TableofContents - Home | MATHESON · qlultra-line® 1.45 41 9x45/46.5/50 23x114/118/127 ss42 19 90...

Transcript of TableofContents - Home | MATHESON · qlultra-line® 1.45 41 9x45/46.5/50 23x114/118/127 ss42 19 90...

http://www.mathesontrigas.com/edge/ Semiconductor Products Catalog V 4.0/SpecRev4.2.1

Table of Contents

High Pressure Gases:Chemical Name –

Page Halocarbon Denomination Formula17 Ammonia NH3

18 Argon Ar19 Arsine AsH3

20 Boron Trichloride BCl321 Boron Trifluoride BF3

22 Carbon Dioxide CO2

23 Carbon Monoxide CO24 Chlorine Cl225 Deuterium D2

26 Dichlorosilane SiH2Cl227 Disilane Si2H6

28 Germane GeH4

29 Halocarbon 14 CF4

30 Halocarbon 23 CHF3

31 Halocarbon 32 CH2F2

32 Halocarbon 41 CH3F33 Halocarbon 116 C2F6

34 Halocarbon 218 C3F8

35 Halocarbon c318 C4F8

36 Halocarbon 1216 C3F6

37 Halocarbon 4110 C5F8

38 Helium He39 Hydrogen H2

40 Hydrogen Bromide HBr41 Hydrogen Chloride HCl42 Hydrogen Fluoride HF43 Krypton Kr44 Methane CH4

45 Methyl Silane SiH3CH3

46 Neon Ne47 Nitric Oxide NO48 Nitrogen N2

49 Nitrogen Trifluoride NF3

50 Nitrous Oxide N2O51 Oxygen O2

52 Phosphine PH3

53 Propylene C3H6

54 Silane SiH4

55 Silcore Si3H8

56 Silicon Tetrachloride SiCl457 Silicon Tetrafluoride SiF4

58 Sulfur Hexafluoride SF6

59 Trichlorosilane SiHCl360 Tungsten Hexafluoride WF6

61 Xenon Xe

Page SDS62 Arsine63 11Boron Trifluoride64 Germanium Tetrafluoride65 Phosphine66 Silicon Tetrafluoride

Page Gas Mixtures67 General Information68 Arsine in N2, H2, He69 Diborane in N2, H2, He70 Phosphine in N2, H2, He71 Silane in N2, H2, He

Page Purification Equipment72-76 Nanochem Purifiers

All information reported in this catalog is intended forreference use only. This publication is intended to provideaccurate information in regard to the subject matter coveredand has been obtained or developed from sources believed tobe reliable such as the coefficients and equations reported byC.L. Yaws and S.N. Naphad in Appendix 5 of Matheson GasData Book, 7th Edition, 2001. Of necessity the information isabbreviated and other information, training and/or education isrequired of the user of this information. Accordingly,Matheson Tri-Gas, Inc. makes no warrantees, guarantees orrepresentations of any kind or nature with respect to theinformation published herein, either express or implied, andwhether arising by law or otherwise, including but not limitedto any implied warranty of merchantability or fitness for anyparticular purpose, and shall not be responsible for any errors,omissions, or damages arising out of use of this information.Matheson shall in no event be liable for any personal injuries,property or other damages of any nature whatsoever, whetherspecial, indirect, consequential or compensatory, directly orindirectly resulting from the publication, use of, or relianceupon the information.

Cylinder dimensions, contents and related data are reported asnominal.

Units: Reported as follows:ppm(*): parts per millionppb(*): parts per billionppt(*): parts per trillion(*)=w: by weight(*)=v: by volume(*)=a: atomic

Purity for all Semiconductor gases is reported as % by Volume, unless otherwise specified.

Please inquire about Pure Gases not reported in the following listings.

Page2-16 Introduction

IntroductionCorporate Overview

2

An Industry Pioneer

Over 80 Years of Experience

In 1927 Matheson Gas Products becamethe first company to offer a reliablesource of high quality scientific gasesand equipment. From the start,Mathesonasserted itsleadership byunderstandingspecialty gasapplicationsand providingproductsspeciallydesigned for these applications. Someof Matheson's more notableaccomplishments include the

Matheson Tri-Gas' Semi-Gas® brand of products has the largestinstalled base of gas handling equipment worldwide. Combinedwith its NANOCHEM® specialty gas purification technology, systemsengineering and comprehensive site management services,Matheson Tri-Gas offers a total integrated solution to itssemiconductor customers.

Matheson Tri-Gas' LabGas Systems® brand of products offers theanalytical laboratory environment a completely integrated solutionfor the proper control and distribution of gas from the "source" tothe "point-of-use."

Tri-CareTM, comprehensive medical gas management programoffered by Matheson Tri-Gas, encompasses all facets of bulk andcylinder gases, cylinder asset management, total quality assuranceand cylinder distribution and safety for the health care industry.

the world’s first commercially produced silane,an accomplishment that earned the industry’sprestigious "SEMMY" Award.

In 1999 Matheson Gas Products merged withTri-Gas, Inc., to form Matheson Tri-Gas. Thismerger combined the analytical andsemiconductor strengths of Matheson GasProducts with the liquid/bulk and industrialcylinder and equipment capabilities of Tri-Gas.As a member of the Tokyo based TaiyoNippon Sanso Corporation (TNSC), MathesonTri-Gas is part of the world’s largest supplierof gases and gas handling equipment.

development of the lecture bottle, nowused by virtually every major college anduniversity in the world, and the supply ofultra pure gases that served as standardsfor the first gas chromatographs.

Matheson's gases also helped forge themost important tool of our era, theintegrated circuit. From the early days ofthe transistor, Matheson was thereproviding the arsine and phosphinewhich made production possible. Astransistors gave way to complexsemiconductor chips, Matheson provided

Total Integrated Solutions

Today, Matheson Tri-Gas remainsan industry leader by deliveringtotal integrated gas solutions.Beyond specialty gases, MathesonTri-Gas offers a broad line ofindustry-proven technologies forthe delivery and purification ofprocess and specialty gases. Weprovide everything from on site airseparation plants to portablecylinders and all the servicesrequired to support these productsand customer applications.Matheson Tri-Gas is positioned toprovide technically superior and innovative products and servicestailored specifically to meet the needs of the semiconductor, analyticaland industrial markets.

Matheson Tri-Gas has continued to developunique products designed to meet themarket needs of our semiconductor,analytical and industrial customers:

IntroductionCorporate Overview

3

Worldwide Capabilities

Matheson Tri-Gas and TNSCprovide a network ofmanufacturing, customer serviceand distribution facilities thatstand ready to ensure a reliablesupply of specialty gases and gashandling equipment. With sitesworldwide, Matheson Tri-Gasproducts can be found in everymajor integrated circuit plant andR&D facilities in North America,Europe and Asia.

The Science of Specialty Gases

Specialty gases play a critical role in analytical and processapplications. With so much at stake, Matheson Tri-Gas offersexcellence in five distinct areas to deliver the highest qualityproduct.

• Raw Materials Selection

As the world’s first specialty gas company, Matheson Tri-Gas hasthe expertise required to select the appropriate raw materials forthe intended product. Acceptance criteria are based on theimpact to the process and product. Non-compliant rawmaterials are rejected. In addition, Matheson Tri-Gas' suppliersare audited on a regular basis and required to meet certificationrequirements.

• Manufacturing

Once the quality requirements of the raw materials are satisfied,Matheson Tri-Gas uses the latest manufacturing, purification andfiltration techniques to produce gases that meet the needs ofthe semiconductor and analytical industries. Matheson Tri-Gashas developed dedicated purification procedures forsemiconductor grade gases that are designed to producerequired purity levels.

Each process is optimized for the specific gas to be purified andcombines high quality filtration with low temperature distillationand gas phase partitioning.

• Mixtures

Volumetric, gravimetric and partial pressure methods are usedfor precise mixing of component gases. In addition, highlyaccurate pressure gauges and specially designed and preciselycalibrated scales are used to ensure proper composition. Finally,mixtures are made homogenous by specialized rolling sequencesdesigned by Matheson Tri-Gas engineers to ensure completeblending.

• Packaging

The handling and treatment of cylinders is key to MathesonTri-Gas' success in specialty gas. Cylinders are prepared using aproprietary treatment designed to remove any moisture,atmospheric and particle contamination. Valves are chosenbased on the specific application. Compatibility of materials,level of purity required and cost impact are included in thedecision making process.

• Analysis

Prior to shipping, Matheson Tri-Gas certifies the quality of all ofits specialty gases to ensure that all of the products meet thecustomer’s specifications. Each sampling program has beendesigned to provide sound statistical evidence of product purity.The analytical methods employed are consistent with the bestavailable techniques as defined by Semi Standards and currentindustry practices.

Matheson Tri-Gas has specialty gas production facilities locatedthroughout the US:

IntroductionCorporate Overview

4

QualityWith the increased cost of "poor quality" in industry today, qualityand consistency become paramount. Matheson Tri-Gas provides afull line of specialty gases and equipment to meet the specificationfor each impurity analyzed. To ensure product consistency andintegrity, all of Matheson Tri-Gas production processes, materialsand analytical tools are managed using statistical control methods.In addition, Matheson Tri-Gas measures its quality system againstISO 9000 series standards.

Research & DevelopmentAt Matheson Tri-Gas, service does not end at the customer’sreceiving dock. Assisting in process and product development isan essential part of the Matheson Tri-Gas offering. By beta-sitetesting new products prior to introduction, Matheson Tri-Gasmaintains a leadership position in providing a global offering offield proven specialty gas and equipment solutions. In addition, astaff of scientists and engineers continually interacts withcustomers to improve material specifications and suggest processimprovements. This results in Matheson Tri-Gas customersachieving the greatest benefit from Matheson Tri-Gas capabilities.

The Matheson Tri-Gas charter is to develop the highest puritymaterials with accurate specifications for metallic and particulateimpurities and the specialized gas handling equipment to ensurepurity. Focusing on developing advancements in new materialsand analytical and production techniques, Matheson Tri-Gasdelivers statically proven process control, state-of-the-art packagingand the ultimate in analytical procedures and equipment.

Matheson Tri-Gas research has led to the continual introduction ofnew products such as:

• ULTIMATM Gases: 99.9999+% purity and guaranteedlow metals content.

• SDS® Safe Delivery Source, a unique approach to thedelivery of arsine, phosphine and enriched borontrifluoride for ion implantation.

• Novel purification media for 33 new gases.

Committed to quality manufacturing and purification processes,Matheson Tri-Gas is dedicated to delivering customer satisfactionby offering total innovative solutions for high purity gases and gashandling requirements.

Advanced Technology Center, Longmont, CO. Matheson Tri-Gas’state-of-the-art primary research and development facility.

Matheson Tri-Gas' Quality Policy

• Quality is meeting the customer’s requirements andexpectations.

• Build quality into every product and service, rather thaninspect it in.

• Continuous improvement requires the participation of allemployees.

• Quality and fitness for purpose are the true measures ofvalue.

The Matheson Tri-Gas family of SDS® Cylinders.

IntroductionCorporate Overview

5

Furthermore, Matheson Tri-Gas isdedicated to enhancing its customers’success by understanding processrequirements and providing value addedsolutions. In addition to the supply ofprocess gases, Matheson Tri-Gas standsready to assist in every phase of specialtygas selection and delivery including:

• Process Piping and DistributionDesign

• Applications Engineering

• Turn-Key Installations

• On-Site Services

• Global Distribution and Sales

These capabilities enable Matheson Tri-Gasto deliver truly comprehensive solutions toimprove overall equipment efficiency andprocess yields.

From the beginning, Matheson Tri-Gas’objective has been to help customers stayabreast of rapid advances in technology bydeveloping custom-tailored products thatmeet the dynamic needs of the industrial,analytical and semiconductor industries.Dedicating resources in new productdevelopment, production, delivery,technical support, and customer service,Matheson Tri-Gas stands ready to deliverthe highest value in the supply of specialtygas solutions worldwide.

Product LineThe semiconductor and analyticalindustries depend on the reliable supply ofhigh-purity process gases and gas handlingequipment to maintain efficientproduction and high yields. In response tothis need, Matheson Tri-Gas offersinnovative application-specific solutions.

Utilizing extensive experience in thespecialty gas business, Matheson Tri-Gashas the processes employed in themanufacturing and the purification ofspecialty gases to produce products whichprovide the most value to its customers.The state-of-the art facility in Gloucester,Massachusetts in just one example. Thisautomated filling operation produces highpurity process gases in a carefullycontrolled environment designed tominimize impurities.

To further ensure purity, Matheson Tri-Gasspecifically designed the ULTRA-LINE®

family of cylinders to maintain theintegrity of the gas. A specific treatmentis applied to the cylinder’s interior wallsthat reduces particulates and othercontaminants. ULTRA-LINE®‚ cylindershave been proven to enhance productstability and extended shelf life.

With the ability to provide customizedmixes and container configurationstailored to meet specific productapplications, Matheson Tri-Gas offers acomprehensive line of specialty gases tothe semiconductor and analyticalindustries.

Matheson Tri-Gas also offers the mostextensive line of gas handling equipmentin the specialty gas industry. Products aredesigned and manufactured at theEquipment Technology Center inMontgomeryville, PA. This 85,000 sq. ft.facility features 4000 sq.ft. of Class 10Protocol clean room space and 30,000sq.ft. of manufacturing space.

Automated Filling Operation,Gloucester, MA. A computer integrated

manufacturing (CIM) environmentdesigned to reduce metal contaminants

and particulates to an absoluteminimum.

Clean room product assembly atEquipment Technology Center,

Montgomeryville, PA.

IntroductionSafety Information

6

Prior to Purchasing Any Compressed Gas:Familiarize all personnel handling any compressed gases with theprocedures recommended in the Material Safety Data Sheet(MSDS), as well as the latest edition of Matheson publicationsGuide to Safe Handling of Compressed Gases, Effects of Exposure toToxic Gases, and Compressed Gas Association's CGA P-1-1991titled "Safe Handling of Compressed Gases in Containers.”

Provide proper instruction and training for all personnel handlingcompressed gases.

Identify and set up a safe and secure area for cylinder inventory.It should be well isolated from working areas and well ventilated.

Isolate a separate area for storing cylinders to be returned toMatheson. Inspect this area routinely to confirm that there are noproblem cylinders that must be attended to between routine pickup periods.

Minimize potential problems associated with hazardous gases byordering the smallest quantity required.

When the Gas Cylinders Arrive at Your Company:Inspect each incoming cylinder to ensure that it is free of leaksand contains the correct product.

Review the current Material Safety Data Sheet (MSDS) providedwith the product.

Store cylinders in an upright position.

Move cylinders in a safe manner using an approved cylinderhand truck with straps and chains.

Secure all cylinders properly while in use and during storage.

Valve plugs and caps are safety devices which need to be safelystored after removing so they can be replaced when the cylinderis ready to be returned to Matheson.

Monitor all cylinder storage areas and locations where cylindersare in use for leaking gases. Use gas detection apparatus designedfor the particular requirement.

Be thoroughly familiar with all emergency procedures andequipment necessary to deal with leaking cylinders and controlequipment. (Fire extinguishers, breathing apparatus, etc.)

Use control equipment recommended for the gas product. (Seethe equipment recommendation listing after each gas and mixtureproduct in the catalog)

• Cylinders containing flammable gases and mixturesshould be properly grounded.

• Control equipment for oxidizing gases and mixturesmust be free of any non-oxidant compatible lubricant,i.e., petroleum-based oils and greases.

• Use proper check valves and purge venting with allhydroscopic corrosive gases.

When Cylinders Are Empty, or Partially Full and No LongerNeeded:Whenever the pressure of the compressed gas in a cylinder isreduced to the minimum required working pressure, close thecylinder valve before detaching from the apparatus and relievepressure in all connecting lines and control equipment in a safemanner.

Replace valve outlet plugs or caps and cylinder valve protectioncaps.

Disconnect cylinders from securing clamps.

Move cylinders to the proper storage location using an approvedcylinder hand truck with straps and chains.

When cylinders are no longer needed they should be returned toMatheson as soon as possible, classified, marked, and labeled asoriginally shipped.

If a Problem Should Occur:Unfortunately, accidents do sometimes occur. When an accidenthappens, will you be prepared? By following a few simpleguidelines it is our sincere hope that you will be better prepared todeal with any emergency situations involving compressed gases.

Pre-Emergency PlanningBe prepared. Dealing with compressed gas emergencies beginswith planning. An emergency response plan should be developedfor the facility. As a minimum, the plan should include:

• Emergency telephone numbers• Emergency response organizational charts• Emergency procedures• Listing of key personnel• Training schedules and documentation• Hazardous materials lists (including storage locations,

quantities, etc.)• Emergency response equipment lists• Facility maps• Evacuation routes

In addition to the above, be sure that local emergency services (firedepartment, emergency medical services, police and hazardousmaterials response teams) are aware of the hazardous materials atyour facility, their location and their hazards.

Response GuidelinesThe following guidelines are based on the four general compressedgas hazard categories: inert, flammable, corrosive and toxic, andshould be used in preparing your specific emergency responseprocedures.

These guidelines should be used to assist you in making decisionsand they are not intended to serve as a substitute for your ownknowledge or judgment. They provide only the most basicinformation and may not be adequate or applicable in allsituations.

You are advised to consult local fire codes and federal and stateenvironmental regulations OSHA, SARA, RCRA . . . etc.

FireConsult the most current version of the MSDS for the product.The MSDS contains information and procedures to follow if a fireshould occur. Some of these procedures can include the following:

• Let burn unless leak can be stopped immediately• Small Fires: Dry chemical or CO2 extinguishers• Large Fires: Water spray, fog or foam extinguishers• Move container from fire area if you can do it without risk• Stay away from ends of tanks

IntroductionSafety Information

7

In the Event of an Incident• Sound an alarm• Evacuate personnel• Shut down equipment• Determine nature of incident---leak, fire, spill, etc.• Determine what gases are involved and type of

containers• Activate your emergency response plan

Emergency Action• Will vary depending on nature of incident and types of

materials involved• If types of materials involved are known---MSDS's

should be consulted to determine the potential hazards.Example: flammable, poison, oxidizer . . . etc.

• Keep unnecessary people away; isolate hazard area anddeny entry

• Stay upwind; keep out of low areas• Wear positive pressure breathing apparatus and full

protective clothing• Evacuate area endangered by gas• Also, in case of water pollution, call local authorities

24-Hour Emergency AssistanceIf you should have an emergency involving any Mathesonproduct, we can be reached through CHEMTREC, the ChemicalTransportation Emergency Center in Washington, DC, at1-800-424-9300.If you are located in Canada, call (613) 996-6666. CANUTECoperates 24 hours per day, seven days per week to provideemergency response information and get expert help on theway.When you call CHEMTREC, be sure to have the followinginformation ready:

• Name of caller and call-back number• Nature and location of the problem• Shipper or manufacturer• Container type• Placard/Label applied• Accessibility• Weather conditions• Local population information• Topographic features• Availability of water

• Cool containers that are exposed to flames with water from theside until well after fire is out

• For massive fire in cargo area, use unmanned hose holder ormonitor nozzles

• If this is impossible, withdraw from area and let fire burn• Withdraw immediately in case of rising sound from venting safety

device or discoloration of tank may be ignited by heat, sparks andflames

• Flammable vapor may spread away from spill• Container may explode in heat of fire• There may exist a risk of vapor explosion and poison hazard

indoors, outdoors, or in sewers• Some of these materials may burn but do not ignite readily• May ignite combustibles (wood, paper, oil, etc.)• Mixture with fuels may explode

Health HazardsConsult the most current version of the MSDS for Hazard identificationand Toxicity information. Some of the Hazard identifications can includethe following:

• May be fatal if inhaled, swallowed or absorbed through skin• Contact may cause burns to skin and eyes• Contact with liquid may cause frostbite• Runoff from fire control or dilution water may cause pollution• Vapors may cause dizziness or suffocation• Fire may produce irritating or poisonous gases

Spill or LeakConsult the most current version of the MSDS for accidental releasemeasures, disposal considerations and ecological information.Accidental release measures can include the following:

• Stop leak if you can do it without risk• No flares, smoking or flames in hazard area• Do not touch spilled materials• Use water spray to reduce vapors• Isolate area until gas has dispersed• Keep combustibles (wood, paper, oil, etc.) away from spilled

material

First AidConsult the most current version of the MSDS sheet for First Aidmeasures, which can include the following:

• Move victim to fresh air, call emergency medical care• If not breathing, give artificial respiration• If breathing is difficult, give oxygen• Remove and isolate contaminated clothing and shoes• In case of contact with material, immediately flush skin or eyes

with running water for at least 15 minutes• Keep victim quiet and maintain normal body temperature• Effects may be delayed, keep victim under observation

IntroductionCylinder Information

8

The gases and mixtures described in this catalog are shipped incarefully constructed cylinders that meet or exceed U.S.Department of Transportation or Transport Canada specifications.

Many small laboratory size cylinders of hazardous liquefied gasesare filled below the U.S. D.O.T. approved capacity to provide anextra margin of safety if the cylinders are exposed to hightemperatures. (Nevertheless, cylinders should never be exposedto temperatures higher than 125 degrees F. / 51.7 degrees C.)

All cylinders are identified by gas name (by stencil or label) andtagged for ready identification and basic hazardous warninginformation. All gases are supplied with valves havingCompressed Gas Association (CGA) approved outlet connections.

The Matheson Cylinder Specification Selection Guide on the nextpage lists the nominal dimensions and tare weights of allcylinders presently in use. The cylinder drawings reported laterindicate the relative size of the cylinders to each other.

Product(s) must not be used without first consulting the MaterialSafety Data Sheet(s). The purchaser and/or user is responsible toinstruct its employees, agents and representatives to strictlycomply with all applicable federal, state and local statutes,regulations and orders regarding the safe handling, transportationand use of the products. In consideration of the hazardous natureof a product(s) the purchaser and/or user are responsible towarn, protect, and train, as appropriate, all employees, customers,and other persons who may be exposed to those hazards.Matheson provides all relevant Material Safety Data Sheet(s) andadditional Material Safety Data Sheets are available upon request.The purchaser and/or user is aware that OSHA regulations mayrequire the purchaser and/or user to develop and implement awritten chemical hazard communications program for employees,customers and/or others with respect to the product(s). It is thepurchaser and/or user responsibility to ensure that all employees,customers, and other persons who might become exposed to theproduct(s) receive and refer to copies of the Material Safety DataSheet(s).

Return of CylindersBefore being offered for transportation, cylinders must have allvalve openings tightly closed. If outlet caps or plugs have beenprovided, these must be securely tightened to the cylinder valveoutlet. All transport caps must be in place and securely tightened.

All cylinders must be marked, labeled and shipped to conformwith all applicable parts of the 49th Chapter of the Code ofFederal Regulations (49CFR) which are the rules and regulationsof the United States Department of Transportation.

WarningOnly cylinders belonging to or having been filled by Mathesonwill be accepted at Matheson Plants. Matheson reserves theright to refuse complete shipments containing cylinders ownedby others. If there are any questions on Matheson cylinderidentification, please contact Matheson for assistance.

Federal law prohibits the improper discarding of a cylinder or thecylinder contents. All returnable cylinders should be returnedprepaid to your nearest Matheson facility. If returned collect,freight charges will be deducted from any credit due.

D.O.T. regulations do not permit our or any vendor ownedcylinders to be refilled without the owner's permission.

Do not allow foreign substances to enter the cylinder or cylindervalve. Specific protection devices are included in this catalog. Iffurther information is needed, contact Matheson.

If contamination takes place, please call Matheson for instructionson how to label and return the cylinder. Cylinders should bereturned with some positive pressure, with the valves tightlyclosed and the transport caps and outlet caps or plugs in place, toprevent contamination and damage to the valve.

Refilling Customer Owned CylindersMatheson will refill customer owned cylinders subject toD.O.T./T.C. regulations and our own safety requirements.Matheson will not be responsible for lost cylinders if properarrangements have not been made before shipping your cylindersto us.

Cylinder Comparison Chart

Nominal InternalMatheson Dimensions Volume Material of Air AirTri-Gas (inches) (liters) Construction Products Liquide BOC Praxair Scott Solkatronic

QK 10x55 49 C A 49 300 UCT K 49

QA 9x51 43.8 C B 44 200 K A 44

QX 8x48 29.5 A B(AL) 30AL 150A AS AL 29

GA 9x26 17.1 C C 16 80 Q B 16

GX 7x33 15.7 A C(AL) 22AL 16A AQ BL --

UA 6x19 7.3 C D-1 7 30 G C 7

UX 7x16 5.9 A D-1(AL) 7AL 30A AG CL --

JA 4x13 2.3 C D 3 12 F D 3

IntroductionCylinder Information

9

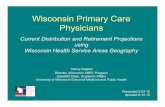

Semiconductor Gases Cylinder Chart

***Material of ConstructionC = Carbon Steel S = Stainless Steel B = Brass H = HastelloyA = Aluminum ASB = Aluminum Silicon Bronze N= Nickel NLC = Nickel-Lined Carbon Steel

Nominal Dimensions* Material ofInternal Volume Diameter x Height Construction*** Tare Weight** Water Capacity

Cylinder cubic ft. liters in cm Cylinder Valve lbs kg lbs kg

QI ULTRA-LINE® II 15.5 439 24 x 83 61 x 211 C ASB/S 1217 552 968 439

XE ULTRA-LINE® 7.47 211.7 24 x 45 61 x 114 S S 243 110 465.6 211.7

QK ULTRA-LINE® 1.73 49 10 x 55/56.5/60 25 x 140/144/153 C S 138 63 108 49

QZ ULTRA-LINE® 1.7 47.5 10 x 54/55.5/59 25 x 137/141/150 A S 92.1 41.8 104 47.5

QY ULTRA-LINE® 1.6 46.4 10 x 52/53.5/57 25 x 132/136/145 A S/B 89.6 40.7 102 46.4

QA ULTRA-LINE® 1.55 43.8 9 x 51/52.5/56 23 x 130/134/143 C B 115 52 96.4 43.8

QB ULTRA-LINE® II 1.55 43.8 9 x 51/52.5/56 23 x 130/134/143 C S/H 115 52 96.4 43.8

QF ULTRA-LINE® 1.55 43.8 9 x 51/52.5/56 23 x 130/134/143 C S/H 115 52 96.4 43.8

QN ULTRA-LINE® 1.55 43.8 9 x 51/52.5/56 23 x 130/134/143 NLC S/H 115 52 96.4 43.8

QL ULTRA-LINE® 1.45 41 9 x 45/46.5/50 23 x 114/118/127 S S 42 19 90 41

QE ULTRA-LINE® 1.35 38.4 12 x 30/31.5/35 30 x 76/80/89 S S 75 34 84.5 38.4

QH ULTRA-LINE® 1.04 29.5 8 x 48/49.5/53 20 x 122/126/135 A S 48 22 65 29.5

QX ULTRA-LINE® 1.04 29.5 8 x 48/49.5/53 20 x 122/126/135 A B 48 22 65 29.5

GC ULTRA-LINE® 0.85 24 9 x 30/31.5 23 x 76/80 NLC N 82 37.3 53 24

QM ULTRA-LINE® 0.665 18.8 7 x 45/50.5 18 x 114/128 N N 88 39 41.5 18.8

GA ULTRA-LINE® 0.6 17.1 9 x 26/27.5/31 23 x 66/70/79 C B 44 20 37.7 17.1

GB ULTRA-LINE® II 0.6 17.1 9 x 26/27.5/31 23 x 66/70/79 C S/H 44 20 37.7 17.1

GF ULTRA-LINE® 0.6 17.1 9 x 26/27.5/31 23 x 66/70/79 C S/H 44 20 37.7 17.1

GH ULTRA-LINE® 0.28 8 7 x 27/28.5 18 x 69/73 N N 48 21 17.6 8

UA ULTRA-LINE® 0.26 7.3 6 x 19/20.5/24 15 x 51/55/64 C B 20 9 16.1 7.3

UD ULTRA-LINE® II 0.26 7.3 6 x 19/20.5/24 15 x 51/55/64 C S/H 20 9 16.1 7.3

UF ULTRA-LINE® 0.26 7.3 6 x 19/20.5/24 15 x 51/55/64 C S/H 20 9 16.1 7.3

UH ULTRA-LINE® 0.21 5.9 7 x 16/17.5/21 18 x 41/45/54 A S 15.1 7 13 5.9

JD ULTRA-LINE® 0.15 4.2 4 x 27/28.5 10 x 29/33 N N 14 6 9.3 4.2

JA ULTRA-LINE® 0.08 2.3 4 x 13/14.5/18 10 x 33/37/46 C B 6.6 3 5 2.3

JB ULTRA-LINE® II 0.08 2.3 4 x 13/14.5/18 10 x 33/37/46 C S 6.6 3 5 2.3

JF ULTRA-LINE® 0.08 2.3 4 x 13/14.5/18 10 x 33/37/46 C S 6.6 3 5 2.3

JY ULTRA-LINE® 0.08 2.2 4 x 13/14.5/18 10 x 33/37/46 C S 6.6 3 4.9 2.2

WA ULTRA-LINE® II 0.04 1.1 3.5 x 12/13.5 9 x 30/34 N N 8 3.7 2.7 1.2

WB ULTRA-LINE® II 0.02 0.55 2 x 14/15.5 5 x 36/40 N N 5 2.1 0.9 0.4

SA ULTRA-LINE® 0.016 0.44 2 x 12/13.5/17 5 x 30/34/43 C B 2.2 1 1 0.4

SF ULTRA-LINE® 0.016 0.44 2 x 12/13.5/17 5 x 30/34/43 C S 2.2 1 1 0.4

WY ULTRA-LINE® 0.1 0.4 2 x 12/13.5/17 5 x 30/34/43 C S 2.2 1 1 0.4

*Height is reported as the distance from the bottom of the cylinder to the cylinder neck/ center of the valve outlet/ top of the handwheel**Excluding cap and cylinder valve

IntroductionCylinder Information

10

Cylinder Diagrams

IntroductionCylinder Information

11

Cylinder Diagrams (continued)

IntroductionCylinder Information

12

The drawings of valve outlets and connections shown on theseintroductory pages are those now in use by Matheson Tri-Gas and incommon use by the compressed gas industry. Whenever possible,valve outlets standardized by the Compressed Gas Association andaccepted by the American National Standards Institute are used.

CGAValve Outlet& Conn. No.

Gas CGA/DISS

Ammonia 660/720

Argon 580/718

Arsine 350/632

Boron Trichloride 660/634

Boron Trifluoride 330/642

Carbon Dioxide 320/716

Carbon Monoxide 350/724

Chlorine 660/728

Deuterium 350/724

Dichlorosilane 678/636

Disilane 350/632

Germane 350/632

Halocarbon 14 (Tetrafluoromethane) 320/716

Halocarbon 23 (Fluoroform) 660/716

Halocarbon 32 (Difluoromethane) 350/724

Halocarbon 41 (Methyl Fluoride) 350/724

Halocarbon 4110 (Octafluorocyclopentene) 660/716

Halocarbon 116 (Hexafluoroethane) 660/716

Halocarbon 218 (Perfluoropropane) 660/716

Halocarbon c-318 (Octafluorocyclobutane) 660/716

Halocarbon 1216 (Hexafluoropropylene) 660/716

Helium 580/718

Hydrogen 350/724

Hydrogen Bromide 330/634

Hydrogen Chloride 330/634

Hydrogen Fluoride 660/638

Krypton 580/718

Methane 350/724

Methylsilane 350/632

Neon 580/718

Nitric Oxide 660/728

Nitrogen 580/718

Nitrogen Trifluoride 670/640

Nitrous Oxide 326/712

Oxygen 540/714

Phosphine 350/632

Silane 350/632

Silcore (Trisilane) 350/632

Silicon Tetrafluoride 330/642

Sulfur Hexafluoride 590/716

Tungsten Hexafluoride 670/638

Xenon 580/718

CGAValve Outlet& Conn. No.

Gas CGA/DISS

IntroductionCylinder Information

13

All drawings are arranged in numerical order according to the valveconnection number. The accurate diameter of the valve outlet isgiven below each drawing along with the thread designation. Forease of measurement and identification, approximate fractionaldimensions may be found on each drawing.The left handed portion of each drawing marked "OUTLET"represents the cylinder valve, while the right hand portion marked"CONNECTION" represents the mating connection normally foundin regulators, control valves, and manifolds.

Cylinder Connections Drawings

IntroductionCylinder Information

14

Gas and Gas Mixture Shipping ClassificationsIn December 1990 the Department of Transportation issued newregulations governing the transportation of hazardous materials.The DOT definitions of the three divisions for gases are as follows:

Division 2.1 (Flammable gas).For the purpose of this subchapter, a "flammable gas" (Division 2.1)means any material which is a gas at 20°C (68°F) or less at 101.3kPa (14.7 psi) which:

(1) Is ignitable at 101.3 kPa (14.7 psi) when in a mixture of13 percent or less by volume with air; or

(2) Has a flammable range at 101.3 kPa (14.7 psi) with air of atleast 12 percent regardless of the lower limit.

Division 2.2 (Non-flammable, non-poisonous compressed gas—including compressed gas, liquefied gas, pressurized cryogenicgas and compressed gas in solution).For the purpose of this subchapter, a non-flammable, non-poisonous compressed gas" (Division 2.2) means any material (ormixture) which:

(1) Exerts in the packaging an absolute pressure of 280 kPa(41 psia) at 20°C (68°F) and

(2) Does not meet the definition of Division 2.1 or 2.3.

Division 2.3 (Gas poisonous by inhalation).For the purpose of this subchapter, ‘a gas poisonous by inhalation"(Division 2.3) means a material which is a gas at 20°C (68°F) or lessand a pressure of 101.3 kPa (14.7 psi) (a material which has aboiling point of 20°C (68°F) or less at 101.3 kPa (14.7 psi) andwhich:

(1) Is known to be so toxic to humans as to pose a hazard tohealth during transportation, or

(2) In the absence of adequate data on human toxicity, ispresumed to be toxic to humans because when tested onlaboratory animals it has an LC5O value not more than 5000ml/m3. Division 2.3 is divided into four groups known ashazard zones, which are:

• Hazard Zone A: gases and mixtures with anLC50 ≤ 200 ppmExamples: Arsine, Phosgene

• Hazard Zone B: gases and mixtures with anLC50 ≤ 1000 ppm > 200 ppmExamples: Methyl Bromide, Dichlorosilane

• Hazard Zone C: gases and mixtures with anLC50 ≤ 3000 ppm >1000 ppmExamples: Methyl Mercaptan, Carbonyl Sulfide

• Hazard Zone D: gases and mixtures with anLC50 ≤ 5000 ppm >3000 ppmExamples: Carbon Monoxide, Hydrogen Chloride

The LC50 of a gas mixture can be calculated from the followingformula providing the LC50(s) of the toxic component(s) are known:

LC50 ofGas Mixturein ppm

Further information regarding Division 2.3 classification is shownin 49 CFR 173.116 and 173.133 and the Compressed GasAssociation Pamphlet "Tentative Standard for the Classification ofToxic Gas Mixtures", P-20T-1991.

Also in December 1990, the International Organization forStandardization (ISO) published Standard 10156, "Gases and GasMixtures - Determination of Fire Potential and Oxidizing Abilityfor the Selection of Cylinder Valve Outlets." The methodsdescribed differentiate the diluent effects of different backgroundgases. For example:

The maximum concentration of hydrogen in nitrogenwhich produces a nonflammable mixture is 5.7%, if heliumwere the background gas the value would be 4.45%.

The application of these methods to gas mixtures which containminor components which are both toxic and flammable mixedwith a nonflammable background or diluent gas may yield asmany as 6 different shipping descriptions. For this reason itbecomes unwieldy to show the classifications in association withthe product descriptions.

1 x 106

ppm of Toxic #1 + ppm of Toxic #2 + . . .ppm LC50 of Toxic #1 ppm LC50 of Toxic 2

=

IntroductionCylinder Information

15

Standard 630 & 710 SeriesDiameter-Index Dimensions for Electronic Gases

DIAMETERS IN mmGAS NAME CONN.# *A *BB *CC *MM *NNArsine, Diborane, Disilane, Germane, Hydrogen, 632 .418-.422 .649-.653 .796-.800 .646-.642 .793-.789Selenide, Phosphine, Silane, Trimethyl SilaneHydrogen Chloride, Boron Trichloride, Hydrogen Bromide 634 .418-.422 .663-.667 .782-.786 .660-.656 .779-.775Dichlorosilane, Trichlorosilane, Silicon Tetrachloride 636 .418-.422 .667-.681 .768-.772 .674-.670 .765-.761Tungsten Hexafluoride, Hydrogen Fluoride 638 .418-.422 .691-.695 .754-.758 .688-.684 .751-.747Nitrogen Trifluoride 640 .418-.422 .705-.709 .740-.744 .702-.698 .737-.733Boron Trifluoride, Silicon Tetrafluoride, 642 .418-.422 .719-.723 .726-.730 .716-.712 .723-.719Phosphorus Pentafluoride, Arsenic Pentafluoride,Germanium TetrafluorideNitrous Oxide 712 .418-.422 .649-.653 .883-.887 .646-.642 .880-.876Oxygen 714 .418-.422 .663-.667 .869-.873 .660-.656 .866-.862Carbon Dioxide, Sulfur Hexafluoride, 716 .418-.422 .677-.681 .855-.859 .674-.670 .852-.848Halocarbons 11, 12, 13, 14, 23, 115, 116,Perfluoropropane, Pentafluoroethane,Octafluorocyclobutane and perfluoro-2-ButeneInerts, Nitrogen. Neon, Helium, 718 .418-.422 .691-.695 .841-.845 .688-.684 .838-.834Argon, Xenon, KryptonAmmonia 720 .418-.422 .705-.709 .827-.831 .702-.698 .824-.820Hydrogen Sulfide 722 .418-.422 .719-.723 .813-.817 .716-.712 .816-.806Hydrogen, Carbon Monoxide, Deuterium, Ethane, 724 .418-.422 .733-.737 .799-.803 .730-.726 .796-.792Ethylene, Methane, Methyl Fluoride, H32Diethylzinc, Dimethylzinc, Triethylaluminum, Diethyltelluride 726 .418-.422 .747-.751 .785-.789 .744-.740 .782-.778Chlorine, Fluorine, Nitric Oxide, Chlorine Trifluoride 728 .418-.422 .761-.765 .761-.765 .758-.754 .758-.754

*Body diameters A, BB, and CC as well as nipple diameters A, MM, and NN should be concentricwithin .002 Full Indicator Movement (FIM). These are critical dimensions for safetythat must be adhered to on final product whether plated or not.

IntroductionCylinder Information

16

Restrictive Flow OrificesThe Restrictive Flow Orifice (RFO) is for use in conjunction withhigh purity compressed gas applications in both thesemiconductor and allied chemical industries.

Restrictive Flow Orifices are used to limit the potential danger ofan uncontrolled flow from a compressed gas cylinder. Unchecked,the instantaneous flow from a 44 liter compressed gas cylinderfilled to 2,000 psig can be as much as 20,000 liters per minute. Byinserting an RFO into the outlet of the CGA connection the flowrate would be reduced by a factor of 100 to approximately 200liters per minute.

The Restrictive Flow Orifice is designed to thread into the outletof most CGA connections that have external male threads. Thiswould include the family of DISS face seal connections (CGA 630and 710) that are used in high purity semiconductor applications.

The RFO has no moving parts. It is about 3/8" long and isgenerally constructed of 316LSS. The orifice opening usuallyvaries from 0.006" to 0.060". It is possible to have orifices that areas small as 0.004" and as large as 0.150" depending upon theapplication.

A KEL-F gasket is provided as part of the assembly to help createa seal between the restrictor and the valve body. Refer to Figure 1.

The flow rate through an orifice is a function of the followingvariables:

• Pressure• Temperature• Specific Gravity• Orifice Opening

Correlations assist in predicting the flow of a particular gas ormixture through an RFO. This is done by first determining theflow through the same RFO at the required pressure with areference gas and then adjusting the specific gravity accordingly.

The pertinent equation is presented below.

Flow = The Flow Rate of N2 1at the Same Pressure Specific Gravity

Typical nitrogen flows for different orifice signs at differentpressures can be found in Table I.

By using this table, a reference flow rate for nitrogen can bedetermined and then the reference equation can be used with thisvalue.

For a mixture a "weighted" or "averaged" specific gravity can beused by multiplying the volume or mole fraction of eachcomponent by its specific gravity and then summing.

In addition to providing safety features that have been mandatedby various local and state codes, the restrictive flow orifice alsoresults in a lower flow rate, which is desirable in manysemiconductor applications. While the RFO was not designed tobe a modulator or control valve, it will as its name implies,substantially reduce the flow rate under a specific set of pressureand temperature conditions for a given gas.

More detailed information on restrictive flow orifices is availablefrom your local Matheson Sales Engineer.

Figure 1: Restrictive Flow Orifice

TABLE I Orifice Flow Rate at Varying Pressures

Orifice Pressure-PSIGSize 0 500 1000 2000

0.006 in. 0 slpm 7 slpm 15 slpm 29 slpm0.010 in. 0 slpm l8 slpm 36 slpm 73 slpm0.040 in. 0 slpm 245 slpm 485 slpm —

References

For Phase Break, all data are obtained without correcting for non-ideal gas conditions, and as such are estimates

For RFO flows, all data are corrected for individual gas densities

For Vapor Pressure, all data are calculated using the coefficients and equation reported by C.L. Yaws and S.N. Naphad,Appendix 5 of Matheson Gas Data Book, 7th Edition, 2001

http://www.mathesontrigas.com/edge/ 17 Semiconductor Products Catalog V 4.0/SpecRev 4.32

Ammonia NH3

Grade Semicon 5N ULSI 5N5 ULTIMA 6N4Purity, % 99.999 99.9995 99.99994

Oxygen ≤0.5 ppmv (+Ar): ≤100 ppbv

Nitrogen ≤5 ppmv ≤1.5 ppmv

Carbon Dioxide ≤0.4 ppmv ≤100 ppbv

Carbon Monoxide ≤2 ppmv ≤0.1 ppmv ≤50 ppbv

Hydrogen ≤100 ppbv

Methane ≤2 ppmv ≤0.1 ppmv ≤50 ppbv

Water (+O2): 5 ppmv ≤2.0 ppmv ≤200 ppbv*

*Water is measured by sampling the liquid phase, as this method has been found to produce more repeatable data. Using a typicalPartition Coefficient of 100, the reported value of 200 ppbv corresponds to 2 ppbv in the vapor phase of a full cylinder.• A lot analysis is provided for each order – Individual analysis is provided for ULTIMA grade and available upon request for other grades.• Pneumatic valves, JIS connections available upon request

Internal Volume Liters 49.0 43.8 439

Cylinder Sizes >> QK QB/QF QI

Contentkg 25.0 22.73 227.3

lbs 55.0 50.0 500

Change Point** lbs 0.74 0.67 6.67

CYLINDER

**Recommended Cylinder Change Point at NTP, based on Phase Break, or the amount of product left in the cylinder when the liquid phasehas completely evaporated and only gaseous product is left (estimate based on ideal gas behavior).

DOT Shipping Name Ammonia, Anhydrous UN Number UN 1005 Shipped as

DOT Classification 2.2 (Non-Flammable Gas) ECCN# 1C980Liquefied Gas

DOT Label NON-FLAMMABLE GAS Harmonized # 2814.10.0000

SHIP

Cylinder Pressure 113.9 psig

@NTP 9.0 atm

Specific Volume 1.41 m3/kg

@NTP 22.6 ft3/lb

CAS No 7664-41-7

CGA/DISS/JIS 660/720/W22-14R

Molecular Weight 17.03 g/mol

TLV 25 ppm

LFL-UFL in Air 16 - 25 %

TECHNICAL DATA

Nominal Diameter (OD)xHeight* Material of Construction

Cylinder Treatment cm Inches Cylinder Valve

QK ULTRA-LINE® 25x140/144/153 10x55/56.5/60 CS SS

QB ULTRA-LINE II® 23x130/134/143 9x51/52.5/56 CS SS

QF ULTRA-LINE® 23x130/134/143 9x51/52.5/56 CS SS

QI ULTRA-LINE® 61x211 24x83 CS SS

*Height is reported as the distance from the bottom of the cylinder to the cylinder neck/ center of the valve outlet/ top of the handwheelASB: Aluminum Silicon Bronze CS: Carbon Steel SS: Stainless Steel

VaporTemp, °C 0.0 15.5 21.0 32.2 43.3

PressurePress, psig 47.6 92.8 113.9 165.7 232.0

Temp, °F 32 60 70 90 110

Size, mm 0.254 0.3556 0.508 0.762 1.016

RFO DataSize, inches 0.010 0.014 0.020 0.030 0.040

Flow, sccm 6634 12665 26134 58298 100514

Flow, scf/h 14.0 26.8 55.4 123.5 213.0

NTP = 21°C or 70°F and 101.3 kPa or 1 atm

http://www.mathesontrigas.com/edge/ 18 Semiconductor Products Catalog V 4.0/SpecRev4.22

Argon Ar

Grade Semicon 5N ULSI 6NPurity, % 99.999 99.9999

Oxygen ≤1.0 ppmv ≤300 ppbv

Nitrogen ≤700 ppbv

Carbon Dioxide ≤0.5 ppmv ≤100 ppbv

Carbon Monoxide ≤0.5 ppmv ≤100 ppbv

Methane ≤0.5 ppmv ≤100 ppbv

Water ≤3.0 ppmv ≤500 ppbv

• A lot analysis is provided for each order. – Individual analysis is also available upon request.• Pneumatic valves and JIS connections are available upon request.

Internal Volume Liters 43.8 2.3

Cylinder Sizes >> QF/QA JF/JA/JB

ContentLiters 7,930 340

ft3 280 12

Cylinder Pressure*psig 2,490 2,000

atm 176.1 141.6

* @ NTP

CYLINDER

DOT Shipping Name Argon, Compressed UN Number UN 1006 Shipped as

DOT Classification 2.2 (Non-Flammable Gas) ECCN# EAR99 Compressed

DOT Label NON-FLAMMABLE GAS Harmonized # 2804.21.0000 Gas

SHIP

Specific Volume 0.604 m3/kg

@NTP 9.68 ft3/lb

CAS No 7440-37-1

CGA/DISS/JIS 580/718/22-14R

Atomic Weight 39.95 g/molTECHNICAL DATA

Nominal Diameter (OD)xHeight* Material of Construction

Cylinder Treatment cm Inches Cylinder Valve

QF ULTRA-LINE® 23x130/134/143 9x51/52.5/56 CS SS

QA ULTRA-LINE® 23x130/134/143 9x51/52.5/56 CS Brass

JF ULTRA-LINE® 10x33/37/46 4x13/14.5/18 CS SS

JA ULTRA-LINE® 10x33/37/46 4x13/14.5/18 CS Brass

JB ULTRA-LINE II® 10x33/37/46 4x13/14.5/18 CS SS

*Height is reported as the distance from the bottom of the cylinder to the cylinder neck/ center of the valve outlet/ top of the handwheelCS: Carbon Steel SS: Stainless Steel

Critical Temperature -122.4°C -188.4°F

Critical Pressure 50 atm 711.5 psia

NTP = 21°C or 70°F and 101.3 kPa or 1 atm

http://www.mathesontrigas.com/edge/ 19 Semiconductor Products Catalog V 4.0/SpecRev4.31

Arsine AsH3

Grade ULSI 5N5 ULSI 6N ULTIMA 6N5 ULTIMA II 6N5Purity, % 99.9995 99.9999 99.99995 99.99995

Water ≤2.0 ppmv ≤350 ppbv ≤100 ppbv ≤100 ppbvNitrogen ≤2.0 ppmv ≤250 ppbv ≤50 ppbv ≤50 ppbvOxygen ≤1.0 ppmv ≤40 ppbv ≤20 ppbv ≤20 ppbv

Carbon Dioxide ≤0.5 ppmv ≤40 ppbv ≤10 ppbv ≤10 ppbvCarbon Monoxide ≤0.1 ppmv ≤10 ppbv ≤10 ppbv ≤10 ppbv

Methane ≤0.5 ppmvC1 - C2 ≤500 ppbv ≤100 ppbv ≤50 ppbvC3 - C5 ≤50 ppbvArgon ≤50 ppbv ≤20 ppbv

Germane ≤50 ppbv ≤50 ppbv ≤10 ppbvHydrogen Sulfide ≤50 ppbv ≤50 ppbv ≤50 ppbv

Silane ≤50 ppbv ≤10 ppbvPhosphine ≤25 ppbv

Carbonyl Sulfide ≤25 ppbvNitrous Oxide ≤20 ppbv

• All cylinders are individually analyzed

Internal Volume Liters 43.8 47.5 29.5Cylinder Sizes >> QF QZ QH*

Contentkg 25 29/18.2* 12.7*lbs 55 60/40* 28*

Change Point** lbs 5.1 5.5 3.4

CYLINDER

* Fills available for ULTIMA Grade only**Recommended Cylinder Change Point at NTP, based on Phase Break, or the amount of product left in the cylinder when the liquid phasehas completely evaporated and only gaseous product is left (estimate based on ideal gas behavior).

DOT Shipping Name Arsine UN Number UN 2188 Shipped asDOT Classification 2.3 (2.1) Poison Gas ECCN # 3C004

DOT LabelPOISON GAS / INHALATION

Harmonized # 2850.00.0000Liquefied Gas

HAZARD, FLAMMABLE GAS

SHIP

Cylinder Pressure 204.6 psig@NTP 15.4 atm

Specific Volume 0.31 m3/kg@NTP 5.0 ft3/lb

CAS No 7784-42-1CGA/DISS/JIS 350/632/W22-14L

Molecular Weight 77.95 g/molTLV 0.05 ppmv

LFL in Air 4.5%

TECHNICAL DATA

Nominal Diameter (OD)xHeight* Material of Construction

Cylinder Treatment cm Inches Cylinder ValveQF ULTRA-LINE® 23x130/134/143 9x51/52.5/56 CS SSQZ ULTRA-LINE II® 25x137/141/149 10x54/55.5/59 Aluminum SSQH ULTRA-LINE® 20x122/126/135 8x48/49.5/53 Aluminum SS

*Height is reported as the distance from the bottom of the cylinder to the cylinder neck/ center of the valveoutlet/ top of the handwheelCS: Carbon Steel SS: Stainless Steel

VaporTemp, °C 0.0 15.5 21.0 32.2 43.3

PressurePress, psig 116.2 178.2 204.6 265.1 336.7Temp, °F 32 60 70 90 110

Size, mm 0.254 0.3556 0.508 0.762 1.016

RFO DataSize, inches 0.010 0.014 0.020 0.030 0.040Flow, sccm 5326 10168 20981 46805 80698Flow, scf/h 11.3 21.5 44.5 99.2 171.0

NTP = 21°C or 70°F and 101.3 kPa or 1 atm

Hall Mobility > 120,000 (cm2/Vs) > 160,000 (cm2/Vs) > 180,000 (cm2/Vs)Carrier Concentration < 5x1014 (cm-3) < 1x1014 (cm-3) < 5x1013 (cm-3)

• Performace data above is typical for 10um GaAs/GaAs with growth conditions of V/III ratio: 150 and temperature of 650C. 77K measurements• Pneumatic valves and DIN and JIS connections are available upon request.

http://www.mathesontrigas.com/edge/ 20 Semiconductor Products Catalog V 4.0/SpecRev4.32

Boron Trichloride BCl3

Grade Semicon 4N5 ULSI 5N Gigabit 5N5Purity, % 99.995 99.999 99.9995 Metals, ppbw

Oxygen ≤9 ppmv ≤1.0 ppmv ≤0.5 ppmv Al ≤20 Ni ≤10

Nitrogen ≤30 ppmv ≤4.0 ppmv ≤0.5 ppmv Cr ≤10 Na ≤20

Carbon Dioxide ≤5 ppmv ≤2.0 ppmv ≤0.5 ppmv Ca ≤10 K ≤20

Carbon Monoxide ≤3 ppmv ≤0.5 ppmv ≤0.3 ppmv Cu ≤10 Cd ≤0.5

Methane ≤1 ppmv ≤0.5 ppmv ≤0.5 ppmv Fe ≤30 Ba ≤10

Chlorine ≤1 ppmv ≤1 ppmv ≤0.1 ppmv Li ≤10 Sb ≤10

Phosgene ≤0.1 ppmv As ≤20 Pb ≤10

Hydrogen Chloride ≤1.0 ppmv Mg ≤10 Mn ≤10

Silicon Tetrachloride ≤2.0 ppmv Si ≤10 Zn ≤10

• A lot analysis is provided for each order – Individual analysis is also available upon request.• Pneumatic valves, JIS connections available upon request.

Internal Volume Liters 43.8 2.3

Cylinder Sizes >> QF JF

Contentkg 50 45 31.8 18.2 2.3

lbs 110 100 70 40 5

Change Point* lbs 0.66 0.03

CYLINDER

*Recommended Cylinder Change Point at NTP, based on Phase Break, or the amount of product left in the cylinder when the liquid phasehas completely evaporated and only gaseous product is left (estimate based on ideal gas behavior).

Cylinder Pressure 4.4 psig

@NTP 1.34 atm

Specific Volume 0.21 m3/kg

@NTP 3.3 ft3/lb

CAS No 10294-34-5

CGA/DISS/JIS 660/634/W22-14R

Molecular Weight 117.17 g/mol

TLV 1 ppm

TECHNICAL DATA

Nominal Diameter (OD)xHeight* Material of Construction

Cylinder Treatment cm Inches Cylinder Valve

QF ULTRA-LINE® 23x130/134/143 9x51/52.5/56 CS SS

JF ULTRA-LINE® 10x33/37/46 4x13/14.5/18 CS SS

*Height is reported as the distance from the bottom of the cylinder to the cylinder neck/ center of the valve outlet/ top of the handwheelCS: Carbon Steel SS: Stainless Steel

VaporTemp, °C 0.0 15.5 21.0 32.2 43.3

PressurePress, psig -5.6 1.7 4.4 13.9 25.1

Temp, °F 32 60 70 90 110

Size, mm 0.254 0.3556 0.508 0.762 1.016

RFO DataSize, inches 0.010 0.014 0.020 0.030 0.040

Flow, sccm 412 787 1623 3621 6243

Flow, scf/h 0.9 1.7 3.4 7.7 13

NTP = 21°C or 70°F and 101.3 kPa or 1 atm

DOT Shipping Name Boron Trichloride UN Number UN 1741 Shipped as

DOT Classification2.3 Poison Gas, Hazard

ECCN # EAR99Zone C

Liquefied Gas

DOT LabelPOISON GAS / INHALATION

Harmonized # 2812.10.5050HAZARD, CORROSIVE GAS

SHIP

http://www.mathesontrigas.com/edge/ 21 Semiconductor Products Catalog V 4.0/SpecRev4.32

Boron Trifluoride BF3

Grade ULSI 4N5 11B EnrichedPurity, % 99.995 99.9

Oxygen ≤25 ppmv

Oxygen + Nitrogen + Argon ≤10 ppmv

Nitrogen ≤25 ppmv

Carbon Dioxide ≤10 ppmv ≤25 ppmv

Argon ≤25 ppmv

Sulfur Dioxide ≤10 ppmv ≤25 ppmv

Hydrogen Fluoride ≤25 ppmv

Isotopic Purity, 11B >99.7%

• A lot analysis is provided for each order – Individual analysis is also available upon request.• Pneumatic valves and JIS connections available upon request

Internal Volume Liters 2.3 0.44

Cylinder Sizes >> JB/JF SF/SA

Contentg 400 180 35

lbs 0.88 0.39 0.077

Cylinder Pressure*psig 700 400 400

atm 50.2 29.1 29.1

* @ NTP

CYLINDER

DOT Shipping Name Boron Trifluoride, Compressed UN Number UN 1008 Shipped as

DOT Classification2.3, Poison Gas Hazard Zone B

ECCN # EAR99 Compressed(Gas Poisonous by Inhalation)GasDOT Label POISON GAS / INHALATION HAZARD Harmonized # 2812-90-0000

SHIP

Specific Volume 0.35 m3/kg

@NTP 5.6 ft3/lb

CAS No 7637-07-02

CGA/DISS/JIS 330/642/W22-14L

Molecular Weight 67.81 g/mol

TLV 1 ppmTECHNICAL DATA

Size, mm 0.254 0.3556 0.508 0.762 1.016

RFO DataSize, inches 0.010 0.014 0.020 0.030 0.040

Flow, sccm 10640 20313 41916 93505 161215

Flow, scf/h 22.5 43.0 88.8 198.1 341.6

NTP = 21°C or 70°F and 101.3 kPa or 1 atm

Nominal Diameter (OD)xHeight* Material of Construction

Cylinder Treatment cm Inches Cylinder Valve

JB ULTRA-LINE II® 10x33/37/46 4x13/14.5/18 CS SS

JF ULTRA-LINE® 10x33/37/46 4x13/14.5/18 CS SS

SF ULTRA-LINE® 5x30/34/43 2x12/13.5/17 CS SS

SA ULTRA-LINE® 5x30/34/43 2x12/13.5/17 CS Brass

*Height is reported as the distance from the bottom of the cylinder to the cylinder neck/ center of the valve outlet/ top of the handwheelCS: Carbon Steel SS: Stainless Steel

http://www.mathesontrigas.com/edge/ 22 Semiconductor Products Catalog V 4.0/SpecRev 4.21

Carbon Dioxide CO2

Grade ULSI 5NPurity, % 99.999

Oxygen ≤1 ppmv

Nitrogen ≤1 ppmv

Carbon Monoxide ≤0.2 ppmv

Total Hydrocarbons (CH4) ≤4 ppmv

Water ≤2 ppmv

Hydrogen ≤1 ppmv

• A lot analysis is provided for each order. – Individual analysis is also available upon request.• Pneumatic valves and JIS connections are available upon request.• A FLET (Full Length Educator Tube) is available upon request.

Internal Volume Liters 43.8 17.1

Cylinder Sizes >> QF/QA/QB GF/GA

Contentlbs 60 24

kg 27.2 10.9

Change Point* lbs 19.56 7.64

CYLINDER

DOT Shipping Name Carbon Dioxide UN Number UN 1013 Shipped as

DOT Classification 2.2 (Non-Flammable Gas) ECCN # 1C980 Liquefied

DOT Label NON-FLAMMABLE GAS Harmonized # 2811.21.0000 Gas

SHIP

Nominal Diameter (OD)xHeight* Material of Construction

Cylinder Treatment cm Inches Cylinder Valve

QF ULTRA-LINE® 23x130/134/143 9x51/52.5/56 CS SS

QA ULTRA-LINE® 23x130/134/143 9x51/52.5/56 CS Brass

QB ULTRA-LINE II® 23x130/134/143 9x51/52.5/56 CS SS

GF ULTRA-LINE® 23x66/70/79 9x26/27.5/31 CS SS

GA ULTRA-LINE® 23x66/70/79 9x26/27.5/31 CS Brass

*Height is reported as the distance from the bottom of the cylinder to the cylinder neck/ center of the valve outlet/ top of the handwheelCS: Carbon Steel SS: Stainless Steel

Critical Temperature 31°C 87.9°F

Critical Pressure 72.85 atm 1,071 psia

NTP = 21°C or 70°F and 101.3 kPa or 1 atm

*Recommended Cylinder Change Point at NTP, based on Phase Break, or the amount of product left in thecylinder when the liquid phase has completely evaporated and only gaseous product is left (estimate based onideal gas behavior).

Cylinder Pressure 830 psig

@NTP 59.4 atm

Specific Volume 0.54 m3/kg

@NTP 8.74 ft3/lb

CAS No 124-38-9

CGA/DISS/JIS 320/716/W22-14R

Molecular Weight 44.01 g/mol

TECHNICAL DATA

http://www.mathesontrigas.com/edge/ 23 Semiconductor Products Catalog V 4.0/SpecRev 4.31

Carbon Monoxide CO

Grade ULSI 3N5 ULSI PLUS 4N5Purity, % 99.95 99.995 Metals, ppbw

Oxygen ≤100 ppmv ≤6 ppmv Al ≤1 Mn ≤1

Nitrogen ≤250 ppmv ≤10 ppmv Cd ≤1 Ni ≤1

Carbon Dioxide ≤50 ppmv ≤15 ppmv Ca ≤1 Mg ≤1

Total Hydrocarbons ≤3 ppmv Cr ≤1 K ≤2

Methane ≤3 ppmv Cu ≤1 Na ≤5

Water ≤3 ppmv ≤1 ppmv Fe ≤5 Zn ≤1

Iron Pentacarbonyl ≤1 ppmv ≤0.5 ppmv Pb ≤1

Hydrogen ≤1 ppmv

• A lot analysis is provided for each order. – Individual analysis is also available upon request.• For gas phase impurities, a metal analysis is performed periodically.• Pneumatic valves and JIS connections are available upon request.NOTE: Aluminum cylinders with brass valves are the recommended package for CO.

Internal Volume Liters 46.4 43.8 29.5

Cylinder Sizes >> QY QB QH/QX

Contentm3 6.9 4.96 3.3

ft3 244 175 118

Cylinder Pressure* psig 2,216 1,650 1,650

* @ NTP

CYLINDER

DOT Shipping Name Carbon Monoxide, compressed UN Number UN 1016 Shipped as

DOT Classification2.3 Poison Gas Hazard Zone D

ECCN # 1C980 Compressed(Gas Poisonous by Inhalation)GasDOT Label INHALATION HAZARD FLAMMABLE GAS Harmonized # 2811.29.0000

SHIP

Specific Volume 0.86 m3/kg

@NTP 13.8 ft3/lb

CAS No 630-08-0

CGA/DISS/JIS 350/724/W22-14L

Molecular Weight 28.01 g/molTECHNICAL DATA Critical Temperature -140.2°C -220.4°F

Critical Pressure 35.7 atm 507.5 psia

NTP = 21°C or 70°F and 101.3 kPa or 1 atm

Nominal Diameter (OD)xHeight* Material of Construction

Cylinder Treatment cm Inches Cylinder Valve

QY ULTRA-LINE® 25x132/136/145 10x52/53.5/57 Aluminum SS/Brass

QB ULTRA-LINE II® 23x130/134/143 9x51/52.5/56 CS SS

QH/QX ULTRA-LINE ® 20x122/126/135 8x48/49.5/53 Aluminum SS/Brass

*Height is reported as the distance from the bottom of the cylinder to the cylinder neck/ center of the valve outlet/ top of the handwheelCS: Carbon Steel SS: Stainless Steel

http://www.mathesontrigas.com/edge/ 24 Semiconductor Products Catalog V 4.0/SpecRev 4.31

Chlorine Cl2

Grade Semicon 4N ULSI 5N ULSI PLUS 5NPurity, % 99.99 99.999 99.999 Metals, ppbw

Oxygen ≤50 ppmv ≤1.0 ppmv ≤1.0 ppmv Ca ≤10 Ni ≤300

Nitrogen ≤50 ppmv ≤2.0 ppmv ≤2.0 ppmv Cd ≤10 K ≤100

Carbon Dioxide ≤30 ppmv ≤4.0 ppmv ≤4.0 ppmv Cr ≤100 Na ≤50

Carbon Monoxide ≤5 ppmv ≤0.5 ppmv ≤0.5 ppmv Cu ≤100 Zn ≤20

Methane ≤1 ppmv ≤0.1 ppmv ≤0.1 ppmv Fe ≤200

Water ≤2.0 ppmv Total Metals: ≤1,000

• A lot analysis is provided for each order. – Individual analysis is also available upon request.• Pneumatic valves, JIS connections available upon request.

Internal Volume Liters 439 43.8

Cylinder Sizes >> QI QF/QB

Contentkg 499.4 50 45.4 31.8

lbs 1,100 110 100 70

Change Point* lbs 20.4 2.04

CYLINDER

*Recommended Cylinder Change Point at NTP, based on Phase Break, or the amount of product left in the cylinder when the liquid phasehas completely evaporated and only gaseous product is left (estimate based on ideal gas behavior).

DOT Shipping Name Chlorine UN Number UN 1017 Shipped as

DOT Classification2.3 Poison Gas, Hazard Zone B

ECCN # EAR99 Liquefied (Gas Poisonous by Inhalation)GasDOT Label INHALATION HAZARD, CORROSIVE GAS Harmonized # 2801.10.0000

SHIP

Cylinder Pressure 85.3 psig

@NTP 7.0 atm

Specific Volume 0.34 m3/kg

@NTP 5.4 ft3/lb

CAS No 7782-50-5

CGA/DISS/JIS 660/728/W26-14R

Molecular Weight 70.91 g/mol

TLV 0.5 ppm

TECHNICAL DATA

VaporTemp, °C 0.0 15.5 21.0 32.2 43.3

PressurePress, psig 38.9 72.1 85.3 122.4 166.0

Temp, °F 32 60 70 90 110

Size, mm 0.254 0.3556 0.508 0.762 1.016

RFO DataSize, inches 0.010 0.014 0.020 0.030 0.040

Flow, sccm 2519 4810 9925 22141 38174

Flow, scf/h 5.3 10.2 21.0 46.9 80.9

NTP = 21°C or 70°F and 101.3 kPa or 1 atm

Nominal Diameter (OD)xHeight* Material of Construction

Cylinder Treatment cm Inches Cylinder Valve

QI ULTRA-LINE® 61x211 24x83 CS SS

QF ULTRA-LINE® 23x130/134/143 9x51/52.5/56 CS SS

QB ULTRA-LINE II® 23x130/134/143 9x51/52.5/56 CS SS

*Height is reported as the distance from the bottom of the cylinder to the cylinder neck/ center of the valve outlet/ top of the handwheelCS: Carbon Steel SS: Stainless Steel

http://www.mathesontrigas.com/edge/ 25 Semiconductor Products Catalog V 4.0/SpecRev 4.32

Deuterium D2

Grade Semicon 4N5 ULSI 5NPurity, % 99.995 99.999

Enrichment, % 99.5 99.8Oxygen ≤ 1.0 ppmv ≤1.0 ppmv

Nitrogen ≤5.0 ppmv ≤1.0 ppmv

Carbon Dioxide ≤2.0 ppmv ≤1.0 ppmv

Carbon Monoxide ≤1.0 ppmv ≤1.0 ppmv

THC ≤ 1.0 ppmv ≤1.0 ppmv

Water + D2O ≤5.0 ppmv ≤1.0 ppmv

Hydrogen* ≤150 ppmv ≤100 ppmv

Hydrogen Deuteride* ≤5,000 ppmv ≤3,000 ppmv

*Not included in over-all purity analysis• A lot analysis is provided for each order. – Individual analysis is also available upon request.• Pneumatic valves and JIS connections are available upon request.

Internal Volume Liters 43.8

Cylinder Sizes >> QA/QF

ContentLiters 6,000

ft3 212

Cylinder Pressure**psig 2,200

atm 155.7

** @ NTP

CYLINDER

DOT Shipping Name Deuterium Compressed UN Number UN 1957 Shipped as

DOT Classification 2.1 (Flammable Gas) ECCN # 0C004 Compressed

DOT Label FLAMMABLE GAS Harmonized # 2845.90.0000 Gas

SHIP

Specific Volume 5.99 m3/kg

@NTP 95.9 ft3/lb

CAS No 7782-39-0

CGA/DISS/JIS 350/724/W22-14L

Molecular Weight 4.03 g/molTECHNICAL DATA Critical Temperature -234.8°C -390.6°F

Critical Pressure 16.9 atm 241.3 psia

NTP = 21°C or 70°F and 101.3 kPa or 1 atm

Nominal Diameter (OD)xHeight* Material of Construction

Cylinder Treatment cm Inches Cylinder Valve

QA ULTRA-LINE® 23x130/134/143 9x51/52.5/56 CS Brass

QF ULTRA-LINE® 23x130/134/143 9x51/52.5/56 CS SS

*Height is reported as the distance from the bottom of the cylinder to the cylinder neck/ center of the valve outlet/ top of the handwheelCS: Carbon Steel SS: Stainless Steel

http://www.mathesontrigas.com/edge/ 26 Semiconductor Products Catalog V 4.0/SpecRev 4.31

Dichlorosilane SiH2Cl2Grade Semicon 2N ULSI Plus 3N

Purity, % 99.0(w) 99.9(w)**Oxygen + Argon ≤1.0 ppmv

Nitrogen ≤1.0 ppmv

Carbon Dioxide ≤1.0 ppmv

Carbon Monoxide ≤1.0 ppmv

Methane ≤1.0 ppmv

Hydrocarbons (C2-C4) ≤1.0 ppmv

Hydrogen Chloride ≤500 ppmw

Monochlorosilane ≤0.3% w ≤250 ppmw

Other Chlorosilanes ≤1% w

Trichlorosilane ≤500 ppmw

Silicon Tetrachloride ≤200 ppmw

Resistivity, N-type, ohm-cm > 200 > 400

Individual Metals – Al* ≤1.0 ppbw ≤50 ppta

As* ≤0.2 ppbw ≤50 ppta

B* ≤0.1 ppbw ≤300 ppta

P* ≤0.3 ppbw ≤300 ppta

C* ≤1,000 ppbw ≤300 ppba

Fe* ≤50 ppbw ≤2 ppbw

Ga* ≤10 ppta Mn ≤0.2 ppbw

Sb* ≤10 ppta Mo ≤0.2 ppbw

Additional Metals:In* ≤10 ppta Ni ≤0.2 ppbw

Cr ≤0.2 ppbw Na ≤0.2 ppbw

Cu ≤0.2 ppbw Zn ≤0.2 ppbw

O* ≤200 ppba*Total deposited metals**Total Purity excluding HCl

• A lot analysis is provided for each order.• Individual analysis is also available upon request.• Pneumatic valves and JIS connections are available upon request.

Internal Volume Liters 41 43.8

Cylinder Sizes >> QL QF

Contentkg 40.9 43.1

lbs 90 93

Change Point*** lbs 0.6 0.7

CYLINDER

***Recommended Cylinder Change Point at NTP, based on Phase Break, or theamount of product left in the cylinder when the liquid phase has completelyevaporated and only gaseous product is left (estimate based on ideal gas behavior).

UN Number UN 2189

DOT Shipping Name Dichlorosilane

DOT Classification 2.3 (Poison Gas)

DOT Label POISON GAS, FLAMMABLE GAS

ECCN # EAR99

Harmonized # 2827.39.9050

SHIP

Cylinder Pressure 8.6 psig

@NTP 1.7 atm

Specific Volume 0.24 m3/kg

@NTP 3.83 ft3/lb

CAS No 4109-96-0

CGA/DISS/JIS 678/636/W22-14L

Molecular Weight 101.01 g/mol

TECHNICAL DATA

NTP = 21°C or 70°F and 101.3 kPa or 1 atm

VaporTemp, °C 0.0 15.5 21.0 32.2 43.3

PressurePress, psig -4.1 4.3 8.6 18.1 30.8

Temp, °F 32 60 70 90 110

Size, mm 0.254 0.3556 0.508 0.762 1.016

RFO DataSize, inches 0.010 0.014 0.020 0.030 0.040

Flow, sccm 553 1056 2178 4860 8379

Flow, scf/h 1.2 2.2 4.6 10 18

http://www.mathesontrigas.com/edge/ 27 Semiconductor Products Catalog V 4.0/SpecRev 4.31

Disilane Si2H6

Grade Semicon 3N ULSI 4N8Purity, % 99.9 99.998

Oxygen + Argon ≤1 ppmv

Nitrogen ≤2 ppmv

Carbon Dioxide ≤1 ppmv ≤1 ppmv

Methane ≤1 ppmv ≤1 ppmv

Water ≤1 ppmv ≤1 ppmv

Air ≤5 ppmv

Chlorosilanes ≤0.2 ppmv

Higher Silanes* ≤50 ppmv

Siloxanes ≤5 ppmv

Silane ≤1000 ppmv ≤1000 ppmv*

Resistivity, N-type >1000 ohm-cm

*Not included in over-all purity analysis.• A lot analysis is provided for each order – Individual analysis is also available upon request.• Pneumatic valves, JIS connections available upon request.

Internal Volume Liters 43.8 17.1 7.3

Cylinder Sizes >> QF GF UF

Contentkg 5 3 2

lbs 11 6.6 4.4

Change Point** lbs 0.9 0.3 0.1

CYLINDER

**Recommended Cylinder Change Point at NTP, based on Phase Break, or the amount of product left in the cylinder when the liquid phasehas completely evaporated and only gaseous product is left (estimate based on ideal gas behavior).

DOT Shipping Name Compressed Gas Flammable, NOS (Disilane) UN Number UN 1954

DOT Classification 2.1 (Flammable Gas) ECCN # EAR99

DOT Label FLAMMABLE GAS Shipped as Liquefied Gas

SHIP

Cylinder Pressure 33 psig

@NTP 3.35 atm

Specific Volume 0.35 m3/kg

@NTP 5.6 ft3/lb

CAS No 1590-87-0

CGA/DISS/JIS 350/632/W22-14L

Molecular Weight 62.22 g/mol

TECHNICAL DATA

Critical Temperature 159°C 317.9°F

Critical Pressure 52.3 atm 744 psia

Size, mm 0.254 0.3556 0.508 0.762 1.016

RFO DataSize, inches 0.010 0.014 0.020 0.030 0.040

Flow, sccm 1412 2696 5564 12411 21399

Flow, scf/h 3.0 5.7 12 26 45

NTP = 21°C or 70°F and 101.3 kPa or 1 atm

Nominal Diameter (OD)xHeight* Material of Construction

Cylinder Treatment cm Inches Cylinder Valve

QF ULTRA-LINE® 23x130/134/143 9x51/52.5/56 CS SS

GF ULTRA-LINE® 23x66/70/79 9x26/27.5/31 CS SS

UF ULTRA-LINE® 15x51/55/64 6x19/20.5/24 CS SS

*Height is reported as the distance from the bottom of the cylinder to the cylinder neck/ center of the valve outlet/ top of the handwheelCS: Carbon Steel SS: Stainless Steel

http://www.mathesontrigas.com/edge/ 28 Semiconductor Products Catalog V 4.0/SpecRev 4.31

Germane GeH4

Grade Semicon 5NPurity, % 99.999

Oxygen+ Argon ≤0.5 ppmv

Nitrogen ≤2.0 ppmv

Carbon Dioxide ≤2.0 ppmv

Carbon Monoxide ≤1.0 ppmv

Methane ≤1.0 ppmv

Water ≤1.0 ppmv

Chlorogermanes ≤5.0 ppmv

Digermane* ≤20.0 ppmv

Germoxanes ≤5.0 ppmv

Hydrogen* ≤50.0 ppmv

Trigermane ≤1.0 ppmv

*Not included in over-all purity analysis.• A lot analysis is provided for each order – Individual analysis is also available upon request.• Pneumatic valves, JIS connections available upon request.

Internal Volume Liters 29.5 17.1 7.3

Cylinder Sizes >> QH GF UF

Contentkg 1 0.5 0.1

lbs 2.2 1.1 0.22

Cylinder Pressure**psig 160 118 45

atm 12.3 9.3 5.3** @ NTP

CYLINDER

DOT Shipping Name Germane UN Number UN 2192 Shipped as

DOT Classification 2.3 (Toxic Gas) ECCN # EAR99 Compressed

DOT Label TOXIC GAS, FLAMMABLE GAS Harmonized # 2851.00.0000 Gas

SHIP

Critical Temperature 94.7°C 34.8°F

Critical Pressure 56.6 atm 805.3 psia

Size, mm 0.254 0.3556 0.508 0.762 1.016

RFO DataSize, inches 0.010 0.014 0.020 0.030 0.040

Flow, sccm 4257 8127 16769 37408 64497

Flow, scf/h 9.0 17.2 35.5 79.3 136.7

Specific Volume 0.32 m3/kg

@NTP 5.1 ft3/lb

CAS No 7782-65-2

CGA/DISS/JIS 350/632/W22-14L

Molecular Weight 76.62 g/molTECHNICAL DATA

Nominal Diameter (OD)xHeight* Material of Construction

Cylinder Treatment cm Inches Cylinder Valve

QH ULTRA-LINE® 20x122/126/135 8x48/49.5/53 Aluminum SS

GF ULTRA-LINE® 23x66/70/79 9x26/27.5/31 CS SS

UF ULTRA-LINE® 15x51/55/64 6x19/20.5/24 CS SS

*Height is reported as the distance from the bottom of the cylinder to the cylinder neck/ center of the valve outlet/ top of the handwheelCS: Carbon Steel SS: Stainless Steel

NTP = 21°C or 70°F and 101.3 kPa or 1 atm

http://www.mathesontrigas.com/edge/ 29 Semiconductor Products Catalog V 4.0/SpecRev4.21

Halocarbon 14 (Tetrafluoromethane) CF4

Grade Semicon 3N5 ULSI 5NPurity, % 99.95 99.999

Oxygen ≤100 ppmv

Nitrogen ≤400 ppmv

Carbon Dioxide ≤10 ppmv (+CO) ≤1 ppmv

Carbon Monoxide ≤20 ppmv

Other Halocarbons ≤2.0 ppmv

Water ≤10 ppmv ≤2.0 ppmv

Air ≤5.0 ppmv

Sulfur Hexafluoride ≤1.0 ppmv

Acidity as HF ≤1.0 ppmv

• A lot analysis is provided for each order. – Individual analysis is also available upon request.• Pneumatic valves and JIS connections are available upon request.

Internal Volume Liters 43.8

Cylinder Sizes >> QF/QA/QB

Contentlbs 70

kg 31.82

CYLINDER

DOT Shipping NameCompressed Gas NOS

UN Number UN 1982 Shipped as(Tetrafluoromethane)

DOT Classification 2.2 (Non-Flammable Gas) ECCN # EAR99 Compressed

DOT Label NON-FLAMMABLE GAS Harmonized # 2903.30.2010 Gas

SHIP

Cylinder Pressure 2,000 psig

@NTP 141.6 atm

Specific Volume 0.27 m3/kg

@NTP 4.4 ft3/lb

CAS No 75-73-0

CGA/DISS/JIS 320/716/W22-14L

Molecular Weight 88.00 g/mol

TECHNICAL DATA

Critical Temperature -45.6°C -50.2°F

Critical Pressure 38.1 atm 542.3 psia

NTP = 21°C or 70°F and 101.3 kPa or 1 atm

Nominal Diameter (OD)xHeight* Material of Construction

Cylinder Treatment cm Inches Cylinder Valve

QF ULTRA-LINE® 23x130/134/143 9x51/52.5/56 CS SS

QA ULTRA-LINE® 23x130/134/143 9x51/52.5/56 CS Brass

QB ULTRA-LINE II® 23x130/134/143 9x51/52.5/56 CS SS

*Height is reported as the distance from the bottom of the cylinder to the cylinder neck/ center of the valve outlet/ top of the handwheelCS: Carbon Steel SS: Stainless Steel

http://www.mathesontrigas.com/edge/ 30 Semiconductor Products Catalog V 4.0/SpecRev 4.21

Halocarbon 23 (Trifluoromethane) CHF3

Grade Semicon 4N5 ULSI 5NPurity, % 99.995 99.999

Oxygen + Nitrogen ≤50 ppmv

Oxygen + Nitrogen + Carbon Monoxide ≤20 ppmv

Carbon Dioxide ≤10 ppmv

Water ≤20 ppmv ≤5 ppmv

Other Organics ≤10 ppmv

Acidity as HCl ≤0.1 ppmw ≤0.1 ppmw

• A lot analysis is provided for each order. – Individual analysis is also available upon request.• Pneumatic valves and JIS connections are available upon request.

Internal Volume Liters 43.8

Cylinder Sizes >> QF/QA/QB

Contentlbs 70

kg 31.82

Change Point* lbs 28.2

*Recommended Cylinder Change Point at NTP, based on Phase Break, or the amount ofproduct left in the cylinder when the liquid phase has completely evaporated and onlygaseous product is left (estimate based on ideal gas behavior).

CYLINDER

DOT Shipping Name Trifluoromethane UN Number UN 1984 Shipped as

DOT Classification 2.2 (Non-Flammable Gas) ECCN # EAR99 Liquefied

DOT Label NON-FLAMMABLE GAS Harmonized # 2903.30.2010 Gas

SHIP

Cylinder Pressure 635 psig

@NTP 45.7 atm

Specific Volume 0.343 m3/kg

@NTP 5.5 ft3/lb

CAS No 75-46-7

CGA/DISS/JIS 660/716/W22-14L

Molecular Weight 70 g/mol

TECHNICAL DATA

VaporTemp, °C 0.0 15.5 21.0 32.2 43.3

PressurePress, psig 347 529 635 802 1040

Temp, °F 32 60 70 90 110

NTP = 21°C or 70°F and 101.3 kPa or 1 atm

Nominal Diameter (OD)xHeight* Material of Construction

Cylinder Treatment cm Inches Cylinder Valve

QF ULTRA-LINE® 23x130/134/143 9x51/52.5/56 CS SS

QA ULTRA-LINE® 23x130/134/143 9x51/52.5/56 CS Brass

QB ULTRA-LINE II® 23x130/134/143 9x51/52.5/56 CS SS

*Height is reported as the distance from the bottom of the cylinder to the cylinder neck/ center of the valve outlet/ top of the handwheelCS: Carbon Steel SS: Stainless Steel

http://www.mathesontrigas.com/edge/ 31 Semiconductor Products Catalog V 4.0/SpecRev4.4

Halocarbon 32 (Difluoromethane) CH2F2

• A lot analysis is provided for each order – Individual analysis is also available upon request.• Other Organics = H12, H22, H23, H134a

Internal Volume Liters 43.8 17.1 7.3

Cylinder Sizes >> QF GF UF

Contentlbs 64 25 11

kg 29.1 11.35 5

Change Point* lbs 4.3 1.7 0.7

CYLINDER

*Recommended Cylinder Change Point at NTP, based on Phase Break, or the amount of product left in the cylinder when the liquid phasehas completely evaporated and only gaseous product is left (estimate based on ideal gas behavior).

Cylinder Pressure 207 psig

@NTP 15.6 atm

Specific Volume 0.45 m3/kg

@NTP 7.2 ft3/lb

CAS No 75-10-5

CGA/DISS/JIS 350/724/W22-14L

Molecular Weight 52 g/mol

TECHNICAL DATA

VaporTemp, °C 0.0 15.5 21.0 32.2 43.3

PressurePress, psig 102 172 207 279 372

Temp, °F 32 60 70 90 110

NTP = 21°C or 70°F and 101.3 kPa or 1 atm

Nominal Diameter (OD)xHeight* Material of Construction

Cylinder Treatment cm Inches Cylinder Valve

QF ULTRA-LINE® 23x130/134/143 9x51/52.5/56 CS SS

GF ULTRA-LINE® 23x66/70/79 9x26/27.5/31 CS SS

UF ULTRA-LINE® 15x51/55/64 6x19/20.5/24 CS SS

*Height is reported as the distance from the bottom of the cylinder to the cylinder neck/ center of the valve outlet/ top of the handwheelCS: Carbon Steel SS: Stainless Steel

DOT Shipping Name Difluoromethane Shipped as

DOT Classification 2.1 (Flammable Gas)Liquefied

DOT Label FLAMMABLE GAS GasUN Number UN 3252

SHIP

Grade ULSI 4N ULTIMA 4N8Purity, % 99.99 99.998

Nitrogen ≤40 ppmv ≤5 ppmv

Oxygen ≤10 ppmv ≤2 ppmv

Carbon Dioxide ≤15 ppmv ≤1 ppmv

Methane ≤2 ppmv ≤1 ppmv

Water ≤5 ppmv ≤1 ppmv

Carbon Tetrafluoride ≤5 ppmv ≤1 ppmv

Other Organics ≤100 ppmv ≤10 ppmv

Carbon Monoxide ≤1 ppmv

Acidity as HF ≤0.1 ppmw

http://www.mathesontrigas.com/edge/ 32 Semiconductor Products Catalog V 4.0/SpecRev 4.32

Halocarbon 41 (Methyl Fluoride) CH3F

Grade Semicon 4N ULSI 4N5Purity, % 99.99 99.995

Oxygen ≤20 ppmv < 5 ppmv

Nitrogen ≤70 ppmv < 20 ppmv

Carbon Dioxide < 10 ppmv

Carbon Monoxide < 10 ppmv

Methane < 5 ppmv

Water ≤10 ppmv < 2 ppmv

Acidity as HF Please Inquire

• A lot analysis is provided for each order. – Individual analysis is also available upon request.• Pneumatic valves and JIS connections are available upon request.

Internal Volume Liters 43.8 17.1 7.3

Cylinder Sizes >> QF GF UF

Contentlbs 18 7 3

kg 8.2 3.2 1.4

Change Point* lbs 8.4 3.3 1.4

CYLINDER

*Recommended Cylinder Change Point at NTP, based on Phase Break, or the amount of product left in the cylinder when the liquid phasehas completely evaporated and only gaseous product is left (estimate based on ideal gas behavior).

DOT Shipping Name Methyl Fluoride UN Number UN 2810 Shipped as

DOT Classification 2.1 (Flammable Gas) ECCN # EAR99 Liquefied

DOT Label FLAMMABLE GAS Harmonized # 2903.30.2050 Gas

SHIP

Cylinder Pressure 538 psig

@NTP 38.85 atm

Specific Volume 0.71 m3/kg

@NTP 11.36 ft3/lb

CAS No 593-53-3

CGA/DISS/JIS 350/724/W22-14L

Molecular Weight 34 g/mol

TECHNICAL DATA

VaporTemp, °C 0.0 15.5 21.0 32.2 43.3

PressurePress, psig 259 398 538 606 790

Temp, °F 32 60 70 90 110

NTP = 21°C or 70°F and 101.3 kPa or 1 atm

Nominal Diameter (OD)xHeight* Material of Construction

Cylinder Treatment cm Inches Cylinder Valve

QF ULTRA-LINE® 23x130/134/143 9x51/52.5/56 CS SS

GF ULTRA-LINE® 23x66/70/79 9x26/27.5/31 CS SS

UF ULTRA-LINE® 15x51/55/64 6x19/20.5/24 CS SS

*Height is reported as the distance from the bottom of the cylinder to the cylinder neck/ center of the valve outlet/ top of the handwheelCS: Carbon Steel SS: Stainless Steel

http://www.mathesontrigas.com/edge/ 33 Semiconductor Products Catalog V 4.0/SpecRev4.21

Halocarbon 116 (Hexafluoroethane) C2F6

Grade ULSI 5N ULSI Plus 5NPurity, % 99.999 99.999

Oxygen ≤2.0 ppmv

Oxygen + Nitrogen + Carbon Dioxide + Carbon Monoxide ≤25 ppmv

Nitrogen ≤8.0 ppmv

Carbon Dioxide ≤0.5 ppmv

Carbon Monoxide ≤0.5 ppmv

Water ≤5 ppmv ≤1.5 ppmv

Other organics ≤0.5 ppmv

Acidity as HCl ≤0.1 ppmw ≤0.1 ppmw

• A lot analysis is provided for each order. – Individual analysis is also available upon request.• Pneumatic valves and JIS connections are available upon request.

Internal Volume Liters 43.8

Cylinder Sizes >> QF/QA/QB

Contentlbs 95

kg 43.18

Change Point* lbs 19.1

*Recommended Cylinder Change Point at NTP, based on Phase Break, or the amount ofproduct left in the cylinder when the liquid phase has completely evaporated and onlygaseous product is left (estimate based on ideal gas behavior).