Calculating SLP Workload Ann Slone Supervisory Network May 29, 2014.

SUBMITTED FOR - Slone Assoclogin.sloneassoc.com/login/documents/26 12 19 10 Pad Mounted...Sound...

Transcript of SUBMITTED FOR - Slone Assoclogin.sloneassoc.com/login/documents/26 12 19 10 Pad Mounted...Sound...

SUBMITTED FOR:Shop Drawings Approval Approved as Submitted

WE ARE SENDING:

Letter Your Use Approved as NotedPrints As Requested Returned After LoanChange Order Review and Comment ResubmitPlans SubmitSamples ReturnedSpecifications Returned for Corrections

Other: Made from Submittal

SENT VIA:Attached

Separate Cover Via: Mail

ü

ü

ü

ü

üDue Date:

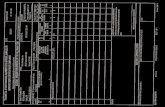

TRANSMITTALNo. 00033

ACTION TAKEN:

TO: Slone Associates, Inc.835 Gil Harbin Industrial Blvd.

PROJECT: Ft. Gillem-Enclave Force ProtectionPROJECT NO.: 20918

Ft. Gillem, GA 30297100 Flankers Road Phone:

Fax:404-734-3340770-956-1322

DATE:

REF:

FAX:

5/19/2010

Submittals

229-244-7778229-244-6709Valdosta, GEORGIA 31601

ATTN: Santiago F. IturraldePHONE:

ITEM NO. COPIES DATE ITEM NUMBER REV. NO. DESCRIPTION STATUS

0 NEW5/19/2010 SUT 001 Dwg: Title: Dry-Type Transformer ShopDrawings Desc: Original Submission

26-12-19 SD-02a

REMARKS:

Expedition ®

CC: Signed:Andrew Hannon

Prop No: 6F2-1E4Q6W6 Item: 000001 Date:04/22/2010

Catalog No:QRDM880 Design No:CJ902373

300 KVA Type OA ANSI Three Phase Padmounted Transformer

12470 GRDY / 7200 - 480Y/277 (2) - 2.5% Above and Below in HV 95 kv BIL 60 Hz

Dead Front, Loop feed, Six HV Bushing, Staggered LV

Bayonet Exp. Fuse + Partial Range CLF, Minimum Dims, 20 inch deep Cabinet

Dimensions are in inches and estimated. Not for construction.

* This dimension represents cabinet depth and door.

Oil Gallons: 202 Total Weight(lbs): 5362

24.4 34.7

28.5

8.0

4.5 30.6 3.5

4.6

21.460.4

68.9

52.2

52.2

60.4

Product Configurator

Quotation Section 26 12 19.10 2.2

Cust Name: FT GILLIUM End User: FT GILLIUM Date: 04/22/2010

Rev 3

Prop Number: 6F2-1E4Q6W6 Cat. Number: QRDM880 BaaNIV Quotation No: 112322

Description: 300 KVA Type OA ANSI Three Phase Padmounted Transformer Item: 000001

12470 GRDY / 7200 - 480Y/277 (2) - 2.5% Above and Below in HV 95 kv BIL 60 Hz

Dead Front, Loop feed, Six HV Bushing, Staggered LV

Bayonet Exp. Fuse + Partial Range CLF, Minimum Dims, 20 inch deep Cabinet

Temp. Rise: 65 °C Bolts:Pentahead Windings Material HV: CU LV: AL

Paint Finish: Munsell 7GY 3.29/1.5 Padmount Green Stainless Steel (Base & Sill,Cabinet)

DOE Standard Compliant Design. Sound level according with NEMA TR-1

Quantity: 1

Performance: Type of Losses: Guaranteed 85C Pallet: Runners

NL Watts: 539 LL Watts: 1453 %IZ: 3.86 %Iex: 2.00 TOC: 17319 FACT A: 0.000 FACT B: 0.000 Cust Part No: Shipment Est: 8 Weeks Ship To: Georgia

Accessories: BU: CJ902373 1 - Over Pressure Relay 10 psi 1 - Standard Liquid Level Gauge VIAT 1 - Provision for TC 1 - Handhole 10” x 18” 6 - 200 Amp HV Bushing well removable stud 35 kV Cooper 6 - 95 kV BIL insert - 200 Amp (15 kV) 4 - 1” Stud type with 6 holes blade 1500A - LV Bushing 1 - Standard Pressure Relief Valve 1 - Thermometer VIAT 3 - Dual Element Expulsion Fuse 3 - Partial Range CLF 1 - Vacuum Pressure Gauge VIAT 1 - 1 inch Drain Valve with 3/8 inch sampler in LV 1 - 1 Switch 2 pos. 300 A 1 - Warning Decal Per Nema fig. 1 2 - Danger Decal Per Nema fig. 2 1 - Standard Nameplate 3 - Flapper Valve 2 - Plastic GRD Connector Plug 2 - Jacking facilities 3 - elbow arresters 6 - standoff bushings 3 - feed-through inserts 202.48 - Beta Fluid CSE: ELIUD DE LA ROSA

Page 1 of 4 RE-PRINTED FORMA 3.2-B

Product Configurator

Quotation II. - GENERAL COMMENTS & CLARIFICATIONS Prolec GE designs, manufactures and test transformers in accordance with the latest applicable sections of ANSI, NEMA and

IEEE Standards. We take exceptions to all other codes and standards. Prolec GE quoted based on point 6.9.1.2 page 59 only The cables should be provide by the contractor We take exception to fuse cutouts We take exception to metering package We take exception to bolted tank cover. We take exception to CT grounding lug Prolec GE will provide standard impedance & losses values Execution will be by others. Transformers are tested according to ANSI Routine Standard Test Code for Transformers C57.12.90

Revision 1 We have changed the LV to 480Y/277 and the material have changed to Al-Al Revision 2 Please add a 112.5 kVA transformer identical to the 300kVA quoted in REV 1. Revision 3 We quoted based on Section 26 12 19.10 pages 1 through 16 1.1 Prolec GE designs, manufactures and test transformers in accordance with the latest applicable sections of ANSI, NEMA and

IEEE Standards. We take exceptions to all other codes and standards. The FM is not included on quote due is out of our scope 1.3 According our standard submittal package (Drawings, Test Reports, Order Acknowledgement, O&M’s (Operations Manual), Bill of lading) 1.4.2 Not apply 1.5 By others 2.1 Not apply 2.2.1 The steel isolating barriers will not be provided due are not part of our scope. We are quoting steel barriers 2.2.1.1 The protective caps will not be provided due are not part of our scope 2.2.1.1.g By others 2.2.1.2.b By others 2.2.2.c Delta connection in primary side is not included on this quote according originall information submitted. 2.2.2.h Not apply. We are quoting DOE final rules. 2.2.2.1 We do not comply with NLL 438 watts we are quoting 539 per design restriction The impedance we are quoting is 3.86 as shows above. If there are any issue with this please advise before place the order 2.3 We are quoting according NEMA 260 2.4 By others

Page 2 of 4 RE-PRINTED FORMA 3.2-B

Product Configurator

Quotation 2.5 By others 2.6 By others 2.7.1 Prolec GE will charge $1750USD for witness test or inspection. The customer agent is responsible for furnishing his own transportation, lodging and food expense. Transformers will be tested in accordance with the latest revision of the “Standard Test Code for Transformers” ANSI/IEEE C57.12.90. The units will be shipped upon completion of all tests satisfactory. 2.7.2 This point is not included on quote unless the customer required specialy due have an additional price each one 2.7.3 DGA test has an additional price of $500. Part 3 By others III. - DRAWING AND SHIPMENT CYCLES (WEEKS) Description For Record Drawings For Approval Drawings Mailing of Drawings 2-4 2-4 Drawings return N/A 4* Transformer Shipment (ARO) 8 After Release 8 DOE – Distribution Transformers Energy Conservation Standards Information

The United States Department of Energy (DOE) issued its final ruling on distribution transformer efficiency. Distribution transformers manufactured in or imported into the U.S. on or after January 1, 2010 will be required to comply with DOE standards.

Transformers quoted do MEET DOE Standards. If transformers are required by January 2010 and/or beyond, designs quoted will change. More information on DOE Final Rule visit: http://www.eere.energy.gov/buildings/appliance_standards/commercial/distribution_transformers.html

If Buyer exceeds the approval drawing cycle time allowed, the shipment will extend at least accordingly to the extra time taken.

Prolec-GE reserves the right to substitute, at its discretion, materials used to manufacture the products. Should Prolec-

GE substitute any materials, it will make reasonable efforts to notify the Buyer. If Prolec-GE believes that a substitution of material will affect any express performance guarantees, it will notify Buyer and the performance guarantees will be adjusted to reflect the use of the new material.

Customer will return approval drawings by (Add 2 weeks) with the release for manufacture, otherwise price will be subject of revision according to clause 1Q stated in our quotation letter section IV.

Actual shipment and drawings will depend on factory backlog at the time of the purchase order acceptance. Shipment dates are approximate and are based upon prompt receipt of all necessary information from Buyer.

Price Clause 1Q applies along with GE Terms and Conditions of Sales listed in ES104 Rev3. All Changes must be resolved before order entry.

IV. - TERMS, CONDITIONS & WARRANTY

The Buyer may not make any public announcement in relation to the Contract (including to any purchase orders or related contractual documents), including the fact that it exists, without the prior written approval of Seller on such terms and conditions as Seller thinks fit.

The following applies unless specified otherwise: Clause 1Q

1. This quotation expires 30 calendar days from its date unless terminated sooner by notice.

Page 3 of 4 RE-PRINTED FORMA 3.2-B

Product Configurator

Quotation

Page 4 of 4 RE-PRINTED FORMA 3.2-B

2. The prices stated herein are firm provided: A. The order is released, with complete engineering details for shipment within 90 calendar days from the date of

order or at the Company's earliest convenience thereafter.

or B. If drawings for approval are required, the drawings must be returned and approved within 60 calendar days of the

original mail in date of the drawings by the Company with products covered by the drawings released for manufacture. Such release must call for shipment within 90 calendar days from the date of order or at the Company's earliest convenience thereafter. Drawing resubmit, which are required for any reason other than to correct Company errors, will not extend the 60-day period for release.

3. In the event that the customer for any reason does not comply with the conditions in paragraph 2 above and/or shipment is

delayed for a reason not within the control of the Company, the price shall be increased 1.5% for each full month or fraction thereof that shipment* is there by delayed after the 90-day period form the date of order.

In the event the Company has been delayed by any of the causes specified in the clause entitled "Excusable Delays" which

is set forth In the Company’s Conditions of Sale, "Shipment" shall mean the actual date of shipment.

Standard warranty coverage applies (unless otherwise noticed): 12 months from energization or 18 months from date of shipment, whichever occurs first.

All items are sold F.C.A. Laredo, TX, USA, with transportation allowed to any common carrier delivery point within the confines of the continental United States, excluding Alaska.

Terms of payment are 100% net cash within 30 days from date of shipment.

There will be a 1.5% charge per month of the total invoice price beginning 30 days after the date of the invoice, but the amount shall not be in excess of the applicable usurious rate.

The sale of any product or service by GE-Prolec is expressly conditioned upon Buyer's assent to the terms (Form ES104 (Rev 3) contained herein. Any additional or different terms proposed by Buyer are expressly objected to and will not be binding upon GE-Prolec unless specifically agreed in writing by GE-Prolec's authorized representative.

ES104_Rev3.doc

Regards,

ELIUD DE LA ROSA Marketing – Distribution Division

Three-Phase Pad-Mounted Transformers

3PPMTR-1208-1

������������

��� � � �

��� ������ �

�� ��������� �

���� �

���������� �

����������� �

�������� ������ � �

��

����� �������� ����� ���������

��������

� � � �

����������������� � � �

�������������� ��������������������� � ����������

������������� � �������������������!����� � ����������

��"�������������� ������������������������� � ����������

��#���$����� ������������������������� � ����������

� � � �

� � � �

� � � �

������������ � � �

�����%�����&�

�'��������"�����(�� �������������������)� � ���*������

+��,��-�%�����

��.�,����� ��������������������� � ���*������

� � � �

� � � �

� � � �

��������������� � � �

..���,�/���-�� ����������������������!� � ���������

��,"��,�/���-�� ������������������������ � ���������

� � � �

� � � �

� � � �

����������� � � �

�������+����-�(�� �������������� � !����������

%��0�(�� ������������� � �

� � � �

� � � �

� � � �

������������ � � �

%�-���-���."���(�� ����������������������*� � !���������

1����"��(�� ����������������������� ������"��.���

������-� ���

��"�,�%�2��� ���������������������*� � !���������

� � � �

�

gThree-Phase, Pad-MountedDistribution Transformers for Underground Service

GEI–79025M Instructions

Pad-Mounted Distribution TransformersIntroduction

2

The equipment covered by these instructions should beoperated and serviced only by competent techniciansfamiliar with good safety practices. These instructions arewritten for such personnel and are not intended as asubstitute for adequate training and experience in safeoperating procedures for this type of equipment.

The pad-mounted transformer is designed for under-ground service and for outdoor mounting on a concretepad. It is the responsibility of the installer and user toensure that the interface between the pad andtransformer, including the cable compartment, isproperly sealed so that foreign objects can not be insertedinside the cable compartment. The primary andsecondary cables enter the transformer from below,through openings in the concrete pad.

The pad-mounted transformer is furnished with separatehigh- and low-voltage compartments equipped withhinged doors. The high-voltage compartment is notaccessible until the low-voltage compartment door isopened. The low-voltage compartment door has aprovision for a user-installed padlock. All live parts arecompletely enclosed in locked compartments with ade-quate baffling for safety. A hood over the tank handhold,accessible through the cabinet, provides protectionagainst tampering and the environment.

i

GEI–79025M

WARNINGS, CAUTIONS, AND NOTESAS USED IN THIS PUBLICATION

WARNINGSWarning notices are used in this publication to emphasize that hazardous voltages, currents, orother conditions that could cause personal injury or death are present in this equipment or maybe associated with its use.

Warning notices are also used for situations in which inattention or lack of equipment knowledgecould cause either personal injury or damage to equipment.

CAUTIONSCaution notices are used for situations in which equipment might be damaged if care is not taken.

NOTESNotes call attention to information that is especially significant to understanding and operatingthe equipment.

This document is based on information available at the time of its publication. While efforts havebeen made to ensure accuracy, the information contained herein does not cover all details orvariations in hardware and software, nor does it provide for every possible contingency inconnection with installation, operation, and maintenance. Features may be described herein thatare not present in all hardware and software systems. GE Industrial Systems assumes no obligationof notice to holders of this document with respect to changes subsequently made.

GE Industrial Systems makes no representation or warranty, expressed, implied, or statutory, withrespect to, and assumes no responsibility for the accuracy, completeness, sufficiency, or usefulnessof the information contained herein. No warrantees of merchantability or fitness for purpose shallapply.

The following are trademarks of GE Company: Sureguard™ GP.

R-TEMP® is a registered trademark of Cooper Power Systems.

Arc Strangler® is a registered trademark of the Cooper Power Systems.

© 1998 GE CompanyAll Rights Reserved

Pad-Mounted Distribution TransformersTable of Contents

ii

Chapter 1. Safety Hazard Information ..................................................................................................... 1

Chapter 2. Receiving, Handling, and Storage2–1 Receiving ................................................................................................................................................ 32–2 Handling ................................................................................................................................................ 32–3 Storage .................................................................................................................................................... 3

Chapter 3. Installation3–1 Foundation............................................................................................................................................. 43–2 Inspection............................................................................................................................................... 43–3 External Electrical Connections ........................................................................................................... 43–4 Cabinet Closing...................................................................................................................................... 4

Chapter 4. Venting4–1 Operation above 3000 Feet.................................................................................................................... 6

Chapter 5. Operation5–1 Service Conditions ................................................................................................................................. 75–2 Load Operation ..................................................................................................................................... 75–3 Low-Voltage Accessories ........................................................................................................................ 7

Current Transformer ...................................................................................................................... 7Thermometers (1/2 NPT) ............................................................................................................. 7Liquid-Level Gage............................................................................................................................ 7Pressure Vacuum Gage (1/4 NPT)................................................................................................ 7Pressure-Relief Device (1/4 NPT).................................................................................................. 7Low-Voltage Molded-Case Circuit Breakers ................................................................................... 7

5–4 High-Voltage Accessories....................................................................................................................... 8Internal Oil-Immersed Fuses .......................................................................................................... 8Bayonet Oil-Fused Cutout ............................................................................................................... 8Nonloadbreak Dry-Well, Current-Limiting Fuseholder ................................................................ 8Loadbreak Dry-Well Fuseholder................................................................................................... 10Oil-Submersible Protector............................................................................................................. 10External Surge Arresters ............................................................................................................... 11

5–5 High-Voltage Bushings ........................................................................................................................ 11Porcelain Bushing Construction .................................................................................................. 11Separable Insulated Connectors................................................................................................... 12

5–6 Tap Changer Operation...................................................................................................................... 125–7 Dual-Voltage Switch ............................................................................................................................. 135–8 Internal Loadbreak Switches ............................................................................................................... 14

Radial-Feed Switch ........................................................................................................................ 14Loop-Feed Switches ....................................................................................................................... 14Loop-Radial Switchese................................................................................................................... 15Interlocked Alternate-Source Switch ............................................................................................ 15Loop Switch with ON-OFF Radial Switch..................................................................................... 16T-Blade Sectionalizing Switch....................................................................................................... 16

Pad-Mounted Distribution TransformersTable of Contents

iii

V-Blade Switch ...............................................................................................................................16Cooper Power Systems Arc Strangler® Switch.............................................................................17S&C Pad-Mounted Gear ................................................................................................................17

Chapter 6. Insulating Liquid ...........................................................................................................................18

Chapter 7. Maintenance7–1 Internal Inspection ..............................................................................................................................197–2 Bushing Maintenance..........................................................................................................................197–3 External Finish Maintenance..............................................................................................................19

Chapter 8. General Information8–1 When You Need Service .......................................................................................................................208–2 Renewal Parts .......................................................................................................................................20

Pad-Mounted Distribution TransformersList of Figures and Tables

iv

Figures1. Thermometer accessory.......................................................................................................................................... 7

2. Liquid-level gage accessory. .................................................................................................................................... 7

3. Pressure vaccuum gage accessory. .......................................................................................................................... 7

4. Bayonet fuses. .......................................................................................................................................................... 8

5. Safety baffle over the fuses. ..................................................................................................................................... 9

6. Safety baffle over the fuses ...................................................................................................................................... 9

7. Fuse removal.......................................................................................................................................................... 10

8. Nonloadbreak fuse replacement .......................................................................................................................... 10

9. Removal of a loadbreak fuse................................................................................................................................. 10

10. Loadbreak dry-well fuse replacement................................................................................................................... 10

11. Clamp-type live-front porcelain high-voltage bushing. ....................................................................................... 12

12. Blade-type live-front porcelain high-voltage bushing.......................................................................................... 12

13. Separable insulated connectors (typical arrangement)...................................................................................... 12

14. Tap changer. ......................................................................................................................................................... 13

15. Dual-voltage switch................................................................................................................................................ 13

16. Radial-feed switch.................................................................................................................................................. 14

17. Schematic of the radial-feed switch. ..................................................................................................................... 14

18. Loop-feed switches................................................................................................................................................. 15

19. Schematic of the loop-feed switch ........................................................................................................................ 15

20. Loop-radial switches.............................................................................................................................................. 15

21. Schematic of the loop-radial switch...................................................................................................................... 15

22. Schematic of the interlocked alternate-source switch ......................................................................................... 15

23. Loop switch with ON-OFF radial switch............................................................................................................... 16

24. Schematic of the loop switch with ON-OFF radial switch. .................................................................................. 16

25. T-blade sectionalizing switch................................................................................................................................ 16

26. V-blade switch........................................................................................................................................................ 16

27. T-blade switch function ........................................................................................................................................ 17

28. V-blade switch function......................................................................................................................................... 17

Tables1. Recommended electrical clearances...................................................................................................................... 5

2. Operating conditions.............................................................................................................................................. 7

3. Nonloadbreak fuseholder ratings........................................................................................................................... 9

4. Loadbreak dry-well fuseholder ratings................................................................................................................. 11

5. Internal loadbreak switch ratings......................................................................................................................... 14

6. Flash and fire points for choices of insulating fluids. ......................................................................................... 18

Pad-Mounted Distribution TransformersChapter 1. Safety Hazard Information

1

The following warning notes apply to the operation ofthis equipment. Failure to comply with these warningsmay result in serious personal injury or damage to theequipment.

Tank Ground

WARNING: The first electrical connection mademust be to ground the transformer tank. Thisconnection is made from the tank ground pad to apermanent low-impedance ground. The tank groundmust also be connected to the system ground. Failure tocomply may result in serious personal injury or damageto the equipment.

External Electrical Connections

WARNING: Make only the connections andoperate only at the voltages authorized by the diagramsand information on the transformer name plate. Theavailable transformer neutrals should be connected tothe system neutrals. Each lead and connection not inuse should be insulated from ground and from all otherleads and connections. Failure to comply may result inserious personal injury or damage to the equipment.

Tap Changer

WARNING: The tap changer must not be operatedwhile the transformer is energized. Failure to complymay result in serious personal injury or damage to theequipment.

Dual-Voltage Switch

WARNING: The dual-voltage switch must not beoperated while the transformer is energized. Check thename plate and the switch position for the correctvoltage before placing the unit in service. Failure tocomply may result in serious personal injury or damageto the equipment.

Low-Voltage Circuit Breaker

CAUTION: With the secondary circuit breakeropen there may be sufficient coupling to the windingsfor a shock hazard to exist at the secondary terminals.Ground the open secondary terminals before workingon the secondary service.

Lifting

WARNING: Use all the lifting lugs when lifting thetransformer. Use proper spreaders to obtain a verticallift. Do not use the radiators for lifting or jacking.Failure to comply may result in serious personal injuryor damage to the equipment.

Venting

WARNING: Always release any possible pressure inthe tank by carefully venting the pressure-relief valvebefore attempting to remove handhole covers or similarcovers, including relief diaphragms and shipping covers(when used). Failure to comply may result in seriouspersonal injury or damage to the equipment.

Bayonet Fusing

CAUTION: Read the instructions supplied with thebayonet cutout before operating.

Dry-Well Nonloadbreak Fuse Holder

WARNING: Deenergize transformer beforeremoving or installing fuse holder cap assembly. Failureto comply may result in serious personal injury ordamage to the equipment.

Dry-Well Loadbreak Fuse Holder

WARNING: Do not exceed the fuse holder rating.Failure to comply may result in serious personal injuryor damage to the equipment.

Pad-Mounted Distribution TransformersChapter 1. Safety Hazard Information

2

Oil Level

WARNING: Oil must be at the proper level beforevoltage is applied to the transformer. Failure to complymay result in serious personal injury or damage to theequipment.

Internal Fuses

WARNING: Deenergize the transformer beforeattempting to remove internal fuses. Failure to complymay result in serious personal injury or damage to theequipment.

Air Switches

WARNING: The fuse or switch may be energized inthe OPEN position. Read the switch manufacturer’sinstructions before operating. Failure to comply mayresult in serious personal injury or damage to theequipment.

S&C Air Switch

WARNING: Use the S&C Loadbuster tool to oper-ate the switch or fused disconnect. Failure to complymay result in serious personal injury or damage to theequipment.

Internal Loadbreak Switches

WARNING: These switches are designed tointerrupt load current only. They are not suitable forinterrupting fault currents. Do note exceed the switchrating. Failure to comply may result in serious personalinjury or damage to the equipment.

Mounting Pad

WARNING: There must be no gaps between thecabinet and the pad, otherwise the tamper resistance ofthe transformer is compromised. Failure to comply mayresult in serious personal injury or damage to theequipment.

Bushings

CAUTION: Remove all dirt and foreign materialfrom all bushings before placing the unit in service.Follow manufacturer’s instructions for installingseparable-insulated high-voltage connectors. Do notoperate beyond the manufacturer’s rating.

Pad-Mounted Distribution TransformersChapter 2. Receiving, Handling, and Storage

3

2–1 ReceivingImmediately upon receipt of the equipment, and beforeputting it into service, inspect the transformer for anydamage that may have occurred during shipment orstorage. If rough handling is evident, file a damage claimwith the transport company immediately and notify thenearest General Electric Sales Office promptly. Tightenany parts that may have loosened during shipment.

2–2 Handling

WARNING: Use all the lifting lugs when lifting thetransformer. Use proper spreaders to obtain a verticallift. Do not use the radiators for lifting or jacking.Failure to comply may result in serious personal injuryor damage to the equipment.

Lifting lugs are provided for lifting the complete trans-former. Jacking space is provided in the base of thetransformer to facilitate lifting with jacks. The trans-former must never be moved or lifted by placing jacks ortackle on the radiators, the high-voltage and low-voltagecompartments, or other attachments. When using a forklift to move the transformer, lift from the tank rear withthe shipping skid in place.

2–3 StorageTransformers should be stored with the tank sealed andfilled with oil to the proper level. Compartment doorsshould be closed to prevent damage to bushings andaccessories. The storage area should be a flat, dry surfaceand the transformer should be protected frommechanical damage.

Pad-Mounted Distribution TransformersChapter 3. Installation

4

3–1 Foundation

WARNING: There must be no gaps between thecabinet and the pad, otherwise the tamper resistance ofthe transformer is compromised. Failure to comply mayresult in serious personal injury or damage to theequipment.

The foundation necessary for the installation of a pad-mounted distribution transformer should have footingsdeep enough to prevent settling and heaving in areaswhere the ground freezes. The surface of the concretepad should be level to ensure that there are no gapsbetween the compartment and the concrete pad.

Brackets are provided on the transformer base for boltingthe transformer to the pad. Carefully lower the trans-former to the pad with the unit level to avoid damage tothe cabinet.

3–2 InspectionThe transformer covered by this instruction is shippedready for installation and will not require drying unlessmoisture has been allowed to accidentally enter duringtransit. It has been filled with oil at the factory to the 25°C liquid level and sealed. Check the level by one of thefollowing methods:

• Read the liquid level gauge.

• Vent the pressure-relief valve and then carefullyremove the pipe plug located in the low-voltagecompartment for this purpose. Reseal after use.

WARNING: Oil must be at the proper level beforevoltage is applied to the transformer. Failure to complymay result in serious personal injury or damage to theequipment.

3–3 External Electrical Connections

WARNING: The first electrical connection mademust be to ground the transformer tank. Thisconnection is made from the tank ground pad to apermanent low-impedance ground. The tank groundmust also be connected to the system ground. Failure tocomply may result in serious personal injury or damageto the equipment.

WARNING: Make only the connections andoperate only at the voltages authorized by the diagramsand information on the transformer name plate. Theavailable transformer neutrals should be connected tothe system neutrals. Each lead and connection not inuse should be insulated from ground and from all otherleads and connections. Failure to comply may result inserious personal injury or damage to the equipment.

Line connections must be made so that no undue strain isplaced on the bushings. Refer to Table 1 forrecommended minimum electrical clearances.

3–4 Cabinet ClosingBefore leaving the unit, close the cabinet and lock it withthe user-installed padlock provision and any otherauxiliary locking means that may be supplied. Thepadlock shackle should provide a snug fit in its opening.

Pad-Mounted Distribution TransformersChapter 3. Installation

5

Rated Line–Line

kV (max)Bil kV

TestkV

Clearance Line–Ground (in.)

Clearance Line–Line (in.)

Barrier* Thickness(max in.)

1.2 30 10 1.24 1.24 none

5 60 19 2.002.50

2.503.00

0.156none

8.6 75 26 3.203.50

3.504.00

0.156none

15.5 95 34 3.205.00

4.005.50

0.156none

25 125 40 4.205.70

4.706.00

0.156none

35 125 40 5.507.00

6.507.50

0.188none

25 or35 150 50 9.00

7.5010.008.50

none0.250

* Barrier must be high-quality nonhygroscopic and track-resistant material.

Table 1. Recommended electrical clearances.

Pad-Mounted Distribution TransformersChapter 4. Venting

6

The transformer should be vented to the atmospherebefore it is placed in service if it has been pressurized forleak tests or storage.

WARNING: Always release any pressure in the tankby carefully venting the pressure-relief valve beforeattempting to remove handhole covers or similar covers,including relief diaphragms and shipping covers (whenused). Failure to comply may result in serious personalinjury.

4–1 Operation above 3000 FeetIf a transformer is to be operated at 3000 feet or higherabove sea level, the internal and external pressures mustbe equalized before the transformer is put into operation.To equalize pressures, carefully open the pressure-reliefvalve at approximately 25° C. Release the valveimmediately.

Refer to ANSI C57.12.00.4 for information on how ele-vations above 3000 feet affect transformer ratings.

Pad-Mounted Distribution TransformersChapter 5. Operation

7

5–1 Service ConditionsTable 2 is a list of the normal operating conditions forthe transformers covered by this guide. Refer to ANSIC57.12.00.4 for detailed information on operation indifferent service conditions.

Parameter Operating RangeWeather temperature –20° to 40 ° CMaximum daily averagetemperature 35° C

Elevation 1000 m and below

Humidity Daily average not toexceed 95%

Gage pressure 7 psig

Table 2. Operating conditions.

5–2 Load OperationFor continuous loading in standard ambient tempera-ture, the total balanced load on a transformer should notexceed the name plate rating. Prolonged overloadingmay result in shortened transformer life (see ANSIC57.91). Voltage should be applied only to transformersfilled to the correct level with insulating liquid.

5–3 Low-Voltage AccessoriesCurrent TransformerGeneral Electric Type JAB-0 and JKY-0 current trans-formers are designed to fit the low-voltage bushings.Other styles and potential transformers are available formounting inside the low-voltage compartment.

Thermometers (1/2 NPT)A dial-type thermometer accessory, when supplied, islocated under oil in the low-voltage compartment. Thethermometer dial, shown in Figure 1, reads from 0–160°C.

Liquid-Level GageA liquid-level gage accessory, when supplied, is located inthe low-voltage compartment. The gage dial, shown inFigure 2, reads over the range LO–25 C–HI.

Figure 1. Thermometer accessory.

Figure 2. Liquid-level gage accessory.

Pressure Vacuum Gage (1/4 NPT)A pressure gage accessory, when supplied, is located inthe low-voltage compartment above the bushings in theair space. The gage dial, shown in Figure 3, reads from –10 psig to +10 psig.

Figure 3. Pressure vacuum gage accessory.

Pressure-Relief Device (1/4 NPT)The pressure-relief device is located in the low-voltagecompartment near the top of the tank. The automaticpressure-relief device relieves excessive internal tankpressure in the tank air space. The device opens at 8–12psig and reseals at a positive pressure.

Low-Voltage Molded-Case Circuit BreakersGeneral Electric molded-case circuit breakers, whensupplied, are located in the low-voltage compartment.Contact the nearest GE Sales Office for application data.

Pad-Mounted Distribution TransformersChapter 5. Operation

8

5–4 High-Voltage Accessories

Internal Oil-Immersed FusesA pad-mounted transformer may be provided withinternal fuses in series with the high-voltage winding.Their function is to remove the transformer from the linein case of an internal failure. When supplied with a low-voltage circuit breaker, the fuse will carry high-voltagecircuit currents in excess of those allowed by the breaker.

Access to the fuses is provided by a handhole in thetransformer cover.

WARNING: Deenergize the transformer beforeattempting to remove internal fuses. Failure to complymay result in severe personal injury or death.

Bayonet Oil-Fused Cutout

CAUTION: Read the instructions supplied with thebayonet cutout before operating.

Within the rating of this device, the transformer may beequipped with bayonet oil-fused cutouts, shown in Figure4, to provide a load-break function. The oil-immersedexpulsion fuses are externally replaceable. The fault-sensing fuse protects the line from transformer faults.

Figure 4. Bayonet fuses.

The load-sensing fuse provides secondary overload pro-tection. The cutout is not recommended for closing onfaults.

To replace a bayonet fuse, use the following procedure:

CAUTION: Use a hot stick to remove bayonet cut-outs.

WARNING: Deenergize the transformer beforeattempting to remove internal fuses. Failure to complymay result in severe personal injury or death.

1. Vent the transformer to equalize the pressure withthe supplied pressure-relief valve. Release the valvewhen the tank pressure is equalized.

2. Open the latch.

3. Rotate the cutout one-quarter turn.

4. Press down firmly to break the gasket seal.

5. Withdraw the cutout quickly and uniformly.

Instructions for replacing the bayonet fuse are packedwith each replacement fuse or may be obtained from thefuse manufacturer.

Nonloadbreak Dry-Well, Current-LimitingFuseholder

WARNING: Deenergize the transformer beforeattempting to remove or install a fuseholder capassembly. Failure to comply may result in severe per-sonal injury or death.

This accessory combines the high interrupting capabilityof general-purpose, full-range current-limiting fuses withdry-well fuseholders. These fuseholders are operable witha hot stick. The nonloadbreaking fuseholder assemblyhas an integral warning notice and an interlocked safetybaffle, shown in Figure 5, to prevent removal of the fusewhile the transformer is energized.

Nonloadbreaking fuseholders are mechanically inter-locked with a loadbreak switch; be careful not to defeatthis arrangement. When the transformer is deenergizedby operation of the loadbreak switch, the safety baffle canbe moved, permitting access to the fuses, as shown inFigure 6.

Nonloadbreaking fuseholders are available withmaximum voltage ratings of 8.3 kV, 15.2 kV, and 21.1 kVand with impulse withstands of 95-kV BIL, 125-kV BIL,and 150 kV-BIL. Table 3 lists the complete ratings.

Pad-Mounted Distribution TransformersChapter 5. Operation

9

Figure 5. Safety baffle over the fuses.

Figure 6. Safety baffle moved from over the fuses.

Maximum VoltageRating, kV 8.3 15.2 21.1 21.1

BIL, kV 95 125 125 150HIPOT, kV 34 40 50 50Corona Extinction, kV 11 19 26 26Continuous CurrentRating, A (unfused) 160 160 160 160

Momentary CurrentRating, A RMS symm.10 cycles (unfused)

10,000 10,000 10,000 10,000

Acceptable Fuses*(must be orderedseparately)

2.8 and 4.3 kV all sizes to100 A; 5.5 kV all sizes to

75 A; 8.3 kV all sizes to 40A

15.5 kV all sizesto 40 A

23 kV all sizesto 25 A

23 kV all sizesto 25 A

* GE Sureguard™ GP or Cooper Power Systems NX®

Table 3. Nonloadbreak fuseholder ratings.

Nonloadbreak Fuse Replacement

WARNING: Deenergize the transformer beforeattempting to remove or install a fuseholder capassembly. Failure to comply may result in severe per-sonal injury or death.

To replace a fuse, use the following procedure:

1. Deenergize the transformer. Open the loadbreak switchto deenergize the transformer and allow the safetybaffle to be released for access to the fuseholders, asshown in Figure 6.

2. Remove the draw-out assembly using a hot stick andthe pulling eye on the cap assembly, as shown inFigure 7. Carefully withdraw the assembly to avoiddamaging the contacts.

3. Replace the blown fuse with a fuse of the samerating. To replace the fuse, loosen the two set screwson the draw-out rod assembly and the two set screwson the contact assembly. Remove the fuse and installthe new fuse. Tighten the two set screws on thecontact assembly and the set screws on the draw-outrod assembly. Figure 8 shows the locations of theparts.

4. Replace the draw-out fuseholder assembly in thefuseholder tube, taking care to not damage thecontents. Seat the assembly firmly within thefuseholder tube. Avoid the introduction of foreignmatter into the fuse holder tube.

5. Move the safety baffle to cover the pulling eyes andengage the loadbreak switch to energize thetransformer and interlock the baffle.

Pad-Mounted Distribution TransformersChapter 5. Operation

10

Figure 7. Fuse removal with a hot stick.

Figure 8. Nonloadbreak fuse replacement.

Loadbreak Dry-Well Fuseholder

WARNING: Do not exceed the fuseholder rating.Failure to comply may result in serious personal injuryor damage to the equipment.

This fuseholder is similar to the nonloadbreak model,with the addition of a loadbreak switching device. Theswitching device uses the rod and bore principle toaccomplish loadbreak within the fuseholder.

Available ratings are 8.3 kV at 95 kV BIL and 15.2-kV at125-kV BIL. Table 4 lists the complete ratings.

Loadbreak Fuse Replacement

Figure 9 shows loadbreak fuses. The details of the partsinvolved are illustrated in Figure 10.

Removal – Attach a hot stick to the pulling eye. Rapidlywithdraw the draw-out assembly from the fuseholderhousing.

Installation – With the fuse assembly attached to the hotstick, insert the draw-out assembly until the contact springhas just entered the fuse housing. Rapidly push the draw-out assembly into the housing until the cap is seated inthe spring clips.

Figure 9. Loadbreak fuses.

Figure 10. Loadbreak dry-well fuse replacement.

Oil-Submersible ProtectorThe oil-submersible protector (OSP) is a partial-rangecurrent-limiting fuse that is used in series with anexpulsion fuse to provide full-range protection. The OSPis designed to clear high-current faults (up to 50,000 Asymmetrical), while the expulsion link clears low-currentfaults. These fuses are located under oil beneath thetransformer handhold. Either internal expulsion fuses orbayonet fuses are available as the series expulsion fuse.

The bayonet or internal expulsion fuse is available forreplacement. Refer to the sections Internal Oil-ImmersedFuses and Bayonet Oil-Fused Cutout for instructions.Replacement of the OSP fuse requires removal of themain tank cover. Refer to the nearest GE-approved serviceshop for this type of repair.

Pad-Mounted Distribution TransformersChapter 5. Operation

11

Maximum VoltageRating, kV 8.3 15.2**

BIL, kV 95 125HIPOT, kV 34 40Corona Extinction, kV 11 19Continuous CurrentRating, A (unfused) 160 160

Momentary CurrentRating, A RMS sym 10cycles (unfused)

10,000 10,000

Acceptable Fuses*(must be orderedseparately)

2.8 and 4.3 kV all sizes to100 A; 5.5 k V all sizes to75 A; 8.3 kV all sizes to 40

A

15.5 kV all sizes to 40 A

Load Make and BreakRating, Three-Phase

20 operations at 100 A (8.3kV L–G, 14.4 kV L–L)

20 operations at 100 A (15kV L–L)

Fault Close In, A RMSsym (fused) 10,000 10,000

* GE Sureguard™ GP or Cooper Power Systems NX®.** Fuseholder may be applied as a loadbreak device in three-phase applications

where the line–line voltage will not exceed 15 kV.

Table 4. Loadbreak dry-well fuseholder ratings.

External Surge Arresters

CAUTION: If induced-voltage tests are made on atransformer with arresters, the arresters must bedisconnected during the test and reconnected after thetest is completed. Surge arresters should also bedisconnected before cables are hi-potted or tested withhigh-current dc.

Specific recommendations for arrester applications maybe obtained from the nearest GE Sales Office. Whenprovided, arresters are mounted in the high-voltagecompartment.

Arrester and tank-ground connections should be com-pleted before the high-voltage line is connected. With thelow-voltage neutral and the high-voltage arrestersconnected to the tank and ground, the arresters areplaced in direct shunt relation to the transformerinsulation, thus giving the most effective protection.

5–5 High-Voltage Bushings

CAUTION: Remove all dirt and foreign materialfrom all bushings before placing the unit in service.Follow the manufacturer’s instructions for installingseparable insulated voltage connectors. Do not operatebeyond the manufacturer’s ratings.

Porcelain Bushing Construction (ANSIC57.12.22)The standard high-voltage bushing is made of porcelainand is provided with a clamp-type terminal up through500 kVA, as shown in Figure 11, and a three-hole bladeabove 500 kVA, as shown in Figure 12.

The clamp-type terminals accommodate cables from #8through 2/0. The high-voltage terminals are oriented forvertical take-off of primary cables entering thecompartment from below.

Pad-Mounted Distribution TransformersChapter 5. Operation

12

Figure 11. Clamp-type live-front porcelain high-voltage bushing.

Figure 12. Blade-type live-front porcelain high-voltage bushing.

Separable Insulated Connectors (ANSIC57.12.26)Separable insulated connector components may be uni-versal bushing wells, integrated bushings, or bushing wellswith inserts (switch modules) installed. See Figure 13 fortypical bushing arrangements.

All separable connector components must be dry andclear of any contaminants before connections are made.Unused terminals must be capped before the unit isenergized.

The separable insulated connectors may be either live-break or dead-break. Follow the manufacturer’sinstructions and warnings on the use of these termi-nations.

Figure 13. Separable insulated connectors (typical arrangement)..

WARNING: Read the manufacturer’s instructionsbefore installing separable insulated connectors. Do notoperate beyond the manufacturer’s rating. Failure tocomply may result in serious personal injury or damageto the equipment.

5–6 Tap Changer OperationThe tap changer operating handle, shown in Figure 14, isgenerally located in the high-voltage compartment. Theoperating handle can be operated by hand or hot stick. Alocking screw and/or padlock provision preventinadvertent operation of the switch. The tap changer isshipped connected for the rated name plate voltage.

WARNING: Deenergize the transformer beforeoperating the tap changer. Failure to comply may resultin serious personal injury, death, or damage to theequipment.

Pad-Mounted Distribution TransformersChapter 5. Operation

13

Figure 14. Tap changer.

To change taps, use the following procedure:

1. Deenergize the transformer.

2. Open the high-voltage compartment.

3. See the name plate for the proper voltage adjust-ment.

4. Back out the locking screw.

5. Using a hot stick or hand, pull out the spring-loadedhandle, turning it to the desired position.

6. Allow the pointer to drop into the slotted indexplate, between the corresponding alphabetic sectionson the index plate.

7. Engage the locking screw.

8. If padlock security is required, place a padlockthrough the operating handle.

5–7 Dual-Voltage Switch

WARNING: Deenergize the transformer beforeoperating the dual-voltage switch. Check the name plateand switch position for the correct voltage beforeplacing the unit in service. Failure to comply may resultin serious personal injury, death, or damage to theequipment.

The dual-voltage switch accessory, when supplied, has anexternal operating control generally located in the high-voltage compartment. The control handle can bepadlocked, is operated with a hot stick, and is spring

loaded, providing a positive indication of voltageswitching. Two positions are marked 1 and 2, with thecorresponding high-voltage values.

To operate the dual-voltage switch, shown in Figure 15,use the following procedure:

1. Deenergize the transformer.

2. Open the high-voltage compartment.

3. See the name plate for the proper voltage adjust-ment.

4. Back out the locking screw.

5. Using a hot stick or hand, pull out the spring-loadedhandle, turning it to the desired position.

6. Engage the locking screw.

7. If padlock security is required, place a padlockthrough the operating handle.

Figure 15. Dual-voltage switch.

When the pointer is in the 2 position, the primary coilsare connected for operation at the series voltage of aseries-multiple rated transformer or the wye voltage of adelta-wye rated transformer. When the pointer is in the 1position, the primary coils are connected for operation ateither the multiple or delta voltage. Unless otherwisespecified, the dual-voltage switch is shipped in the 1(multiple or delta) position.

Pad-Mounted Distribution TransformersChapter 5. Operation

14

5–8 Internal Loadbreak Switches

WARNING: These switches are designed tointerrupt load current only. They are not suitable forinterrupting fault currents. Do not exceed the switchrating. Failure to comply may result in serious personalinjury, death, or damage to the equipment.

NOTE: Internal switching is not available withsilicone fluid.

The internal loadbreak switch is a gang-operated and islocated under oil. It is connected between the primarybushings and the transformer fuses and windings. Thisswitch is designed for occasional load interruption andcan be used to deenergize the transformer. The operatinghandles and the name plate indicating the switchpositions are located in the high-voltage compartment. A0.875-inch hole is provided in the control for operationwith a hot stick. See Table 5 for rating and servicinginformation.

Radial-Feed SwitchThe radial-feed, two-position internal oil switch, shown inFigure 16, is a gang-operated loadbreak switch. It isoperated by a hot stick and uses a manually chargedovertoggle storage spring assembly that is independent ofoperator speed. The spring-loaded operating mechanismensures quick load breaking and load making operation.It can be used to deenergize the transformer. Theoperating handle and name plate are located in the high-voltage compartment. Figure 17 is a schematic of thisswitch.

Figure 16. Radial-feed switch.

Figure 17. Schematic of the radial-feed switch.

Loop-Feed SwitchesThe loop-feed switch arrangement, shown in Figure 18,consists of two two-position, gang-operated, internal oilswitches. It may be used for sectionalizing and loopconnections, such as selection of power sources in a loop-feed primary distribution system, isolating faulted cablesor transformers, or isolating transformers for change outor maintenance. Six high-voltage bushings are furnishedwith a typical application. Three bushings are identifiedas A source and three as B source. Figure 19 is aschematic of this switch arrangement.

Parameter Two-Position T Blade V BladeMaximum Voltage, kV 38 15 25 35BIL, kV 150 95 125 150One-Minute Withstand, kV 70 34 40 50Maximum Continuous andLoadbreak Current, A 300 600 300 200

Momentary and FaultClose, A RMS sym. 12,000 10,000 10,000 10,000

Momentary and FaultClose, A RMS asym. 19,000 10,000 10,000 10,000

Table 5. Internal loadbreak switch ratings.

Pad-Mounted Distribution TransformersChapter 5. Operation

15

Figure 18. Loop-feed switches.

Figure 19. Schematic of the loop-feed switch.

The switch positions are as follows:

1. Both pointers CLOSED. This position permits loopfeed for adjacent transformers with the transformerenergized.

2. Left-hand pointer CLOSED, right-hand pointerOPEN. Only one side of the loop (A bushings) isconnected to the transformer windings.

3. Left-hand pointer OPEN, right-hand pointerCLOSED. Only one side of the loop (B bushings) isconnected to the transformer windings.

4. Both pointers OPEN. Both sides of the loop (A and Bbushings) are disconnected, thus isolating anddeenergizing the transformer windings from theloop-feed system.

Loop-Radial SwitchesTwo two-position loadbreak switches, shown in Figure 20,may be used to obtain a combination of the loop andradial switch functions. The combination consists of atransformer switch (line B) and a loop switch (line A).Figure 21 is the schematic for this arrangement.

Figure 20. Loop-radial switches.

Figure 21. Schematic of the loop-radial switch.

The switch positions are as follows:

1. Both pointers CLOSED. The loop is closed by con-necting line A to line B and the transformer isconnected to the loop.

2. Left-hand pointer CLOSED, right-hand pointerOPEN. The transformer is disconnected from theloop and the loop is closed.

3. Left-hand OPEN, right-hand pointer CLOSED. Theloop is open and the transformer is connected tosource B.

4. Both pointers OPEN. The transformer is deenergizedand the loop is open.

Interlocked Alternate-Source SwitchThe alternate-source switch is used for the selection ofeither of two voltage sources to energize the transformer.An interlock on the switch handle allows the transformerto be energized from only one source at a time. Figure 22is a schematic for this switch.

Figure 22. Schematic of the interlocked alternate-source switch.

Pad-Mounted Distribution TransformersChapter 5. Operation

16

Loop Switch with ON-OFF Radial SwitchThis combination, shown in Figure 23, provides thefunctions of the loop and radial switches, allowing thetransformer to be deenergized and either loop to bedeenergized. Figure 24 is a schematic for this switch.

Figure 23. Loop switch with ON-OFF radial switch.

Figure 24. Schematic of the loop switch with ON-OFF radial switch.

T-Blade Sectionalizing SwitchThe T-blade sectionalizing switch, shown in Figure 25,rotates 360° in either direction for alternate-sourceselection. It is operated with a hot stick. A spring-loadedmechanism ensures quick load breaking and positivecontact engagement in all positions. Switching can beaccomplished in one-third to one-half of a cycle, whichminimizes power outages. The T-blade switch allows theloop to be energized while the transformer isdeenergized. Figure 27 is a diagram of T-blade switchfunction.

NOTE: Internal switching is not available withsilicone fluid.

Figure 25. T-blade sectionalizing switch.

V-Blade SwitchThe V-blade switch, shown in Figure 26, allows the loopand the transformer to be deenergized at the same time.Figure 28 is a diagram of V-blade switch function.

Figure 26. V-blade switch.

Pad-Mounted Distribution TransformersChapter 5. Operation

17

Figure 27. T-blade switch function.

Figure 28. V-blade switch function.

Cooper Power Systems Arc Strangler®

SwitchTransformers may be equipped with either radial or loop-feed Arc Strangler switches mounted in the high-voltagecompartment. These switches are equipped with current-limiting fuses. The Arc Strangler must be cocked before aswitch or fuse assembly can be closed. Follow the CooperPower Systems instructions for operating these devices.The load-break function is provided by either fuses orblades.

S&C Pad-Mounted GearWhen S&C air switches or fused disconnects are used,follow the manufacturer’s instructions for operation.When operated with the S&C loadbuster tool, thesedisconnects function as loadbreak switches.

WARNING: Use the S&C loadbuster tool to operatethe switch or fused disconnect. Failure to comply mayresult in serious personal injury or death.

Pad-Mounted Distribution TransformersChapter 6. Insulating Liquid

18

The transformer was thoroughly dried at the factory andfilled with insulating oil to the correct level beforeshipping. Three-phase pad-mounted transformers areavailable with oil, R-TEMP®, and silicone insulatingfluids. Oil is generally the standard choice for outdoorapplications where flash and fire points are not an issue.For applications requiring less-flammable liquids, R-TEMP and silicone insulating fluids are generallyspecified. Internal switching is not available in GEsilicone-filled transformers. R-TEMP is the standardchoice when switching is required.

The approximate flash and fire points of the threechoices of insulating fluids are listed in Table 6.

Parameter Oil R-TEMP® SiliconeFlash Point, °C 149 284 300Fire Point, °C — 312 340

Table 6. Flash and fire points for choices of insulating fluids.

The correct level for the fluid at approximately 25° C is atthe liquid-level plug or the 25° C mark on the liquid-levelgauge. When it is necessary to add to or refill the tank,the work should be done in a clean, dry room. Thetransformer should be filled with the same type ofinsulating fluid as originally installed at the factory. A fillprovision is located on the front plate in the low-voltagecompartment and a drain is located in one of thecompartments.

Pad-Mounted Distribution TransformersChapter 7. Maintenance

19

7–1 Internal Inspection

WARNING: Deenergize the transformer beforeattempting any internal inspection. Failure to complymay result in serious personal injury or death.

WARNING: Always release any pressure in the tankby carefully venting the pressure-relief valve beforeattempting to remove handhole covers or similar covers,including diaphragms and shipping covers (whenused). Failure to comply may result in serious personalinjury or death.

If the transformer must be opened for internal inspectionor fuse replacement, take proper precautions to preventthe entrance of moisture and other foreign matter intothe transformer. Remove the hood and clean off the tankcover.

For access, remove the handhole cover. Place thehandhole gasket nuts and washers in storage for reuse.Examine the underside of the cover for signs of moisture.Look inside the transformer for blown fuses, brokenleads, and loose parts. If fuses are blown, replace them. Ifany bushings are damaged, repair or replace themthrough the handhole, as described below.

If internal damage is suspected, the following procedureis recommended.

1. Remove the tank cover, lower the liquid to the top ofthe core, and carefully inspect the interior to note ifany damage has occurred.

2. Take an oil sample from the bottom of the tank. Ifmoisture is found inside the tank, arrangementsshould be made to dry the transformer.

3. After inspection and any repairs, refill the unit withdry insulating liquid to the 25° C level. Fill veryslowly in a vacuum chamber. Hold a partial vacuumon the unit (up to –3 psig) for four hours afterrefilling. Do not use the tank as a vacuum chamber.a. If the unit cannot be filled under vacuum, fill it

through the handhole, directing the flow of oil sothat aeration of the liquid is prevented. Forinstance, direct a slow flow of the liquid againstthe upper tank wall.

b. If a vacuum is not available, the unit should beallowed to sit for at least 24 hours before it istested or energized.

c. Tilt the unit during filling to prevent entrapmentof air in the coils and insulation.

7–2 Bushing Maintenance

WARNING: Deenergize the transformer beforeattempting bushing maintenance. Failure to complymay result in serious personal injury or death.

Lower the liquid level before removing bushings. In mostcases, the high-voltage bushings may be changed byremoving the external clamp hardware and carefullypulling the bushing out. Access to the internal lead allowsit to be disconnected. Replace the bushing and carefullyinsert it back in its hole on the tank.

Low-voltage bushings may be changed externally orthrough the main tank cover handhole. Where the leadsare fastened internally with nuts, first loosen the 10-32screws. Where split blocks are used, loosen the hardwarein the block itself. Where neither of the above is used, thebushing may be replaced externally by removing theclamps and pulling the bushing out of its hole. The leadhardware may be removed and the bushing changed. Besure to reinstall the hardware in the original sequence.

The gasket must be located so that it will seal properlyand not be damaged during repair to the unit. Thegasket and bushings may be reused if they areundamaged. After repairs have been completed, refill theunit with dry insulating liquid to the 25° C level.

7–3 External Finish MaintenanceThe condition of the transformer finish should beexamined at regular intervals. If the finish is weathered,clean it thoroughly and refinish with a good grade ofdurable paint, as recommended by GE.

Pad-Mounted Distribution TransformersChapter 8. General Information

20

Complete instructions for sampling, testing, and dryingoil and drying transformers, along with operating dataand recommendations, can be obtained upon request tothe nearest GE Sales Office.

8–1 When You Need ServiceIf you need service on products manufactured by GEIndustrial Systems, a world-wide service organization isready to serve you. Warranty administration, site-testingservices, installation, system studies, maintenance,trouble-shooting, site repairs, and training seminars areprovided by GE and the GE Factory Authorized ServiceTeam. Shop repairs, reconditioning, or rebuilding ofelectrical apparatus are provided by members of the GEFactory Authorized Service Team in their shop or on yourpremises. Contact your GE Sales Office or a FactoryAuthorized Service Team member for full informationabout these services.

8–2 Renewal PartsOrders for renewal parts may be placed by describing thepart and giving the rating and serial number appearingon the name plate of the transformer.

gGE Industrial Systems

General Electric CompanyShreveport, Louisiana 71109

GEI79025 R14 1098 © 1998 General Electric Company