Technical drawing

-

Upload

meheng1001 -

Category

Education

-

view

660 -

download

0

description

Transcript of Technical drawing

www.topcadservices.com

PRESENT article

CAD Technical Drawing for engineers and

technicians.

1.Technical drawing for engineers and

technicians.

In a few words, Technical Drawing is a discipline

for visual communication, which can also show

us how something functions and how it’s

constructed and designed. Internationally

knows as drafting. A Technical Drawing is an

excellent way for engineering communication.

Most designers, architects, engineers,

technicians use this discipline for work and

communicating between them.

There are many standards, symbols, units and

ways of presentations. People who make these

drawings are known as drafting technicians.

Depending on the discipline (architecture,

engineering, design), there are lots of methods

of drawing and sketches.

Explaining for technical drawing.

Let we explain what is technical drawing by

example of two PARTS(they are mechanical

parts but excellent examples for explanation).

First one is a holder and is a symmetrical part

and second is a tail pipe and is not symmetrical

part. We can explain them by presentation of:

-Three views(2D drawing);

-Axonometric view in 3D presentation.

No matter how complex are technical drawings

of the parts are symmetrical and not

symmetrical pieces.

System of lines are used for drawing a technical

drawing

Lines used for the preparation of the technical

drawing are following:

Thick lines are used for drawing the outline;

Thin line is used for hatch, dimensioning and

placement of symbols;

Center line is used for showing symmetry.

Dashed line is used for drawing invisible parts

in the respective views and drawings.

On the images below we can clearly see the

lines, type and weight too.

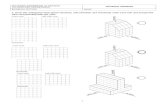

The first example is a three-view model of an

object, in this case, a part holder, which is a

mechanical engineering drawing. We can see

that the object is symmetric, that’s why we use

the three-view in 2D presentation. A standard

technical drawing of an object is in 2D which

shows the three views (upper or bottom,

frontal and side view), and in some cases if

necessary, an extra detail is shown.

Axonometric view is the 3d presentation. On

the images below we can clearly see the 2D and

3D presentation.

The three views. On the upper left we can see

the frontal view, bottom left is the top view and

on the right side the side view is shown with a

cross section.

At not symmetrical parts we use the six-view in

2D presentation. Technical drawing of an object

is in 2D which shows the six views (top view,

bottom view, frontal view, left side view, right

side view, back view), and in some cases if

necessary, an extra detail is shown.

Axonometric view is the 3d presentation also.

On the images below we can clearly see the 2D

and 3D presentation.

2.Section views.

Section views. There are several types of

section views: cross-section view, half section

view, quarter section view partial selection

view and etc. We use some of them depending

on the drawing.

Cross section view is used to show the holes,

lines, details that can not be seen in all of the

three views. On the drawing, there is one

section view that shows us the big hole where a

circle profile will pass through.

A partial cross section is shown in the frontal

view, on the lower right, that helps us see the

small hole where probably ll entered some

screw. Therefore, we are using partial cross-

section to show some elements that can not be

seen even if we make a cross-section view.(Also

we can see the section view on the images up).

3.Dimensions-Elevations

Dimensions are used to show us the length,

width, the bending of a line and etc.

Dimensions also tell us the intensity of an

angle, diameter of a circle and other

geometrical features. Difference is made by the

shape of the head of the dimension or knows as

elevation – kota. So there are many types like:

architectural, engineering, designers, geological

and e.t.c

Information on measures subjects enrolled in

numerical form, the drawing and thus its

transmission becomes independent of the

accuracy of the drawing. Parts drawings that

contain information on measures objects are

called elevations. Elevation consists of the

following elements:

-Number of elevation;

-Arrow;

-Measuring lines and;

-Auxiliary measurement lines.

Number of elevation dictate items action. They

are entered with the technical writing above

surveyors around the middle. So that they can

be read from the bottom to up and from the

left to right. One should avoid drawing

measures with other measures, and auxiliary

measuring lines narrower wheel closer and

further from the edge of broader subjects,

including the spacing between parallel

surveyors must be steady and sufficient for

registration numbers. Dimensions number, not

cross any other line. Size of the witness

numbers depends on the nominal line width,

but at least 2.5 mm.

Arrows determine for where to where is some

measure. They must not exceed the auxiliary

measuring lines or edges. Typically drawing a

line in the auxiliary measurement or edges, and

exceptionally, if there is not enough space for

them they are drawn from outside. In the case

of repeated dimensioning, when there is not

enough space inside, the arrows are replaced

by a dot. Dimensions arrows depend on the

nominal width of the line.

Measuring lines is a line parallel with the

length of which indicates surveyors measure

can not be replaced by another line. The

spacing between parallel surveyors must be

steady and sufficient for registration numbers.

The distance should not be too small between

surveyors and edges.

Auxiliary measuring lines drawn to measure

objects outside the drawing objects. When is it

appropriate solution can be replaced by an

edge case. Can be crossed with all other types

of lines except surveyors. For slightly inclined

edges, if this improves the vividness can be

drawn and skewed.

Dimensioning can be performed in series,

parallel and combined.

In series dimensioning the leader is drawing

mutually parallel, starting from a certain area.

See example in the image below.

Parallel dimensioning consists of entering a

series of individual wheel to continue to one

another. See example in the image below.

Combined dimensioning is a combination of

the previous two methods and is most

commonly used. See example in the image.

Level dimensioning in section view and in floor

plan is made with symbols shown at the image.

They show the height in cross section and in

floor plan. See example in the images below.

Make comparison about the dimension style. In

first two images below are mechanical, next

two images are architectural-construction.

3.PARTS

A standard technical drawing of an object is in

2D which shows the three views (upper or

bottom, frontal and side view), and in some

cases if necessary, an extra detail is shown.

Axonometric view is the 3d presentation. On

the images below we can clearly see the 2D and

3D presentation.

At not symmetrical parts we use the six-view in

2D presentation. Technical drawing of an object

is in 2D which shows the six views (top view,

bottom view, frontal view, left side view, right

side view, back view), and in some cases if

necessary, an extra detail is shown.

Axonometric view is the 3d presentation also.

On the images below we can clearly see the 2D

and 3D presentation.

4.ASSEMBLY

Assembly, the act of combining components in

manufacturing.

Assembly is also technical draw. Represents

combination of parts combination of pieces

interlinked.

For assembly is necessary to connect at least

two parts that will work mutually.

On the images below we can clearly see some

assembles.

VISIT US CLICK HERE TOPCADSERVICES

Read more:

http://www.topcadservices.com/2012/tehnical

-drawing/#ixzz2rq6T20y6