THIN-FILM MEASUREMENTwcam.engr.wisc.edu/Public/Tools/Analysis/Filmetrics F20 technical...The two...

-

Upload

truongquynh -

Category

Documents

-

view

219 -

download

5

Transcript of THIN-FILM MEASUREMENTwcam.engr.wisc.edu/Public/Tools/Analysis/Filmetrics F20 technical...The two...

ADVANCED THIN-FILM MEASUREMENT SYSTEMS

TAKING

THE

MYSTERY

OUT OF

THIN-FILM MEASUREMENT

IntroductionThin film

Very thin layers of material that are deposited on thesurface of another material (thin films) are extremelyimportant to many technology-based industries. Thinfilms are widely used, for example, to provide passiva-tion, insulating layers between conductors, diffusionbarriers, and hardness coatings for scratch and wearresistance. The fabrication of integrated circuits con-sists primarily of the deposition and selective removalof a series of thin films.

Films typically used in thin-film applications rangefrom a few atoms (<10Å or 0.0001 µm) to 100 µmthick (the width of a human hair.) They can be formedby many different processes, including spin coating,vacuum evaporation, sputtering, vapor deposition, anddip coating.

To perform the functions for which they weredesigned, thin films must have the proper thickness,

composition, roughness, and other characteristicsimportant to the particular application.

These characteristics must often be mea-sured, both during and after thin-

film fabrication.

The two main classes of thin-film measurement are opticaland stylus based techniques.Stylus measurements

measure thickness androughness by monitoringthe deflections of a fine-tipped stylus as it isdragged along the surface of

the film. Stylus instrumentsare limited in speed and

accuracy, and they require a“step” in the film to measure

thickness. They are often the pre-ferred method when measuring

opaque films, such as metals.

Optical techniques determine thin-film characteris-tics by measuring how the films interact with light.Optical techniques can measure the thickness, rough-ness, and optical constants of a film. Optical constantsdescribe how light propagates through and reflects froma material. Once known, optical constants may berelated to other material parameters, such as composi-tion and band gap.

Optical techniques are usually the preferred methodfor measuring thin films because they are accurate,nondestructive, and require little or no sample prepara-tion. The two most common optical measurementtypes are spectral reflectance and ellipsometry. Spectralreflectance measures the amount of light reflected froma thin film over a range of wavelengths, with the inci-dent light normal (perpendicular) to the samplesurface. Ellipsometry is similar, except that it measuresreflectance at non-normal incidence and at two differ-ent polarizations. In general, spectral reflectance ismuch simpler and less expensive than ellipsometry, butit is restricted to measuring less complex structures.

n and k DefinitionsOptical constants (n and k) describe how light prop-

agates through a film. In simple terms, the electromag-netic field that describes light traveling through a mate-rial at a fixed time is given by:

where x is distance, λ is the wavelength of light, and nand k are the film's refractive index and extinction coef-ficient, respectively. The refractive index is defined asthe ratio of the speed of light in a vacuum to the speedof light in the material. The extinction coefficient is ameasure of how much light is absorbed in the material.

A • cos (n x) • exp (-k x)

A B O U T T H I N - F I L M M E A S U R E M E N T S

THIN-FILM MEASUREMENT

2πλ

2πλ

2

Spectral Reflectance BasicsSingle Interface

Reflection occurs whenever light crosses the interfacebetween different materials. The fraction of light that is

reflected by an inter-face is determinedby the discontinuityin n and k. For lightreflected off of amaterial in air,

To see how spectral reflectance canbe used to measure optical constants, consider thesimple case of light reflected by a single nonabsorbingmaterial (k=0). Then:

Clearly, n of the material can bedetermined from a measurement of R. In real materials,n varies with wavelength (that is to say, real materialsexhibit dispersion), but since the reflectance is known atmany wavelengths,n at each of thesewavelengths is alsoknown, as shownhere.

Multiple InterfacesConsider now a thin film on top of another material.

In this case both the top and bottom of the film reflectlight. The total amount of reflected light is the sum ofthese two individual reflections. Because of the wavelikenature of light, the reflections from the two interfacesmay add together either constructively (intensities add)

or destructively(intensities sub-tract), dependingupon their phaserelationship.Their phase rela-tionship is deter-mined by thedifference inoptical path lengths of the two reflections, which in turnis determined by thickness of the film, its optical con-stants, and the wavelength of the light. Reflections arein-phase and therefore add constructively when the lightpath is equal to one integral multiple of the wavelengthof light. For light perpendicularly incident on a transpar-ent film, this occurs when , where d is thethickness of the film and i is an integer (the factor of twois due to the fact that the light passes through the filmtwice.) Conversely, reflections are out of phase and adddestructively when the light path is one half of a wave-length different from the in-phase condition, or when

. The qualitative aspects of these reflec-tions may be combined into a single equation:

From this, we can see thatthe reflectance of a thinfilm will vary periodically with 1/wavelength, which isillustrated below. Also, thicker films will exhibit a greaternumber of oscillations over a given wavelength range,while thinner films will exhibit fewer oscillations, andoftentimes only part of an oscillation, over the samerange.

R ≈ A + B cos nd( )4πλ

R =(n - 1)2 + k2

(n +1)2 + k2

2nd = (i +1/2)λ

2nd = iλ

R = n -1n +1

2

Determination of thickness (d) Determination of refractive index (n)

d = 500 Å d = 5000 Å d = 20,000 Å n = 3 n = 4 n = 5

3

Crystalline Semiconductor:

Amorphous Semiconductor:

A B O U T T H I N - F I L M M E A S U R E M E N T S

The amplitude and periodicity of the reflectance ofa thin film is determined by the film's thickness,optical constants, and other properties such as inter-face roughness. In cases where there is more than oneinterface, it is not possible to solve for film propertiesin closed form, nor is it possible to solve for n and k ateach wavelength individually. In practice, mathemati-cal models are used that describe n and k over a rangeof wavelengths using only a few adjustable parameters.A film's properties are determined by calculatingreflectance spectra based on trial values of thicknessand the n and k model parameters, and then adjustingthese values until the calculated reflectance matchesthe measured reflectance.

Cauchy:

Amorphous Semiconductor:

Mathematical Models for n & k

Determining Film Properties from Spectral ReflectanceModels for n and k

There are many models for describing n and k as afunction of wavelength. When choosing a model for aparticular film, it is important that the model be able toaccurately describe n and k over the wavelength rangeof interest using as few parameters as possible. Ingeneral, the optical constants of different classes ofmaterials (e.g., dielectrics, semiconductors, metals, andamorphous materials) vary quite differently with wave-length, and require different models to describe them(see below.) Models for dielectrics (k=0) generally havethree parameters, while nondielectrics generally havefive or more parameters. Therefore, as an example, tomodel the two-layer structure shown below, a total of18 adjustable parameters must be considered in thesolution.

n(λ) = A + B + CB Cλ2 λ4

k(λ) = 0

ε2(E)= 2nk = ∑ • If E > Eg , or = 0 if E < Eg

AiCiE0i (E-Egi)2 1

(E2-E0i2)2+Ci

2E2 E

Fitting parameters: ε1(∞), A1, C1, Eg1, E01, … (total of 5, 9 or 13)

ε1(E)= n2-k2 = ε1(∞) + ds (Kramers-Kronig relationship)2P sε2(s)π s2-E2∫∞

0

j =1, 2 or 3

i =1

Fitting parameters: ε1(∞), A1, B1,E01, … (total of 4,7 or 10)

ε1(E)= n2-k2 = ε1(∞) + ds (Kramers-Kronig relationship)2P sε2(s)π s2-E2∫∞

0

ε2(E)= 2nk = ∑Ai

Bi+(E-E0i)2

j =1, 2 or 3

i =1

Fitting parameters: A, B, C (total of 3)

Crystalline Semiconductor:

4

Number of Variables,Limitations of Spectral Reflectance

Spectral reflectance can measure the thickness, rough-ness, and optical constants of a broad range of thinfilms. However, if there is less than one reflectanceoscillation (ie. the film is very thin), there is less infor-mation available to determine the adjustable model para-meters. Therefore, the number of film properties thatmay be determined decreases for very thin films. If oneattempts to solve for too many parameters, a uniquesolution cannot be found; more than one possible com-bination of parameter values may result in a calculatedreflectance that matches the measured reflectance.

An example of the reflectance from a very thin film,50Å of SiO2 on silicon is shown below, where it is com-pared to the reflectance from a bare silicon substrate. Inthis case, measuring the thickness, roughness, and n ofthe SiO2 requires five parameters to be determined.Clearly, the change in the spectra caused by adding 50Åof SiO2 does not require five parameters to describe, anda unique solution cannot be found unless some addi-tional assumptions are made.

Depending upon the film and the wavelength rangeof the measurement, the minimum single-film thicknessthat can be measured using spectral reflectance is in the10Å to 300Å range. If one is trying to measure opticalconstants as well, the minimum thickness increases tobetween 100Å and 2000Å, unless minimal parameteriza-tion models can be used. When solving for the opticalproperties of more than one film, the minimum thick-nesses are increased even further.

Spectral Reflectance versus EllipsometryGiven the restrictions listed above, spectral reflectance

can be used to measure a large percentage of technologi-cally important films. However, when films are too thin,too numerous, or too complicated to be measured withspectral reflectance, oftentimes they can be measuredwith the generally more powerful technique of spectro-scopic ellipsometry. By measuring reflectance at non-normal incidence (typically around 75° from normal)ellipsometry is more sensitive to very thin layers, and thetwo different polarization measurements provide twice asmuch information for analysis. To carry the idea evenfurther, variable-angle ellipsometry can be used to takereflectance measurements at many different incidenceangles, thereby increasing the amount of informationavailable for analysis.

The following pages of this brochure describe spectralreflectance systems available from Filmetrics. If you areuncertain whether spectral reflectance or ellipsometry isappropriate for your film measurements, please call us todiscuss your application. If spectral reflectance cannotsatisfy your needs, we will be happy to refer you to areputable source for ellipsometry.

5

F I L M E T R I C S A D V A N C E D R E F L E C T O M E T R Y

Thickness, refractive index, andextinction coefficients are measuredquickly and easily with Filmetrics’advanced spectrometry systems.Simply plug the Filmetrics systeminto your computer’s parallel portand start making measurements.The entire system sets up inminutes and measurements can bemade by anyone with basic com-puter skills. This simple hardwareand intuitive software providesthin-film knowledge to a wholenew group of users.

From near infrared to ultraviolet

Systems are available with wave-lengths from 215 nm to 1700 nmenabling thickness measurementsof films 10 angstroms to 350 µmthick. The Filmetrics systemsmeasure transparent thin filmsmade from virtually all commonmaterials.

Easy to use softwareThe familiar and user friendly

interface provided by Filmetricssoftware is quickly mastered.Measurements are made at aboutone per second. Measured data,along with meaurement details, areeasily saved and exportedd withstandard Windows file saving andclipboard methods. Plus, DynamicData Exchange allow for easy inte-gration with other programs.

Thin-Film Measurements on your bench top

AWA R D W I N N I N G P R O D U C T S

100100100Issue:

File Name: Artist:

Completed: Modified:

To Network:

--- XLogo/100b BJ 10-1-96 0-00-96 0-00-96

Art Director

Prod. Editor

Mag. Editor In Network:

YES NO

RD SIGN - OFF Date:

Date:

Date:

R&D 100 AwardThe Filmetrics in-situ system, Model

F30, was selected as one of the 100 mosttechnologically significant new productsof 1997 by R&D Magazine.

6

COMPLEX MEASUREMENTS MADE SIMPLE

Choose from a listof common filmtypes, or define your own

Both the measured and calculated reflectance spectra are displayed so that theintegrity of the measurement may easily be judged. The measured n and k curvesmay also be plotted.

Measurementresults are displayedin an easy-to-readformat

A wide range of reflectance wavelengths areavailable, from 220 to 1700 nm

One measurement– One mouse click

Photonics Spectra Circle of ExcellenceThe Filmetrics F20 was chosen as one of the 25 most

significant new products of 1998 by Photonics SpectraMagazine.

7

Semiconductor Process Films— Lab / Process

Filmetrics measurement systems areroutinely used to measure the thickness,roughness, and optical constants ofoxides, SiNx, photoresist, and othersemiconductor process films. In addi-tion to these single layer applications,many two- and three-layer film measure-ments are also possible. An example ispolysilicon/SiO2 on silicon, which isused in SOI applications. The screen tothe right shows a typical measurementresult for the structure modeled onpage 4.

F I L M E T R I C S A D V A N C E D S P E C T R O M E T R Y

REAL WORLD APPLICATIONS

In-Situ Measurements —

The flexible optical probe assembly makes on-line and in-situthickness measurements possible. All that is required is opticalaccess for normal-incidence reflectance measurements. Call usfor more details about interfacing with your productionequipment.

8

Optical Coatings —

Thin films are used for scratch resistanceand/or antireflection coatings in manyindustries. Automotive plastics, eyeglasslenses, and many plastics packaging applica-tions use thin films. For hardcoats, a primerlayer is often applied first for improved filmadhesion. Filmetrics systems are capable ofmeasuring the thickness of these layers indi-vidually or simultaneously, regardless of thepresence of coatings on the backside of thesample.

Flat Panel Display Applications —

Proper polyimide and resist thicknesses are critical toyield in flat panel display manufacturing. Besides mea-suring these materials, Filmetrics systems can alsomeasure cell gap spacing, for both empty and filled cells.

9

F I L M E T R I C S F 2 0

F20Thin-Film Measurements inSeconds

Bench top measurements ofthickness, optical constants(n and k) and transmittance aremade quickly and easily by theModel F20. This versatile hard-ware can be configured to measuretransparent or translucent filmsthat are 30 Å to 350 µm in thick-ness. Typical accuracy is within afew angstroms. Spot size isadjustable over a wide range.

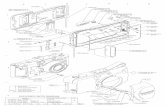

Accessories

A wide variety of stages, chucks,and special measurement heads areavailable to fixture most samplegeometries.

Surprisingly Low Price

Filmetrics has combined simplic-ity with affordable pricing to deliverbreakthrough value. ContactFilmetrics or your local reseller todiscuss your measurement applica-tion and learn how Filmetrics turnsthe expensive task of thin-film mea-surements into a simple and inex-pensive proposition.

Wafer chucks make samplehandling easy

Accessories are available for measuringnonstandard samples

Transmittance maybe measured with a simplestage modification

10

Turns Your Microscope into aFilm ThicknessMeasurement Tool

For thickness measurements onpatterned surfaces and other applica-tions that require a spot size as smallas 10 microns.

For most common microscopes,the F40 is a simple bolt-on attach-ment. Standard c-mount adapter pro-vided for CCD camera viewing ofmeasurement location.

In-Situ Measurements

For process applications, Filmetrics offers systems that need onlyoptical access. Interfaces to a wide range of control systems areavailable.

F I L M E T R I C S F 3 0 , F 4 0 & F 5 0

F40F30

F50Thickness Mapping System

Extends F20 thickness measurement functionality andintuitive operation to automated mapping of large areasamples.

Map sample uniformity in minutes. Five points to hun-dreds of points as fast as one second per point. Standardchucks available for up to 12” diameter wafers. Customchucks also available.

11

Filmetrics, Inc., 9335 Chesapeake Drive, San Diego, CA 92123(858) 573-9300 • Fax: (858) 573-9400 • E-mail: [email protected] our Web site: www.filmetrics.com

Specifications subject to change without notice

No part of this document may be duplicated without written consent from Filmetrics, Inc.

© 2006 Filmetrics, Inc. Rev. 02.06

Printed in the USA

12

Filmetrics, founded in 1995, has established itself as aninnovator in the thin-film measurement industry.Filmetrics offers a complete line of thin-film measure-ment products, ranging from tabletop instruments tofully automated semiconductor systems, with aninstalled base of more than 2,000 systems worldwide.We are continually developing new products and tech-nologies that deliver greater efficiency, superior ease-of-use and unparalleled support to the world of thin-filmmetrology.