEAR TRAIN AND LOW SPRAG ASSEMBLY ............................................................................. REVERSE SUN GEAR AND HUB ASSEMBLY .................................................................................................... CENTER SUPPORT ASSEMBLY ........................................................................................................................... REDUCTION ANNULUS AND UNDERDRIVE CLUTCH HOUSING ASSEMBLY .......................................... 2ND BRAKE CLUTCH PISTON AND RETAINER ASSEMBLY ......................................................................... REDUCTION SERVO ASSEMBLY .........................................................................................................................

DIRECT CLUTCH HOUSING ASSEMBLY ........................................................................................................... 4 SPEED OUTPUT SHAFT SUPPORT .................................................................................................................. 5 SPEED OUTPUT SHAFT SUPPORT AND DIRECT SPRAG ASSEMBLY ..................................................... DIRECT SPRAG FREEWHEEL DIRECTION ...................................................................................................... LOW SPRAG FREEWHEEL DIRECTION ............................................................................................................ REDUCTION CARRIER AND OUTPUT SHAFT ASSEMBLY ............................................................................ VALVE BODY ASSEMBLY ...................................................................................................................................... CHECK BALL LOCATIONS ....................................................................................................................................TRANSMISSION ASSEMBLY (4 SPEED) .....................................................................................................................TRANSMISSION ASSEMBLY (5 SPEED) .....................................................................................................................

REDUCTION BAND ADJUSTMENT .............................................................................................................................TORQUE SPECIFICATIONS ..........................................................................................................................................THRUST BEARING IDENTIFICATION .......................................................................................................................

SPECIAL SERVICE TOOLS ...........................................................................................................................................

3456 7 8

141516 17 1920

2124

45484951556266 66 707576

788182848586 889197

100112124125126

8/12/2019 V5A51 Application Chart

http://slidepdf.com/reader/full/v5a51-application-chart 3/3

Selector Lever Position/Gear

Under Drive

Clutch

Over Drive

Clutch

Low/Rev BrakeClutch

2nd BrakeClutch

Low Sprag

Direct Sprag

Reduct.BrakeBand

Direct Clutch

Gear Ratio

Park

Reverse

Neutral

"D" 1st

"D" 2nd

"D" 3rd

"D" 4th

"D" 5th

"3" 1st

"3" 2nd

"3" 3rd

"2" 1st

"2" 2nd

"L" 1st

ON ON

ReverseClutch

ON ON ON

ON ON

ON ON* ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

HOLD HOLD

HOLD

HOLD

HOLD

HOLD

HOLD

HOLD

HOLD

HOLD

3.865

3.789

3.789

3.789

3.789

2.057

2.057

2.057

1.000

1.421

1.421

.731

ON ON

ON ON

ON

ON

ON

ON ON

ON ON HOLD

ON ON

ON ON

ON ON HOLD

ON ON

ON ON HOLD

Figure 4

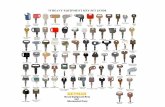

V5A51 COMPONENT APPLICATION CHART

OUTPUT SPEED

SENSOR

UNDERDRIVE CLUTCH

LOW SPRAG

LOW/REVERSE CLUTCH

REVERSE CLUTCH

2-4 BRAKE CLUTCH

OVERDRIVE CLUTCH

DIRECT CLUTCH

REDUCTION

BRAKE BAND

INPUT SPEED

SENSOR

DIRECT SPRAG

* Operates only when stopped in "D" 1st gear (Approximately 10 KMH {6.2 MPH} or less).

The 5 speed units from late 2001 thru current, are equipped with a "Sport Tronic" feature. This is a selector lever with twooperation gates, a Main gate and a Manual gate as shown on page 10. All manual positions below the "D" position must beachieved in the Manual gate with Plus or Minus indicators.

6

Copyright © 2008 ATSG

AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information

V5A51 COMPONENT APPLICATION CHART

TORQUE CONVERTER

CLUTCH