Spg Textiles_Jan_Feb.2015.PDF

-

Upload

sunil-kumar-sharma -

Category

Documents

-

view

47 -

download

1

Transcript of Spg Textiles_Jan_Feb.2015.PDF

SPIN SOTUTION

What are the most commonQuality parameters testedthrough a modern Evennesstester? Give short descrip-tion for each parameter.

. ^ 1201 51 050-5

-10

-20

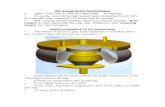

Fig.1 : Representation for Deviation Rate

Mathematical Representation for Deviation Rate

Dlagram of1-5m cut tendn

A. Following qualiry pdrametersmay obtained through a modernevenness tester:

1. U % or unevenness %.2, CVm or % Coefficient of variation of

mass.3 .

5.6.7.8.

Imperfections i.e. Thic( Thin & nepsof different diameters.% Deviation Rate.Irregularity lndex.Relative Count.Yarn Hairiness.FD/km or Foreign Fibre (Dark).

Short description;1, U 7o or unevenness 0/o: Irregularityor unevenness of mass. This indicatesthe amount of overall mass variationin % from the mean mass of the testedsample. Values are based on the 1 cm, cutlength. This shows the Overall amountof mass variation over the test Iength innumerical value.

2. CVm or 0/o Coefficient of variationofmass: This numerical value representto overall mass variation based on a curlength of one cm.

This shows the overall magnitude ofmassvariation along a material and show littlereaction to long term mass variations.

3.lmperfections i.e. Thic\ Thin &nepsof different diameters: Impedectionare considered as frequently occurringfaults and generally represented as a sumof Neps; Thick & Thin places per km. ofyarn. The "0/0" level may be selected forthick or thin places corresponds to the

6 | Spinning Textiles I jan-Feb 2015

)-rD R , , . , : u ' . l 0 0 o t o

I"ToT

cross sectional increase or decrease inyarn.

A thick or thin place is counted ifthe de-crease or increase surpasses the pre-set%o value. A thickorthin place has a lengthcorresponds ifs fibre length for example30 mm for short staple fibres [i.e, Cotton,etc.J and 60 mm for long staple fibres [i,e,Wool, polyester etc.].

Thin place considered as decrease of di-ameter from mean value as: -300/0, - 400/0,-50 %o & -60 %o while thick places consid-ered as increase in diameter from meanvalue as: +35%, + 500/s, +'70o/n & +7Q0 o/n.A yarn nep is counted if the yarn diam-eter surpasses the chosen value. The %level selection ofthe nep corresponds tothe cross-sectional increase in Frn.

A reference length of 1 mm for short sta-ple and 4 mm for long staple fibres con-sidered for counting of yarn neps. Nepscounted as increase in yarn diameter of+1400/0, + 200o/o +280 0/o & +400 o/o.

4.0/o Deviation Rate: The % deviation

Deviation rate was introduced by theJapan Spinners Inspection Foundationand generally used by fapanesecustomers or spinning mills.

deviation exceed or falls below a cenatnIimit.

The cut length factor in meters averageout the shortet higher deviations.

DR = Total relative length in % of alldeviations of the mass signal whichsurpass the limit +/- X 0/o over a total testlength in metec with the cutlength ofthecurve being y meter Value of 1.S m cutlength and +/- 5 % limit usually useo asstandard setfings. Refer Fig.1

5. lrregularity tndex The yarn ir-regularity index is the ratio of actuallymeasured CV as compared to the theo-retically achievable CV . This show howclose a yarn achul iffegularity (i.e. CV.n)w.rt theoreticalllr achievable irregular-ity (i.e. CV-). 'I'he index is a measure ofhow well particular fibres have been pro-cessed into yams.

/r\/

1,',6"* o; il'r"*h'ip = iJ:EL vt,-

100wnereLY t i n - - - -

v nrate describes by what percentage a mass n = No. offibres in yarn cross section.

SP]I lSOLUTION

lrregularity index is used to distinguishthe followingl

To compare the yarn quality of twodifferent yarn lotofsame count madefrom two different fibres.Similar yarns with different countcan directly be compared with eachother to check the suitabil ity of f ibre

Quality for a require count pattern.

6. Relative Count: The relative countgives the mass deviation in %o of thewhole test length of each test sampleas compared to the average mass of allsamples.

This value is an indication of relativecount dev ia l ion and eount ra r ia t ionsin between bobbins. The relative countmeasurement cannot provide the abso-lute count measure, it's only shows thecorrelation with respect to between-bob-bin variation. Relative count determinedwith the capacitive method. The meanvalue ofthe sample is always set as either100 % or 0 %. The cut length is variableand may be selected as 50m, 100m, 200m& 450m or as manual input,

7. Yarn Hairiness: The ratio of the totallength ofprotrudingfibres in cm for eachcm of yarn. The hairiness value is theaverage o I a l l the one cenr imeter ha i r i -ness value within a yarn test sample. Theha i r iness vJ lue is the ra t io o f two lengthshence there is no unit. Evenness testeralso provides the Standard deviation ofha i r iness as 'sh" va lue . The "sh va lue is ameasu re o f Ihe shor t te rm hd i r iness vdr i .ation between 1 cm cut length over thewhole yarn test length.

B. Foreign Matter: Some modern even-ness testers also competent to detect theforeign matters. The coloured foreign fi-bres measured through an optical sensorwhile to determine the vegetable mattera combination of the mass measurement0f the capacitive sensor and the opticalsensor ls used.

The foreign matter sensor measures allforeign matter and classifies the eventsin the foreign matter class matrix. Thenumber o f fo re ign mat te r FD inc lud ingvegetable matter and seed coats obtainedin results table as FD/Km.

I I Spinning Texti les I jan-Feb 2015

[. Unevenness or Um ozo: The

What is the basic differencebetween U o/o & CVm Vo?

Unevenness is the most common

Parameter used to express massvariation in a yarn. It is the percentagemass deviation of the unit length ofmaterial and is caused by uneven fibredistribution along the length. The U 0/o

is proportionate to the intensity of themass variations around the mean value.Refer Fig.2:

The deviation in mass per unit lengthi.e. al, a2, a3....etc. are represented asblocks above and below the mean valuedepending upon whether the deviationsare on the pos i l i ve o r negat ive s ide , I f ris the average mass per unit length, thenthe average mass ofthe fibre strand overa length of the yarn corresponding totime T is given by

The Um% may be expresses as :

a l+ a2 + . . . .a , , \100

A

Mass

Therefore Um %o may be representedby the ratio of two areas expressed as apercentage.

Mathematical RepresentationIn mathematical form U %o is expressedas follows:

f l v t l' / l " r " l

U...%:l-----:-xl00s- X T

Coefficient of variation or CVm%o:CVm % is represented to coefficient ofvariation of mass for cut length of onecentimeter

The mass variation can be consideredto conform approximately to a normaldistribution when a homogeneous fibrecomposition is available. Refer Fig.3:

A measure of the size of these massvariation is the standards deviation s,which is expressed as:

X

Frg. 2: Cf , rphicr l Representr t ron of L lnevenne\s.

Time (T)

t( t-r. , In - I

a .: , , , , , , , , , , , , , T , , , , , , , , , . . . . . . . . . . . . - . v , . . . . . . , , . . . . . . . . . . 9 - . . . . - - . . . . . . : . : . : -

Time (T)--'+

Fig.3 :Craphical Representalion of Coefficient of Variation CVm 0/0

SPIN SOLUTION

The Coefficient of variation CVm 0/o

is defined as the standard deviationexpressed as a percentage ofmean.

Standard DeYiation x 100cv%:Mean

Mathematical Representation: In math-ematical form, CV. % is expressed as fol-lows:

cv-%:ry

The large deviations from the mean valueare much more intensively taken intoconsideration in the calculation ofCVm 0/o

rather than Um% due to the squaring ofthe term ln nl. The CVm is preferred

more and more to the unevenness Um%ovalue.

A.

What is relationship betweenIrregularity Umo/o and CVm %?

If the fibre assembly required tobe tested is normally distributedwith respect to its mass variation,

then the relationship between Um % &CVm % may be established as follows

t_l l , ^ -

sy CVmo - 1 .25 xU -oA

CltnOr Um"/o - -

1 .25

Where an ideal normal distribution ofthe fibre assembly cannot be assumed,above conversion factor will be subject toerror Above conversion factor valid onlyfor a symmetrically distributed mass var-iation, refer Fig,4, If the mass variationis distributed asymmetrically and assem-blies with frequentand accentuated thickplaces the following conversion must beused. Refer Fig. 5 & Fig. 6.

CVm %o > 1.25 x Um %

If strong periodic mass variations areavailable in a fibre assembly the follow-ing calculation factor must be used. ReferFig.7

C V m % < 1 . 2 5 x U m 7 0

10 | Spinning Texti les I jan-Feb 2015

Fig. 4: A normal Symmetrical Distribution.

Fig. 5: Distribution showing excess ive mean value variation.

Flg. 6: Asymmetrical Dlstr ibution.

Fig.7: Distribution showing strong periodic variations.

by Mr. Sunil Kumar Sharma,Dy. General Manager[QAD, PPC & Customer Care]LoknayaklNSSSG Ltd.Shahada, Nandurbar (MSl

Disclaimer: The views expressed ;n thissection reflect solely the opinion of thecontributor's and do not representthe viewsof SPINNING TEXTILES Magazine. Readers areadvised to consult an expert before applyingany solution given here.

i[,'