The Economics of Ethanol from Sweet Sorghum

-

Upload

luiz-lacerda-fh -

Category

Documents

-

view

214 -

download

0

Transcript of The Economics of Ethanol from Sweet Sorghum

-

8/7/2019 The Economics of Ethanol from Sweet Sorghum

1/14

The Economics of Ethanol from Sweet SorghumUsing the MixAlco Process

Michael H. LauJames W. Richardson

Joe L. OutlawMark T. Holtzapple

Rene F. Ochoa

Lime water slurry

Air

Blower

Cooling wateror

heat source

PumpDrain pipe

Liner

Cover

Biomass

Gravel

Sugar Juice Grain LeavesBagasse

Fermentation Fermentation Co-generation Other uses

DDGS Ethanol Ethanol Electricity Heat

Sweet Sorghum

Pretreatment

fermentationDewater

Acid

springing

Hydrogenation

Lime kiln

Biomass

LimeCalcium carbonate

Carboxylate

salts

Carboxylic

acids

Mixedalcohols

Hydrogen

AFPCAgricultural and Food Policy Center

The Texas A&M University System

-

8/7/2019 The Economics of Ethanol from Sweet Sorghum

2/14

The Economics of Ethanol from Sweet SorghumUsing the MixAlco Process

Michael H. LauJames W. Richardson

Joe L. OutlawMark T. Holtzapple

Rene F. Ochoa

AFPC Research Report 062

August 11, 2006

AFPCAgricultural and Food Policy Center

The Texas A&M University System

-

8/7/2019 The Economics of Ethanol from Sweet Sorghum

3/14

Biomasshasthepotentialtoprovideasustainablesupplyofenergy.Ithasthefollowingadvan

tagesoverfossilfuels:

Renewablesourceofenergythatdoesnotcon

tributetoglobalwarmingasithasaneutra

effectoncarbondioxideemissions;

Biomassfuelshavelowsulfurcontentanddo

notcontributetosulfurdioxideemissions;

Effective use of residual andwastemateria

forconversiontoenergy;

Biomassisadomesticsource thatisnotsubject to world price uctuations or uncertainties

inimportedfuels.

However,animportantconsiderationwithbio

massenergysystemsisthatbiomasscontainsles

energyperpoundthanfossilfuels(SterlingPlan

et).Driedbiomasshas aheatingvalueof 5,000

8,000Britishthermalunits(BTU)perpoundwith

virtuallynoashorsulfurproducedduringcombus-

tion(Osburn,1993).Otherestimatesshowtheen

ergycontentofagriculturalresiduesinthe4,300to7,300BTUperpoundduetomoisturecontent

(http://bioenergy.ornl.gov/index.html).Incomplete

combustion of biomass produces organic matter

and carbon monoxide pollution. There is also a

socialdebate over theuse of landandwater for

foodproductionversusenergyproduction(ACRE

Mazza).Biomasscouldhaveanimportantimpact

onthesocio-economicdevelopmentofruralpopu

Figure 1: Sweet Sorghum and Grain Sorghum Trials nearAmarillo.Source: Travis Miller.

TheUnitedStatesisbecomingmoredependent

onethanolproductionas a renewablefuel

sourcetodecreasedependencyonforeignoil.

Theincreaseindemandforrenewablefuels,due

inparttotheEnergy Policy Act of 2005,hasledto

increasedresearchonalternativerenewablefuels

from biomass.One such avenueof research has

beentheconversionofbiomasstorenewablefuels,and specically sweet sorghum, as an ethanol fuel

stock.

Biomass Energy

Biomassisusedtodescribeanyorganicmatter

from plants that derives energy from photosyn-

theticconversion.Itisauniqueresourcewhichis

theonlyrenewablesourceofcarbon.Biomassisa

versatileenergysourcethatcanbeeasilystored

andtransformed intoliquidfuel, electricity,andheat through various processes (World Energy

Council,1994).Biogas,biodiesel,ethanol,metha-

nol,diesel,andhydrogenareexamplesofenergy

carriersthatcanbeproducedfrombiomass(Bas-

sam).

Traditional sources of biomass include fuel

wood,charcoal,andanimalmanure.Modernsourc-

esofbiomassareenergycrops,agricultureresidue,

andmunicipalsolidwaste(ACRE).Biomassfuels

areproducedmainlyin countries thathave sur-

plusofagriculturecommodities(Shapouri,2003).Biomasscanbedividedintothreecategories;sugar

feedstock(sugarcane),starchyfeedstock(grains),

and cellulose feedstock (brous plant material)

(Badger, 2002). Estimates show 512 million dry

tons of biomass residues ispotentiallyavailable

intheUnitedStatesforuseasenergyproduction

(Mazza).

Ithasbeenestimatedthatbiomasscouldsup-

plyallcurrentdemandsforoilandgasif6percent

of contiguousU.S. land areawas put into culti-

vation of biomass feedstocks (Osburn, 1993). Nonetcarbondioxidewouldbeaddedtotheenviron-

mentifbiomassenergyreplacedfossilfuels(Os-

burn, 1993). Fuelsderived from biomass are re-

newable and are sufciently similar to fossil fuels

toprovidedirectreplacement(Bassam).TheU.S.

DepartmentofEnergybelievesthatbiomasscould

replace10percentoftransportationfuelsby2010

and50percentby2030(SterlingPlanet).

-

8/7/2019 The Economics of Ethanol from Sweet Sorghum

4/14

lations and the diversication of the energy sup-

ply(RenewableEnergyWorld,2000).

Combustion, gasication, liquefaction, and bio-

chemicalaretheprimarywaysofconvertingbio-

mass into energy.Combustion burns biomass to

produce heat. Gasication produces gas that can

becombustibleinaturbine.Liquefactionproduces

anoxygenatedliquidthatcansubstituteforheat-ingoil.Thebiochemicalprocessconvertsbiomass

toliquidfuelthroughafermentationprocess(Ve-

ringa,ACRE).Biodieselandethanolareanexam-

pleofthisprocess.

Ethanolfromcellulosebiomassmaterialisstill

intheresearchanddevelopmentphase (Mazza).

Thereis currently onlyonecommercialcellulose

ethanol facility in operation (Canada) with an-

otherplantunderdevelopmentinSpain.Thelack

ofreal-worldexperiencewithcellulosebiomassto

ethanolproductionhaslimitedinvestmentintherst production facilities (California Energy Com-

mission,1999).Ethanolfromcellulosehasthead-

vantageofafaster rateof reactionthanthetra-

ditional fermentation process. However, ethanol

productionusingcelluloseiscostlyduetotheneed

foracidhydrolysisofthebiomasspricingitabove

expectedlong-rungasolineprices(Badger,2002).

MixAlco,aprocessdevelopedatTexasA&MUni-

versity,hastheadvantageofnoextraprocessing

ofthebiomassisneededforfuelconversion.

Sweet Sorghum

Sorghum (Figures 1 and 2) has been identi-

ed as a preferred biomass crop for fermentation

intomethanolandethanolfuel(MillerandCreel-

man, 1980; Creelman et al., 1981). Sorghum is

amongthemostwidely adaptablecerealgrasses

potentiallyusefulforbiomassandfuelproduction

(Hons,et al.,1986).Theadaptationofsorghumto

sub-humid and semiarid climates has extended

sorghumproductionintolargerregionsthanotherwarm-cerealgrains.

Sorghumisrelativelyinexpensivetogrowwith

high yieldsand can be used to producea range

ofhighvalueaddedproductslikeethanol,energy,

and distillersdried grains (Chiaramonti, et al.).

Sorghumcanproduceapproximately30drytons/

haperyearofbiomassonlowqualitysoilswith

lowinputsoffertilizerandlimitedwaterperdry

tonofcrop,halfofthatrequiredbysugarbeetand

athirdoftherequirementforsugarcaneorcorn

(RenewableEnergyWorld,2000). Moststoverorcropresidueisplowedbackinto

thegroundtoreplenishnutrientsandusedtore

ducesoilerosion.Smallamountsareharvestedfor

livestockfeed.Studiestoestimatesorghumresi

dueyieldforbiomassproductionaveragesapprox

imately1.75tons/acre(Franzluebbers,et al.,1995

Gallagher,et al.;Hons,et al,1986;Powell,et al.

1991).

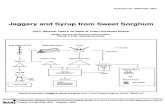

Figure 3 shows a simplied diagram of alterna

tiveprocessestoconvertsweetsorghumtoenergy

fuel. Corn processing is very similar as the twocrops are interchangeable. Sorghum production

can be separated into grains (for consumption

livestock feed, ethanol production), sugar juice

(extractedfromthecaneandusedforethanolpro

duction),andstover(usedforenergyproduction,

plastics) (Chiaramonti, et al.). Sorghum easily

convertstoothervalueaddedproductsmakingi

aversatileinput.

Figure 2: Texas A&M University Crop Scientist with HybridSorghum.Source: Travis Miller.

-

8/7/2019 The Economics of Ethanol from Sweet Sorghum

5/14

Althoughstudies(Gallagher,et al.;Wiedenfeld,

1984;CommitteeonBiobasedIndustrialProducts,

2000;MillerandCreelman,1980;Creelmanet al.,

1981) show sorghum stover is a good potential

candidateforcelluloseenergyproduction,nohis-

toricalvaluesareavailableforresiduecostsand

yields. Agriculture residue price for energy pro-

duction is based on the opportunity cost for the

growerplusharvestingandbalingcost.

Residues are desirablerawmaterials foren-ergy productionbecause utilizing them does not

require covering landcostwhichare included in

thegrainenterprise.Residue supplydependson

opportunity costs at the farm level and the as-

sumptionthatreasonablesoilconservationprac-

ticeswillbefollowed.Theamountofresiduesup-

pliedis anapproximation foracquisition cost by

processingfacilities.Growthisexpectedtooccur

in crop residue resource due to increase crop

yieldsanddeclininglivestockdemandforfor

age(Gallagher).

MixAlco Process

While the MixAlco process has not been

testedatacommercialscale,thetechnologyap

pearstoholdatremendousamountofpromise

TheMixAlcoprocesscanconvertawidevarietyofbiomassmaterialsuchassewersludge,ma-

nure, agriculture residues, agriculture crops

intoacidsandalcoholfuelsusingmicroorgan

isms,water,steam,limeandhydrogenthrough

an anaerobic process (Holtzapple, 2004). Two

different versions of the MixAlco process are

available. Version one is the original process

which produces mixed alcohol fuels. Version

Figure 3: Simplifed Diagram o Alternative Processes to Convert Sweet Sorghum to Energy Fuel.

Source: Chiaramonti, et al.

Sugar Juice Grain Leaves Bagasse

Fermentation Fermentation Co-generation Other uses

DDGS Ethanol Ethanol Electricity Heat

Sweet Sorghum

Pretreatment

fermentationDewater

Acid

springingHydrogenation

Lime kiln

Biomass

LimeCalcium carbonate

Carboxylate

salts

Carboxylic

acids

Mixed

alcohols

Hydrogen

Figure 4: Schematic o the MixAlco Process

Source: Holtzapple, 2004.

-

8/7/2019 The Economics of Ethanol from Sweet Sorghum

6/14

twoproducescarboxylateacidsandprimaryal-

cohols(ethanol). Figure 4 summarizes the MixAlco process.

Thisprocessdiffersfromtheuseofacidhydro-

lysisofbiomassmaterialtoproduceethanol.The

MixAlcoprocesscallsformixingbiomasswitha

nutrientsourcesuchasmanureorsewagesludge

ataratioof80percentto20percent.Thereare

fourphasestotheprocess:pretreatmentandfer-

mentation, dewatering, acid springing, and hy-

drogenation.

Duringthepretreatmentphase,biomass,lime

and calcium carbonate are blended and storedinalargepile.Airisblownupthroughthepile

whilewateristrickleddownthroughthepile.The

combinationof air and limeremoves ligninfrom

the biomass reducing the pHand rendering the

bio-matterdigestible.Thepileistheninoculated

withanaerobicmicroorganismsfromsalineenvi-

ronments.Themicroorganismsdigestthebiomass

formingcarboxylicacidscommonlyknownasvola

tile fattyacids (VFAs)such asacetic,propionic

Figure 6: Schematic o the Fermentation Facility.

Source: Holtzapple, 2004.

Concentrated

roduct

Fresh

water

Lime water slurry

Air

Blower

Cooling wateror

heat source

PumpDrain pipe

Liner

Cover

Biomass

Gravel

Figure 5: Schematic o the MixAlco Pretreatment Process

Source: Holtzapple, 2004.

-

8/7/2019 The Economics of Ethanol from Sweet Sorghum

7/14

Figure 7: MixAlco Pilot Plant Photos.Source: Martk T. Holtzapple.

andbutyricacids.TheVFAscombinewithcalcium

carbonatetoformcarboxylatesalts,whichareex-tractedfromthepilewithwater.

Fourreactorpilesarecreatedofequalvolume.

Figure5andFigure6showtheschematicofthe

pretreatmentandfermentationfacility.Eachre-

actoris shaped likeaconetominimizematerial

use.Fora44ton/hourfacility,eachreactorhasa

basediameterof397feetandis115feethigh.The

fuelpileiscoveredwithageomembranetoresist

theweather,wind,andsun.Thebaseconsistsofa

one-meter-thicklayerofgravelthatisdividedby

bermedwallstocollecttheVFAsolution. From fermentation,the VFAsolutioniscon-

centratedusing a vapor compression evaporator

during the dewatering phase. The fermentation

brothcontainingtheVFAsareheatedto100Cand

mixedwithhigh-molecular-weightacid(e.g.,hep-

tanoic) to acidify the fermentation broth.Steam

andlimearethanusedtoremovenon-condensable

gasesandcalciumcarbonate.Thetreatedfermen-

tationbrothisheatedto212Candwaterisevapo-

ratedfromthesolutionconcentratingthesalts.

Acidspringingconvertsthecarboxylatesaltsintocarboxylateacidandcalciumcarbonate.The

concentratedbrothisblendedwithcarbondiox-

ide and a low-molecular-weight tertiary amine

(triethyl) to form insoluble calcium carbonates

and amine carboxylates. Approximately 75% of

the calcium carbonate removed can be used in

the pretreatment and fermentation phase and

theremaining25percentisconvertedtolimeus-

ingaspeciallimekiln.Mostofthewateristhen

removedleavingaconcentratedaminecarboxyl

ate. Thecarboxylateacidsareblendedwithhigh

molecular-weight alcohols to form esters and

water. Thewater is evaporated andremaining

esters are mixed with high-pressure hydrogen

to form alcohols. The resulting ethanol fuel is

cooledandstoredfortransportationtobemixed

withgasolinefuel.Largestoragetanksareused

toholdtheethanolfueluntilshipping.

Byproducts

MixAlcoproduceswater,heat, carbon diox

ide,calciumcarbonate,andresidualbiomassas

byproducts.TheMixAlcofacilitycanbealmost

self-sufficient after the first year of operation

ifthenecessaryequipmentforlimeproduction,

waterrecycling,andsteamcapture,andboilers

are inplace.Water can bereused for the pre

treatmentandfermentationphase.Calciumcar-

bonatecanbemanufacturedintolimeandused

in the pretreatment and fermentation phase

Theheatgeneratedcanbetransferredtodryertoaidintheevaporationduringthedewatering

phase.

TheMixAlcostructure is completely sealed

fromtheoutsideenvironmentandallcarbondi

oxidegasproducedcanbecollected.Thecarbon

dioxidecanbereleasedonceitisscrubbedto

removeodororsoldtooilrefineriestobepumped

intooilwellsandaidinthecollectionofoil.How

ever,thecarbondioxidemarketisverylimited.

-

8/7/2019 The Economics of Ethanol from Sweet Sorghum

8/14

Incentive Packages -Location Choices

Historical Data

Stochastic Variables

Exogenous and Control Variables

Equations and Calculations

Financial Statements Income StatementStatement of Cash FlowsBalance Sheet

Key Output Variables Net IncomeEnding Cash BalanceDividends PaidEnding Real Net WorthNet Present Value

Risk Ranking of Alternative Scenarios

Residual biomass is the largest byproduct

produced.MixAlco differs from corn-based etha-

nolproductionthatproducesdistillerdriedgrains

withsolubles(DDGS)thatbecanbesoldtolive-

stockoperations forfeed.Approximately 20per-

centofthebiomassfeedstockisresidualbiomass

when the MixAlco process is complete. The re-

sidualbiomasscanbeusedinternallytogeneratepowerandsteamforthefacilityoritcanbesoldto

coal-red power plants as a fuel source to reduce

sulfuremissions.

Net Energy Balance of MixAlco

ThenetenergybalanceofMixAlcoalcoholfuel

is dependent upon which feedstock isusedas a

fuelsource. Initial testing has shown ethanol

produced fromMixAlcohasa slightlyhigheren-

ergy content than corn-based ethanol. A gallonofgasolinecontainsapproximately125,000BTU/

gallon and corn-based ethanol contains 84,000

BTU/gallon (Holtzapple, 2004). The energy con-

tentofMixAlcoproducedethanolisapproximately

95,000BTU/gallon.Theenergycontentforthere-

sidual biomassbyproductis similartocoal.It is

substitutable for coal in co-ring energy produc-

tionfacilitiesandcanreducesulfur

emissions.

MixAlco Feedstock Requirements

Initial research into MixAlco

used sugarcane bagasse as feed-

stock as it is widely available

around the world. However, the

supplyof sugarcane in theUnited

Statesislimitedtothefourstates

producing sugarcane and is not

largeenoughtosupportlarge-scale

MixAlcoproduction.Theamountof

feedstockrequiredisdependentonthe desired output size for the fa-

cility.Thefeedstockisdecomposed

at the same rateforall cropsand

all plant sizes. The efciency of the

MixAlco process isalsostillunder

experimentation.Versiontwoofthe

MixAlco process has increased al-

coholyieldpertonofbiomassfrom

approximately90to100gallons/ton

inversiononeto130to140gallons/ton.However,

theethanolproducedfromversiontwohasalower

energycontentthanthealcoholproducedinver

sionone.

MixAlcofeedstockdemanddiffersfromethano

feedstockdemandasyear-roundsupplyisnotnec

essary. The MixAlco process only requires feed

stockinputonceayeartobuildthefuelpile.Thisisadvantageouswhencomparedtootherformsof

biomassenergyproduction.Biomasscanbeused

for other types of energy production (burning

digesting)butagain, havenot foundcommercia

success.

Economic Analysis

Asimulationmodelwasdevelopedfortwoal

ternativeMixAlcoplantsizes(44ton/hourand176

ton/hour)usingsweetsorghumasfeedstock.Forbothplants,economicfeasibilitywasexaminedfor

twoinitialinvestmentamounts(Baserepresent

ingtheexpectedcostsandBasePlus30percent

representingBasecostsplus30percent);withand

withoutincentives;andthreealternativeregions

inTexas(Panhandle,CentralTexas,andCoasta

Bend). A simplied diagram of the model and the

Figure 8: Diagram o the Simulation Model.

-

8/7/2019 The Economics of Ethanol from Sweet Sorghum

9/14

alternative scenariosare presented inFigures 8

and9.

Common nancial statements for each alterna-

tivescenarioweredeveloped.Stochasticvariables

wereincorporatedintothemodeltocapturerisk.

Specic key output variables were calculated and

compared foreach alternative scenario from the

nancial statements.

Results

Key Output Variables

For all the scenarios analyzed, the projected -

nancialfeasibilityresultsshowapositivenetpres-

entvalue(NPV)overthe16yearplanninghorizon

withonlyasmallprobabilityofbeingnegative.

Netincomeisexpectedtoremainpositiveand

increaseslightlyforallscenarios.Theprobabilityofnegativenetincomeislessthan30percentin

the rst year for all scenarios and only 1 percent

thereafteryears2006to2019.Asexpected,netin-

comefortheBasePlus30initialinvestmentsce-

narioislowerinallcasesduetohigherdeprecia-

tioncostsandhighercapitalimprovementcosts.

Becausenet income remainspositive, ending

cashbalanceincreasesannually.Theprobabilityof

negative ending cash balance is less than ve per-

centin2005andlessthanonepercentfrom2006

to2019for all scenarios.Also,annualdividendspaidarepositiveforallscenarios.Real net worth

increases to 2014 and than attens out for all sce-

narios because of the increasing deation factor.

RealnetworthishighestinthePanhandleRegion

forthe 44ton/hourand 176 ton/hour production

facilitiesbecauseoftheadditionalinitialinvest-

mentcostsneededforwellsandwaterrights.For

the Plus30initial investmentscenario, real net

worthishigherforallscenariosasexpected.The

probabilityofrealnetworthbeingnegativeisless

thanonepercentforallscenarios

Community Impacts

The economic impacts of locating aMixAlco

productionfacilityinthePanhandle,CentralTex-

as,andCoastalBendRegionswereanalyzedusing

theRegional IndustryMultiplierSystem (RIMS)

and thesummation of the simulated discounted

wages,haulingcosts,propertytax,andadditional

farmerincomefrom2005to2019foreachregionTheRIMSmethodpresentsthedirectandindirect

benets to the community. The simulation results

representdirectimpactsfromtheMixAlcoproduc

tionfacility.

Theestimatedadditionalcapitalspendingwas

$50millionto$65millionforthe44ton/hourfacil-

itywithanadditionalhousehold income of$124

millionto$133million.Forthe176ton/hourpro

duction facility, the local economy would benet

from $407 million to $440 million in additiona

spendingand$72million to$78millioninadditionalhouseholdincome.Theseeconomicgainsfo

thelocaleconomyarequitelargeandindicatelo

catingaMixAlcoproductionfacilityintheregion

wouldhaveasubstantialandpositiveimpacton

thelocaleconomy.

Forthedirectimpacts,haulingrevenueswere

thelargestdirectcontributortotheregionrang-

ingfrom$42millionfora44ton/hourproduction

facilityto$190millionfora176ton/hourfacility.

Central

Panhandle

Coastal Bend

44 T/H

176 T/H

44 T/H

176 T/H

44 T/H

176 T/H

Base

Plus 30

Base

Plus 30

Base

Base

Plus 30

Plus 30

Base

Plus 30

Base

Plus 30

Incentive

No Incentive

Incentive

No Incentive

Incentive

No Incentive

Incentive

No Incentive

Incentive

No Incentive

Incentive

No Incentive

Location Plant Size InvestmentLevel

Local Incentive

Texas

Figure 9: Flow Chart o Alternative Scenarios.

-

8/7/2019 The Economics of Ethanol from Sweet Sorghum

10/14

The summeddiscountedwageswere$12million

fora44ton/hourfacilityand$27.5millionfora

176ton/hourfacility.Farmersreceiveasubstan-

tialincreaseinadditionalrevenuewithahighof

$20millionforthe44ton/hourproductionfacility

to$65millionfora176ton/hourproductionfacil-

ity.Propertytaxrevenueforthelocalcommunity

variesandisdependentontheofferoftaxabate-ments.

Sensitivity Analysis

Elasticitiesforkeyinputvariableswereesti-

matedtodeterminewhichvariableshadthegreat-

esteffectonfeasibilityintermsofNPV.Fromthe

analysis,ethanolprice,ethanolyield,andhydro-

gen price arethe three variables with the high-

estelasticities.Aonepercentannualincreasein

ethanolpriceoryieldwouldincreaseNPVbysixtosevenpercentdependingontheplantsize.In

termsofcost,ifhydrogenpriceincreasesoneper-

cent each year,NPVwoulddecreaseby2.5 to3

percentfortheproductionfacility.Thecalculated

elasticitiesforallotherinputcostvariableswere

lessthan0.25percent.

Conclusions

Thepromisingresultsforproductionofethanol

fromtheMixAlcoprocessshouldbeviewedwithcaution.TheanalysisusestheEnergyInformation

Administrationslong-termforecastforwholesale

gasolinepricewherepricesareexpectedtocontin-

uallyincreasefrom2005to2019.Theuncertainty

intheworldoilmarketcausedbythecurrentwar

intheMiddleEastcoulddramaticallyaffectthe

feasibilityof aproduction facility.Theseoutside

factorscannotbecontrolled.

Also, the MixAlco process is still being rened

andtheproductiondatausedinthisanalysisare

primarily derived from small-scale pilot plants.Thesenumbers,suchasethanolyieldpertonof

feedstock, could vary in commercial conditions.

Morethanlikely,MixAlcowillfollowanadoption

curve for new technology where the process is ne

tuned over the rst few years before full efciency

canbereached.

Theresultsindicatethateithersizeplantwill

be protable given current assumptions. A positive

NPV is forecastedwith increasing networth for

a44ton/hourand176 ton/hourproductionfacil

ityinthePanhandle,CentralTexas,andCoasta

BendregionsofTexas.Potentialinvestorscanuse

the results todeterminethe location,plantsize

andkeyvariablesindecidingifaproductionfacil

ityshouldbeconstructed.

Furthermore,theresultsofthisstudyprovide

useful information to compare the risk and benetsbetweenthealternativeplantsizesandlocations.

Investingsubstantialamountsofmoneyinanew

technologyisariskydecision.Understandingand

incorporatingvariabilityintothemodelallowsfor

aprobabilisticanalysiswhereaprobabilityrange

canbeassignedforeachoutcome.Theprobabilis-

ticframework givesdecisionmakersmuchmore

informationthanadeterministicestimate.

Theresultsalsoshowtheadditionalbusiness

activityassociatedwithaMixAlcoproductionfa

cilitywouldincreasecapitalspendingandhouseholdincomeboostingthelocaleconomy.MixAlco

hasthepotentiallytobeafeasiblealternativeto

corn-based ethanol production offering substan

tialeconomicgainsforthecommunity.

Study Limitations

There are several limitations to this study

First,silage yieldsand silage priceswere inter

polatedfromhistoricalgrainyieldsandbudgets.

Thesenumbersareonlybestestimatesofwhattheexpected forageyieldandpricewouldbe.Actua

datafromexperimentalplotscollectedfromindi

vidualfarmerswouldgiveabetterrepresentation

oftheexpectedyieldandcostforsorghumsilage

Yieldisheavilydependentonweather,especially

for dry-land farming in the Panhandle, Centra

Texas,andCoastalBendregionsofTexas.

Second, this study assumed specically grow

ingsilageforenergyproduction.Sorghumsilage

isusedasfeedstockbecauseofitshighyieldchar

acteristics,lowcostsofproduction,andadaptabilitytobegrownindifferentclimates.A20percent

premiumwasincludedinthepricetoenticefarm-

erstoharvestsorghumforsilageratherthanfor

grainwhichmayormanynotbenecessary.How

ever, MixAlco would directly compete with the

dairyindustryforsorghumsilagewhichmayraise

priceshigherthanexpected.Thehighersorghum

silage price could dampen the nancial outlook for

MixAlco.

-

8/7/2019 The Economics of Ethanol from Sweet Sorghum

11/14

Residual biomass, such as tree clippingsand

farmingresidues,arenotconsideredinthisstudy.

Agriculturalresiduescouldofferalowcostalter-

native to growing crops specically for energy con-

version.Studiesshowsorghumproducesoneton

ofresidualmatterforeverytonofgrainproduced.

Harvesting thesorghumforgrainandcollecting

theresidualbiomasscouldbeaviablealternative.TheabilityofMixAlcotoconvertanybiomassma-

terialtoalcoholfuelmakesitanattractivealter-

native forethanol production.Largeamounts of

available residual biomass represent a low cost

feedstocksourcethatcanbeusedforenergypro-

duction(Gallagher,et al.).

Third, electricity prices, natural gas prices,

steamprices,andlimepriceswerenotseparated

by region. The differences in price between re-

gionsmaybesmall,butforcompleteness,asepa-

ratepriceshouldbeusedineachregion.Also,thepricesareaveragepricesforTexas.Betterprices

maybeobtainedfromnegotiationswithproviders

ineachregion.

Fourth,locationincentivesmay be available

The location incentives used in this study were

generalizedforeachregionafterdiscussionwith

thelocalChamberofCommerceandEconomicDe

velopmentCorporations.Eachstatedthatthein

centives are project specic and negotiated on an

individualbasis.Theycouldnotprovideacomplete

and specic incentive package for a production facilitywithouttheproperinformationtoevaluate.

Lastly,thisstudyconsiderstheproductiono

ethanol on premise and shipping the nished fuel

to reneries for blending. Smaller acid production

facilities could ship acid to a centrally located

largehydrationfacility.Theremaybecostadvan-

tagestoshippingacidstoacentralhydrationfa-

cilitylocatedclosetoalargehydrogenproduction

facility. This would reduce the cost of hydrogen

andnegatetheproblemsassociatedwithshipping

ethanol.However, littledata isavailable on thepricingandshippingcostforacidsaswellasthe

costsforlarge-scaleproductionofhydrogen.

-

8/7/2019 The Economics of Ethanol from Sweet Sorghum

12/140

References

AustralianCRCfor RenewableEnergyLtd. (ACRE) What isBio-

mass.Websitehttp://acre.murdoch.edu.au,1999.

Badger,P.C.EthanolfromCellulose:AGeneralReview.Trends in

New Crops and Uses,2002.

Bassam,N.E.Global Potential of Biomass for Transport Fuels.In-

stituteofCropandGrasslandScience,Braunschweig,Germany,

2004.

California Energy Commission. Evaluation of Biomass-to-Ethanol

Fuel Potential in Calfornia: A Report to the Governor and Cali-fornia Environmental Protection Agency .Sacramento,CA,1999.

Chiaramonti,D.,G. Grassi, A.Nardi,and H.P.Grimm.ECHI-T:

Large Bio-Ethanol Project from Sweet Sorghum in China and

Italy.EnergiaTrasportiAgricoltura,Florence,Italy,2004.

Committee on Biobased Industrial Products. Biobased Industrial

Products: Priorities for Research and Commercialization .Wash-

ingtonD.C.,NationalResearchCouncil,

2000.Creelman,R.A.,L.W.Rooney,andF.R.Miller.Paperpresented

atAmericanAssociationofCerealChemist,St.Paul,MN,1981.

Franzluebbers,A. J., F.M. Hons,and V.A. Saladino. Sorghum,

Wheat,andSoybeanProductionasAffectedbyLong-TermTill-

age,CropSequence,andNFertilization.Plant and Soil Vol.

173(1995):55-65.

Gallagher,P.W.,M.Dikeman,J.Fritz,E.Wailes,W.Gauthier,and

H. Shapouri. Supply and Social CostEstimates for Biomass

fromCropResiduesintheUnitedStates.Environmental and

Resource Economics24(2003):335-358.

Holtzapple, M. MixAlco Process. Unpublished manuscript, Texas

A&MUniversity,CollegeStation,TX,2004.

Hons,F.M.,R.F.Moresco,R.P.Wiedenfeld,andJ.T.Cothren.Ap

pliedNitrogen andPhosphorus Effects onYield andNutrien

UptakebyHigh-EnergySorghumProducedforGrainandBio

mass.Agronomy Journal Vol,76,No.6(1986):1069-1078.

Mazza,P.Ethanol:FuelingRuralEconomicRevival.Climate Solu

tions Report,2001.

Miller,F.R.,andR.A.Creelman.Sorghum-ANewFuel.Paperpre

sented at theAmerican SeedTrade Association Annual Corn

SorghumRes.Conference,Chicago,IL,1980.

Osburn,L.,andJ.Osburn.BiomassResourcesforEnergyandIn

dustry.Websitewww.ratical.org/renewables,1993.

Powell,J.M.,F.M.Hons,andG.G.McBee.NutrientandCarbohydratePartitioninginSorghumStover. Agronomy JournalVol

83,No.6(1991):933-937.

Renewable Energy World. Bioethanol-Industrial World Perspec

tive. Website www.jxj.com/magsandj/rew/200_03/bioethanol

html,2000.

Shapouri,H.TheU.S.BiofuelIndustry:PresentandFuture.Un

publishedmanuscriptpresentedatthe 2003ConferenceAgro

Demain,Reims,France,December2003.

SterlingPlanet.EnergyfromBiomass.Websitewww.sterlingplan

et.com,2004.

Veringa,H.J.Advanced Techniques for Generation of Energy from

Biomass and Waste.ECNBiomass,2004.

Wiedeneld, R.P. Nutrient Requirements and the Use of Efciency

bySweetSorghum.Energy Agriculture3(1984):49-59.

World Energy Council.New Renewable Energy Resources. London

KoganPage,1994.

-

8/7/2019 The Economics of Ethanol from Sweet Sorghum

13/14

A policy research report presents the final results of a research project

undertaken by AFPC faculty. At least a portion of the contents of this report

may have been published previously as an AFPC issue paper or working paper.

Since issue and working papers are preliminary reports, the final results

contained in a research paper may differ - but, hopefully, in only marginal

terms. Research reports are viewed by faculty of AFPC and the Department of

Agricultural Economics, Texas A&M University. AFPC welcomes comments

and discussions of these results and their implications. Address such comments

to the author(s) at:

Agricultural and Food Policy Center

Department of Agricultural Economics

Texas A&M University

College Station, Texas 77843-2124

or call (979) 845-5913.

-

8/7/2019 The Economics of Ethanol from Sweet Sorghum

14/14

Copies of this publication have been deposited with the Texas State Library in compliance with the State Depository

Law.

Mention of a trademark or a proprietary product does not constitute a guarantee or a warranty of the product by The

Texas Agricultural Experiment Station or Cooperative Extension Service and does not imply its approval to the

exclusion of other products that also may be suitable.

![THE POTENTIAL OF SWEET SORGHUM [Sorghum bicolor (L · The Potential of Sweet Sorghum [Sorghum Bicolor (L.) Moench] As A Bio- Resource for Syrup and Ethanol Production in Kenya EVANS](https://static.fdocuments.us/doc/165x107/5f0f52697e708231d44395b9/the-potential-of-sweet-sorghum-sorghum-bicolor-l-the-potential-of-sweet-sorghum.jpg)