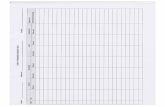

Staff Training & Licencing Register · SSSP - STAFF TRAINING & LICENSING REGISTER CONTACT EMAIL...

Transcript of Staff Training & Licencing Register · SSSP - STAFF TRAINING & LICENSING REGISTER CONTACT EMAIL...

Ben SkertenChris HeyesJackson SearleBen WarneBrad SmithCemil JeyhanClayton TamainuDavid O'KaneElijah Webb PurcellGarth HarrisGeoffrey HeckHarrison WindelburnJames AndersonJames YoungJohan SteynJohn DyksmaJoshua BasnettJoshua KaminerLuke JudgeMaarten van der ZandeMatthew WilsonMitu Pu-TamainuOliver AndrewReece RickardSean O'ReillyStefan HemaraTalbot KupaWerner Doman

NAME

Staff Training & Licencing Register

SSSP - STAFF TRAINING & LICENSING REGISTER

CONTACT EMAIL SITE SAFE PGDB NUMBER W/ HEIGHTS CONFINED [email protected]@[email protected]@[email protected]@[email protected]@[email protected]@[email protected]@[email protected]@[email protected]@[email protected]@[email protected]@[email protected]@[email protected][email protected]@[email protected]@[email protected]

0215449640212480535021 204 4556021654491027 23872600215446220212480169021455210021 556 8710216654950210246432502107767970210449531021 544 772021142999402154453002121049710212108814021544068021 544 07602102563778021 544 19402165457902108408716021088948200211809759021466402021443539

26709[Expires: 2018-03-31]28084[Expires: 2018-03-31]28653[Expires: 2018-03-31]18457[Expires: 2018-03-31]29875[Expires: 2018-03-31]28804[Expires: 2018-03-31]

3038830023[Expires: 2018-03-31]28449[Expires: 2018-03-31]31321[Expires: 2018-03-31]

24603[Expires: 2018-03-31]17464[Expires: 2018-03-31]29370[Expires: 2018-03-31]23590[Expires: 2018-03-31]30496[Expires: 2018-03-31]

20021[Expires: 2018-03-31]24412[Expires: 2018-03-31]30080[Expires: 2018-03-31]21217[Expires: 2018-03-31]29660[Expires: 2018-03-31]

2804630074[Expires: 2018-03-31]29221[Expires: 2018-03-31]29982[Expires: 2018-03-31]

475928[Expires: 2018-04-08]485617[Expires: 2018-07-04]479891[Expires: 2018-10-17]

490751682620[Expires: 2018-12-08]

530942[Expires: 2017-10-02]

514425[Expires: 2017-04-17]

636565[Expires: 2018-05-24]448102[Expires: 2018-12-12]682617[Expires: 2018-01-10]

311579[Expires: 2018-12-07]

710975[Expires: 2019-06-19]312394[Expires: 2018-12-12]377272[Expires: 2017-04-10]483024[Expires: 2018-08-10]259387682628[Expires: 2018-12-07]456197[Expires: 2018-12-08]

650743[Expires: 2018-08-10]498288[Expires: 2018-12-08]682625[Expires: 2018-12-08]

171114/09[Expires: 2016-11-17]18426

587224[Expires: 2017-07-09]

3093[Expires: 2018-02-08]23229

6166[Expires: 2019-02-22]

6259

Tool, Plant & Equipment

Staff Competency Register pt 1

SSSP - STAFF COMPETENCY REGISTER PT 1

Ben Skerten

Chris Heyes

Jackson Searle

Ben Warne

Brad Smith

Cemil Jeyhan

Clayton Tamainu

David O'Kane

Elijah Webb Purcell

Garth Harris

Geoffrey Heck

Harrison Windelburn

Jacob Kelly

James Anderson

James Young

Johan Steyn

John Dyksma

John Rigby

Joshua Basnett

Joshua Kaminer

Luke Judge

Maarten van der Zande

Matthew

Wilson

Mitu Pu-Tam

ainu

Oliver Andrew

Reece Rickard

Sean O'Reilly

Stefan Hemara

Talbot Kupa

Werner Dom

an

Digger

Step ladder

10mm Thread Cutters

32-100mm Copper Expander

9' Grinder

Concrete Saw

Axe

Battery Compressor

Bench Crox Tool

Chain Saw

Concrete Mixer

Copper Tee Puller

Core Drill

Concrete Breaker

Drain Acid

Drop Saw

Tool, Plant & Equipment

Staff Competency Register pt 2 - 2017

SSSP - STAFF COMPETENCY REGISTER PT 2

Ben Skerten

Chris Heyes

Jackson Searle

Ben Warne

Brad Smith

Cemil Jeyhan

Clayton Tamainu

David O'Kane

Elijah Webb Purcell

Garth Harris

Geoffrey Heck

Harrison Windelburn

Jacob Kelly

James Anderson

James Young

Johan Steyn

John Dyksma

John Rigby

Joshua Basnett

Joshua Kaminer

Luke Judge

Maarten van der Zande

Matthew

Wilson

Mitu Pu-Tam

ainu

Oliver Andrew

Reece Rickard

Sean O'Reilly

Stefan Hemara

Talbot Kupa

Werner Dom

an

Saber Saw

Drainage Rods

EF Welder – Large

Expander/Drift

Fusio Tool

Galv Threader

Gas Crimp Tool

Gas Kembla Tool

Gas Set

Hand Held Concrete Hilti Drill

Hilti 166 Gauge Nibbler

Hilti Concrete Gun

Hilti Wet Vac

Hitachi Breaker

Hole Saw Kit Wood

Kembla Chain Slide Tool

Tool, Plant & Equipment

Staff Competency Register pt 3 - 2017

SSSP - STAFF COMPETENCY REGISTER PT 3

Ben Skerten

Chris Heyes

Jackson Searle

Ben Warne

Brad Smith

Cemil Jeyhan

Clayton Tamainu

David O'Kane

Elijah Webb Purcell

Garth Harris

Geoffrey Heck

Harrison Windelburn

Jacob Kelly

James Anderson

James Young

Johan Steyn

John Dyksma

John Rigby

Joshua Basnett

Joshua Kaminer

Luke Judge

Maarten van der Zande

Matthew

Wilson

Mitu Pu-Tam

ainu

Oliver Andrew

Reece Rickard

Sean O'Reilly

Stefan Hemara

Talbot Kupa

Werner Dom

an

Kembla Lever Sliding Sleeve Tool

Magnum Welder

Makita 750W Hand Drill

Makita 9' Grinder

Makita Angle Drill

Makita High Speed Drill

Makita Skill Saw

Mounted Hilti Core Drill

Multi Tool Renovator

Pickaxe

Plate Compactor

Power Air Compressor

Scaffold

Shovel

Sledge Hammer

Steel Bar

Tool, Plant & Equipment

Staff Competency Register pt 4 - 2017

SSSP - STAFF COMPETENCY REGISTER PT 4

Ben Skerten

Chris Heyes

Jackson Searle

Ben Warne

Brad Smith

Cemil Jeyhan

Clayton Tamainu

David O'Kane

Elijah Webb Purcell

Garth Harris

Geoffrey Heck

Harrison Windelburn

Jacob Kelly

James Anderson

James Young

Johan Steyn

John Dyksma

John Rigby

Joshua Basnett

Joshua Kaminer

Luke Judge

Maarten van der Zande

Matthew

Wilson

Mitu Pu-Tam

ainu

Oliver Andrew

Reece Rickard

Sean O'Reilly

Stefan Hemara

Talbot Kupa

Werner Dom

an

Steel Stud Punch

Submersible Pump

Tarpaulin

Tube Cutter

Whacker

Water Blaster

EMPLOYER: MCB PLUMBING LTD

SSSP - STIE INSPECTIO

N CH

ECKLIST

Person(s) involved:

Site inspection checklist

1. Site control

Hazard board and signage up-to-date

Environmental plan – issues

Toolbox talk last date / /

Safety inductions for all on site

Safety notice board current

6. Cranes/hoist/lifting equipment

Proper lift assessment plan done

Crane certification current

Slings/chains certified

Operator procedures in place

Inspections being done

Man cage available

Emergency plan in place

11. Chemicals

Correctly stored

Safety Data Sheet (SDS) available

Operators using PPE

12. Tools

PAT tool WoF current and secure

Staff trained in tool use (SWPS)

PAT signage on site

13. Scaffolding

Notifiable weekly Scaftag/current

Handrails/mid-rails

Toe boards

Platforms

Ladders/stairs

Base sound

Work platforms clear

Platforms trip free

Planks tied down

Headroom clear

Ties/bracing adequate

7. Compressed air equipment

In good condition

Appropriate guards fitted

Trained user

9. Welding/gas cutting

Hot work permits being issued

Fire extinguishers on hand

Operators using PPE

10. Electrical equipment

Main board lockable/weatherproof

Current tagged and damage-free leads

Current tagged plant

Current tagged lifeguards

Leads safely placed

Equipment in good condition

Appropriate guards on equipment

Adequate temporary lighting

8. Excavations

Correctly shored

2. Site facilities

Offices clean, adequate & good lighting

Smoko sheds – clean, potable water

Toilets – clean, washing water

Tool/equipment sheds adequate

3. General site tidiness and accessways

Clear, safe access to work areas

Stairways and accessways clear

Hoardings/fence and gates secure

Loose materials secure from wind

4. Personal safety equipment

Signage displayed and legible

Hardhats being worn

Correct footwear being worn

Glasses/ear muffs/vests/masks used 14. Ladders

Good condition

Secured top and bottom

Stays to step ladders

Working 2 steps down

5. First aid/fire prevention

First aid box Available

Accident register

Fire extinguishers Available

Current (12 mth)

Sufficient number

Evacuation Procedure current

15. Fall hazards

Floor edges Floor openings

Lift shafts Stairs

Signature of Technicians Date

Time

SSSP - ONSITETO

OLBO

XTALKSToolbox Talk

AGENDA ITEMS

HEALTH AND SAFETY ISSUES

Issues raised Action By who and when

ATTENDEES

Date

Time

Signature of Management

Site activities /safe work practices/incident reports and investigations discussed

Issues outstanding from previous briefings Action By who and when

Positive safe-action observations Action By who and when

Name Signature Name Signature

Incidents or injuries Action By who and when

Job plans reviewed Action By who and when

Principal Contractor/Company

SITE NAME

TECHNICANS DETAILSFull name

Phone Number Position

Date

SSSP - RISK ASSESSMEN

T MATRIX / H

IERARCHY O

F CON

TROLS

Cons

ider

the

seve

rity

of in

jury

/illn

ess

Consider the likelihood of a hazardous event occurring

Very unlikely to happen

Unlikely to happen

Possibly could happen

Likely to happen

Very likely to happen

Catastrophic (e.g fatal)

Moderate Moderate High Critical Critical

Major (e.g Permanent Disability) Low Moderate Moderate High Critical

Moderate (e.g Hospitalisation/Short or

Long Term Disability)Low Moderate Moderate Moderate High

Minor (e.g First Aid)

Very Low Low Moderate Moderate Moderate

Superficial (e.g No Treatment Required) Very Low Very Low Low Low Moderate

Risk Assessment Matrix

Hierarchy of controlsMost

Effective

Least Effective

ELIMINATE:1 Eliminate the hazard - remove it completely from your workplace. If this isn’t reasonably practicable, then...

MINIMISE:2 Substitute the hazard - with a safer alternative. If this isn’t reasonably practicable, then...

3 Isolate the hazard - as much as possible away from the workers. If this isn’t reasonably practicable, then...

4 Use engineering controls - adapt tools or equipment to reduce the risk. If this isn’t reasonably practicable, then...

5 Use administrative controls - change work practices and organisation. If this isn’t reasonably practicable, then...

6 Use personal protective equipment (PPE) - this is the last option after you have considered all the other options for your workplace.

Job Name: Job Number: Date: Page:

Location:

Staff Member: TA No./Rev.

PPE Required:- Hard Hat Hi – viz Safety Boots Ear Muffs Safety Glasses Other ………………………………………...

Equipment For This Job:

SEQUENCE OF BASIC TASK POTENTIAL SIGNIFICANT HAZARDS

RISK

HAZARD CONTROL METHOD

Consequence :H = High, M=Medium, L=Low

Likelihood : P=Possible, U=Unlikely, R=Rarely

Control: M=Minimise, E=Eliminate , I=Isolate

Training/Certification Site Safe Commercial Passport Site Safe Working at Height PCA Crane Operator Certificate PCA Rigger /Dogman Certificate Site induction Company Induction

PPE Requirement Safety Boots Hard Hat /Gloves HiViz Vest Retractable Harnesses Static Line (8mm steel) Safety Glasses Hearing Protection

SIGN OFF OF SAFE WORK METHOD PROCEDURE:NAME:__________________________________DATE:________________

Acknowledgement: I have read and understand this Task Analysis and will comply with its requirements

NAME:

NAME:

NAME:

NAME:

NAME:

NAME:

_________________________________________________________DATE:________________SIGN:_________________

_________________________________________________________DATE:________________SIGN:_________________

_________________________________________________________DATE:________________SIGN:_________________

_________________________________________________________DATE:________________SIGN:_________________

_________________________________________________________DATE:________________SIGN:_________________

_________________________________________________________DATE:________________SIGN:_________________

Task Analysis Form

SIGN OFF OF SAFE WORK METHOD PROCEDURE:NAME:__________________________________DATE:________________

SITE DETAILS

CONTRO

L

LIKELYHOOD

CONSEQ

UEN

CE

PERSONNEL

TASK

SSSP - TASK ANALYSIS FORM

SSSP - SAFE WO

RK METH

OD STATEM

ENT (SW

MS)

Safe work method statement

Signed

ATTENDEES

Name Signature Name Signature

STEP 2 - SETUP POTENTIAL HAZARDS

STEP 3 - CARRY OUT WORKS POTENTIAL HAZARDS

STEP 4 - CLEAN AND EXIT POTENTIAL HAZARDS

Work Actitivity

Date

PPE required Hi Vis Gloves Safety glasses Hearing protection Long sleeves Hard hat

STEP 1 - ARRIVAL POTENTIAL HAZARDS

VERY LOW LOW MEDIUM HIGH VERY HIGH

SITE NAME

TECHNICANS DETAILSFull name

Phone Number Position

Date

IMPLEMENT CONTROLS

IMPLEMENT CONTROLS

IMPLEMENT CONTROLS

IMPLEMENT CONTROLS

VERY LOW LOW MEDIUM HIGH VERY HIGH

VERY LOW LOW MEDIUM HIGH VERY HIGH

VERY LOW LOW MEDIUM HIGH VERY HIGH

VERY LOW LOW MEDIUM HIGH VERY HIGH

VERY LOW LOW MEDIUM HIGH VERY HIGH

VERY LOW LOW MEDIUM HIGH VERY HIGH

VERY LOW LOW MEDIUM HIGH VERY HIGH

SSSP - SAFE WO

RK METH

OD STATEM

ENT (SW

MS)

Safe work method statement Pt 2

Signed

STEP 6 POTENTIAL HAZARDS

STEP 7 POTENTIAL HAZARDS

STEP 8 POTENTIAL HAZARDS

Date

STEP 5 POTENTIAL HAZARDS

VERY LOW LOW MEDIUM HIGH VERY HIGH

IMPLEMENT CONTROLS

IMPLEMENT CONTROLS

IMPLEMENT CONTROLS

IMPLEMENT CONTROLS

VERY LOW LOW MEDIUM HIGH VERY HIGH

VERY LOW LOW MEDIUM HIGH VERY HIGH

VERY LOW LOW MEDIUM HIGH VERY HIGH

VERY LOW LOW MEDIUM HIGH VERY HIGH

VERY LOW LOW MEDIUM HIGH VERY HIGH

VERY LOW LOW MEDIUM HIGH VERY HIGH

VERY LOW LOW MEDIUM HIGH VERY HIGH

STEP 9 POTENTIAL HAZARDS

IMPLEMENT CONTROLSVERY LOW LOW MEDIUM HIGH VERY HIGH

VERY LOW LOW MEDIUM HIGH VERY HIGH

IDENTIFIED HAZARD OR HARMS INITIAL RISK ASSESSMENT

CONTROLS PUT IN PLACE

Site/job hazard and risk register

LEVEL OF CONTROL

RESIDUAL RISK ASSESSMENT

INCLUDE IN TOOLBOX?

Yes No

Yes No

Yes No

Yes No

Yes No

Yes No

Yes No

Yes No

Yes No

Yes No

Yes No

Yes No

Yes No

Yes No

Yes No

Yes No

Yes No

Yes No

SSSP - SITE/JOB HAZARD AND RISK REGISTER

EMPLOYER: MCB PLUMBING LTD

SSSP - NEAR M

ISS /ACCIDENT / IN

CIDENT REPO

RT AND IN

VESTIGATION

Person(s) involved:

Near Miss/ Incident/ Accident Report & Investigation Form Pt 1

Fatal Serious Harm Minor Harm No Harm / Near Miss

Nil First Aid H&CC Doctor Hospital

What treatment was given ?

By Whom

Contributory Factors (refer to these when identifying the cause of the near miss/ incident/ accident) Immediate Causes Substandard Acts

- Guarding- Defective tools or Equipment- Hazardous arrangements Unsafe conditions- Unsafe design Housekeeping- Unsafe environmental conditions- Unsafe positioning

- Operating without authority- Disabling safety devices- Using unsafe equipment- Non use of Personal Protective Equipment- Non use of lock out/ isolation systems- Distraction / fooling about

Contact No:

DESCRIPTION OF WHAT HAPPENED

DESCRIBE THE CAUSE OF THE NEAR MISS / INCIDENT / ACCIDENT

TREATMENT

SEVERITY

DETAILS OF NEAR MISS / INCIDENT / ACCIDENT

Location

Date Time am/pm

Employee Contractor Other (Specifty)Independent Contractor

Position

SSSP - - NEAR M

ISS /ACCIDENT / IN

CIDENT REPO

RT AND IN

VESTIGATION

IDENTIFIED AND CHANCEHas the significant hazard been identified?

Near Miss/ Incident/ Accident Report & Investigation Form Pt 2

If yes, please investigate this hazard and update the Hazard Register in your department or section accordingly

MANAGERS COMMENTS

HEALTH AND SAFETY CO-ORDINATOR'S COMMENTS

CHANCE OF NEAR MISS, INCIDENT OR ACCIDENT RECURRING

CORRECTIVE ACTIONWhat will be done or steps taken to minimise the risk of this happening again

Action By Whom Completed

One off Daily Weekly Monthly

Person in control of the workplace Name

PositionSigned

Name Position

Signed

Is post critical event testing required?DateIf Yes, advise Occupational Health Nurse

DateSigned

INCIDENT RECORDED ON ACCIDENT REGISTER & CORRECTIVE ACTIONS COMPLETED?

EMPLOYER: MCB PLUMBING LTD

SAFETY: ACCIDENT & IN

CIDENT IN

VESTIGATION

REPORT

NAME OF INVESTIGATOR:

PARTICULARS OF INCIDENT Day of Incident (circle)

M T W T F S S

Time Project/Site Date Reported

INJURED PERSON

Name: Address:

Age: Phone number:

Reported date of incident: Length of employment: Time on job:

TYPE OF INJURY: Bruising Dislocation Other(specify)

Remarks:

Strain/sprain Scratch/abrasion Internal

Fracture Amputation Foreign body Injured part of body:

Laceration/cut Burn scald Chemical reaction

Property/material damaged: Nature of damage:

Object/substance inflicting damage:

Description

Describe what happened (space overleaf for diagram – essential for all vehicle incidents):

What were the causes (root and contributing causes) of the incident?

Root causes – safety system failures:

Contributing causes – unsafe acts and conditions:

Prevention

What action has or will be taken to prevent a recurrence? Tick items already actioned (use space overleaf if required)

Completed X

By whom When

Type of treatment given: Name of person giving First Aid: Doctor/Hospital:

Incident investigated by: Date: WORKSAFE NZ advised: Yes / No

Date:

Accident & Incident Investigation Report

BRANCH/DEPARTMENT:

DAMAGED PROPERTY

INCIDENT

ANALYSIS

TREATMENT AND INVESTIGATION OF INCIDENT

SAFETY: NO

TICE OR RECO

RD OF ACCIDEN

T/SERIOU

S HARM

1. Particulars of employer, self-employed person or principal: (Business name, postal address and telephone number)

2. The person reporting is: an employer a principal a self-employed person

3. Location of place of work:

(Shop, shed, unit nos., floor, building, street nos. and names, locality/suburb, or details of vehicle, ship or aircraft)

4. Personal data of injured person:

Name

Residential address

Date of birth Sex (M/F)

5. Occupation or job title of injured person: (Employees and self-employed persons only)

6. The injured person is: an employee self

a contractor (self-employed person) other

7. Period of employment of injured person:(Employees only) 1st week 1st month 1-6 months

1-5 years Over 5 years 6 months-1 year Non-employee

8. Treatment of injury: None First Aid only Doctor but no hospitalisation Hospitalisation

9. Time and date of accident/serious harm:

Time am/pm

Date Shift Day Afternoon Night

Hours worked since arrival at work (Employees and self-employed persons only)

10. Mechanism of accident/serious harm: Hitting objects with part of the body Being hit by moving objects Heat, radiation or energy Chemicals or other substances

Fall, trip or slip Sound or pressure Body stressing Biological factors Mental stress

11. Agency of accident/serious harm: Machinery or (mainly) fixed plant Mobile plant or transport Powered equipment, tool or appliance Non-powered handtool, appliance or equipment Chemical or chemical product Material or substance Environmental exposure (e.g. dust, gas) Animal, human or biological agency (other than bacteria or virus) Bacteria or virus

12. Body part: Head Neck Upper limb Lower limb

Trunk Multiple locations

Fatal

Systemic internal organs

13. Nature of injury or disease: (Specify all) Fracture of spine Other fracture Dislocation Sprain or strain Head injury Internal injury of trunk Amputation, including eye Open wound Superficial injury Bruising or crushing Foreign body Burns Nerves or spinal chord

Puncture wound Poisoning or toxic effects Multiple injuries Damage to artificial aid Disease, nervous system Disease, musculoskeletal system Disease, skin Disease, digestive system Disease, infectious or parasitic Disease, respiratory system Disease, circulatory system Tumour (malignant or benign) Mental disorder

14. Where and how did the accident/serious harm happen?(If not enough room, attach separate sheet or sheets)

15. If notification is from an employer: Yes No (a) has an investigation been carried out?

(b) was a significant hazard involved? Yes No

Signature and date: ________________________ ___ / ___ / ___

Name and position: (Use capitals)

Notice or Record of Accident/Serious Harm

DeathSerious head injury Serious burnSpinal injury Serious lacerations

If applicable to any of these listed it is required to be lodged as a Notifiable serious injury to www.worksafe.co.nz

Injury or illness that requires (or would usually require) medical treatment within 48 hours of exposure to a substance

Amputation of any body partSeparation of skin from underlying tissue (scalping or degloving) Injury or illness that requires (or would usually require) immediate hospital admittance Serious infection (incl occupational zoonosis)

Loss of bodily functions Serious eye injury

DATE

Accident / Incident Register

STAFF ACCIDENT / INCIDENT REGISTER

TIME DETAILS (NAME OF INJURED/DESCRIPTION OF EVENT ACTION TAKEN (FIRST AID, REVIEW, CHANGES)

S/HARM INVESTIGATIONOUTCOMES DISCUSSED AT MEETING & DATE

CARRIED OUT BY WHO AND DATE COMPLETED

Glue Substance Breathing in Vapours & Fumes, skin contact

Wear appropriate safety gear, ventilation mask, goggles, gloves & protective clothing. Use in a ventilated area.

Primer Substance Breathing in Vapours & Fumes, skin contact,

Wear appropriate safety gear, ventilation mask, goggles, gloves &

protective clothing. Use in a ventilated area.

POTENTIAL HARM IDENTIFIED HAZARD SIGNIFICANT HAZARD CONTROLS REGULAR CHECK OF HAZARD CONTROLS IN PLACE DATE CHECKED DATE CHECKED DATE CHECKED

Hazardous Substance/Dangerous Register

SSSP - HAZARDOUS SUBSTANCE / DANGEROUS REGISTER

SAFETY DATA SHEET

Marley Joint Primer

Issued: 06/01/2016 Version: 6 Page 1 of 7

1 IDENTIFICATION OF THE PRODUCT AND OF THE SUPPLIER

Product Name Marley Joint Primer Hazard Statement Classified as Hazardous according to HSNO in New Zealand.

Classified as a Dangerous Good according to NZS5433:1999 Transport of Dangerous Goods on Land.

Recommended Use Solvent cleaner – customer branded

Supplier Bostik New Zealand Limited Street Address 19 Eastern Hutt Road, Wingate, Lower Hutt, New Zealand Telephone ++64 4 567 5119

Facsimile ++64 4 567 5412

Website www.bostik.co.nz

Emergency Telephone Number National Poisons Centre 0800 POISON or 0800 764 766

Emergency Response In New Zealand 0800 CHEMCALL or 0800 243 622 In Australia 1800 033 111 Globally ++64 3 353 0199

2 HAZARDS IDENTIFICATION

Note: This product contains both volatile (solvents) and non-volatile components. During the normal use of this product, the hazardous volatile components evaporate and dissipate. The remaining non-volatile component is not hazardous.

Hazard Statement DANGER Highly flammable liquid and vapour. Precautions Keep away from ignition sources such as heat, sparks and open flames.

Do not handle until safety precautions have been read and understood.

HSNO Classifications 3.1B Highly flammable liquid and vapour

6.3B Causes mild skin irritation

6.4A Causes serious eye irritation

6.9B (I) May cause damage to organs through repeated exposure

SAFETY DATA SHEET

Marley Joint Primer

Issued: 06/01/2016 Version: 6 Page 2 of 7

3 COMPOSITION / INFORMATION ON INGREDIENTS

Chemical Name CAS Proportion

Methyl ethyl ketone 78-93-3 Medium Acetone 67-67-1 Medium Non-hazardous materials - To 100%

High = >60% Medium = 10% - 60% Low = 1% - 10% Very Low = < 1%

4 FIRST AID MEASURES

If poisoning occurs, contact the National Poison Centre (New Zealand 0800 POISON or 0800 764 766).

First Aid Inhalation Remove person to fresh air. Remove contaminated clothing and loosen

remaining clothing. Allow person to assume most comfortable position and keep warm. Keep at rest until fully recovered. Get medical advice if breathing becomes difficult.

Skin Contact Remove contaminated clothing and wash skin with warm soapy water. Do not scrub. If swelling, redness, blistering or irritation occurs, get medical assistance.

Eye Contact Immediately hold open and flood with water for at least 15 minutes. Eyelids to be held open. Get medical advice.

Ingestion Rinse mouth with water. Get medical advice immediately. Do NOT give anything to drink. Do NOT induce vomiting because of risk of aspiration. Never give anything by the mouth to an unconscious patient. Watch for toxic effects.

Advice to Physician Treat symptomatically. Effects may be delayed.

5 FIRE FIGHTING MEASURES

Clear fire area of all non-emergency personnel.

Type of Hazard Flammable Liquid HAZCHEM Code 3[Y]E Fire Hazard Properties Toxic gases / vapours / fumes of carbon dioxide (CO2), carbon

monoxide (CO). Solvent vapours may form explosive mixtures with air. Vapours are heavier than air and may spread along ground to sources of ignition.

Extinguishing Media Water fog, foam, dry chemical, carbon dioxide

SAFETY DATA SHEET

Marley Joint Primer

Issued: 06/01/2016 Version: 6 Page 3 of 7

Unsuitable Extinguishing Media

Do not use a water jet.

Precautions for Firefighters

Wear full protective equipment, including self contained breathing apparatus.

Additional Advice Keep adjacent containers cool by spraying with water.

6 ACCIDENTAL RELEASE MEASURES

Small Spills Extinguish all ignition sources. Avoid sparks, flames and heat. Clean up immediately. Wear protective equipment to prevent skin and eye contamination. Avoid inhalation of vapours. Wipe up with absorbent (rag or paper towels). Collect and seal in properly labelled containers or drums for disposal or recycling.

Large Spills Extinguish all ignition sources. Avoid sparks, flames, heat and the build up of static electricity. Consider evacuation of area and/or site. Alert Emergency Services if required. Slippery when spilt. Avoid accidents and clean up immediately. Wear protective equipment to prevent skin and eye contamination. Avoid inhalation of vapours by wearing appropriate respirator. Contain spill to prevent run off into drains and waterways. Use absorbent (rags, soil, sand, or other inert material). Collect using spark-free shovels (ie. plastic) and seal in properly labelled containers or drums for disposal or recycling. See Disposal section of this SDS for further details.

7 HANDLING AND STORAGE

Handling Avoid breathing of or contact with material. Use only in well ventilated areas. Keep away from heat, sparks, open flames and any other sources of ignition. Static electricity must be avoided. Wear the appropriate personal protection equipment as specified in this SDS to prevent eye and skin contact. Wash thoroughly after handling.

Storage Store in a cool, dry, well ventilated place and out of direct sunlight. Keep away from heat, sparks, open flames and any other sources of ignition. Static electricity must be avoided. Store away from any incompatible materials as defined in Section 10 of this SDS. Keep containers closed when not in use. Check regularly for leaks. For unit sizes of 20 litres or more, store according to HSNO.

8 EXPOSURE CONTROLS / PERSONAL PROTECTION

Workplace Exposure Guidelines Substance WES-TWA WES-STEL

Methyl Ethyl Ketone 180 ppm

Acetone 500 ppm 1000 ppm

SAFETY DATA SHEET

Marley Joint Primer

Issued: 06/01/2016 Version: 6 Page 4 of 7

Engineering Controls Use in a well ventilated area only. Vapour is heavier than air. Prevent concentration in hollows or sumps. Do NOT enter confined spaces where vapour may have collected. Keep containers in a well ventilated area. Explosion proof general and local exhaust ventilation system is required.

Personal Protection Equipment

Avoid fume inhalation. Wear organic vapour respirator, especially if working in a poorly ventilated area. Selection of the correct cartridge is essential. Avoid skin contact. Avoid repeated and prolonged skin contact. Wear overalls or similar protective clothing. Wear solvent resistant gloves, and enclosed footwear. Avoid eye contact. Wear safety glasses, goggles or appropriate face shield.

9 PHYSICAL AND CHEMICAL PROPERTIES

Appearance Red liquid. Odour Ketone Flash Point oC -17Boiling Point oC 56 - 80Lower & Upper Flammability Limits % 1.5 – 9.7 Auto-ignition Temperature oC 550 Percent Volatile by weight 100 Specific Gravity 0.8 Solubility in Water High

High = >60% Medium = 10% - 60% Low = 1% - 10% Very Low = < 1%

10 STABILITY AND REACTIVITY

Stability of Substance This material is stable when stored and used as directed. Conditions to Avoid Avoid heat, sparks, flames and any other sources of ignition. Incompatible Materials Strong oxidising agents. Hazardous Decomposition Products

Thermal decomposition is highly dependant on conditions. A complex mixture of airborne solids, liquids and gases, including carbon monoxide, carbon dioxide and other organic compounds will be evolved when this material undergoes combustion or thermal or oxidative degradation.

Hazardous Reactions Will react with strong oxidising agents.

11 TOXICOLOGICAL INFORMATION

SAFETY DATA SHEET

Marley Joint Primer Issued: 06/01/2016 Version: 6 Page 5 of 7

Information given in this Safety Data Sheet is based on the data on the components and the toxicology of similar products. No adverse health effects are expected if the product is handled in accordance with this SDS and the product label. Symptoms or effects that may arise if the product is mishandled and overexposure occurs are: Acute Oral Toxicity Not toxic Acute Dermal Toxicity Not toxic Acute Inhalation Toxicity Not toxic Skin Irritation Expected to cause mild skin irritation. Eye Irritation Expected to cause serious eye irritation. Sensitisation (Respiratory & Contact)

Not expected to be a sensitiser.

Carcinogenicity Not a suspected carcinogen. Reproductive / Developmental Toxicity

Not expected to cause damage to fertility or the unborn child.

Mutagenicity Not expected to be mutagenic. Target Organ Systemic

May cause damage to organs through prolonged or repeated exposure.

12 ECOLOGICAL INFORMATION Acute Toxicity Aquatic Not harmful to aquatic life. Soil Not harmful to the soil environment. Terrestrial Vertebrate Not harmful to terrestrial vertebrates. Terrestrial Invertebrate Not harmful to terrestrial invertebrates. Persistence and degradability

The solvent in this product is readily biodegradable. The remainder of the product is expected to biodegrade slowly.

Bioaccumulation

No data available on the product itself, however the individual components do not significantly bioaccumulate.

Mobility Miscible with water. Similar density to water. 13 DISPOSAL CONSIDERATIONS Substance Disposal

Do not dispose of down drains or into local waterways. Recycle or recover whenever possible. Dispose of substance to a hazardous or special waste collection point or through a licensed contractor. Normally suitable for incineration by an approved agent.

Container Disposal

Recycle if possible, or dispose of to a hazardous or special waste collection point.

SAFETY DATA SHEET

Marley Joint Primer Issued: 06/01/2016 Version: 6 Page 6 of 7

Beware: Empty flammable liquid drums present an explosion hazard if cut by flame or welding torch. Ensure drums are thoroughly cleaned and ventilated.

Local Legislation

Disposal should be in accordance with Hazardous Substances (Disposal) Regulations 2001, and with any other applicable regional and national laws and regulations.

14 TRANSPORT INFORMATION Land Transport (NZS 5433:1999 Transport of Dangerous Goods on Land) UN Number 1133 Proper Shipping Name ADHESIVES containing flammable liquid DG Class 3 Subsidiary Risk Not applicable Packing Group II HAZCHEM Code 3[Y]E Marine Transport (IMDG) Identification Number 1133 Proper Shipping Name ADHESIVES containing flammable liquid Class / Division 3 Packing Group II Marine Pollutant No Air Transport (IATA) UN Number 1133 Proper Shipping Name ADHESIVES containing flammable liquid Class / Division 3 Packing Group II 15 REGULATORY INFORMATION

The regulatory information is not intended to be comprehensive. Other regulations may apply to this material. Environmental Risk Management Authority (ERMA) Group Standard Number: Surface Coatings and Colourants (Flammable) Group Standard 2006 HSNO Approval Number HSR002662 Hazardous Substances and New Organisms Act (HSNO): The following are trigger quantities for this substance by itself in a place.

SAFETY DATA SHEET

Marley Joint Primer

Issued: 06/01/2016 Version: 6 Page 7 of 7

Approved Handler Test Certificate 250 litres, when in containers > 5 litres 500 litres, when in containers ≤ 5 litres

Tracking Not applicable

16 OTHER INFORMATION

SDS Revisions Safety Data Sheets are updated at least every 5 years. Obtain the latest version by visiting www.bostik.co.nz.

Reason for Issue Update classification based on EPA guidelines SDS Distribution The information in this document should be made available to all who may

handle this product.

This SDS summarises at the date of issue our best knowledge of the health and safety hazard information of this product, and in particular how to safely handle and use the product in the workplace. Since Bostik New Zealand Limited cannot anticipate or control the conditions under which the product may be used, each user must, prior to usage, review this SDS in the context of how the user intends to handle and use the product in the workplace.

If clarification or further information is needed to ensure that an appropriate assessment can be made, the user should contact Bostik New Zealand Limited.

Our responsibility for product as sold is subject to our standard terms and conditions, a copy of which is sent to our customers and is available upon request.

Key / Legend SDS Safety Data Sheet

HSNO Hazardous Substances and New Organisms Act 1996

WES-TWA The time-weighted average exposure standard designed to protect the worker from the effects of long-term exposure.

WES-STEL The 15 minute average exposure standard. This applies to any 15 minute period in a working day and is designed to protect the worker against adverse effects of irritation, chronic or irreversible tissue change, or narcosis that may increase the likelihood of accidents. The WES-STEL is not an alternative to WES-TWA; both the short-term and time-weighted average exposures apply.

Disclaimer This information is based on our current knowledge and is intended to describe the product for the purposes of health, safety and environmental requirements only. It should not therefore be construed as guaranteeing any specific property of the product.

SAFETY DATA SHEET

Page 1 of 5 Date of Issue: 18/02/2015

PVC Pipe, Conduit, Moulded Fittings

Section 1: Identification of Product and Supplier

Product Name Trade Names: Optim, Stormline, Stratus, Genex, Classic, Stormcloud, FL2, Typhoon, Ovation, Magnum, RP65, RP80, Agriduct. Other names and variants: PVC pipe, conduit and moulded fittings, unplasticised PVC, unmodified PVC (UPVC, uPVC, PVC‐U) modified PVC (MPVC, mPVC, PVC‐M).

Product Use Pipes and fittings for water supply, irrigation, sewerage, drainage, industrial process piping Telecommunications and electrical conduit

Supplier Marley New Zealand Ltd 32 Mahia Road Manurewa 2243 New Zealand Telephone Number, +64 9 279 2799 Facsimile Number, +64 9 279 2798

Further Information Available From: Technical Manager, +64 9 279 2799

Emergency: Technical Manager, +64 9 279 2799

Section 2: Hazards Identification

Statement of Hazardous Nature NON‐HAZARDOUS PRODUCT NON‐DANGEROUS GOODS According to NOHSC criteria and ADG Code

Poisons Schedule Not listed.

Hazard Statements None required.

Precautionary Statements None required.

Other Hazards Refer to Section 7 Handling and Storage for general precautions for use.

SAFETY DATA SHEET

Page 2 of 5

Section 3: Composition/Information on Ingredients

Composition and Form Manufactured rigid solid tubes of various dimensions for plumbing and water distribution as described in Section 1.

Chemical Composition CAS Number Chemical Name/s Proportion 9002‐86‐2 Poly(vinyl chloride) polymer 70 – 80% 471‐34‐1 calcium carbonate filler 3 – 16%

Modifiers (chlorinated PE, & 0 ‐ 5% Acrylics) Stabiliser & lubricants 1.6 – 6%

13463‐67‐7 titanium dioxide 1.2 – 4%

Section 4: First‐Aid Measures

Swallowed There are no known health effects for the ingestion of PVC. Ingestion is unlikely to occur due to the physical size and dimensions of the products. However, small particles may be generated by sawing or mechanically breaking the products or similar means.

Eye Inapplicable to the solid product except for mechanical injury. Dust/small particles from sawing or other mechanical process may affect eyes if not protected. Hydrochloric acid and other fumes emitted during combustion can cause irritation to the eyes. Flush with copious quantities of water and treat symptomatically.

Skin Inapplicable to the solid product except for mechanical injury. Dust/small particles from sawing or other mechanical process may affect eyes if not protected. There have not been reports of Irritation arising from such dust and small particles. Hydrochloric acid and other fumes emitted during combustion can cause irritation to the skin. Flush with copious quantities of water and treat symptomatically.

Inhaled Inapplicable to the solid product due to the physical size and dimensions of the products. For inhalation of fumes and gaseous by‐products (hydrochloric acid, carbon monoxide etc), remove the patient immediately from exposure and seek medical advice.

Notes to Physician Treat symptomatically.

Section 5: Fire‐fighting Measures

Extinguishing Media Water, water‐fog or foam to extinguish fire. Carbon dioxide or dry chemical are suitable but are considered not as efficient due to lack of cooling capacity.

Fire Fighting Wear fully protective body suit with self‐contained breathing apparatus (S.C.B.A.) to prevent contact with fumes and gases produced during combustion.

Fire/Explosion Hazard

SAFETY DATA SHEET

Page 3 of 5

Combustible, self‐extinguishing. Not an explosion risk. If forced to burn, it will emit dense acrid fumes containing hydrochloric acid (highly acidic and severe irritant), carbon dioxide (asphyxiant), carbon monoxide (toxic) and possibly phosgene (toxic). All are potentially lethal in sustained exposure.

Fire Incompatibility Oxidising agents.

HAZCHEM Code Does not meet the criteria for classification. Personal Protection Wear fully protective body suit with self‐contained breathing apparatus (S.C.B.A.) to prevent contact with fumes and gases produced during combustion and appropriate gloves and footwear.

Section 6: Accidental Release Measures

Minor Spills Collect products and bundle or secure safely. If necessary, isolate area to prevent damage to /destruction of products by vehicles etc. Broken parts may be sharp and eye protection and gloves are recommended.

Major Spills Isolate area as necessary to prevent further damage. Collect products and bundle or secure safely. Broken product and parts may have sharp edges and eye protection and gloves are recommended.

Section 7: Handling and Storage

Procedure for Handling Check security of bundles of pipes before releasing strapping and retaining frames. Injury can be sustained by rolling of pipes. Unpack crates and bundles on a flat surface and ensure that free stacks are adequately chocked. Do not climb on stacks. Normal safe practices should be employed when working with the material; a well ventilated area and the use of eye and protection, dust masks and gloves are recommended when sawing, grinding (with abrasive wheel) and handling. When heating for bending or other forming, use hot water or air with appropriate safeguards. Use of an open flame is inadvisable.

Storage Store in appropriate areas (outside or in warehouse) in accordance with site safety requirements. Do not store with oxidising agents.

Section 8: Exposure Controls / Personal Protection

Exposure Controls No exposure controls are necessary as products are inert and all additives are encapsulated within the polymer matrix and present no hazard under conditions of normal use and good occupational work practice.

Personal Protection Eye Glasses

SAFETY DATA SHEET

Page 4 of 5

Glasses are recommended in case of accidental knock when handling pipe and especially when working pipes mechanically, sawing etc.

Hands/Feet Safety footwear and gloves.

Other

Engineering Controls Appropriate controls for safe working when handling and mechanically working e.g. sawing.

Section 9: Physical and Chemical Properties

Appearance Opaque rigid solid tubes with diameters ranging from 15 mm to 400 mm with lengths up to 12 metres. Colour of pipe varies depending upon application e.g. white, grey, blue, yellow, green, and orange. The pipe can be with or without jointing sockets and with or without ribbed or profiled exterior. Products are also various fitting to match e.g. tees, bends reducers, couplings etc.

Odour: Nil pH: Nil effect, insoluble

Melting point Softens at >750C. Initial boiling point and range Not applicable Flash point Not applicable Evaporation rate Not applicable Flammability Will burn in contact with flame Upper/lower flammability Not applicable Vapour pressure Not applicable Vapour density Not applicable Relative density 1.3 – 1.6 Solubility insoluble in water Partition coefficient: Not applicable octanol/water Auto‐ignition temperature Not applicable Decomposition temperature starts at 1400C but is time dependent Viscosity Not applicable

Section 10: Chemical Stability and Reactivity Stable under normal conditions of storage and use.

Incompatible materials Do not store with oxidising agents.

Hazardous decomposition products Product will start to decompose if maintained at temperatures of >1400C. Decomposition products are hydrochloric acid, carbon dioxide, carbon monoxides and possibly phosgene.

SAFETY DATA SHEET

Page 5 of 5

Section 11: Toxicological Information LD50 Value Not applicable The products are inert and insoluble and consist of a fused polymer matrix which also encapsulates all additives.

Section 12: Ecological Information

Ecotoxicity No adverse effects on environment have been reported. The product can be physically removed from waterways by means appropriate to the size of the article. It is recommended that local environmental agencies are notified.

Section 13: Disposal Considerations Recycle where possible. Refer to state/territory environmental protection agency/ authority. Normally suitable for disposal as general waste land fill.

Section 14: Transport Information

Land Transport (Road/Rail) Not classified as a dangerous goods.

Marine Transport Not classified as a dangerous goods.

Air Transport Not classified as a dangerous goods.

Section 15: Regulatory Information There is no safety, health or environmental regulations specific to these products.

Section 16: Other Information This information is based on our present knowledge. However, this shall not constitute a guarantee for any specific product features and shall not establish a legally valid contractual relationship.

Department Issuing MSDS: Technical Services, A u c k l a n d Contact: Stephen Tredwell First Issue

SAFETY DATA SHEET

Marley Clear SC Substance Number: 030873 Issued: 27 April 2012 Version: 4 Page 1 of 8

1 IDENTIFICATION OF THE PRODUCT AND OF THE SUPPLIER Product Name MARLEY CLEAR SC

Hazard Statement Classified as Hazardous according to HSNO in New Zealand.

Classified as a Dangerous Good according to NZS5433:1999 Transport of Dangerous Goods on Land.

Recommended Use Adhesive – customer branded

Supplier Bostik New Zealand Limited

Street Address 19 Eastern Hutt Road, Wingate, Lower Hutt, New Zealand

Telephone ++64 4 567 5119

Facsimile ++64 4 567 5412

Website www.bostik.co.nz Emergency Telephone Number National Poisons Centre

0800 POISON or 0800 764 766 Emergency Response In New Zealand 0800 CHEMCALL or 0800 243 622

In Australia 1800 127 406

Globally ++64 3 353 0199 Date of Preparation 01 February 2007 2 HAZARDS IDENTIFICATION Note: This product contains both volatile (solvents) and non-volatile components. During the normal use of this product, the hazardous volatile components evaporate and dissipate. The remaining non-volatile component is not hazardous. Hazard Statement DANGER Highly flammable liquid and vapour.

Precautions Keep away from ignition sources such as heat, sparks and open flames.

Do not handle until safety precautions have been read and understood. HSNO Classifications 3.1B Highly flammable liquid and vapour

6.1C Acute toxicity – Toxic if swallowed or if in contact with skin

6.3B Causes mild skin irritation

6.4A Causes severe eye irritation

6.7B Suspected of causing cancer

SAFETY DATA SHEET

Marley Clear SC Substance Number: 030873 Issued: 27 April 2012 Version: 4 Page 2 of 8

6.9B May cause damage to organs through prolonged or repeated exposure

9.2B Ecotoxic in the soil environment

9.3C Harmful to terrestrial vertebrates 3 COMPOSITION / INFORMATION ON INGREDIENTS Chemical Name CAS Proportion

Methyl Ethyl Ketone (2-Butanone) 78-93-3 Medium

Cyclohexanone 108-94-1 Medium

Furan, tetrahydro- 109-99-9 Medium

Non-hazardous materials - To 100%

High = >60% Medium = 10% - 60% Low = 1% - 10% Very Low = < 1% 4 FIRST AID MEASURES If poisoning occurs, contact the National Poison Centre (New Zealand 0800 POISON or 0800 764 766). First Aid Inhalation Remove person to fresh air. Remove contaminated clothing and loosen

remaining clothing. Allow person to assume most comfortable position and keep warm. Keep at rest until fully recovered. Get medical advice if breathing becomes difficult.

Skin Contact Remove contaminated clothing and wash skin with warm soapy water. Do not scrub. If swelling, redness, blistering or irritation occurs, get medical assistance.

Eye Contact Immediately hold open and flood with water for at least 15 minutes. Eyelids to be held open. Get medical advice.

Ingestion Rinse mouth with water. Get medical advice immediately. Do NOT give anything to drink. Do NOT induce vomiting because of risk of aspiration. Never give anything by the mouth to an unconscious patient. Watch for toxic effects.

Advice to Physician Treat symptomatically. Effects may be delayed.

5 FIRE FIGHTING MEASURES Clear fire area of all non-emergency personnel.

SAFETY DATA SHEET

Marley Clear SC Substance Number: 030873

Issued: 27 April 2012 Version: 4 Page 3 of 8

Type of Hazard Flammable Liquid

HAZCHEM Code 3[Y]E

Fire Hazard Properties Unknown due to the complex nature of this material. Fumes from complete or incomplete combustion of this material may include carbon dioxide, carbon monoxide, water vapour, oxides of nitrogen, hydrogen chloride or a wide variety of innocuous or toxic fumes. Solvent vapours may form explosive mixtures with air. Vapours are heavier than air and may spread along ground to sources of ignition.

Extinguishing Media Water fog, foam, dry chemical, carbon dioxide

Unsuitable Extinguishing Media

Do not use a water jet.

Precautions for Firefighters

Wear full protective equipment, including self contained breathing apparatus.

Additional Advice Keep adjacent containers cool by spraying with water.

6 ACCIDENTAL RELEASE MEASURES

Small Spills Extinguish all ignition sources. Avoid sparks, flames and heat. Avoid accidents and clean up immediately. Wear protective equipment to prevent skin and eye contamination. Avoid inhalation of vapours. Wipe up with absorbent (rag or paper towels). Collect and seal in properly labelled containers or drums for disposal or recycling.

Large Spills Extinguish all ignition sources. Avoid sparks, flames, heat and the build up of static electricity. Consider evacuation of area and/or site. Alert Emergency Services if required. Slippery when spilt. Avoid accidents and clean up immediately. Wear protective equipment to prevent skin and eye contamination. Avoid inhalation of vapours by wearing appropriate respirator. Contain spill to prevent run off into drains and waterways. Use absorbent (rags, soil, sand, or other inert material). Collect using spark-free shovels (ie. plastic) and seal in properly labelled containers or drums for disposal or recycling. See Disposal section of this SDS for further details.

7 HANDLING AND STORAGE

Handling Avoid breathing of or contact with material. Use only in well ventilated areas. Keep away from heat, sparks, open flames and any other sources of ignition. Static electricity must be avoided. Wear the appropriate personal protection equipment as specified in this SDS to prevent eye and skin contact. Wash thoroughly after handling.

SAFETY DATA SHEET

Marley Clear SC Substance Number: 030873

Issued: 27 April 2012 Version: 4 Page 4 of 8

Storage Store in a cool, dry, well ventilated place and out of direct sunlight. Keep away from heat, sparks, open flames and any other sources of ignition. Static electricity must be avoided. Store away from any incompatible materials as defined in Section 10 of this SDS. Keep containers closed when not in use. Check regularly for leaks. For unit sizes of 20 litres or more, store according to HSNO.

8 EXPOSURE CONTROLS / PERSONAL PROTECTION

Workplace Exposure Guidelines Substance WES-TWA WES-STEL

Methyl Ethyl Ketone (2-Butanone) 150 ppm 300 ppm

Cyclohexanone 25 ppm -

Furan, tetrahydro- 100 ppm -

Engineering Controls Use in a well ventilated area only. Vapour is heavier than air. Prevent concentration in hollows or sumps. Do NOT enter confined spaces where vapour may have collected. Keep containers in a well ventilated area. Explosion proof general and local exhaust ventilation system is required.

Personal Protection Equipment

Avoid fume inhalation. Wear organic vapour respirator, especially if working in a poorly ventilated area. Selection of the correct cartridge is essential. Avoid skin contact. Avoid repeated and prolonged skin contact. Wear overalls or similar protective clothing. Wear solvent resistant gloves, and enclosed footwear. Avoid eye contact. Wear safety glasses, goggles or appropriate face shield.

9 PHYSICAL AND CHEMICAL PROPERTIES

Appearance Thin transparent liquid with bluish florescence

Odour Solvent

Flash Point oC -15

Boiling Point oC 66 – 154

Lower & Upper Flammability Limits % 1.7 – 10.9

Auto-ignition Temperature oC Not determined

Percent Volatile by weight 80

Specific Gravity 1.0

Solubility in Water Medium

High = >60% Medium = 10% - 60% Low = 1% - 10% Very Low = < 1%

SAFETY DATA SHEET

Marley Clear SC Substance Number: 030873

Issued: 27 April 2012 Version: 4 Page 5 of 8

10 STABILITY AND REACTIVITY

Stability of Substance This material is stable when stored and used as directed.

Conditions to Avoid Avoid heat, sparks, flames and any other sources of ignition.

Incompatible Materials Strong oxidising agents.

Hazardous Decomposition Products

Thermal decomposition is highly dependant on conditions. A complex mixture of airborne solids, liquids and gases, including carbon monoxide, carbon dioxide, hydrogen chloride and other organic compounds will be evolved when this material undergoes combustion or thermal or oxidative degradation.

Hazardous Reactions Will react with strong oxidising agents.

11 TOXICOLOGICAL INFORMATION

Information given in this Safety Data Sheet is based on the data on the components and the toxicology of similar products.

No adverse health effects are expected if the product is handled in accordance with this SDS and the product label. Symptoms or effects that may arise if the product is mishandled and overexposure occurs are:

Acute Oral Toxicity Toxic if swallowed. LD50 >300 mg/kg bw.

Acute Dermal Toxicity Toxic in contact with skin. LD50 >1000 mg/kg bw.

Acute Inhalation Toxicity Toxic if inhaled. LC50 >10 mg/L in air.

Skin Irritation Causes mild skin irritation.

Eye Irritation Causes eye irritation.

Sensitisation (Respiratory & Contact)

Not expected to be a sensitiser.

Carcinogenicity Suspected of causing cancer.

Reproductive / Developmental Toxicity

Not expected to cause damage to fertility or the unborn child.

Mutagenicity Not expected to be mutagenic.

Target Organ Systemic May cause damage to organs through prolonged or repeated exposure.

SAFETY DATA SHEET

Marley Clear SC Substance Number: 030873

Issued: 27 April 2012 Version: 4 Page 6 of 8

12 ECOLOGICAL INFORMATION

Acute Toxicity Aquatic Not harmful to aquatic life.

Soil Ecotoxic in the soil environment.

Terrestrial Vertebrate Harmful to terrestrial vertebrates.

Terrestrial Invertebrate Not ecotoxic to terrestrial invertebrates.

Persistence & degradability The solvent in this product is readily biodegradable. The remainder of the product is expected to biodegrade slowly.

Bioaccumulation No data available on the product itself, however the individual components do not bioaccumulate.

Mobility Partially miscible with water. Similar density to water.

13 DISPOSAL CONSIDERATIONS

Substance Disposal Do not let this product enter the environment. Do not dispose of down drains or into local waterways. Recycle or recover whenever possible. Dispose of substance to a hazardous or special waste collection point or through a licensed contractor. Normally suitable for incineration by an approved agent.

Container Disposal Recycle if possible, or dispose of to a hazardous or special waste collection point. Beware: Empty flammable liquid drums present an explosion hazard if cut by flame or welding torch. Ensure drums are thoroughly cleaned and ventilated.

Local Legislation Disposal should be in accordance with Hazardous Substances (Disposal) Regulations 2001, and with any other applicable regional and national laws and regulations.

14 TRANSPORT INFORMATION

Land Transport (NZS 5433:1999 Transport of Dangerous Goods on Land) UN Number 1133

Proper Shipping Name ADHESIVES containing flammable liquid

DG Class 3

SAFETY DATA SHEET

Marley Clear SC Substance Number: 030873

Issued: 27 April 2012 Version: 4 Page 7 of 8

Subsidiary Risk Not applicable

Packing Group II

HAZCHEM Code 3[Y]E

Marine Transport (IMDG) Identification Number 1133

Proper Shipping Name ADHESIVES containing flammable liquid

Class / Division 3

Packing Group II

Marine Pollutant No

Air Transport (IATA) UN Number 1133

Proper Shipping Name ADHESIVES containing flammable liquid

Class / Division 3

Packing Group II

15 REGULATORY INFORMATION

The regulatory information is not intended to be comprehensive. Other regulations may apply to this material.

Environmental Risk Management Authority (ERMA) Group Standard Number: Surface Coatings and Colourants (Flammable, Toxic [6.1]) Group Standard 2006 HSR002667

Hazardous Substances and New Organisms Act (HSNO): The following are trigger quantities for this substance by itself in a place.

Approved Handler Test Certificate 250 litres, when in containers > 5 litres 500 litres, when in containers ≤ 5 litres

Tracking Not applicable

16 OTHER INFORMATION

SDS Revisions Safety Data Sheets are updated at least every 5 years. Obtain the latest version by visiting www.bostik.co.nz.

A vertical bar in the margin indicates an amendment from the previous version.

SAFETY DATA SHEET

Marley Clear SC Substance Number: 030873

Issued: 27 April 2012 Version: 4 Page 8 of 8

Reason for Issue 5 Year update – no changes

SDS Distribution The information in this document should be made available to all who may handle this product.

This SDS summarises at the date of issue our best knowledge of the health and safety hazard information of this product, and in particular how to safely handle and use the product in the workplace. Since Bostik New Zealand Limited cannot anticipate or control the conditions under which the product may be used, each user must, prior to usage, review this SDS in the context of how the user intends to handle and use the product in the workplace.

If clarification or further information is needed to ensure that an appropriate assessment can be made, the user should contact Bostik New Zealand Limited.

Our responsibility for product as sold is subject to our standard terms and conditions, a copy of which is sent to our customers and is available upon request.

Key / Legend SDS Safety Data Sheet

HSNO Hazardous Substances and New Organisms Act 1996

WES-TWA The time-weighted average exposure standard designed to protect the worker from the effects of long-term exposure.

WES-STEL The 15 minute average exposure standard. This applies to any 15 minute period in a working day and is designed to protect the worker against adverse effects of irritation, chronic or irreversible tissue change, or narcosis that may increase the likelihood of accidents. The WES-STEL is not an alternative to WES-TWA; both the short-term and time-weighted average exposures apply.

Disclaimer This information is based on our current knowledge and is intended to describe the product for the purposes of health, safety and environmental requirements only. It should not therefore be construed as guaranteeing any specific property of the product.

SSSP - CON

FINED SPACE EN

TRY PERMIT

Permit - Confined space entrySITE NAME

Hot Equipment/SurfacesFalls

Sewer

Exposed electrical partsWelding/Burning/Fumes

Oxygen enriched atmosphere

Portable Lighting

GFCI Protection

Forced Air Ventilator

Tripod

Other

Safety Equipment Required

Emergency Channel Radio (Mandatory)

Respirator

Fire Extinguisher Ladders

Harness

Lifeline/Lanyard

Mechanical Retrieval Device

Special Clothing (Eg. Tyvek)

Goggles

Observer/Entrant Communication Visual Radio Voice

Confined space hazard assessment

Oxygen deficient atmosphere

Carbon Monoxide (CO)Flammables/Combustibles

Corrosives

EngulfmentProtruding Objects

Impalement Hazards

Slippery surfaces

Painting or Solvent fumes

Chlorine

Stored pressure

Moving Mechanical Parts

Meter

Pre-entry & periodic atmospheric testing

Atmosphere Periodic Reading

Safe LimitsPre Entry Reading

Periodic Reading

Periodic Reading

Periodic Reading

Authorized Entrant(s)

Authorized Observer(s)

Cancelled-work completeAuthorization for entry permit

Signature Date

I have reviewed this permit and all procedures with participants and addressed ALL recognized Safety/Health Hazards.

TECHNICANS DETAILS

Full name

Time of initial entry Location

Date of inital entry

Continuous Atmospheric Monitoring

Forced Air Ventilation

Ventilate space prior to entry

Burning and Welding Permit

Worksafe Notified

Other

Confined space preporation/isolation

SOP/JSA reviewed by all entrants

Work area isolated with signs/barriers

All input/discharge lines capped/plugged TLT

Vessel contents drained/flushed/neutralized Vessel cleaned and purged

Space Sampled by:Date CalibratedBump TestedCalibrated

Sample Time

Oxygen Level (02)

Lower Explosive Limit

Carbon Monoxide (CO2)

Hydrogen Sulfide (H2S)

------------------

> 19.5 – 23.5% <

Below 10% LEL

< 25.0 ppm

< 10.0 ppm

Name CSE Licence Number Sign in Time in Sign out Time out

Standby Rescue

Observer

Authorizing Person Authorizing Person

SSSP - HO

TWO

RKS PERMIT

Hotworks PermitSITE NAME

TECHNICANS DETAILS

DETAILS OF PERMIT

Full name

Phone Number Position

Date

Requested time for works

Type of plant to be used

FIRE PREVENTION RULES

Contingencies in place

Signature of person issuing permit:

Combustible material within 10 m will be either

Fire hose on standby

Fire extinguisher(s)

Mandatory fire watcher

Protected with

Principal Contractor/Company

SPECIAL CONDITIONS

Date

The work area has been inspected by the permit issuer 30 minutes a�er completion of work. No smoldering fires werediscovered.

(Describe)

Fire equipment to be provided as follows:

Start time

End time

Butane/Map Gas Welding Torch

Other

Oxygen Acetylene Welding Plant

Location of work

Description of work

Removed from area

Non-combustible curtainsMetal guards of Flameproof covers

Or

• Barricades, warning signs and spark/flash screens must be provided to protect other personnel in the area.• The work area, trenches, pits, etc. must be clear of flammable liquids, gases or vapors. • All floor and wall openings within 10 metres of the work being conducted must be covered to prevent transmission of sparks.• The hot work area and any adjoining area must be patrolled from the start of work until 30 minutes a�er the work is completed

1. The equipment must be cleaned of all combustibles.2. Containers must be purged of all flammable vapours.

Time

WORK ON ENCLOSED EQUIPMENT (Tanks, containers, ducts, etc.)

Signature of Technician