TCI 2015 OKETEC Co. Ltd

-

Upload

tci-network -

Category

Economy & Finance

-

view

223 -

download

0

Transcript of TCI 2015 OKETEC Co. Ltd

Oketec Co., Ltd

Eui Seon Jo

Parallel Session 1.1 : Performance of Outstanding Enterprise Participating in the Cluster Program

Company Outline

2

2000 OKETEC established

2005 ISO-9001;2000 and KS-9001;2000 certifications obtained

2007 Selected as a small- to mid-sized venture company and INNO-BIZ (small- to mid-sized company engaged in technological innovation)

2010 ISO-14001;2004 and KS-14001:2009 certifications obtained

2011 Plant expanded and relocated, and affiliated research center established (No. 2011210537)

2013 Designated as a leading company of a strategic industry of North Jeolla Province

2014 CE certification (Europe) obtained for automated clutch, and Productivity Management System (PMS) certificate obtained

One Kwang Environment Technology (OKETEC)

August 19, 2000

Lee Dong-geun

400-7, Gungseong-ro, Wanggung-myeon, Iksan City, North Jeolla Province

Room no. 401 at the Korea Institute of Carbon Convergence Technology at 110-11, Banryong-ro, Deokjin-gu, Jeonju City, North Jeolla Province

HISTORY

Affiliated research center

Headquarters / Plant

CEO

Date of establishment

Company name

Business Areas

4

Automated system for assembling automotive engine parts

Hydraulic bending system for automotive parts

Bearing matching assembly equipment Hub bearing cleaning and drying equipment

Production/processing assembly automation

Automatic transport system for automotive exterior materials

Film logistics automation transport conveyor

Automatic transport system for car wheel covers

Automated facility for removal of water repellent coating solution from glass surfaces

Logistics/return system automation

Electronic clutch control device Enhanced gear-shifting convenience Fuel reduction of 10 to 25%

Automated clutch

Grease weight measuring equipment Index unit repeatability measuring equipment Coated surface vision inspection equipment Measurement equipment to determine shaft

heat treatment, etc.

Measurement/inspection equipment automation

Roll Forming system Automatic production assembly line

for automotive parts Automatic ultrasonic welding system Automotive engine parts processing

line supply system, etc.

Robot/servo system automation

CFRP Drive Shaft R&D Making products lightweight by applying

carbon composites

Carbon material parts

Factors that led to Project Participation

5

Corporate growth Credibility

OKETEC

CUSTOMER

KICOX

Corporate support is provided by operating a mini cluster by area

R&D as well as non-R&D support

Information is shared at seminars and technical exchange conferences

Advanced technologies are obtained by establishing overseas market development teams

R&D Execution Details

6

Project name Execution details Period Government organization

Production technology commercialization support

project

Development of a semi-auto clutch for commercial vehicles using a non-contacting displacement meter

(supervised the project) 2010.11~2011.10 KICOX

Production technology commercialization support

project

Development of suspension bushing for passenger cars of high quality and high functionality, based on strengthening

of dissimilar material adhesive force as per demand (participated in the project)

2014.06~2015.06 KICOX

Project name Execution details Period Government organization

Total marketing support project

Creation of an electronic catalogue 2012.08~2012.10 KICOX

Industrial Innovation Movement 3.0

Implementation of a 3D design system for building of automation equipment 2013.08~2014.05 KICOX

Product manufacturing support project

Development of an automated clutch controller in consideration of convenience of drivers of public-works

project vehicles 2013.11~2014.04 KICOX

Total marketing support project

Domestic and overseas market development (Britain) 2014.09.29~10.05 KICOX

Market development team for entry into the Indian

market Automotive parts export consultation and corporate visit 2014.10.28~11.02 KICOX

Total marketing support project

Domestic and overseas market development (Domestic exhibition) 2014.11.05~11.08 KICOX

R&D execution details

Non-R&D execution details

Automated Clutch

7

Clutch coupling Clutch decoupling

This clutch control device for flexible driving of commercial vehicles enables more fuel reduction This automatic control device for clutch pedaling while driving enhances operational

convenience Functionality for fuel reduction and improved driver convenience(automatic implementation of half clutch)

It can be used together with the previous clutch device(for safety)

The driving unit that is connected to the stepping motor moves at a certain speed, just like a half clutch

The clutch is activated when the air cylinder is pushed by the air that comes in when the valve is opened

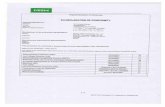

Development of a fuel reduction device (automated clutch)

8

1st generation 2nd generation 3rd generation

Vehicle information Sensor CAN communication CAN communication

Clutch drive Step motor Air pressure Step motor

Start function ○ × ○

Flexible drive ○ ○ ○

Installation cost High Low Middle

Installation time 10H 4H 4H

Major applied

vehicle Commercial vehicle Truck

Commercial vehicles and

others

Pros The control range is large to enable

application to all vehicles

Focus is placed on flexible driving of

trucks

An automatic start function

was assigned

Clutch precision position

control is enabled

Cons Excessive installation time is needed Lack of clutch precision position

control -

There was a need to develop a controller that would enable precision position control to allow start function-centered clutch operation control, which is required for work vehicles, etc.

Developed a controller that allows the collection of vehicle information based on CAN communication and step motor drive control that enables precision position control

Electronic controller & CAN communication

Development of a fuel reduction device (automated clutch)

9

The clutch is controlled using an electronic control system, resulting in enhanced driver convenience and fuel reduction

This product is an improvement to the robot clutch. Use of CAN communication reduces and simplifies the great number of sensors and processes that were previously used. This leads to reduced installation time

System is optimized to simplify installation and to improve fuel efficiency

It is used in parallel with the previous clutch to ensure safety in case of a problem

OBD-II CAN communication terminal

Consists of the mechanical driving unit, which automatically controls the clutch,

and the control unit that controls the driving unit

Automated clutch

Composition of control unit

CAN commu-nication unit

Sensing

unit

Operat-ing unit

Driving unit

Product competitiveness

10

Intellectual property rights(Five registered and three applications submitted in Korea)

No. Patent/Program Country Date of application

(registration) Application (registration)

number Notes

1 CLUTCH CONTROLLER FOR

VEHICLE China Nov 24, 2011 /Nov 28, 2013

ZL 200980152836.0 /2014.11.28

Registration

2 Clutch Control Device US May 23, 2014 14/360,411 Application

3 Clutch Control Device India June 23, 2014 1266/MUMP/2014 Application

4 Clutch control device for fuel

reduction and device-based fuel reduction method

PCT June 9, 2015 PCT/KR2015/005780 Application

Fuel efficiency is improved as a result of flexible driving based on clutch control

The automated clutch is an eco-driving device that is based on such flexible driving. It can lead to fuel reduction effects of around 10 to 25%.

More operational convenience for drivers

The gear can be shifted by an on/off switch that is attached to the gear

knob, without having to use the clutch pedal. The vehicle’s power

transmission is conveniently cut off/accessed to allow flexible driving.

Fail-safe function The previous clutch device of the clutch pedal can be used together. Also, the product can be attached without changing the vehicle structure.

Background of commercialization

11

In the US and Europe, even small commercial vehicles are included in the scope of greenhouse gas and fuel efficiency management. In 2016, Korea will include 3.5-ton or less trucks to the scope of management

Commercial vehicles emit 78% of nitrogen oxide (NOx) and 72% of particulate matter (PM10) from among mobile emissions on roads (2012 assessment, Ministry of Environment)

01 Demand for measures on commercial vehicle fuel reduction in

response to regulations on vehicle CO₂ emissions

Schedule after the effectuation of the Kyoto Protocol

Effectuation of the K

yoto P

rotocol

First commitment

period

Second commitment

period

Korea has no choice but to

participate

Advanced countries

commenced greenhouse gas

reduction

Reduction-related negotiations were carried out for the

second commitment period: Increased pressure on Korea

Van

Two-wheeled vehicle

Truck for personal use

Passenger car

The share of total greenhouse gas emissions accounted for by the road transportation sector

Industry

Home, commerce

Road

Background of commercialization

12

02 Demand for commercialization with China’s carbon credits

China’s commercial vehicle market is rapidly growing at an annual average of 10.6%

China’s carbon emissions trading scheme is resulting in higher interest in fuel reduction

Demand for commercialization through a joint venture in China

(10 thousand, As of Year 2013)

The sum of the market size of countries in second through tenth place is similar to the size of the market of China

Market with less than 100 thousand

“There is a need to make inroads into China for continued growth”

Source: IHS

China US India Brazil Russia Indonesia Germany Japan Britain France

Reduction effects

for customers

< 화물차 유가 보조금(2012년) >

For a 25-ton vehicle (Fuel efficiency: 2.5km/L) Average fuel cost of KRW 6 million/month x 10 to 25% reduction = KRW 600 thousand – KRW 1.5 million/month KRW 600 thousand-KRW 1.5 millionx12 months = KRW 7.2 million-KRW 18 million/year reduction effects (The device investment cost is recovered in around four months)

Category As of December 2013

Truck 3,285,707

Bus 96,362

Special vehicle 65,998

Total 3,448,067

Ten branches in different metropolitan areas x Five installation locations = Around 50 installation locations

Domestic truck market : 1 million x 2% = 20 thousand/year x KRW 2.5 million = KRW 50 billion

Automated clutch installation cost : KRW 2.5 million / vehicle

Domestic demand and commercialization

Estimated demand

Expected domestic bases

< Registered commercial vehicles in Korea>

13

Conclusion

14

KICOX led OKETEC’s growth The different types of support provided by KICOX enabled efficient R&D,

including the identification of items and process improvements. Support was provided for R&D, which was needed for corporate growth, as

well as consulting, PR materials, production of pilot products, and market development teams.

An assessment was carried out on the company’s overall status and improvements were made to address shortcomings based on consulting on business and technology development.

KICOX also made arrangements so that the company could receive support from many support groups in North Jeolla Province and the academic sector.

Support provided by connecting the company to support organizations in North Jeolla Province The company was provided with support for R&D programs from the Cheonbuk

Regional Small Medium Business Administration. Support was provided for production of pilot products, technology consulting, test

equipment, and technology training by KICOX, Jeonju National Defense Venture Center, Jeonbuk Technopark, and Chonbuk National University TIC.

Research personnel and technology support was provided by Chonbuk National University, Jeonju University, Wonkwang University, and Korea Polytechnics.

Support from KICOX and professional consultants enabled the company to engage in

product development. Various support projects led to sales improvement and growth