TRB Committee AFH50 – PCC Pavement …onlinepubs.trb.org/onlinepubs/webinars/110601.pdfTRB...

Transcript of TRB Committee AFH50 – PCC Pavement …onlinepubs.trb.org/onlinepubs/webinars/110601.pdfTRB...

TRB Committee AFH50 – PCC Pavement Construction TRB Committee AFD50 – Rigid Pavement Design

2011 TRB Webinar Improved Practices for Design and Construction of Continuously Reinforced Concrete Pavements (CRCP) – Part 2: Construction June 1, 2011 Time: 1:00 PM – 3:00 PM EDT

TIME TOPIC

1:00 PM Webinar Instructions – Lisa Marflak, Transportation Research Board (TRB)

1:05 PM Webinar Overview – Roger Schmitt, Florida Department of Transportation and Dulce Rufino Feldman, California Department of Transportation (Caltrans)

1:10 PM CRCP Technical Considerations – Shiraz Tayabji, Fugro Consultants, Inc.

1:20 PM CRCP Plans and Specification Highlights – Lisa Lukefahr, Texas Department of Transportation

1:35 PM Concrete Requirements for CRCP – Paul Tikalsky, University of Utah

1:45 PM CRCP Construction Best Practices – Mike Plei, CMC Americas

2:15 PM CRCP Repairs – Jeff Roesler, University of Illinois at Urbana-Champaign

2:30 PM Questions and Answers

3:00 PM Adjourn

Transportation Research Board WebinarOrganized by TRB Committees:Rigid Pavement Design (AFD50)

Portland Cement Concrete Pavement Construction (AFH50)

Roger Schmitt, P.E.Florida DOT

Dulce Rufino Feldman, Ph.D., P.E.California DOT

June 1, 2011

Webinar Overview: Improved Practices for Design and Construction of CRCP

Part 2 Construction

Presentation Outline

CRCP Technical Considerations (10 min)

Shiraz Tayabji, Fugro Consultants, Inc.

CRCP Plans and Specification Highlights (15 min)

Lisa Lukefahr, Texas Department of Transportation

Concrete Requirements for CRCP (10 min)

Paul Tikalsky, University of Utah

Presentation Outline (Cont.)

CRCP Construction Best Practices (30 min)

Mike Plei, Commercial Metals Company, Inc.

CRCP Repairs (15 min)

Jeff Roesler, University of Illinois at Urbana-Champaign

Questions and Answers

Transportation Research Board WebinarOrganized by TRB Committees:

Rigid Pavement Design (AFD50)

Portland Cement Concrete Pavement Construction (AFH50)

Improved Practices for Continuously Reinforced Concrete

Pavements: Part 2 - Construction

CRCP Technical ConsiderationsShiraz Tayabji, Fugro Consultants, Inc.

June 1, 2011

2

What is CRCP?CRCP differs from other concrete pavements

No transverse joints

Continuous longitudinal reinforcement interacts

with concrete to produce tight cracks at about 3

to 6 ft spacing

CRCP can extend, joint-free, for many miles

with breaks provided only at structures

Continuous

Longitudinal

Steel

Concrete slab (no transverse joints)

CRCP: A Low Maintenance

Long-Life Pavement

First introduced in1921

Production use during 1940s

Widely used since 1960s

Over 30,000 lane miles in the U.S.

Majority of Interstate system in IL,

TX, OR ; used in other states too

Several States use CRCP as

pavement of choice for highways

with heavy truck traffic

3

The design of CRCP has evolved over the

years and is currently based on a combination of:

Experience of highway agencies

Experimental road tests

Research studies

Empirical design procedures (AASHTO 1986/93)

Mechanistic-empirical design procedures

(AASHTO MEPDG & other)

Theoretical concepts as well as empirical

data are needed to obtain more reliable designs

Design Basis for CRCP

4

CRCP Failure Modes

Structural failure (addressed by structural

design): Design Webinar (April 2011)

Materials related failure (addressed by material

selection, concrete mixture design/proportioning

& construction practices): This Webinar

Ride related failure:

Initial ride: addressed by construction quality

This Webinar

Long-term ride degradation: addressed by

structural design, materials selection & construction

quality 5

Punchouts (Traffic related)

Load

Wide Cracking(Design/construction

related)

CRCP Structural Failure Modes

CRCP Structural Design Criteria

Crack spacing is ideally

between 3 and 6 ft

Crack width is

recommended to be very

narrow (typically ~0.020-in. at

the top of the slab)

Cracks MUST be tight for a

high crack load transfer

effectiveness (need >90%)

7

CRCP Key Design Features

Structural section

Base/subbase

Drainage

Slab thickness (Not the only design feature)

Widened lane/shoulder type

Steel amount, placement, layout

Terminal treatment

Concrete properties - strength & durability

8

9

CRCP Design Issues:

Terminal Joints

Wide flange beam

joints

Accommodates

movement

Preferred by

many agencies

Anchor lugs

Restrains end

movement

CRCP Concrete

Strength

Flexural: 600 to 650 psi (each 50 to 60 psi ~ 1 in.)

Compressive: ~4,000 psi

Modulus, E: ~4,000,000 psi

Durability - Free of Materials Related Distress (eg., ASR, D-cracking, etc.)

Workability – Very important for CRCP

CRCP Design Elements

Thickness: 6 to 14 in.

Base type: Granular, ATB, CTB; stabilized permeable bases not recommended

Reinforcement:

0.65 to 0.8 %, typically single layer

Placed on transverse steel

Need to manage design/construction compatibility

Design concrete strength & thickness matched with design steel amount

If actual thickness is larger or concrete strength is higher, crack spacing/width may be affected

12

Summary

CRCP has the potential to provide long-term zero-maintenance service life under heavy traffic loading, provided marginal features/conditions are not built into the pavement.

Quality construction is essential for long-life CRCP

Greetings from Washington

THANK YOU!

Texas Experience and Directions

Elizabeth (Lisa) Lukefahr, P.E.

Texas Department of Transportation

June 1, 2011

TRB Webinar on Improved Practices for Construction of CRCP

Outline

Primary Distress Types in Texas CRCP

Specification Efforts to Prevent or Mitigate Distress

Summary

“Punchout” is Primary Distress in Texas

Punchout: 1 per 8.8 lane miles

Concrete Patch: 1 per 4.6 lane miles

Asphalt Patch: 1 per 88 lane miles

Majority of punchouts in Texas not directly related to design: construction/materials related

Information courtesy M. Won, R.S. 0-6274

4

I: Header Steel Design and/or Construction (consolidation) Issues

Photo courtesy M. Won, R.S. 0-6274

Photo courtesy M. Won, R.S. 0-6274

II: Shallow Spalling Associated with High CoTE/MoE Coarse Aggregates

New Initiatives

Slab support system

ME design procedures

Bridge terminal systems

CoTE requirement

Photo courtesy M. Won, IAC MTIA018

III: Mid-Slab Cracking Associated with High CoTE/MoE Coarse Aggregates or

(in rarer instances) Low k-value

Design and Specification Efforts to Prevent or Mitigate Distress

Header Punchouts:

Continued research efforts looking into steel design

Collaboration with paving industry to develop better construction specifications and practices

oConsolidation

oCuring

Design and Specification Efforts to Prevent or Mitigate Distress (Cont.)

Shallow Spalling:Specification requirement for max concrete

coefficient of thermal expansion (CoTE):

oPreviously specified value 6.0 µstrain/ F

oFuture requirement of 5.5 µstrain/ F

Will have 2 standards based on concrete CoTE:

oLow CoTE (<4.8); less long. steel (~ 0.55%)

oRegular CoTE (>4.8, <5.5) (~0.63%)

Continued investigation into role of modulus of elasticity (MoE) and thermal properties such as conductivity, etc.

Design and Specification Efforts to Prevent or Mitigate Distress (Cont.)

Mid-Slab Cracking Associated with High CoTE/MoE Coarse Aggregates or Low k-value

Specification Requirement for maximum concrete coefficient of thermal expansion

Regional, site-specific testing (plate, FWD, DCP) to better quantify subgrade support and/or subbase layers

oTxDOT currently requires 1 of 2 Subbase options: 4” HMAC or 6” CTB + 1” bond breaker

Summary

Excellent CRCP performance

Majority of punchout distress in Texas related to construction/materials

Initiatives to further improve CRCP performance:

Improved header design and construction

CoTE testing and specification requirementsoMaximum CoTE requirement

o2 CRCP standards: low CoTE and regular CoTE

MoE testing

Better site-specific k-value design input

PAUL TIKALSKY, UNIVERSITY OF UTAH

Concrete Requirements for CRCP

T R B W E B I N A R O N I M P R O V E D P R A C T I C E S F O R C O N T I N U O U S L Y R E I N F O R C E D C O N C R E T E P A V E M E N T S :

P A R T 2 - C O N S T R U C T I O N

J U N E 1 , 2 0 1 1

CRCP: Concrete Design Requirements

Fresh Concrete Properties

Hardened Concrete

Mechanical Properties

Chemical Properties

Durability

Tikalsky – University of Utah

Tikalsky – University of Utah

Fresh Concrete Properties

Low to Moderate Slump

Reduce subsidence

Placement without excessive manipulation

3.5 to 5.0% Air

Mitigates damage from freezing and thawing

Modest amounts reduce scaling

Concrete Requirements for CRCP

Moderate Strength

Low Shrinkage

Modest Strength Development

Low Thermal Expansion

Blended Cement to resist ASR, etc…

Low Diffusion Concrete

Tikalsky – University of Utah

Moderate Strength

3500 to 4000 psi minimum 28-day compressive strength

Higher strength concrete develops higher modulus and stiffness (restraint)

Lower strength concrete creeps more

Lower strength concrete has lower amounts of paste

Tikalsky – University of Utah

Low Shrinkage

Less than 500 maximum 28-day shrinkage

Larger size maximum size aggregates shrink less

Lower paste content concrete shrinks less

Moderate w/cm 0.42-0.47 is easily placed and shrinkage is modest

Well-graded aggregates and coarse sand

PCA, Kosmatka'

Tikalsky – University of Utah

Modest Strength Development

28-day to 7-day strength ratio < 1.25

Rapid strength develop high stiffness at early age

Plastic strains develop lower stresses and reduce cracking of concrete

Drying shrinkage stains are reduced in impact

Tikalsky – University of Utah

Low Thermal Expansion

Thermal Expansion of aggregates less than 6.0 x 10-6 / F

Reduces thermal stresses; thereby reduces cracking.

Reduces diurnal and other cyclic strains

Tikalsky – University of Utah

Blended Cements

Reasons for Blending Cost savings

Increased production

Energy savings

Reduce carbon footprint

Other Factors

Sulfate resistant

ASR resistant

Lower heat

Low permeability

Type IS 25-70% granulated blast

furnace slag

Silicates and alumino-silicates with calcium

Type IP 15-40% fly ash or natural

pozzolan

Silicates and alumino-silicates with calcium

Tikalsky – University of Utah

Pozzolans

Low Calcium Fly Ash; Class F

GGBFS: Grade 100 or 120

Natural Pozzolans

Tikalsky – University of Utah

Low Diffusion Concrete

Resist Corrosion Potential

Moderate W/CM

Pozzolans

Resist Saturation during F-T cycles

}Macro-Cell Action

e-

Anode

Cathode

Local Anode Local Cathode

e-

O2 & MoistureDeicing Salts (Cl-)

Micro-Cell Action

Tikalsky – University of Utah

Recommended Air Contents

Tikalsky – University of Utah

THANK YOU!

Transportation Research Board WebinarOrganized by TRB Committees:Rigid Pavement Design (AFD50)

Portland Cement Concrete Pavement Construction (AFH50)

Improved Practices for Continuously Reinforced Concrete Pavements: Part 2 - Construction

CRCP ConstructionMichael Plei, Commercial Metals Company, Inc.

June 1, 2011

What Affects CRCP Performance?

CRCP performance is sensitive to design parameters: slab thickness, amount of longitudinal bars, base friction, temperature assumptions

CRCP performance is sensitive to construction quality: bar placement, concrete material uniformity, consolidation, curing, weather conditions

CRCP Layers

Aggregate Base

Separation Layer

CRC Pavement

Cement- or Lime-Treated Base

Separation Layer

CRC Pavement

Subgrade Subgrade

Outline – Constructing CRC Pavement

Pavement Materials

Base/Subbase/Subgrade

Steel Reinforcement

Concrete

Paving Operation

Special Details

Outline – Constructing CRC Pavement

Pavement Materials

Base/Subbase/Subgrade

Steel Reinforcement

Concrete

Paving Operation

Special Details

Base/Subbase/Subgrade CRCP performance

depends on Support – should be

uniform

Friction between base or separation layer and slab: friction forces develop due to restraint of pavement slab expansion/contraction

Base provides support for control of grade, bar placement & paving Ensure grade, density &

surface meets specs

Steel Reinforcement

Materials

Support

Placement

Splicing/Lapping

Steel Reinforcement – Materials

Deformed steel reinforcing bars conforming to ASTM A615/AASHTO M31

Grade 60 (metric grade 420), yield strength 60,000 psi

Main bars are longitudinal Bar sizes #4, #5, #6, #7 -

depending on slab thickness & percent steel

Occasionally epoxy coated, if in corrosive environment

Longitudinal Bars Carry tensile stress that is transferred from concrete

Vertical placement affects performance: load transfer, crack width, crack spacing, resistance to corrosion

Quantity of bars based on ratio of steel/concrete area, shown as %

Industry targets range from 0.60 to 0.80%

With these percentages stress in bars kept below ¾ of yield strength

12” slab with #6 (Metric #19) bars at 5” o.c. = 28 bars = 0.73% steel

8” slab with #5 (Metric #13) bars at 6” o.c. = 25 bars = 0.65% steel

Check for minimum Bond Area of 0.030 sq in. per cubic in. of concrete. Source: FHWA "Technical Advisory Continuously Reinforced Concrete Pavement“ T5040.14, June 5, 1990

Longitudinal Bars Standard mill lengths are 60’

Brought to jobsite in bundles

Bars should not have kinks or bends that may prevent proper assembly, placement or performance

Transverse Bars

Most often placed first to support longitudinal bars Used as tie bars in multi-lane paving Provide some restraint if longitudinal cracks

develop

Bar Placement Manual Method:

seat bars on bar supports prior to concrete slip-forming

Common work-rate = 1000 lbs/manhour

Work-rate with TBAs = 1300 lbs/manhour, according to AHT

Mechanical Method (out of favor): vibrate into concrete during concrete slip-forming

Bar Supports

Arrangement & spacing of supports is such that bars are supported in proper position without permanent deflections or displacement occurring during paving (in excess of allowed tolerances)

Should have sufficient bearing at base to prevent overturning & to avoid penetration into base

Should not impede placing & consolidation of concrete

Welding of individual supports to transverse bars is permitted

Individual Bar Supports

Continuous Bar Supports

Bar Placement

Size Weight per 60’, lbs

#4 40

#5 63

#6, shown 90

#7 123

Bar Placement

Typical horizontal

placement

tolerances +/- ½”

Bar Placement

Longitudinal secured

by wire ties or clips

Welding longitudinal

bars to transverse

bars is not permitted

Lap Splices of Bars Only applies to long.

bars Splicing pattern

staggered or skewed to avoid rebar/concrete interference

Minimum lap length to ensure sufficient load transfer thru bond development length

Splices secured with 3 tie wires

Outline – Constructing CRC Pavement

Pavement Materials

Base/Subbase/Subgrade

Steel Reinforcement

Concrete

Paving Operation

Special Details

Test Slab or Mock-UpTest or Mock-up

Slabs

Pre-Paving Rebar Inspection

Inspect:

Depth & cover

Horizontal placement

Lap lengths & splice pattern

Tying of bars

Bar supports

Concrete Paving – Daytime

Concrete Paving – Nighttime

Steady Concrete Delivery

Have a good truck haul plan:

Are truck routes well planned out?

Are at least 2 trucks waiting to avoid stops/starts?

Are biggest haul trucks being used to maintain continuity?

Concrete Delivery

Concrete Delivery

Concrete DeliveryConcrete Placement

Concrete Vibrating

Maintain uniform concrete mix

Concrete Consolidating

Provide proper consolidation

Concrete FinishingConcrete Finishing

Concrete TexturingConcrete Curing

If the evaporation rate is too low, then potential for long crack spacing patterns exists

If the evaporation rate is too high, then short crack spacing patterns & reduced concrete strengths can result

Joint Sawing

Only need to saw

a longitudinal joint

Inspection During Paving Concrete materials testing

Slab thickness measurement

Longitudinal bar depth measurement

Ambient Conditions During Paving

Understand effects of changes in temperature, wind, relative humidity, etc., since they affect concrete volume changes

Use FHWA “Hiperpav” to evaluate changes in ambient conditions or materials at jobsite

CRCP Crack Formation A crack will occur when & where concrete stress

exceeds tensile strength of concrete

In CRCP, most transverse cracks form at very early ages before pavement is open to traffic

If concrete slab is assumed to be homogeneous, the new crack will occur at midpoint between 2 previously formed transverse cracks because maximum concrete stress due to environmental loads occurs at the midpoint

Because tensile strength of concrete is governed by weakest element in it, however, variation exists in concrete tensile strength from location to location

CS = crack spacing

Edge, 12” CRCP

Crack at 2 days

I-75 Tifton, Georgia, 2010

Hot Weather Paving

Texas: concrete temperature max. at 95 F, wetting of base & rebar just in front of paver

Virginia: outside temperature max. 104 F

Illinois: concrete temperature max. at 95 F, whitewash on asphalt base

Georgia: no extra measures taken

Australia NSW: “Concrete Placing Concrete shall not be placed when the air temperature in the shade is below 5 C or above 38 C. The temperature of the concrete shall be neither less than 10 C nor more than 32 C”

Outline – Constructing CRC Pavement

Pavement Materials

Base/Subbase/Subgrade

Steel Reinforcement

Concrete

Paving Operation

Special Details

Transverse Construction Joints Placed whenever paving

operations interrupted for more than 30 minutes

Weak spot with no natural aggregate interlock, rely solely on longitudinal bars for load transfer

Add additional bars thru each side of joint

No lap splices near joint

Special manual concreting: concern, especially at corners

Transverse Construction Joints

Stabilize adjacent slab temp. if more than 5 days elapse before continuation to reduce potential high tensile stresses in longitudinal bars

Accomplished by placing insulation material on completed slab for distance from free end for specified time prior to placing new concrete

Bad construction joint (above);

bad construction joint repair

End Terminals – Wide Flange

To accommodate

movement, use wide

flange (Burdell) joints

End Terminals – Anchor Lugs

To resist movement, use anchor lugs (rely on resistance of soil; cannot be used for cohesionless soils)

Anchor lug terminal consists of 3-5 transverse reinforced concrete lugs

Placed in subgrade prior to pavement placement

Rebar extends up from lugs to tie to pavement

Shoulders for CRCP Shoulders with edge support (tied) – minimal maintenanceJointed plain concrete (OK, IL)

o Must be paved after CRCP mainline reaches satisfactory strengtho Keep tie bars within middle 1/3 of JPC panel, away from transverse joint;

use bondbreaker

Continuously reinforced concrete (TX, GA, AR, AZ)o Same section as mainline

Shoulders without edge support – requires maintenanceRoller-compacted concrete (GA)Asphalt

Widened mainline slab (widened lane)Usually with roller-compacted or asphalt shoulders (VA, GA,

IL ISTHA)At least 13 feet wide, striped at 12 feetMoves stresses due to loads away from slab edge

Shoulders for CRCP

FHWA Technical Advisory T5040.29 recommends that shoulders be constructed of the same materials as the mainline pavement to facilitate construction, improve performance, and reduce maintenance costs

Benefit of CRCP shoulders:Can be constructed with mainline lanes or

separately, in no special sequenceCan be used as a future travel lane

Recommended to offer alternate shoulder types to contractors to price according to chosen construction staging

Blockout for Utility Access

Construction Wrap-Up

Familiarization with unique CRCP aspects

Refer to Project specifications, special provisions, Pavement Manual, Standard Drawings

Most important: bar placement, concrete consolidation, curing

Transverse construction joint & end terminal details

Recognition of effects of changes in ambient conditions

CRCP Ready for 30+ Years

CRCP Ready for 40+ Years

Continuously Reinforced Concrete Pavement (CRCP) Repairs

Jeffery RoeslerAssociate Professor

University of Illinois at Urbana-Champaign

June 1, 2011

CRCP Repair and Rehabilitation

Distress Mechanisms

Temporary PatchingAsphalt full-depth repairs

Permanent PatchingPartial- and Full-Depth Repairs

Terminal Joint Repair

RehabilitationOverlays (AC or PCC)

Reconstruction

CRCP Repair and Restoration

Determine distress (type, extent, severity) Repair isolated/localized areas of distress to

preserve pavementFull-Depth Repair (FDR)Partial-Depth Repair (PDR)

Prevent reoccurrence by delaying and/or stopping deteriorationRetrofit w/ tied shouldersRetrofit with edge drains

Restore ride quality, e.g., diamond grinding or AC overlay

CRCP Distress Types Punchout

Transverse crack deterioration

Moderate/high severity cracks

Spalling along cracks

Rebar corrosion, steel overstress/yielding

Localized distress: construction & terminals joint

Longitudinal and horizontal cracking

Plastic shrinkage cracks

Blowup

D-cracking & ASR

Existing patch repair deterioration

D-Cracked Concrete (Freeze-Thaw)

I-39 CRCP Photos (16 yr)

Spalling along Transverse Cracks

Aggregate shape & bond with paste

Poor finishing, curing

Infiltration of incompressibles

Construction Joint Deterioration

Inadequate vibration & consolidation

Inadequate reinforcing details across cold joint

Stabilize adjacent slab temperature if >5 days elapsed.

Longitudinal Cracking Crack paralleling sawed centerline joint:

Caused by late sawing or loading slab before sawing

Crack in interior (center 8 ft) of lane:

Due to temp. stresses, base problems

Can lead to crack spalling, eventual faulting, & infiltration of water causing further damage to foundation

Horizontal Cracking Punchout-like distress

with Y- & X-shaped cracks forming “fishheads”

Delamination occurring at level of reinforcing steel when at mid-slab

High reinforcement amounts, difficulty in consolidation

Shear stress in slabs has parabolic distribution, with highest stress at mid-slab

Horizontal Cracking (Cont.)

CRCP Edge Punchouts Common distress Punchouts formation steps:Shoulder-slab seal lossMoisture infiltration leads to

erosion, loss of supportErosion, loss of support

leads to slab edge deflection under heavy traffic

Slab edge deflection leads to longitudinal cracking

Transverse cracks deteriorate & lose aggregate interlock

Concrete breaks into blocksSteel bars yield or rupture

CRCP Repair Basics for Success

Patch Timing Deterioration extent Restore support layer Proper load transfer design & maintain

steel continuity Quality of construction & repair materials Curing & opening to traffic Consider ambient conditionsAvoid crushing of patch concrete or

adjacent existing concrete

CRCP Full-Depth Repair PurposeReplace distressed concrete

oPunchouts

oDeteriorated transverse/longitudinal cracks

oLocalized distress

oBlow-ups

oD-cracking

oDeteriorated repairsPrevent further deterioration of CRCPPrepare for eventual resurfacing

Full-depth bituminous patches not recommendedTemporary repair

Full-depth patches with plain concreteRarely recommended

Full-Depth Repair Procedure

Define the patch area

Saw and remove the concrete

Prepare the patch area

Install reinforcement

Place and finish concrete

Cure the concrete

Open to traffic

National Guidelines for CRCP Repair Minimum repair length6 ft if rebar is tied/lap spliced

4 ft if rebar is mechanically-spliced or welded

Transverse cut should be perpendicular to centerlineCracks tend to cross skewed cuts

If not possible, cut along crack

Repairs should not be closer than 18 in.

Full width patches recommendedMinimum repair width 6 ft

Replace as single area

Full & Partial-Depth Sawcuts

Source: NHI, 2001

CRCP Full-Depth Repair (Plan)

CRCP Full-Depth Repair (Profile)

Patch Reinforcing Steel Placement

Match existing rebar sizes

Connect to existing rebar

Tied lap splice, mechanical or welded splice

Provide support (chairs) to prevent bending

Provide minimum 2.5 inch concrete cover

Provide supplemental transverse rebar

Drilling & grouting some rebar into existing concrete can be used to maintain continuity

Reinforcing Steel Placement

Source: NHI, 2001

Partial-Depth Repair Repair for localized distress

that exist in upper 1/3 of slab or surface

Retard future deterioration Identify repair dimensions

Locate unsound concrete; area extends beyond visible distress

Repairs are square or rectangular

Min. dimensions of 100 x 300 mm (4 x 12 in.)

Remove concrete by sawing & chipping to sound concrete

Clean repair area by sandblasting or high-pressure water blasting, followed by air blowing

Illinois DOT Repair & Rehabilitation Recommendations

Full-depth repair

NO partial-depth repair

Fiberglass fabric repair system

No longer used

Asphalt overlay

Concrete overlays of CRCP

Unbonded CRCP overlays

CRCP Patching PerformanceIllinois DOT

Lap splices in patches Tied splices >16 in. for #5 bar; 22 in. for #6 bar

Welded splices >8 in.

Patch lengthMin 4.5ft (tied steel) and 3.0ft (welded)

18 inches from transverse crack

Full width patches (preferred)

Extra deep concrete patches (CRCP, subbase, subgrade)

Partial-depth patches for concreteDon’t use partial depth AC patches

Full-depth asphalt lasts 1 to 2 years

No steel patches didn’t perform well esp. w/ D-crackingSource: Darter et al., 1982

IDOT StudyCRCP Patch Performance

Conventional CRCP patch provided best performance with:Transverse reinforcement @ 12-in c-c

Slight improvement w/ steel fibers

Drilled Tie bar as anchorage for longituidnal steel in CRCP patchesDidn’t work well

Unsuccessful use of mechanical coupler

Source: Jenkins 1998

IDOT Patching Technique

Class A PatchSource: IDOT

IDOT Patching Technique, con’t

Class A PatchSource: IDOT

IDOT Patching Technique, con’t (2)

Class A PatchSource: IDOT

IDOT Patching Technique, con’t (3)

Class A PatchSource: IDOT

SHRP2 Project R05

Precast reinforced panels used with slots at top and bottom

Based on South Carolina DOT approach

Source: Tayabji, 2010

Other Restoration Methods

Diamond grinding Lane-shoulder joint sealing Shoulder repairTied shoulder or extended laneAC shoulder repair

Pressure grouting and slab jacking Subdrainage/retrofitted edge drains Cathodic protection (?) Cross-stitching longitudinal cracks

Repair of Expansion/Terminal Joints

Terminal joints accommodate movement minimizing potential for damage to adjacent structures

Deterioration of joint causes:

Spalling

Water Infiltration

Roughness

Terminal Joint Repair

Poor Section I-57/I-64 NB

Rehabilitation/Resurfacing

Rehabilitate to increase structural and functional capacity

Rehabilitation when number of failures (i.e. punchouts) exceed:10 to 20 PO per mile (IDOT)

10 PO per mile (M-E PDG)

Pavement resurfacing to extend service lifePavement has medium levels of distress

Preservation is no longer effective

Resurfacing and Reconstruction

Resurfacing methods

Bonded concrete overlay

Unbonded concrete overlay

oLong-term rehabilitation solution

HMA overlay over intact CRCP

oIncrease functional capacity and cost-effective

HMA overlay over rubblized CRCP

oRepairs pavements with high level of distresses

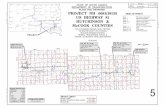

Unbonded CRCP (2002)Clark County, IL

4” Asphalt BASE

8” CRCPBITUMINOUS

SHOULDER

BITUMINOUS OVERLAY

BITUMINOUS OVERLAY

MILL OR OVERLAY TO GRADE LINE

12” UNBONDED

CRCP OVERLAY

12” PCC

SHOULDERS12” PCC

SHOULD.

12 ft. 6 ft.24 ft.

Proposed I-57 / I-64 Mt. Vernon (2011)

Mill existing HMA overlay

Rubblize existing 8-inch CRCP

Place 3-inch HMA interlayer

10.5-in. CRCP overlay w/ 0.7% steel

CRCP Repair / Rehabilitation Summary

Full-Depth RepairPatch size, bar continuity, support layer

Partial-Depth Repair – less common

Asphalt patching – minimal effectiveness

Overlay optionsAC overlay of CRCP

AC overlay w/ Rubblization

CRCP Unbonded Overlay of Existing CRCP

Bibliography Zollinger, D. G. and E. J. Barenberg, “Continuously Reinforced Pavements:

Punchouts and other Distresses and Implications for Design,” University of Illinois and Illinois Department of Transportation, Report No. FHWA-IL-UI-227, 1990.

Hall, K. T., M. I. Darter, and W. M. Rexroad, “Performance of Bare and Resurface JRCP and CRCP on the Illinois Interstate Highway System-1991 Update,” University of Illinois and Illinois Department of Transportation, Report No. FHWA-IL-UI-244, 1993.

Darter, M. I., T. L. Barnett, and D. J. Morrill, “Repair and Preventative Maintenance Procedures for Continuously Reinforced Concret Pavement,” University of Illinois and Illinois Department of Transportation, Report No. FHWA-IL-UI-191, 1982.

“Construction Handbook on PCC Pavement Rehabilitation,” Federal Highway Administration, US Department of Transportation, January 1984.

“Resurfacing of D-cracked CRC Pavements,” Construction Memorandum No. 95-59, Bureau of Materials and Physical Research, Illinois Department of Transportation, January, 1995.

Talley, A., “ The Dan Ryan Expressway: A look back (and forward) at the CRCP that works,” Long Life Concrete Pavements Conference, 2006.

Bibliography (Cont.) Pava, J. D., “Performance Monitoring of Mechanistically-Designed

Pavements,” , Bureau of Materials and Physical Research, Illinois Department of Transportation, Report No. FHWA-IL-PRR-159, 2011.

Jenkins, P. F., “Design, Construction, and Analysis of CRCP Patching Techniques,” , Bureau of Materials and Physical Research, Illinois Department of Transportation, Report No. FHWA-IL-PRR-124, 1998.

Tayabji, S., “Jointed Full-depth Repair Of Continuously Reinforced Concrete Pavements,” FHWA ACPT Techbrief.

"Unbonded Concrete Overlay - Pavement Interactive." Welcome to Pavement Interactive! - Pavement Interactive. 30 May 2011 <http://pavementinteractive.org/index.php?title=Unbonded_Concrete_Overlay>.

Lenz, R. W., “Pavement Design Guide,” Texas Department of Transportation, 2011.

Edward , R. Harrington, William E. Uffner, and Richard T. Janicki. "Chemically Modified High Oil Asphalt - Owens-Corning Fiberglas Corporation." Patent Searching and Invention Patenting Information. Web. 30 May 2011. <http://www.freepatentsonline.com/4485145.html>.