Us 2683020

-

Upload

luisfilippini -

Category

Documents

-

view

1 -

download

0

description

Transcript of Us 2683020

-

July 6, 1954

Filed Oct. 9, 1953

J. NICKLE

SAFETY DEVICE 2,683,020

' 2 Sheets-Sheet l

INVENTOR Jm'msou NmKLs'

evAZm/M W A 7' TOQNE Y

-

vJuly 6, 1954

Filed Oct. 9, 1953

l I A

J. NICKLE '

SAFETY DEVICE

'I/IIIIIIL

Q. '

2,683,020

I 2 Sheets-Sheet 2

ll "Hun-"ml 3

I/NVENTOQ Janus! NIcKLG'

swab/1&5, 409 ATTORNEY

-

Patented July 6, 1954

UNITED " STATES PATENT 2,683,020

2,683,020

OFFICE SAFETY DEVICE

Johnson Nickle, Edmonton, Alberta, Canada Application October 9, 1953, Serial No. 385,205

~ 1 Claim.

. 1 7 p

This device relates generally to safety appa ratus and more particularly to a safety device for drilling rig to prevent the travelling block from being pulled into the crown block on top of the derrick by the draw works.

It is an object of this device to provide appa ratus that may be installed at any point around the cable drum of the draw works and, when installed, it is adjustable to a desired point on the cable drum. An additional object is to provide a safety

device that is actuated by the cable that is being coiled around the cable drum. A further object is to provide a device that

will be actuated by the cable being coiled around the drum in either direction. A still further object is to provide a device

that will not be damaged should the cable not spool properly on the cable drum. A still further object is to provide a safety de

vice that is actuated by the cable being coiled in layers on the cable drum and, when actu ated, will return automatically to the pre-actu ated position when the cable is unwound from the cable drum. Various other objects and advantages of this

device will become obvious to those skilled in the art on reading the following speci?cation in the light of the attached drawings. It must be understood that the information disclosed therein is by way of example and illustration only and is not to be construed as a limitation. The invention herein is to be limited only by the terms of the appended claim and by the prior art. In the drawings wherein only one preferred

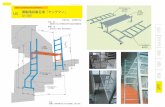

embodiment of theinventive idea is illustrated Figure 1 is a view in isometric projection illus~ trating the safety device mounted in position over a cable drum of a draw works. ' Figure 2 is a broken-away view, enlarged and

partly in section to illustrate the internal mech anism of the safety device. Figure 3 is a broken-away reduced end view

of the apparatus illustrated in Figure 1. With reference now to the drawings and par

15

25

30

35

40

45

ticularly Figure 1, there will be seen the draw . works drum designated by the numeral | on which the cable 2 is being wound. The draw works drum is of conventional design and ob viously would be provided with a suitable power source, clutch and braking mechanisms which have been omitted from the drawings in the interests of clarity. Reference will be made later in the speci?cation to the actuation of the draw

50

55

v|l| against the valve seat 2|.

(Cl. 254173)

works clutch and brake mechanism and it must be understood that this is the conventional clutch and brake mechanism commonly found on draw work assemblies. The safety device is desig nated generally by the numeral 3 and reference to Figure 1 will illustrate how the safety device is suspended over the drum I by the bracket 4 which is adapted to operate slideably along the longitudinal members 5, 5, of the supporting framework. The longitudinal members 5; 5 are supported in position above the draw works drum by the vertical supports 6, 6. Reference to Figure 2 in the drawings will

illustrate the internal construction of the safety device designated generally by the numeral 3 in Figures 1 and 3. The safety device comprises the ball 9 mounted freely at the lower end of the housing 1 and contained therein by the ball seat 8. The ball 9 is provided with the ?nger l0 protruding downwardly therefrom and the ?nger It has the extension [I engaged threadably thereon. Within the housing 7 the ball 9 is pro vided with the depression l3 in which the second ball I2 is seated. The second ball I 2 is adapted to move freely

vertically within the housing 7 and, as stated heretofore, rests normally in the depression IS in the top of the ball 9. a 7 Immediately above the second ball l2 in the

housing | is located the valve M which is spring loaded by the spring I! to rest normally against the valve seat 2|. Suitable 0 rings I5 and I6 are provided to ensure the airtight ?t of the valve

A guide for the valve I4 is provided by the cap It at the top of the housing 1. \ _ The air inlet to the housing 1 is provided at l9 while the air outlet is provided at 213 and it will be obvious that air would pass from the inlet l9 through the housing '| and out through the outlet 20 whenever the valve I4 is raised from the valve seat 2|. Raising of the valve I4 from the valve seat 2| is accomplished whenever the ball 9 is rotated within its seat by a lateral pressure against the ?nger I6. It will be obvious that any movement of the ball 9 within the ball seat 8 will force the second ball l2 out of the depression l3 against the lower end of the valve M and raise the valve I4 upwardly in the hous ing 1 and away from the valve seat 2|. Eleva~ tion of the valve | 4 from the valve seat 2| will allow air pressure to pass through the housing 1 from the air inlet H! to the air outlet 20. Air from the outlet 20 is then led by the pipe 22 (seen in Figure 1) to a suitable air cylinder which will~

-

2,683,020 3

open an additional valve and release further air to set the master clutch on the draw works and then to a second suitable cylinder to set the air brakes on the cable drum.

Reference to the drawings and particularly to Figure 2 therein will illustrate the cable 2 being wound on the cable drum and it will be obvious immediately how the winding of this cable on the drum will act against the ?nger 10 to rotate the ball 9 within its housing 8. What I claim as my invention is: In combination with the cable drum of a drill

ing rig draw works, such cable drum having air operated clutch and brake mechanisms; a safety device for controlling the air supply to the said clutch and brake mechanisms comprising a cas ing having an inlet port leading to the. said air supply and an outlet port leading to the, said clutch and brake mechanisms; an airtight valve controlling the passage of air through the said casing from the said inlet port to the said out let port; a spring adapted to hold the said valve normally in the closed position; a ball mounted

15

20

4 universally in the said casing; a ?nger ?xed to the said ball and projecting outside the said cas ing; a depression in the surface of the said ball Within the said casing; a second ball positioned freely within the said casing and adapted to rest normally in the said depression in the ?rst named ball, such second named ball being further adapted to move within the said casing to actu ate the said valve, on rotation of the ?rst named ball in its universal mounting; means for sup porting the said safety device over the said cable drum with the said ?nger in the path of cable being wound on the said drum.

References Cited in the ?le of this patent UNITED STATES PATENTS

Number Name Date 1,109,373 Truran __________ __ Sept. 1, 1914 2,502,710 Duncan __________ __ Apr. 4, 1950 2,530,766 Halderman ______ __ Nov. 21, 1950 2,659,514 Crookston ________ __ Nov. 17, 1953 2,659,575 Seljos ___________ __ Nov. 17, 1953

![[en-us] bosch-home.com/us/mybosch mybosch [en-us] Dishwasher](https://static.fdocuments.us/doc/165x107/615cc8afbe7e0d1e5a38c77e/en-us-bosch-homecomusmybosch-mybosch-en-us-dishwasher.jpg)