Steel Beams

Transcript of Steel Beams

-

Corus Construction & Industrial

Structural sections

in accordance with European specifications

13502 Corus Euro Cover.qxd 22/3/06 10:37 am Page 2

-

13502 Corus Euro Cover.qxd 22/3/06 10:37 am Page 3

-

Structural sections in accordance with European specifications

Corus Construction & Industrial 1Corus Construction & Industrial 1

Table des matieres

PageNotations 2Nuances et Prsentation 3Dimensions et Proprits

Profils IPE 4-7Profils HE 8-13

Cornires Ailes Egales 14-15Cornires Ailes Ingales 16-17Tolrances de Laminage

BS EN 10034: 1993 18-19BS EN 10056 2: 1993 20

Bureaux de Vente Corus 27-28

InhaltBezeichnung 2Stahlsorten und Qualitt 3Querschnittsgrssen

IPE Profile Gem Euronorm 4-7Profils HE Gem Euronorm 8-13

Gleichschenkliger Winkelstahl 14-15Ungleichschenkliger Winkelstahl 16-17Walztoleranzen

BS EN 10034: 1993 21-22BS EN 10056 2: 1993 23

Corus Verkaufbros 27-28

ContentsNotation 2Quality and Presentation 3Dimensions and Properties

IPE Beams 4-7HE Wide Flange Beams 8-13

Equal Angles 14-15Unequal Angles 16-17Rolling Tolerances

BS EN 10034: 1993 24-25BS EN 10056 2: 1993 26

Offices and Agents for Corus Exports 27-28

13502 Corus Euro Inners 21/3/06 6:04 pm Page 1

-

Structural sections in accordance with European specifications

2 Corus Construction & Industrial

Notationsen conformitavec EN 1993-1-1A = Section dacier

b = Largeur du profil

d = Hauteur de la portion droite

de lme

G = Poids par mtre courant

h = Hauteur du profil

hw = Hauteur intrieure entre ailes

I = Moment dinertie

i = Rayon de giration

IT = Moment dinertie de torsion

I = Facteur de gauchissement

par rapport au centre de

cisaillement

Iyz = Moment centrifuge

r,r1 = Rayon de cong

r2 = Rayon de cong extrieur

t = Epaisseur

t f = Epaisseur daile

t w = Epaisseur dme

W = Module de flexion lastique

Wpl = Module de flexion plastique

ys = Distance du centre de

gravit suivant laxe y

zs = Distance du centre de

gravit suivant laxe z

Il incombe lutilisateur de

vrifier selon la nuance dacier si

les valeurs des lancements de

lme et des ailes du profil choisi

satisfont aux conditions

dapplication des rgles de

dimensionnement utilises.

Bezeichnungenlaut EN 1993-1-1

A = Querschnittsflche

b = Profilbreite

d = Hhe des geraden

Stegteils

G = Gewicht pro lfd. Meter

h = Profilhhe

hw = Innere Hhe zwischen

Flanschen

I = Flchenmoment

i = Trgheitsbalbmesser

IT = Torsionsflchenmoment

I = Wlbflchenmoment

bezogen auf den

Schubmittelpunkt

Iyz = Flchenzentrifugalmoment

r,r1 = Ausrundungsradius

r2 = Abrundungsradius

t = Strke

t f = Flanschdicke

t w = Stegdicke

W = Elastisches

Widerstandsmoment

Wpl = Plastisches

Widerstandsmoment

ys = Schwerpunktsabstand in

Richtung y-Achse

zs = Schwerpunktsabstand in

Richtung z-Achse

Es solte geprft werden, ob die

Schlankheitsgrade von Steg und

Flansch des ausgesuchten Profils

den in den Anwendebestimmungen

der Baunormen in Abhngigkeit

der Stahlsorten angegebenen

Werte entsprechen.

Notationsaccording toEN 1993-1-1

A = Sectional area

b = Width of section

d = Depth of straight portion

of web

G = Weight per metre

h = Depth of section

hw = Inner depth between flanges

I = Moment of inertia

i = Radius of gyration

IT = Torsional constant

I = Warping constant referred

to the shear centre

Iyz = Centrifugal moment

r,r1 = Radius of root fillet

r2 = Toe radius

t = Thickness

t f = Flange thickness

t w = Web thickness

W = Elastic section modulus

Wpl = Plastic section modulus

ys = Distance of centre of gravity

along y-axis

zs = Distance of centre of gravity

along z-axis

Designers should verify that the

slenderness ratios of web and

flange of the chosen section and

grade comply with the design

codes used.

13502 Corus Euro Inners 21/3/06 6:04 pm Page 2

-

Structural sections in accordance with European specifications

Corus Construction & Industrial 3

Nuances, tolrances etprsentation

Nuances dacier

Nuances dacier de construction

conformment aux normes nationales et

internationales:

(Grades S235JR, S275JR, S275J0,

S275J2 et S355JR, S355J0, S355J2),

ASTM A36, A572 et JIS.

Tolrances de laminage

Sur les dimensions, les profils, le

poids et la longueur conformes

Euronorm, BS EN10034: 1993 et BS

EN10056-2: 1993.

Longueurs

De 6m 24m. Pour certaines tailles, il

est possible de fournir des longueurs

jusqu 27m sur demande spciale.

Finitions

Les profils sont normalement fournis

tels quels ltat lamin, mais on peut

sur demande passer le matriau la

grenaille et le recouvrir dun apprt ou

de peinture.

Marquage

Tous les profiles seront identifis par

une tiquette code barre Corus

standard.

Stahlsorten, toleranzen undqualitt

Stahlsorten

Stahlsorten gemss Nationalen und

Internationalel Normen:

(Grades S235JR, S275JR, S275J0,

S275J2 et S355JR, S355J0, S355J2),

ASTM A36, A572 und JIS.

Walztoleranzen

Mass, Profile, Gewicht und Lnge in

Euronorm, BS EN10034: 1993 und BS

EN10056-2: 1993.

Lngen

Von 6 bis 24m. Bestimmte Grssen bis

27m stehen zur Verfgung nach

Vereinbarung.

Oberflchen

Profile werden normalerweise wie

gewalzt geliefert, auf Wunsch kann das

Material auch gestrahlt und konserviert

werden.

Kennzeichnung

Alle Trger werden durch unsere mit Bar

Code versehenen Standard Corus

Etiketten gekennzeichnet.

Steel grades, tolerancesand presentation

Steel grades

Structural steel grades in accordance

with national and international

standards:

(Grades S235JR, S275JR, S275J0,

S275J2 et S355JR, S355J0, S355J2),

ASTM A36, A572 and JIS.

Rolling tolerances

On dimensions, profile, weight and

length to Euronorm, BS EN10034: 1993

and BS EN10056-2: 1993.

Lengths

From 6m up to 24m. For certain sizes

lengths up to 27m may be supplied by

arrangement.

Finishes

Sections are normally supplied in the

as-rolled condition but arrangements

can be made for material to be shot-

blasted and primed/painted.

Marking

All sections will be identified using the

standard Corus bar coded label.

13502 Corus Euro Inners 21/3/06 6:04 pm Page 3

-

Structural sections in accordance with European specifications

4 Corus Construction & Industrial

Notation page 2

Dsignation

Bezeichnung

Section

IPE 100 A

IPE 100

IPE 120 A

IPE 120

IPE 140 A

IPE 140

IPE 140 R

IPE 160 A

IPE 160

IPE 160 R

IPE 180 A

IPE 180

IPE 180 O

IPE 180 R

IPE 200 A

IPE 200

IPE 200 O

IPE 200 R

IPE 220 A

IPE 220

IPE 220 O

IPE 220 R

IPE 240 A

IPE 240

IPE 240 O

IPE 240 R

IPE 270 A

IPE 270

IPE 270 O

IPE 270 R

IPE 300 A

IPE 300

IPE 300 O

IPE 300 R

G

kg/m

6.89

8.10

8.66

10.4

10.5

12.9

14.4

12.7

15.8

17.7

15.4

18.8

21.3

22.1

18.4

22.4

25.1

26.6

22.2

26.2

29.4

31.6

26.2

30.7

34.3

37.3

30.7

36.1

42.3

44.0

36.5

42.2

49.3

51.7

h

mm

98

100

118

120

137

140

142

157

160

162

177

180

182

183

197

200

202

204

217

220

222

225

237

240

242

245

267

270

274

276

297

300

304

306

b

mm

55

55

64

64

73

73

72

82

82

81

91

91

92

89

100

100

102

98

110

110

112

108

120

120

122

118

135

135

136

133

150

150

152

147

t w

mm

3.6

4.1

3.8

4.4

3.8

4.7

5.3

4.0

5.0

5.6

4.3

5.3

6.0

6.4

4.5

5.6

6.2

6.6

5.0

5.9

6.6

6.7

5.2

6.2

7.0

7.5

5.5

6.6

7.5

7.7

6.1

7.1

8.0

8.5

t f

mm

4.7

5.7

5.1

6.3

5.6

6.9

7.8

5.9

7.4

8.5

6.5

8.0

9.0

9.5

7.0

8.5

9.5

10.5

7.7

9.2

10.2

11.8

8.3

9.8

10.8

12.3

8.7

10.2

12.2

13.1

9.2

10.7

12.7

13.7

r

mm

7

7

7

7

7

7

7

9

9

9

9

9

9

9

12

12

12

12

12

12

12

12

15

15

15

15

15

15

15

15

15

15

15

15

A

cm2

8.78

10.3

11.0

13.2

13.4

16.4

18.3

16.2

20.1

22.6

19.6

23.9

27.1

28.1

23.5

28.5

32.0

33.9

28.3

33.4

37.4

40.2

33.3

39.1

43.7

47.5

39.1

45.9

53.8

56.0

46.5

53.8

62.8

65.9

hw d

mm mm

88.6 74.6

88.6 74.6

107.4 93.4

107.4 93.4

126.2 112.2

126.2 112.2

126.2 112.2

145.2 127.2

145.2 127.2

145.2 127.2

164.0 146.0

164.0 146.0

164.0 146.0

164.0 146.0

183.0 159.0

183.0 159.0

183.0 159.0

183.0 159.0

201.6 177.6

201.6 177.6

201.6 177.6

201.6 177.6

220.4 190.4

220.4 190.4

220.4 190.4

220.4 190.4

249.6 219.6

249.6 219.6

249.6 219.6

249.6 219.6

278.6 248.6

278.6 248.6

278.6 248.6

278.6 248.6

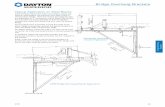

Poutrelles ailes facesparallles de la srie Europenne conformes Euronorme 19-57

Europische I-trgermit parallelen Flanschflchen gema Euronorm 19-57

European specification beamswith parallel flanges in accordance with Euronorm 19-57

t w

y

bz

h

r

y

t f

z

d h w

Bezeichnungen Seite 2 Explanation page 2

Non Standard Section Size. Please refer to account manager for availability of rollings.

13502 Corus Euro Inners 21/3/06 6:04 pm Page 4

-

Structural sections in accordance with European specifications

Corus Construction & Industrial 5

Explanation page 2

Dsignation

Bezeichnung

Section

IPE 100 A

IPE 100

IPE 120 A

IPE 120

IPE 140 A

IPE 140

IPE 140 R

IPE 160 A

IPE 160

IPE 160 R

IPE 180 A

IPE 180

IPE 180 O

IPE 180 R

IPE 200 A

IPE 200

IPE 200 O

IPE 200 R

IPE 220 A

IPE 220

IPE 220 O

IPE 220 R

IPE 240 A

IPE 240

IPE 240 O

IPE 240 R

IPE 270 A

IPE 270

IPE 270 O

IPE 270 R

IPE 300 A

IPE 300

IPE 300 O

IPE 300 R

Iy Iz

cm4

cm4

141 13.1

171 15.9

257 22.4

318 27.7

435 36.4

541 44.9

609 48.8

689 54.4

869 68.3

992 75.7

1063 81.9

1317 101

1505 117

1554 112

1591 117

1943 142

2211 169

2363 166

2317 171

2772 205

3134 240

3481 249

3290 240

3892 284

4369 329

4823 339

4917 358

5790 420

6947 513

7300 516

7173 519

8356 604

9994 746

10500 728

iy iz

cm cm

4.01 1.22

4.07 1.24

4.83 1.42

4.90 1.45

5.70 1.65

5.74 1.65

5.76 1.63

6.53 1.83

6.58 1.84

6.62 1.83

7.37 2.05

7.42 2.05

7.45 2.08

7.44 2.00

8.23 2.23

8.26 2.24

8.32 2.30

8.35 2.21

9.05 2.46

9.11 2.48

9.16 2.53

9.30 2.49

9.94 2.68

9.97 2.69

10.0 2.74

10.1 2.67

11.2 3.02

11.2 3.02

11.4 3.09

11.4 3.03

12.4 3.34

12.5 3.35

12.6 3.45

12.6 3.32

Wy Wz

cm3

cm3

28.8 4.77

34.2 5.79

43.8 7.00

53.0 8.65

63.3 9.98

77.3 12.3

86.0 13.5

87.8 13.3

109 16.7

122 18.7

120 18.0

146 22.2

165 25.5

170 25.2

162 23.4

194 28.5

219 33.1

232 33.8

214 31.2

252 37.3

282 42.8

309 46.1

278 40.0

324 47.3

361 53.9

394 57.4

368 53.0

429 62.2

507 75.5

529 77.6

483 69.2

557 80.5

658 98.1

686 99.0

Wply Wplz

cm3

cm3

33.0 7.52

39.4 9.13

49.9 11.0

60.7 13.6

71.6 15.5

88.4 19.2

99.0 21.3

99.1 20.7

124 26.1

140 29.3

135 27.9

166 34.6

189 39.9

195 39.6

182 36.5

221 44.5

249 51.8

265 53.1

240 48.4

285 58.0

321 66.8

352 71.8

312 62.3

367 73.8

410 84.3

450 90.0

413 82.2

484 96.8

575 118

601 121

542 107

628 125

744 152

780 154

I IT

dm6

cm4

0.0003 0.727

0.0004 1.16

0.0007 0.996

0.0009 1.69

0.0016 1.34

0.0020 2.40

0.0022 3.36

0.0031 1.93

0.0040 3.54

0.0045 5.06

0.0060 2.67

0.0075 4.73

0.0088 6.65

0.0084 7.63

0.0106 4.14

0.0131 6.92

0.0156 9.36

0.0155 11.7

0.0188 5.68

0.0228 9.03

0.0269 12.2

0.0283 16.4

0.0314 8.50

0.0376 13.0

0.0439 17.1

0.0459 22.8

0.0597 10.4

0.0708 15.9

0.0880 25.0

0.0890 29.1

0.107 13.3

0.126 19.9

0.158 31.0

0.155 37.0

Poutrelles ailes facesparallles de la srie Europenne conformes Euronorme 19-57

Europische I-trgermit parallelen flanschflchen gema Euronorm 19-57

European specification beamswith parallel flanges in accordance with Euronorm 19-57

Bezeichnungen Seite 2Notation page 2

G

kg/m

6.89

8.10

8.66

10.4

10.5

12.9

14.4

12.7

15.8

17.7

15.4

18.8

21.3

22.1

18.4

22.4

25.1

26.6

22.2

26.2

29.4

31.6

26.2

30.7

34.3

37.3

30.7

36.1

42.3

44.0

36.5

42.2

49.3

51.7

t w

y

bz

h

r

y

t f

z

d h w

Non Standard Section Size. Please refer to account manager for availability of rollings.

13502 Corus Euro Inners 21/3/06 6:04 pm Page 5

-

Structural Sections in accordance with European Specifications

6 Corus Construction & Industrial

Structural Sections in accordance with European Specifications

Notation page 2

Dsignation

Bezeichnung

Section

IPE 330 A

IPE 330

IPE 330 O

IPE 330 R

IPE 360 A

IPE 360

IPE 360 O

IPE 360 R

IPE 400 A

IPE 400

IPE 400 O

IPE 400 R

IPE 400 V

IPE 450 A

IPE 450

IPE 450 O

IPE 450 R

IPE 450 V

IPE 500 A

IPE 500

IPE 500 O

IPE 500 R

IPE 500 V

IPE 550 A

IPE 550

IPE 550 O

IPE 550 R

IPE 550 V

IPE 600 A

IPE 600

IPE 600 O

IPE 600 R

IPE 600 V

IPE 750 X 137

IPE 750 X 147

IPE 750 X 161

IPE 750 X 173

IPE 750 X 185

IPE 750 X 196

IPE 750 X 210

IPE 750 X 222

G

kg/m

43.0

49.1

57.0

60.3

50.2

57.1

66.0

70.4

57.4

66.3

75.7

81.5

84.0

67.2

77.6

92.4

95.2

104

79.4

90.7

107

111

129

92.1

106

123

134

159

108

122

154

144

184

137

147

160

174

185

197

210

222

h

mm

327

330

334

336

358

360

364

367

397

400

404

407

408

447

450

456

458

460

497

500

506

508

514

547

550

556

560

566

597

600

610

608

618

753

753

758

762

766

770

775

778

b

mm

160

160

162

158

170

170

172

168

180

180

182

178

182

190

190

192

188

194

200

200

202

198

204

210

210

212

210

216

220

220

224

218

228

263

265

266

267

267

268

268

269

t w

mm

6.5

7.5

8.5

9.2

6.6

8.0

9.2

9.9

7.0

8.6

9.7

10.6

10.6

7.6

9.4

11.0

11.3

12.4

8.4

10.2

12.0

12.6

14.2

9.0

11.1

12.7

14.0

17.1

9.8

12.0

15.0

14.0

18.0

11.5

13.2

13.8

14.4

14.9

15.6

16.0

17.0

t f

mm

10.0

11.5

13.5

14.5

11.5

12.7

14.7

16.0

12.0

13.5

15.5

17.0

17.5

13.1

14.6

17.6

18.6

19.6

14.5

16.0

19.0

20.0

23.0

15.7

17.2

20.2

22.2

25.2

17.5

19.0

24.0

23.0

28.0

17.0

17.0

19.3

21.6

23.6

25.4

28.0

29.5

r

mm

18

18

18

18

18

18

18

18

21

21

21

21

21

21

21

21

21

21

21

21

21

21

21

24

24

24

24

24

24

24

24

24

24

17

17

17

17

17

17

17

17

A

cm2

54.7

62.6

72.6

76.8

64.0

72.7

84.1

89.7

73.1

84.5

96.4

104

107

85.5

98.8

118

121

132

101

116

137

142

164

117

134

156

170

202

137

156

197

184

234

175

187

204

221

236

251

268

283

hw d

mm mm

307.0 271.0

307.0 271.0

307.0 271.0

307.0 271.0

334.6 298.6

334.6 298.6

334.6 298.6

334.6 298.6

373.0 331.0

373.0 331.0

373.0 331.0

373.0 331.0

373.0 331.0

420.8 378.8

420.8 378.8

420.8 378.8

420.8 378.8

420.8 378.8

468.0 426.0

468.0 426.0

468.0 426.0

468.0 426.0

468.0 426.0

515.6 467.6

515.6 467.6

515.6 467.6

515.6 467.6

515.6 467.6

562.0 514.0

562.0 514.0

562.0 514.0

562.0 514.0

562.0 514.0

719.0 685.0

719.0 685.0

719.4 685.4

718.8 684.8

718.8 684.8

719.2 685.2

719.0 685.0

719.0 685.0

Poutrelles ailes facesparallles de la srie Europenne conformes Euronorme 19-57

Europische I-trgermit parallelen Flanschflchen gema Euronorm 19-57

European specification beamswith parallel flanges in accordance with Euronorm 19-57

Bezeichnungen Seite 2 Explanation page 2

t w

y

bz

h

r

y

t f

z

d h w

Non Standard Section Size. Please refer to account manager for availability of rollings.

13502 Corus Euro Inners 21/3/06 6:04 pm Page 6

-

Structural Sections in accordance with European Specifications

Corus Construction & Industrial 7

Explanation page 2

Dsignation

Bezeichnung

Section

IPE 330 A

IPE 330

IPE 330 O

IPE 330 R

IPE 360 A

IPE 360

IPE 360 O

IPE 360 R

IPE 400 A

IPE 400

IPE 400 O

IPE 400 R

IPE 400 V

IPE 450 A

IPE 450

IPE 450 O

IPE 450 R

IPE 450 V

IPE 500 A

IPE 500

IPE 500 O

IPE 500 R

IPE 500 V

IPE 550 A

IPE 550

IPE 550 O

IPE 550 R

IPE 550 V

IPE 600 A

IPE 600

IPE 600 O

IPE 600 R

IPE 600 V

IPE 750 X 137

IPE 750 X 147

IPE 750 X 161

IPE 750 X 173

IPE 750 X 185

IPE 750 X 196

IPE 750 X 210

IPE 750 X 222

G

kg/m

43.0

49.1

57.0

60.3

50.2

57.1

66.0

70.4

57.4

66.3

75.7

81.5

84.0

67.2

77.6

92.4

95.2

104

79.4

90.7

107

111

129

92.1

106

123

134

159

108

122

154

144

184

137

147

160

174

185

197

210

222

Iy Iz

cm4

cm4

10230 685

11770 788

13910 960

14690 958

14520 944

16270 1043

19050 1251

20360 1270

20290 1171

23130 1318

26750 1564

28860 1606

30140 1766

29760 1502

33740 1676

40920 2085

42400 2070

46200 2397

42930 1939

48200 2142

57780 2622

59930 2600

70720 3271

59980 2432

67120 2668

79160 3224

86600 3447

102300 4265

82920 3116

92080 3387

118300 4521

110300 3993

141600 5570

159900 5166

166100 5289

186100 6073

205800 6873

223000 7510

240300 8175

262200 9011

278200 9604

iy iz

cm cm

13.7 3.54

13.7 3.55

13.8 3.64

13.8 3.53

15.1 3.84

15.0 3.79

15.0 3.86

15.1 3.76

16.7 4.00

16.5 3.95

16.7 4.03

16.7 3.93

16.8 4.06

18.7 4.19

18.5 4.12

18.6 4.21

18.7 4.13

18.7 4.26

20.6 4.38

20.4 4.31

20.6 4.38

20.5 4.28

20.8 4.47

22.6 4.55

22.3 4.45

22.5 4.55

22.5 4.50

22.5 4.60

24.6 4.77

24.3 4.66

24.5 4.79

24.5 4.66

24.6 4.88

30.3 5.44

29.8 5.31

30.2 5.45

30.5 5.57

30.8 5.65

31.0 5.71

31.3 5.80

31.3 5.82

Wy Wz

cm3

cm3

626 85.6

713 98.5

833 119

874 121

812 111

904 123

1047 145

1111 151

1022 130

1156 146

1324 172

1418 180

1477 194

1331 158

1500 176

1795 217

1851 220

2009 247

1728 194

1928 214

2284 260

2360 263

2752 321

2193 232

2441 254

2847 304

3093 328

3616 395

2778 283

3069 308

3879 404

3629 366

4582 489

4246 393

4411 399

4909 457

5402 515

5821 563

6241 610

6765 672

7152 714

Wply Wplz

cm3

cm3

702 133

805 153

943 185

995 190

907 172

1019 191

1186 227

1265 236

1144 202

1308 229

1503 269

1618 283

1682 304

1495 245

1702 276

2047 341

2115 346

2302 389

1946 301

2195 335

2613 408

2710 414

3169 506

2475 361

2788 400

3264 480

3563 520

4206 632

3142 441

3513 485

4472 639

4176 580

5325 780

4865 614

5110 631

5666 719

6218 810

6691 884

7174 959

7762 1054

8225 1122

I IT

dm6

cm4

0.172 19.6

0.200 28.1

0.247 42.2

0.247 50.6

0.283 27.4

0.315 37.4

0.382 55.7

0.390 68.8

0.434 36.2

0.492 51.3

0.590 73.3

0.611 92.5

0.673 99.6

0.707 47.1

0.794 66.7

1.00 109

0.999 123

1.16 149

1.13 64.3

1.25 89.1

1.55 143

1.55 162

1.97 242

1.72 89.3

1.89 123

2.31 187

2.49 242

3.12 372

2.62 122

2.86 165

3.88 316

3.42 271

4.85 506

7.00 135

7.16 157

8.28 208

9.42 270

10.3 334

11.3 406

12.6 512

13.5 601

Poutrelles ailes facesparallles de la srie Europenne conformes Euronorme 19-57

Europische I-trgermit parallelen Flanschflchen gema Euronorm 19-57

European specification beamswith parallel flanges in accordance with Euronorm 19-57

Bezeichnungen Seite 2Notation page 2

t w

y

bz

h

r

y

t f

z

d h w

Non Standard Section Size. Please refer to account manager for availability of rollings.

13502 Corus Euro Inners 21/3/06 6:04 pm Page 7

-

Structural sections in accordance with European specifications

8 Corus Construction & Industrial8 Corus Construction & Industrial

Notation page 2

Dsignation

Bezeichnung

Section

HE 100 AA

HE 100 A

HE 100 B

HE 120 AA

HE 120 A

HE 120 B

HE 140 AA

HE 140 A

HE 140 B

HE 160 AA

HE 160 A

HE 160 B

HE 160 M

HE 180 AA

HE 180 A

HE 180 B

HE 180 M

HE 200 AA

HE 200 A

HE 200 B

HE 200 M

HE 220 AA

HE 220 A

HE 220 B

HE 220 M

HE 240 AA

HE 240 A

HE 240 B

HE 240 M

HE 260 AA

HE 260 A

HE 260 B

HE 260 M

G

kg/m

12.2

16.7

20.4

14.6

19.9

26.7

18.1

24.7

33.7

23.8

30.4

42.6

76.2

28.7

35.5

51.2

88.9

34.6

42.3

61.3

103

40.4

50.5

71.5

117

47.4

60.3

83.2

157

54.1

68.2

93.0

172

h

mm

91

96

100

109

114

120

128

133

140

148

152

160

180

167

171

180

200

186

190

200

220

205

210

220

240

224

230

240

270

244

250

260

290

b

mm

100

100

100

120

120

120

140

140

140

160

160

160

166

180

180

180

186

200

200

200

206

220

220

220

226

240

240

240

248

260

260

260

268

t w

mm

4.2

5.0

6.0

4.2

5.0

6.5

4.3

5.5

7.0

4.5

6.0

8.0

14.0

5.0

6.0

8.5

14.5

5.5

6.5

9.0

15.0

6.0

7.0

9.5

15.5

6.5

7.5

10.0

18.0

6.5

7.5

10.0

18.0

t f

mm

5.5

8.0

10.0

5.5

8.0

11.0

6.0

8.5

12.0

7.0

9.0

13.0

23.0

7.5

9.5

14.0

24.0

8.0

10.0

15.0

25.0

8.5

11.0

16.0

26.0

9.0

12.0

17.0

32.0

9.5

12.5

17.5

32.5

r

mm

12

12

12

12

12

12

12

12

12

15

15

15

15

15

15

15

15

18

18

18

18

18

18

18

18

21

21

21

21

24

24

24

24

A

cm2

15.6

21.2

26.0

18.6

25.3

34.0

23.0

31.4

43.0

30.4

38.8

54.3

97.1

36.5

45.3

65.3

113

44.1

53.8

78.1

131

51.5

64.3

91.0

149

60.4

76.8

106

200

69.0

86.8

118

220

hw d

mm mm

80 56

80 56

80 56

98 74

98 74

98 74

116 92

116 92

116 92

134 104

134 104

134 104

134 104

152 122

152 122

152 122

152 122

170 134

170 134

170 134

170 134

188 152

188 152

188 152

188 152

206 164

206 164

206 164

206 164

225 177

225 177

225 177

225 177

Poutrelles larges ailes facesparallles de la srie Europenne conformes Euronorme 53-62

Europische warmgewalze breite I-trgermit parallelen Flanschflchen gema Euronorm 53-62

European wide flange beamsin accordance with Euronorm 53-62

Bezeichnungen Seite 2 Explanation page 2

t w

y

bz

h

r

y

t f

z

d h w

Non Standard Section Size. Please refer to account manager for availability of rollings.

13502 Corus Euro Inners 21/3/06 6:04 pm Page 8

-

Structural sections in accordance with European specifications

Corus Construction & Industrial 9Corus Construction & Industrial 9

Explanation page 2

Dsignation

Bezeichnung

Section

HE 100 AA

HE 100 A

HE 100 B

HE 120 AA

HE 120 A

HE 120 B

HE 140 AA

HE 140 A

HE 140 B

HE 160 AA

HE 160 A

HE 160 B

HE 160 M

HE 180 AA

HE 180 A

HE 180 B

HE 180 M

HE 200 AA

HE 200 A

HE 200 B

HE 200 M

HE 220 AA

HE 220 A

HE 220 B

HE 220 M

HE 240 AA

HE 240 A

HE 240 B

HE 240 M

HE 260 AA

HE 260 A

HE 260 B

HE 260 M

G

kg/m

12.2

16.7

20.4

14.6

19.9

26.7

18.1

24.7

33.7

23.8

30.4

42.6

76.2

28.7

35.5

51.2

88.9

34.6

42.3

61.3

103

40.4

50.5

71.5

117

47.4

60.3

83.2

157

54.1

68.2

93.0

172

Poutrelles larges ailes facesparallles de la srie Europenne conformes Euronorme 53-62

Europische warmgewalze breite I-trgermit parallelen flanschflchen gema Euronorm 53-62

European wide flange beamsin accordance with Euronorm 53-62

Bezeichnungen Seite 2Notation page 2

Iy Iz

cm4

cm4

237 92.1

349 134

450 167

413 159

606 231

864 318

719 275

1033 389

1509 550

1283 479

1673 616

2492 889

5098 1759

1967 730

2510 925

3831 1363

7483 2580

2944 1068

3692 1336

5696 2003

10640 3651

4170 1510

5410 1955

8091 2843

14600 5012

5835 2077

7763 2769

11260 3923

24290 8153

7981 2788

10450 3668

14920 5135

31310 10450

iy iz

cm cm

3.89 2.43

4.06 2.51

4.16 2.53

4.72 2.93

4.89 3.02

5.04 3.06

5.59 3.45

5.73 3.52

5.93 3.58

6.50 3.97

6.57 3.98

6.78 4.05

7.25 4.26

7.34 4.47

7.45 4.52

7.66 4.57

8.13 4.77

8.17 4.92

8.28 4.98

8.54 5.07

9.00 5.27

9.00 5.42

9.17 5.51

9.43 5.59

9.89 5.79

9.83 5.87

10.1 6.00

10.3 6.08

11.0 6.39

10.8 6.36

11.0 6.50

11.2 6.58

11.9 6.90

Wy Wz

cm3

cm3

52.0 18.4

72.8 26.8

89.9 33.5

75.8 26.5

106 38.5

144 52.9

112 39.3

155 55.6

216 78.5

173 59.8

220 76.9

312 111

566 212

236 81.1

294 103

426 151

748 277

317 107

389 134

570 200

967 354

407 137

515 178

736 258

1217 444

521 173

675 231

938 327

1799 657

654 214

836 282

1148 395

2159 780

Wply Wplz

cm3

cm3

58.4 28.4

83.1 41.1

104 51.3

84.2 40.6

120 58.8

165 80.9

124 59.9

174 84.8

245 120

191 91.2

245 117

354 170

675 325

258 123

325 156

482 231

884 425

347 163

430 204

643 306

1135 543

446 209

569 270

827 394

1420 678

571 264

745 351

1054 498

2117 1006

715 327

920 430

1283 602

2524 1192

I IT

dm6

cm4

0.0017 2.33

0.0026 5.28

0.0034 9.33

0.0043 2.59

0.0065 6.04

0.0094 13.9

0.0102 3.43

0.0151 8.10

0.0225 20.2

0.0238 6.43

0.0315 12.1

0.0480 31.3

0.108 161

0.0464 8.31

0.0603 14.9

0.0939 42.2

0.200 201

0.0846 12.5

0.108 21.0

0.171 59.7

0.347 258

0.146 15.5

0.194 28.6

0.296 77.0

0.574 313

0.240 22.1

0.329 42.1

0.488 104

1.15 626

0.383 30.1

0.517 54.2

0.755 127

1.73 720

t w

y

bz

h

r

y

t f

z

d h w

Non Standard Section Size. Please refer to account manager for availability of rollings.

13502 Corus Euro Inners 21/3/06 6:04 pm Page 9

-

Structural sections in accordance with European specifications

10 Corus Construction & Industrial10 Corus Construction & Industrial

Notation page 2

Dsignation

Bezeichnung

Section

HE 280 AA

HE 280 A

HE 280 B

HE 280 M

HE 300 AA

HE 300 A

HE 300 B

HE 300 M

HE 320 AA

HE 320 A

HE 320 B

HE 320 M

HE 340 AA

HE 340 A

HE 340 B

HE 340 M

HE 360 AA

HE 360 A

HE 360 B

HE 360 M

HE 400 AA

HE 400 X 107

HE 400 A

HE 400 B

HE 400 M

HE 450 AA

HE 450 X 123

HE 450 A

HE 450 B

HE 450 M

HE 500 AA

HE 500 A

HE 500 B

HE 500 M

G

kg/m

61.2

76.4

103

189

69.8

88.3

117

238

74.2

97.6

127

245

78.9

105

134

248

83.7

112

142

250

92.4

107

125

155

256

99.7

124

140

171

263

107

155

187

270

h

mm

264

270

280

310

283

290

300

340

301

310

320

359

320

330

340

377

339

350

360

395

378

384

390

400

432

425

435

440

450

478

472

490

500

524

b

mm

280

280

280

288

300

300

300

310

300

300

300

309

300

300

300

309

300

300

300

308

300

297

300

300

307

300

300

300

300

307

300

300

300

306

t w

mm

7.0

8.0

10.5

18.5

7.5

8.5

11.0

21.0

8.0

9.0

11.5

21.0

8.5

9.5

12.0

21.0

9.0

10.0

12.5

21.0

9.5

10.0

11.0

13.5

21.0

10.0

10.2

11.5

14.0

21.0

10.5

12.0

14.5

21.0

t f

mm

10.0

13.0

18.0

33.0

10.5

14.0

19.0

39.0

11.0

15.5

20.5

40.0

11.5

16.5

21.5

40.0

12.0

17.5

22.5

40.0

13.0

16.0

19.0

24.0

40.0

13.5

18.5

21.0

26.0

40.0

14.0

23.0

28.0

40.0

r

mm

24

24

24

24

27

27

27

27

27

27

27

27

27

27

27

27

27

27

27

27

27

27

27

27

27

27

27

27

27

27

27

27

27

27

A

cm2

78.0

97.3

131

240

88.9

113

149

303

94.6

124

161

312

101

133

171

316

107

143

181

319

118

136

159

198

326

127

158

178

218

335

137

198

239

344

hw d

mm mm

244 196

244 196

244 196

244 196

262 208

262 208

262 208

262 208

279 225

279 225

279 225

279 225

297 243

297 243

297 243

297 243

315 261

315 261

315 261

315 261

352 298

352 298

352 298

352 298

352 298

398 344

398 344

398 344

398 344

398 344

444 390

444 390

444 390

444 390

Poutrelles larges ailes facesparallles de la srie Europenne conformes Euronorme 53-62

Europische warmgewalze breite I-trgermit parallelen Flanschflchen gema Euronorm 53-62

European wide flange beamsin accordance with Euronorm 53-62

Bezeichnungen Seite 2 Explanation page 2

t w

y

bz

h

r

y

t f

z

d h w

Non Standard Section Size. Please refer to account manager for availability of rollings.

13502 Corus Euro Inners 21/3/06 6:04 pm Page 10

-

Structural sections in accordance with European specifications

Corus Construction & Industrial 11Corus Construction & Industrial 11

Explanation page 2

Dsignation

Bezeichnung

Section

HE 280 AA

HE 280 A

HE 280 B

HE 280 M

HE 300 AA

HE 300 A

HE 300 B

HE 300 M

HE 320 AA

HE 320 A

HE 320 B

HE 320 M

HE 340 AA

HE 340 A

HE 340 B

HE 340 M

HE 360 AA

HE 360 A

HE 360 B

HE 360 M

HE 400 AA

HE 400 X 107

HE 400 A

HE 400 B

HE 400 M

HE 450 AA

HE 450 X 123

HE 450 A

HE 450 B

HE 450 M

HE 500 AA

HE 500 A

HE 500 B

HE 500 M

G

kg/m

61.2

76.4

103

189

69.8

88.3

117

238

74.2

97.6

127

245

78.9

105

134

248

83.7

112

142

250

92.4

107

125

155

256

99.7

124

140

171

263

107

155

187

270

Poutrelles larges ailes facesparallles de la srie Europenne conformes Euronorme 53-62

Europische warmgewalze breite I-trgermit parallelen Flanschflchen gema Euronorm 53-62

European wide flange beamsin accordance with Euronorm 53-62

Bezeichnungen Seite 2Notation page 2

Iy Iz

cm4

cm4

10560 3664

13670 4763

19270 6595

39550 13160

13800 4734

18260 6310

25170 8563

59200 19400

16450 4959

22930 6985

30820 9239

68130 19710

19550 5185

27690 7436

36660 9690

76370 19710

23040 5410

33090 7887

43190 10140

84870 19520

31250 5861

37640 6998

45070 8564

57680 10820

104100 19340

41890 6088

55860 8338

63720 9465

79890 11720

131500 19340

54640 6314

86970 10370

107200 12620

161900 19150

iy iz

cm cm

11.6 6.85

11.9 7.00

12.1 7.09

12.8 7.40

12.5 7.30

12.7 7.49

13.0 7.58

14.0 8.00

13.2 7.24

13.6 7.49

13.8 7.57

14.8 7.95

13.9 7.18

14.4 7.46

14.6 7.53

15.6 7.90

14.7 7.12

15.2 7.43

15.5 7.49

16.3 7.83

16.3 7.06

16.6 7.16

16.8 7.34

17.1 7.40

17.9 7.70

18.2 6.92

18.8 7.27

18.9 7.29

19.1 7.33

19.8 7.59

20.0 6.79

21.0 7.24

21.2 7.27

21.7 7.46

Wy Wz

cm3

cm3

800 262

1013 340

1376 471

2551 914

976 316

1260 421

1678 571

3482 1252

1093 331

1479 466

1926 616

3796 1276

1222 346

1678 496

2156 646

4052 1276

1359 361

1891 526

2400 676

4297 1268

1654 391

1960 471

2311 571

2884 721

4820 1260

1971 406

2568 556

2896 631

3551 781

5501 1260

2315 421

3550 691

4287 842

6180 1252

Wply Wplz

cm3

cm3

874 399

1113 518

1535 717

2966 1396

1066 481

1384 640

1870 869

4079 1912

1197 505

1629 709

2150 938

4436 1950

1342 528

1851 755

2409 985

4718 1952

1496 552

2089 801

2684 1032

4990 1942

1825 599

2166 721

2563 872

3233 1103

5571 1933

2184 624

2837 849

3217 965

3983 1197

6332 1938

2577 648

3950 1058

4815 1291

7095 1931

I IT

dm6

cm4

0.591 35.5

0.786 63.5

1.13 146

2.52 807

0.879 47.8

1.20 87.8

1.69 189

4.39 1411

1.04 53.6

1.51 112

2.07 230

5.01 1506

1.23 60.0

1.83 131

2.46 263

5.60 1512

1.45 67.1

2.18 153

2.89 298

6.15 1513

1.95 81.3

2.37 126

2.95 193

3.82 361

7.43 1520

2.58 91.4

3.62 178

4.15 250

5.27 448

9.28 1534

3.31 103

5.65 318

7.03 548

11.2 1544

t w

y

bz

h

r

y

t f

z

d h w

Non Standard Section Size. Please refer to account manager for availability of rollings.

13502 Corus Euro Inners 21/3/06 6:04 pm Page 11

-

Structural sections in accordance with European specifications

12 Corus Construction & Industrial12 Corus Construction & Industrial

Notation page 2

Dsignation

Bezeichnung

Section

HE 550 AA

HE 550 A

HE 550 B

HE 550 M

HE 600 AA

HE 600 x 137

HE 600 x 151

HE 600 x 174

HE 600 A

HE 600 B

HE 600 M

HE 650 AA

HE 650 A

HE 650 B

HE 650 M

HE 700 AA

HE 700 X 166

HE 700 A

HE 700 B

HE 700 M

HE 800 AA

HE 800 A

HE 800 B

HE 800 M

HE 900 AA

HE 900 A

HE 900 B

HE 900 M

HE 1000 AA

HE 1000 A

HE 1000 B

HE 1000 M

G

kg/m

120

166

199

278

129

137

151

175

178

212

285

138

190

225

293

150

166

204

241

301

172

224

262

317

198

252

291

333

222

272

314

349

h

mm

522

540

550

572

571

575

582

588

590

600

620

620

640

650

668

670

678

690

700

716

770

790

800

814

870

890

900

910

970

990

1000

1008

b

mm

300

300

300

306

300

300

300

300

300

300

305

300

300

300

305

300

300

300

300

304

300

300

300

303

300

300

300

302

300

300

300

302

t w

mm

11.5

12.5

15.0

21.0

12.0

11.8

11.6

13.6

13.0

15.5

21.0

12.5

13.5

16.0

21.0

13.0

12.5

14.5

17.0

21.0

14.0

15.0

17.5

21.0

15.0

16.0

18.5

21.0

16.0

16.5

19.0

21.0

t f

mm

15.0

24.0

29.0

40.0

15.5

17.5

20.6

23.9

25.0

30.0

40.0

16.0

26.0

31.0

40.0

17.0

21.0

27.0

32.0

40.0

18.0

28.0

33.0

40.0

20.0

30.0

35.0

40.0

21.0

31.0

36.0

40.0

r

mm

27

27

27

27

27

27

27

27

27

27

27

27

27

27

27

27

27

27

27

27

30

30

30

30

30

30

30

30

30

30

30

30

A

cm2

153

212

254

354

164

175

193

223

226

270

364

176

242

286

374

191

212

260

306

383

218

286

334

404

252

321

371

424

282

347

400

444

hw d

mm mm

492 438

492 438

492 438

492 438

540 486

540 486

540 486

540 486

540 486

540 486

540 486

588 534

588 534

588 534

588 534

636 582

636 582

636 582

636 582

636 582

734 674

734 674

734 674

734 674

830 770

830 770

830 770

830 770

928 868

928 868

928 868

928 868

Poutrelles larges ailes facesparallles de la srie Europenne conformes Euronorme 53-62

Europische warmgewalze breite I-trgermit parallelen Flanschflchen gema Euronorm 53-62

European wide flange beamsin accordance with Euronorm 53-62

Bezeichnungen Seite 2 Explanation page 2

t w

y

bz

h

r

y

t f

z

d h w

Non Standard Section Size. Please refer to account manager for availability of rollings.

13502 Corus Euro Inners 21/3/06 6:04 pm Page 12

-

Structural sections in accordance with European specifications

Corus Construction & Industrial 13

Explanation page 2

Dsignation

Bezeichnung

Section

HE 550 AA

HE 550 A

HE 550 B

HE 550 M

HE 600 AA

HE 600 x 137

HE 600 x 151

HE 600 x 174

HE 600 A

HE 600 B

HE 600 M

HE 650 AA

HE 650 A

HE 650 B

HE 650 M

HE 700 AA

HE 700 X 166

HE 700 A

HE 700 B

HE 700 M

HE 800 AA

HE 800 A

HE 800 B

HE 800 M

HE 900 AA

HE 900 A

HE 900 B

HE 900 M

HE 1000 AA

HE 1000 A

HE 1000 B

HE 1000 M

G

kg/m

120

166

199

278

129

137

151

175

178

212

285

138

190

225

293

150

166

204

241

301

172

224

262

317

198

252

291

333

222

272

314

349

Poutrelles larges ailes facesparallles de la srie Europenne conformes Euronorme 53-62

Europische warmgewalze breite I-trgermit parallelen Flanschflchen gema Euronorm 53-62

European wide flange beamsin accordance with Euronorm 53-62

Bezeichnungen Seite 2Notation page 2

Iy Iz

cm4

cm4

72870 6767

111900 10820

136700 13080

198000 19160

91870 6993

101500 7893

117100 9287

136400 10780

141200 11270

171000 13530

237400 18980

113900 7221

175200 11720

210600 13980

281700 18980

142700 7673

168900 9471

215300 12180

256900 14440

329300 18800

208900 8134

303400 12640

359100 14900

442600 18630

301100 9041

422100 13550

494100 15820

570400 18450

406500 9501

553800 14000

644700 16280

722300 18460

iy iz

cm cm

21.8 6.65

23.0 7.15

23.2 7.17

23.6 7.35

23.7 6.53

24.1 6.72

24.7 6.94

24.7 6.95

25.0 7.05

25.2 7.08

25.6 7.22

25.5 6.41

26.9 6.97

27.1 6.99

27.5 7.13

27.3 6.34

28.2 6.69

28.8 6.84

29.0 6.87

29.3 7.01

30.9 6.10

32.6 6.65

32.8 6.68

33.1 6.79

34.6 5.99

36.3 6.50

36.5 6.53

36.7 6.60

38.0 5.80

40.0 6.35

40.1 6.38

40.3 6.45

Wy Wz

cm3

cm3

2792 451

4146 721

4971 872

6923 1252

3218 466

3529 526

4024 619

4639 719

4787 751

5701 902

7660 1244

3676 481

5474 782

6480 932

8433 1245

4260 512

4982 631

6241 812

7340 963

9198 1237

5426 542

7682 843

8977 994

10870 1230

6923 603

9485 903

10980 1054

12540 1222

8380 633

11190 934

12890 1085

14330 1222

Wply Wplz

cm3

cm3

3128 698

4623 1106

5591 1340

7934 1936

3624 724

3953 813

4484 952

5203 1108

5351 1155

6426 1390

8773 1930

4161 750

6137 1204

7321 1441

9658 1935

4841 799

5599 977

7033 1256

8328 1494

10540 1928

6226 855

8701 1311

10230 1552

12490 1929

8000 957

10810 1413

12590 1657

14440 1928

9778 1015

12830 1469

14860 1715

16570 1939

I IT

dm6

cm4

4.35 127

7.20 360

8.87 610

13.6 1559

5.40 142

6.13 177

7.32 247

8.57 374

9.00 407

11.0 677

16.0 1570

6.59 158

11.0 458

13.4 749

18.7 1584

8.18 186

10.2 274

13.4 522

16.1 839

21.5 1595

11.5 243

18.3 609

21.9 959

27.9 1657

16.3 322

25.0 749

29.6 1150

34.9 1683

21.4 387

32.2 835

37.8 1267

43.2 1713

t w

y

bz

h

r

y

t f

z

d h w

Non Standard Section Size. Please refer to account manager for availability of rollings.

13502 Corus Euro Inners 21/3/06 6:04 pm Page 13

-

Structural sections in accordance with European specifications

14 Corus Construction & Industrial14 Corus Construction & Industrial

Notation page 2

Dsignation

Bezeichnung

Section

L 90 x 90 x 6

L 90 x 90 x 8

L 90 x 90 x 10

L 90 x 90 x 12

L 100 x 100 x 8

L 100 x 100 x 10

L 100 x 100 x 12

L 100 x 100 x 15

L 120 x 120 x 8

L 120 x 120 x 10

L 120 x 120 x 12

L 120 x 120 x 15

L 150 x 150 x 10

L 150 x 150 x 12

L 150 x 150 x 15

L 150 x 150 x 18

L 200 x 200 x 16

L 200 x 200 x 18

L 200 x 200 x 20

L 200 x 200 x 24

G

kg/m

8.3

10.9

13.4

15.9

12.2

15.0

17.8

21.9

14.7

18.2

21.6

26.6

23.0

27.3

33.8

40.1

48.5

54.2

59.9

71.1

h

mm

90

90

90

90

100

100

100

100

120

120

120

120

150

150

150

150

200

200

200

200

b

mm

90

90

90

90

100

100

100

100

120

120

120

120

150

150

150

150

200

200

200

200

t

mm

6

8

10

12

8

10

12

15

8

10

12

15

10

12

15

18

16

18

20

24

r1

mm

11

11

11

11

12

12

12

12

13

13

13

13

16

16

16

16

18

18

18

18

r2

mm

5.5

5.5

5.5

5.5

6.0

6.0

6.0

6.0

6.5

6.5

6.5

6.5

8.0

8.0

8.0

8.0

9.0

9.0

9.0

9.0

zs

cm

2.41

2.50

2.58

2.66

2.74

2.82

2.90

3.02

3.23

3.31

3.40

3.51

4.03

4.12

4.25

4.37

5.52

5.60

5.68

5.84

ys

cm

2.41

2.50

2.58

2.66

2.74

2.82

2.90

3.02

3.23

3.31

3.40

3.51

4.03

4.12

4.25

4.37

5.52

5.60

5.68

5.84

A

cm2

10.6

13.9

17.1

20.3

15.5

19.2

22.7

27.9

18.7

23.2

27.5

33.9

29.3

34.8

43.0

51.0

61.8

69.1

76.3

90.6

Cornires ailes galesconformes BS EN 10056 1: 1999

Gleichschenkliger winkelstahl gem BS EN 10056 1: 1999

Equal anglesaccording to BS EN 10056 1: 1999

Bezeichnungen Seite 2 Explanation page 2

r 2tr 1

h

t

r 2

b

Non Standard Section Size. Please refer to account manager for availability of rollings.

13502 Corus Euro Inners 21/3/06 6:04 pm Page 14

-

Structural sections in accordance with European specifications

Corus Construction & Industrial 15Corus Construction & Industrial 15

Dsignation

Bezeichnung

Section

L 90 x 90 x 6

L 90 x 90 x 8

L 90 x 90 x 10

L 90 x 90 x 12

L 100 x 100 x 8

L 100 x 100 x 10

L 100 x 100 x 12

L 100 x 100 x 15

L 120 x 120 x 8

L 120 x 120 x 10

L 120 x 120 x 12

L 120 x 120 x 15

L 150 x 150 x 10

L 150 x 150 x 12

L 150 x 150 x 15

L 150 x 150 x 18

L 200 x 200 x 16

L 200 x 200 x 18

L 200 x 200 x 20

L 200 x 200 x 24

iy

cm

2.76

2.74

2.72

2.70

3.06

3.04

3.02

2.98

3.69

3.67

3.65

3.62

4.62

4.60

4.57

4.54

6.16

6.13

6.11

6.06

ly

cm4

80.4

104

127

148

145

177

207

249

256

313

368

445

624

737

898

1050

2342

2600

2851

3331

lz

cm4

80.4

104

127

148

145

177

207

249

256

313

368

445

624

737

898

1050

2342

2600

2851

3331

lu

cm4

127

166

201

235

230

280

328

395

411

497

584

710

990

1170

1430

1680

3720

4150

4530

5280

lv

cm4

33.3

43.1

52.6

62.0

59.9

73.0

85.7

105

107

129

152

186

258

303

370

440

960

1050

1170

1380

lyz

cm4

-46.9

-61.5

-74.2

-86.5

-85.1

-104

-121

-145

-152

-184

-216

-262

-366

-434

-530

-620

-1380

-1550

-1680

-1950

iu

cm

3.47

3.45

3.42

3.40

3.85

3.83

3.80

3.76

4.67

4.63

4.60

4.57

5.82

5.80

5.76

5.73

7.76

7.75

7.70

7.64

iv

cm

1.78

1.76

1.75

1.75

1.96

1.95

1.94

1.94

2.38

2.36

2.35

2.34

2.97

2.95

2.93

2.92

3.94

3.90

3.92

3.90

Wy

cm3

12.2

16.1

19.8

23.4

20.0

24.6

29.1

35.6

29.1

36.0

42.7

52.4

56.9

67.8

83.5

98.8

162

181

199

235

Wz

cm3

12.2

16.1

19.8

23.4

20.0

24.6

29.1

35.6

29.1

36.0

42.7

52.4

56.9

67.8

83.5

98.8

162

181

199

235

iz

cm

2.76

2.74

2.72

2.70

3.06

3.04

3.02

2.98

3.69

3.67

3.65

3.62

4.62

4.60

4.57

4.54

6.16

6.13

6.11

6.06

Cornires ailes galesconformes BS EN 10056 1: 1999

Gleichschenkliger winkelstahl gem BS EN 10056 1: 1999

Equal anglesaccording to BS EN 10056 1: 1999

Bezeichnungen Seite 2Notation page 2 Explanation page 2

vz

u

y

u

v

z s

y s

45

Non Standard Section Size. Please refer to account manager for availability of rollings.

13502 Corus Euro Inners 21/3/06 6:04 pm Page 15

-

Structural sections in accordance with European specifications

16 Corus Construction & Industrial16 Corus Construction & Industrial

Notation page 2

Dsignation

Bezeichnung

Section

L 100 x 65 x 7

L 100 x 65 x 8

L 100 x 65 x 10

L 100 x 75 x 8

L 100 x 75 x 10

L 100 x 75 x 12

L 120 x 80 x 8

L 120 x 80 x 10

L 120 x 80 x 12

L 125 x 75 x 8

L 125 x 75 x 10

L 125 x 75 x 12

L 150 x 75 x 10

L 150 x 75 x 12

L 150 x 75 x 15

L 150 x 90 x 10

L 150 x 90 x 12

L 150 x 90 x 15

L 150 x 100 x 10

L 150 x 100 x 12

L 150 x 100 x 14

L 200 x 100 x 10

L 200 x 100 x 12

L 200 x 100 x 15

L 200 x 150 x 12

L 200 x 150 x 15

L 200 x 150 x 18

G

kg/m

8.77

9.94

12.3

10.6

13.0

15.4

12.2

15.0

17.8

12.2

15.0

17.8

17.0

20.2

24.8

18.2

21.6

26.6

19.0

22.5

26.1

23.0

27.3

33.7

32.0

39.6

47.1

h

mm

100

100

100

100

100

100

120

120

120

125

125

125

150

150

150

150

150

150

150

150

150

200

200

200

200

200

200

b

mm

65

65

65

75

75

75

80

80

80

75

75

75

75

75

75

90

90

90

100

100

100

100

100

100

150

150

150

t

mm

7

8

10

8

10

12

8

10

12

8

10

12

10

12

15

10

12

15

10

12

14

10

12

15

12

15

18

r1

mm

10

10

10

10

10

10

11

11

11

11

11

11

12

12

12

12

12

12

12

12

12

15

15

15

15

15

15

r2

mm

5.0

5.0

5.0

5.0

5.0

5.0

5.5

5.5

5.5

5.5

5.5

5.5

6.0

6.0

6.0

6.0

6.0

6.0

6.0

6.0

6.0

7.5

7.5

7.5

7.5

7.5

7.5

zs

cm

3.23

3.27

3.36

3.10

3.19

3.27

3.83

3.92

4.00

4.14

4.23

4.31

5.31

5.40

5.52

5.00

5.08

5.21

4.81

4.90

4.98

6.93

7.03

7.16

6.08

6.21

6.33

ys

cm

1.51

1.55

1.63

1.87

1.95

2.03

1.87

1.95

2.03

1.68

1.76

1.84

1.61

1.69

1.81

2.04

2.12

2.23

2.34

2.42

2.50

2.01

2.10

2.22

3.61

3.73

3.85

A

cm2

11.2

12.7

15.6

13.5

16.6

19.7

15.5

19.1

22.7

15.5

19.1

22.7

21.7

25.7

31.7

23.2

27.5

33.9

24.2

28.7

33.2

29.2

34.8

43.0

40.8

50.5

60.0

Cornires ailes ingalesconformes BS EN 10056 1: 1999

Ungleichschenkliger winkelstahl gem BS EN 10056 1: 1999

Unequal anglesaccording to BS EN 10056 1: 1999

Bezeichnungen Seite 2 Explanation page 2

t

t

r 2

h

b

r 2r 1

Non Standard Section Size. Please refer to account manager for availability of rollings.

13502 Corus Euro Inners 21/3/06 6:04 pm Page 16

-

Structural sections in accordance with European specifications

Corus Construction & Industrial 17Corus Construction & Industrial 17

Dsignation

Bezeichnung

Section

L 100 x 65 x 7

L 100 x 65 x 8

L 100 x 65 x 10

L 100 x 75 x 8

L 100 x 75 x 10

L 100 x 75 x 12

L 120 x 80 x 8

L 120 x 80 x 10

L 120 x 80 x 12

L 125 x 75 x 8

L 125 x 75 x 10

L 125 x 75 x 12

L 150 x 75 x 10

L 150 x 75 x 12

L 150 x 75 x 15

L 150 x 90 x 10

L 150 x 90 x 12

L 150 x 90 x 15

L 150 x 100 x 10

L 150 x 100 x 12

L 150 x 100 x 14

L 200 x 100 x 10

L 200 x 100 x 12

L 200 x 100 x 15

L 200 x 150 x 12

L 200 x 150 x 15

L 200 x 150 x 18

iy

cm

3.17

3.16

3.14

3.14

3.12

3.10

3.82

3.80

3.77

4.00

3.97

3.95

4.81

4.78

4.75

4.80

4.78

4.74

4.78

4.76

4.74

6.46

6.43

6.40

6.36

6.33

6.29

ly

cm4

113

127

154

133

162

189

226

276

323

247

302

354

501

589

713

533

627

761

553

651

745

1219

1441

1759

1653

2023

2376

lz

cm4

37.6

42.2

51.0

64.1

77.6

90.2

80.8

98.1

114

67.6

82.1

95.5

85.4

99.6

119

146

171

205

198

233

265

210

247

299

803

979

1146

lu

cm4

128

144

175

162

197

230

260

317

370

274

334

391

531

623

753

591

694

841

637

749

856

1290

1530

1860

2030

2480

2920

lv

cm4

22.0

24.8

30.1

34.6

42.2

49.5

46.6

56.8

66.7

40.9

49.9

58.5

55.1

64.7

78.6

88.3

104

126

114

134

154

135

159

193

430

526

623

lyz

cm4

-36.9

-41.6

-51.1

-53.5

-64.7

-75.6

-79.1

-94.8

-108

-74.6

-89.9

-105

-116

-134

-159

-161

-187

-225

-194

-226

-253

-278

-338

-398

-679

-826

-972

iu

cm

3.39

3.37

3.35

3.47

3.45

3.42

4.10

4.07

4.04

4.21

4.18

4.15

4.95

4.92

4.88

5.05

5.02

4.98

5.13

5.11

5.08

6.65

6.63

6.59

7.04

7.00

6.97

iv

cm

1.40

1.40

1.39

1.60

1.59

1.59

1.73

1.72

1.71

1.63

1.61

1.61

1.60

1.59

1.58

1.95

1.94

1.93

2.17

2.16

2.15

2.15

2.14

2.12

3.25

3.23

3.22

Wy

cm3

16.6

18.9

23.2

19.3

23.8

28.1

27.6

34.1

40.4

29.6

36.5

43.2

51.7

61.3

75.2

53.3

63.3

77.7

54.2

64.4

74.3

93.3

111

137

119

147

174

Wz

cm3

7.53

8.54

10.5

11.4

14.0

16.5

13.2

16.2

19.1

11.6

14.3

16.9

14.5

17.1

21.0

21.0

24.8

30.4

25.9

30.7

35.3

26.3

31.3

38.4

70.5

86.9

103

iz

cm

1.83

1.83

1.81

2.18

2.16

2.14

2.28

2.26

2.24

2.09

2.07

2.05

1.99

1.97

1.94

2.51

2.49

2.46

2.87

2.85

2.82

2.68

2.67

2.64

4.44

4.40

4.37

Cornires ailes ingalesconformes BS EN 10056 1: 1999

Ungleichschenkliger winkelstahl gem BS EN 10056 1: 1999

Unequal anglesaccording to BS EN 10056 1: 1999

Bezeichnungen Seite 2Notation page 2 Explanation page 2

vz

y s

u

y

u

v

z s

Non Standard Section Size. Please refer to account manager for availability of rollings.

13502 Corus Euro Inners 21/3/06 6:04 pm Page 17

-

Structural sections in accordance with European specifications

18 Corus Construction & Industrial

Tolerances de laminage BS EN 10034:1993Cette norme europenne prcise les tolrances sur la

forme, les cotes et la masse des profils en I

normaliss et des profils pour poteaux en acier de

construction. Ces tolrances ne sappliquent pas aux

profils semelle effile.

Hauteur du profil (h)

Lcart par rapport la hauteur nominale du profil,

mesure sur la ligne mdiane de lepaisseur de lme,

doit tre compris dans les tolrances donnes dans le

tableau 1 (a).

Tableau 1 (a). Tolrances sur la hauteur et la section

transversale.

Largeur de la semelle (b)

Lcart par rapport la largeur nominale de la semelle

doit tre compris dans les tolrances donnes dans le

tableau 1 (b).

Tableau 1 (b). Tolrances sur la largeur de la

semelle.

Epaisseur de lme (s)

Lcart par rapport lpaisseur nominale de lme,

mesure au point mdian de la dimension (h), doit tre

compris dans les tolrances donnes dans le tableau 1

(c).

Tableau 1 (c). Tolrances sur lpaisseur de lme.

Epaisseur de la semelle (t)

Lcart par rapport lpaisseur nominale de la semelle,

mesure au point situ un quart de la largeur de la

semelle, doit tre compris dans les tolrances donnes

dans le tableau 1 (d).

Tableau 1 (d). Tolrances sur lpaisseur de la

semelle.

18 Corus Construction & Industrial

Hauteur du profil h

mm

Jusqua 180 compris

Plus de 180 et jusqu 400compris

Plus de 400 et jusqu 700compris

Plus de 700

Tolrance

mm

+ 3,0- 2,0

+ 4,0- 2,0

+ 5,0- 3,0

5,0

Largeur de la semelle b

mm

Jusqua 110 compris

Plus de 110 et jusqu 210compris

Plus de 210 et jusqu 325compris

Plus de 325

Tolrance

mm

+ 4,0- 1,0

+ 4,0- 2,0

4,0

+ 6,0- 6,0

Epaisseur de lme s

mm

Moins de 7

De 7 jusqu 10 non compris

De 10 jusqu 20 non compris

De 20 jusqu 40 non compris

De 40 jusqu 60 non compris

60 et plus

Tolrance

mm

0,7

1,0

1,5

2,0

2,5

3,0

Epaisseur de la semelle t

mm

Moins de 6,5

De 6,5 jusqu 10 non compris

De 10 jusqu 20 non compris

De 20 jusqu 30 non compris

De 30 jusqu 40 non compris

De 40 jusqu 60 non compris

60 et plus

Tolrance

mm

+1,5- 0,5

+ 2,0- 1,0

+ 2,5- 1,5

+ 2,5- 2,0

2,5

3,0

4,0

t*

h

b

xx

y

ys

b/4

13502 Corus Euro Inners 21/3/06 6:04 pm Page 18

-

Structural sections in accordance with European specifications

Corus Construction & Industrial 19Corus Construction & Industrial 19

Variation sur querrage (k + k)

La variation sur lquerrage du profil ne doit pas

excder le maximum donn dans le tableau 2 (a).

Tableau 2 (a). Tolrances sur querrage des profils

en I et des profils pour poteaux.

Dcentrage de lme (e)

Lpaisseur au centre de lme ne doit pas scarter de

la position de la largeur mdiane de la semelle de plus

de la distance (e) donne dans le tableau 2(b).

Tableau 2 (b). Tolrances de dcentrage de lme

des profis en I et des profils pour poteaux.

Variation sur rectitude (qxx ou qyy)

Le cambrage doit tre conforme aux valeurs donnes

dans le tableau 3.

Tableau 3. Tolrances de cambrage des profils en I

et des profils pour poteaux.

Tolrance sur la masse

Lcart par rapport la masse nominale dun lot ou

dune pice individuelle ne doit pas excder 4%.

Lcart de masse est la diffrence entre la masse relle

du lot ou de la pice et la masse calcule. La masse

calcule devra tre dtermine en utilisant la densit de

7850 kg/m3.

Tolrance sur la longueur

Les profils doivent tre coups aux longueurs

commandes dans les tolrances de, soit:

a) 50 mm

soit

b) -0 + 100 mm si des longueurs minimales sont

demandes.

L reprsente la longueur utilisable du profil la plus

longue en supposant que les extrmits du profil ont

t coupes dquerre.

Largeur de la semelle b

mm

Jusqua 110 compris

Plus de 110

Hors dquerre des semelles k + k

mm

1,5

2% de b(maximum 6,5mm)

Hauteur de la section h

mm

Plus de 80 et jusqu 180compris

Plus de 180 et jusqu 360compris

Plus de 360

Tolrance qxx et qyysur longueur L

mm

0,30 L

0,15 L

0,1 L

b

h

k1

k

b

h

k1

k

qxx

qyy

b

b2b1

L

L max.

Largeur de la semelle b

mm

Jusqu 110mm inclus

Plus de 110 et jusqu 325compris

Plus de 325

Plus de 110 et jusqu 325compris

Plus de 325

Dcentrage de lme o e = b1-b2

2mm

2,5

3,5

5,0

5,0

8,0

t < 40

t 40

13502 Corus Euro Inners 21/3/06 6:04 pm Page 19

-

Structural sections in accordance with European specifications

20 Corus Construction & Industrial20 Corus Construction & Industrial

Tolrances de laminage BS EN 10056-2:1993Cette norme europenne prcise les tolrances sur la

forme, les cotes et la masse des cornires ailes gales

ou ingales en acier de construction lamin chaud.

Tolrances sur les formes et les dimnsions

longueur daile (a ou b)

Lcart par rapport la longueur nominale de laile doit

tre compris dans les tolrances donnes dans le

tableau 1(a). Dans le cas des cornires ailes ingales,

la longueur de laile la plus longue (a) doit tre utilise

pour dterminer la plage des tolrances.

Tableau 1 (a). Tolrances dimensionnelles.

Epaisseur du profil (t)

Lcart par rapport lpaisseur nominale doit tre

compris dans les tolrances donnes dans le tableau

1(b).

Tableau 1 (b). Tolrances dpaisseur.

Variation sur querrage (k)

La variation sur querrage du profil

ne doit pas excder le maximum

donn dans le tableau 1 (c). Dans le

cas des cornires ailes ingales, la

longueur de laile la plus longue (a) doit tre utilise

pour dterminer la plage des tolrances.

Tableau 1 (c). Tolrances sur querrage

Variation sur rectitude (q)

Le cambrage ne doit pas excder les

tolrances donnes dans le tableau 1

(d). Dans le cas des cornires ailes

ingales, la longueur de laile la plus longue (a) doit tre

utilise pour dterminer la plage des tolrances.

Tableau 1 (d). Tolrances sur cambrage

Tolrance sur la masse

Lcart par rapport la masse nominale dune pice

individuelle ne doit pas excder:

a) 6% de lpaisseur pour t 4 mm, oub) 4% de lpaisseur pour t > 4 mm.

Lcart par rapport la masse nominale est la

diffrence entre la masse relle de la pice et la masse

calcule. La masse calcule doit tre dtermine en

utilisant la densit de 7850 kg/m3.

Tolrance sur la longueur

La tolrance sur la longueur commande doit tre, soit:

a) 50 mm

soit

b) 0 +100 mm si des longueurs minimales sont

demandes.

xx

y

y

t

t

a

b

q

L

Longueur de laile a

mm

Jusqu 50 compris

Plus de 50 et jusqu 100 compris

Plus de 100 et jusqu 150 compris

Plus de 150 et jusqu 200 compris

Plus de 200

Tolerancemm

1,0

2,0

3,0

4.0

+ 6,0-4,0

Epaisseur du profil t

mm

Jusqu 5 compris

Plus de 5 et jusqu 10 compris

Plus de 10 et jusqu 15 compris

Plus de 15

Tolerancemm

0,50

0,75

1,00

1.20

DeviationkkDeviation

Hors dquerre longueur daile

mm

Jusqu 100 compris

Plus de 100 et jusqu 150 compris

Plus de 150 et jusqu 200 compris

Plus de 200

Tolrancemm

1,0

1,5

2,0

3.0

Longueur dailea

mm

Jusqu 150compris

Jusqu 200compris

Plus de 200

Sur longueurtotale

Ecartq

mm

0,4% L

0,2% L

0,2% L

Longueurconsidre

mm

1,500

2,000

3,000

Ecartq

mm

6,0

3,0

3,0

Tolrance

Sur une partie

13502 Corus Euro Inners 21/3/06 6:04 pm Page 20

-