Specification and Requisition for Ball Valves for 6inch 31.38.01.10-Gen Piping class - Basis of...

-

Upload

phungkhanh -

Category

Documents

-

view

670 -

download

54

Transcript of Specification and Requisition for Ball Valves for 6inch 31.38.01.10-Gen Piping class - Basis of...

DOC NO : XXX-3-XXXX-XXX-XX-X-0 REV - 0 Page 1 of 23

Specification and Requisition for Ball Valves

Document no.

XXX-3-XXXX-XXX-XX-X-0

This document is the property of Oman Gas Company. S.A.O.C. Neither the whole nor any part of this document may be disclosed to others or reproduced, stored in a retrieval system, or transmitted in any form by any means (electronic, mechanical, reprographic recording or otherwise) without prior written consent of the owner. Rev Date Prepared

by Checked by

Approved by

Description

0 21.05.16 HA SEI AY Issued for Approval

P.O Box: 799, Postal Code: 133, Al Khuwair, Sultanate of Oman Tel: 24681600 / Fax: 24681678

Website: www.oman-gas.com.om E Mail: [email protected]

Specification and Requisition for Ball Valves

DOC NO : XXX-3-XXXX-XXX-XX-X-0 REV - 0 Page 2 of 23

Chapter Title Page

1. Introduction ............................................................................................................................... 3

1.1 Purpose .......................................................................................................................................................... 31.2 Abbreviations ................................................................................................................................................ 31.3 Definitions ..................................................................................................................................................... 41.4 VENDOR Confirmation of Compliance ...................................................................................................... 4

2. Applicable Codes and Standards ............................................................................................. 4

2.1 Compliance with Shell DEP version 40 and MESC version 13E................................................................ 42.2 Versions of Codes and Standards ................................................................................................................. 42.3 Vendor Awareness of Applicable Codes and Standards .............................................................................. 42.4 Hierarchy of Codes and Standards ............................................................................................................ 4-52.5 List of Applicable Codes and Standards ................................................................................................... 5-7

3. Scope of Supply ......................................................................................................................... 7

4. Technical Requirements ........................................................................................................... 8

4.1 General .......................................................................................................................................................... 84.2 Design / Manufacturing ................................................................................................................................ 84.3 Sour service specification ............................................................................................................................. 84.4 Marking ......................................................................................................................................................... 84.5 Painting and Coating ..................................................................................................................................... 84.6 Spare Parts ..................................................................................................................................................... 8

5. Quality Control, Inspection, Testing and Certification ...................................................... 8-9

5.1 Inspection & Testing ..................................................................................................................................... 9

6. Preparation for Shipment ........................................................................................................ 9

7. Delivery ...................................................................................................................................... 9

8. Warranty ................................................................................................................................... 9

9. Documentation .........................................................................................................................10

9.1 Documentation to be supplied with offer ................................................................................................... 109.2 Documentation to be supplied after award of contract .............................................................................. 10

10. Vendor Responsibility .............................................................................................................10

11. Appendices ................................................................................................................................11

11.1 Appendix-1, Table of Compliance (1 Sheet) ........................................................................................... 11111.2 Appendix-2, Data Sheet for Ball Valves (2 Sheets) .............................................................................. 12-1311.3 Appendix-3, VDRL (7 Sheets) .............................................................................................................. 14-23

Content

Specification and Requisition for Ball Valves

DOC NO : XXX-3-XXXX-XXX-XX-X-0 REV - 0 Page 3 of 23

1.1 Purpose

Oman Gas Company S.A.O.C. (OGC) is the gas transportation company in Oman delivering natural gas to main economic sectors and major consumers comprising of Domestic, Power and

Desalination plants, Fertilizer, Methanol, Petrochemical, Refinery, Steel and Cement plants.

The Company transmits and distributes natural gas to the various consumers through a large network of gas pipelines, compressor stations and gas supply stations. The company's gas pipeline network is spread across the country with more than 2300 kilometers of high pressure

transmission pipelines and ancillary facilities covering Fahud, Muscat, and Sohar in the north and

from Saih -Rawl to Salalah in the south of the country.

The purpose of this document is to define the minimum technical requirements for the purchase

of Lubricated Inverted LTCS Plug Valves as a part of OGC pipeline emergency spares enhancement task.

1.2 Abbreviations

The following abbreviations are used in this Specification:

API American Petroleum Institute.

ASME American Society of Mechanical Engineers.

ASTM American Society for Testing and Materials.

AVME Approved Vendors for Materials and Equipment.

BS British Standards.

CS Carbon Steel.

DEP Design and Engineering Practice (Shell).

DN Diameter Nominal.

GA General Arrangement.

GU Guidelines.

ISO International Organization for Standardisation.

ITP Inspection and Test Plan.

MESC Materials and Equipment Standards and Code.

NACE National Association for Corrosion Engineers.

QA Quality Assurance.

SP Engineering Specifications.

SPIR Spare Parts Interchangeability Report.

TPI Third Party Inspection.

TAT Type Acceptance Testing.

1. Introduction

Specification and Requisition for Ball Valves

DOC NO : XXX-3-XXXX-XXX-XX-X-0 REV - 0 Page 4 of 23

VDRL Vendor Document Requirement Listing.

1.3 Definitions

Principal /Company/Owner : Oman Gas Company (OGC) , SAOC.

Manufacturer / Supplier : The party, which manufactures / supplies the Plug valves.

Shall : Mandatory

Should : Strongly recommended

May : Possible course of action

1.4 VENDOR Confirmation of Compliance

The VENDOR shall complete the Table of Compliance forming Appendix-1 of this specification. Any specification items that cannot be complied with by the VENDOR must be noted accordingly in the Table of Compliance and supported in a separate list of deviations where additional space is required, referring clause by clause to this specification. Only deviations which are accepted by the Company will be incorporated into an eventual Purchase Order.

2. Applicable Codes and Standards

2.1 Compliance with Shell DEP version 40 and MESC version 13E

This contract requires compliance to the versions of the codes and standards listed in Shell DEP version 40 and MESC version 13E. VENDOR shall ensure that this requirement is complied with.

2.2 Versions of Codes and Standards

If no revision or issue date is mentioned for referenced International Codes and Standards, reference should be made to the latest version in force at the time of issue of this document.

2.3 Vendor Awareness of Applicable Codes and Standards

It is assumed that all the referenced standards are in the possession of the Vendor. If, however, any of the Company standards listed are not in the possession of the Vendor, he must immediately notify the PRINCIPAL and request copies. Failure of the VENDOR to notify the PRINCIPAL of any company standards not in its possession and any later impact as a result is the responsibility of the VENDOR. Vendor is responsible for getting International codes / standards without any cost to the Company.

2.4 Hierarchy of Codes and Standards

All specifications, codes and standards listed in this document as applicable, shall be the latest revisions in force at the time of the Purchase Order unless a specific revision has been defined.

Specification and Requisition for Ball Valves

DOC NO : XXX-3-XXXX-XXX-XX-X-0 REV - 0 Page 5 of 23

In the event of any conflict or contradiction between the Company Technical Standards and Procedures the order of priority of the documents shall be in line with the highest possible standards as follows:

First priority : This specification and requisition.

Second priority : Company Standards.

Third priority : Shell Standards.

Fourth priority : International Standards.

Where the PRINCIPAL Technical Standards and Procedures refer to or amend International Codes and Standards (e.g. API, ASME, DIN, BS, etc), these International Codes and Standards shall be deemed to be part of the Specifications.

Any conflicts between this specification and other applicable MESC specifications, Engineering Standards (DEP/PDO-SP), or industry standards, codes, and forms shall be resolved in writing by the supplier or manufacturer Representative.

2.5 List of Applicable Codes and Standards

Company Standards

GU-611-Rev-23a(Jan 2017) PDO Engineering Standards and Procedures.

SP-1131-Rev-5.0 (Aug-2015) Hand-Over and As-Built Documentation (“PLIP”)

SP 1171- Ver 3.0 (Jun 2012) Specification for Quality Management System

Requirements for Product and Service.

SP-1246 (Parts 1 to 5), Ver 2.0

Apr-10.

Specification for Painting and Coating of Oil and Gas

Production Facilities.

SP-2041- Ver 4.0 (Mar.2014) Specification for Cracking Resistant Materials in H2S

Containing Environment

SP-2065-Rev-5.0 (Aug.2015) Document Management for Projects

SP-2154 –Rev-2 (Dec. 2015) Valves Technical Specification.

PR 1984- Ver 2 (Mar.2016) Criticality Rating Procedure.

QHSE-QS-L3-318-R2 Drawing, Document Numbering and Equipment Tagging

Procedure.

QHSE-QS-L2-208-R0 Specification for Quality Assurance.

GME-ENG-L2-203-Rev-1 (Mar.2017)

Additional Technical Requirements for On Plot Ball Valves

Specification and Requisition for Ball Valves

DOC NO : XXX-3-XXXX-XXX-XX-X-0 REV - 0 Page 6 of 23

Note: The references listed in each following standards shall also be referred.

Shell Group Standards (DEP version 40 and MESC version 13E)

DEP 00.00.20.10-Gen. The use of SI quantities and units (endorsement of ISO/IEC

80000).

DEP 30.10.02.11-Gen Metallic materials – selected standards.

DEP 30.10.02.13-Gen Non-metallic materials - Selection and application.

DEP 30.10.02.31-Gen Metallic materials - Prevention of brittle fracture in new assets.

DEP 31.10.00.10-Gen Positive Material Identification (PMI) Program.

DEP 31.38.01.10-Gen Piping class - Basis of design.

DEP 31.38.01.11-Gen Piping – General Requirements.

DEP 39.01.10.11-Gen Selection of materials for life cycle performance (Upstream facility) – Materials selection process.

DEP 39.01.10.12-Gen

Selection of materials for life cycle performance (upstream

equipment) including H2S-containing environments

(amendments and supplements to ISO 15156:2009).

DEP 70.10.90.11-Gen Spare Parts.

MESC SPE 77/130 BALL VALVES

MESC SPE 77/211 Valve Stem, Adapter and Bracket Dimensions for Floating

Ball Valves (Amendments/Supplements to EN 15081)

MESC SPE 77/300A Synopsis of procedure and technical specification for type acceptance testing (TAT) of industrial valves.

MESC SPE 77/302 Valves – General Requirements.

MESC SPE 77/312 Fugitive Emission Production Testing.

(Amendments/Supplements to ISO 15848-2).

MESC SPE 85/203 Graphitic Packing Material (Amendments/Supplements to

ASTM F2168).

Specification and Requisition for Ball Valves

DOC NO : XXX-3-XXXX-XXX-XX-X-0 REV - 0 Page 7 of 23

MESC SPE 85/204 Packing Material, Graphite and Carbon Braided Yarn

(Amendments/Supplements to ASTM F 2191).

Note: The references listed in each following standards shall also be referred.

International standards (Latest)

ASME B16.5 Pipe flanges and flanged fittings.

ASME B16.34 Valves-Flanged, Threaded & welding end.

ASME V Non-destructive examination.

ASME SEC VIII: Div I Rules for Construction of Pressure Vessels.

ASME Sec IX Welding and brazing qualifications.

ASME B31.3 Process Piping.

ASME B16.10

Face to Face & End to End Dimensions of Valves.

API 6D/ ISO 14313 Specification for Pipeline valves.

API 6FA Specification for fire test for valves.

API 607

Fire test for soft-seated quater turn valve.

ISO 10474 Steel and Steel Products, Inspection documents.

ISO 9001: 2015 Quality Management Systems –Requirements.

ISO 10497 Testing of valves – Fire type testing requirements

ISO 5211 Industrial Valves – Part-Turn Actuator Attachment

BS EN 10204 Metallic Products – Types of Inspection Documents.

BS 6755-2 Specification for fire type testing requirements.

NACE MR-01-75/ ISO

15156

Petroleum and natural gas industries – Materials for use in H2S-

containing environments in oil and gas production.

Note: The references listed in each following standards shall also be referred.

3. Scope of Supply

The vendor scope of supply covers but not limited to the design, engineering, fabrication, assembly, inspection, testing, painting, certification, documentation, packing, shipping and delivery of Ball Valves according to this specification and datasheets (Refer Appendix –2).

Specification and Requisition for Ball Valves

DOC NO : XXX-3-XXXX-XXX-XX-X-0 REV - 0 Page 8 of 23

4. Technical Requirements

4.1 General

VENDOR shall submit the duly filled table of compliance as per Appendix-1, signed and stamped Ball valve data sheet (Appendix-2) and Vendor Document Requirement Listing (VDRL) form Appendix-3. The deviations if any shall be listed in the Table of complaince along with technical offer.

For drawing / document numbering OGC standard QHSE-QS-L3-318-R2 shall be followed.

4.2 Design / Manufacturing

Ball valves shall be manufactured in accordance with this specification and the requirements specified in the valve data sheets (Refer Appendix –2). Ball valves shall comply SP-2154 & GME-ENG-L2-203 requirements.

4.3 Sour service specification

All MOC of Ball valves shall comply with NACE MR 01-75/ISO 15156 (all parts), DEP 39.01.10.12-Gen and SP-2041.

4.4 Marking

Marking shall be as per API 6D/ ISO 14313, and MESC SPE 77/130.

4.5 Painting and Coating

Painting and coating (External) shall be done as per is PCS-1 of SP-1246 with colour RAL 9010.

4.6 Spare Parts

Vendor shall submit E-SPIR forms with all necessary spare parts detail and comply DEP 70.10.90.11-Gen.

5. Quality Control, Inspection, Testing and Certification

Vendor shall comply Quality requirement in line with ISO 9001-2008, QHSE-QS-L2-208 and SP-1171.

Vendor shall submit Inspection and Test Plan (ITP) for Principal review and approval. Third Party Inspection (TPI) shall be involved to witness specific stage QC hold points as identified in the ITP.

QA/QC activities shall be in alignment with the requirements stated in Appendix C of PR 1984 – Criticality Rating Procedure for the specific criticality rating indicated for the item under procurement, and vendor shall confirm acceptance without any deviations”.

Criticality rating – 3 as PR-1984 shall be followed for Ball Valves.

Specification and Requisition for Ball Valves

DOC NO : XXX-3-XXXX-XXX-XX-X-0 REV - 0 Page 9 of 23

The Vendor shall submit inspection certificates as per MESC SPE 77/302, clause 9.

For the tests witnessed by TPI, Inspection certificate as per ISO 10474-3.2/EN 10204-3.2 shall be provided.

5.1 Inspection & Testing

For all Ball valves inspection shall be done as per MESC SPE 77/302 and relevant MESC SPEs mentioned in the valve data sheets in addition to project specific ITP (Inspection and Test Plan). ITP shall cover the entire fabrication process and should be submitted by Vendor for Company’s review and approval, prior to commence of fabrication. A copy of all internal and subcontractor’s procedure shall be produced for Company’s review, as called on the ITP.

Company shall advise the extent of Company or Company’s Third Party involvement during stage inspection and Factory Acceptance Testing and Integration Testing along with Company’s comments / approval of the Quality Plan / Inspection Test Plan. However, Company reserves the right to audit, inspect or participate in tests as per its discretion, which will be communicated to Vendor in a timely manner.

Company or Company’s nominated representative shall access at any time to all premises of Vendor / Sub-Vendor for inspection, testing and Quality audits.All procedures shall be approved by the Principal.

6. Preparation for Shipment

Special care SHOULD be taken for the packaging of delicate equipment. Any damage resulting from poor packing SHALL be on account of SUPPLIER and SHALL be replaced within the agreed period.

Packing for shipment shall be in accordance with Company’s shipping instruction. Ball valves shall be protected against damage and corrosion during transport and storage. Vendor shall submit the preservation procedure of equipment and/or material in line with applicable Company / Shell standards.

7. Delivery

The valves in assembled condition SHALL be delivered to Company’s stores (OGC, Mabella Stores) Sultanate of Oman or as otherwise as directed in the Purchase Order.

8. Warranty

The VENDOR shall provide warranty for the supplied item as below.

Eighteen (18) months from the date of delivery, in accordance with the delivery terms, or within twelve (12) months after the Goods have been put into commercial operation following satisfactory completion of the commissioning and testing programme, if any, whichever expires first, or results from a cause reported.

Specification and Requisition for Ball Valves

DOC NO : XXX-3-XXXX-XXX-XX-X-0 REV - 0 Page 10 of 23

9. Documentation

All documents as per VDRL (Appendix – 3) shall be supplied as applicable during bidding stage as well as after award of purchase order.

9.1 Documentation to be supplied with offer

The vendor shall provide the following information as a minimum with the offer. These documents shall include but shall not be limited to,

a. Table of Compliance and deviations to specifications, if any (Refer Appendix-1).

b. Completed (Signed and stamped) data sheet for the Ball valves in Appendix – 2.

c. Fabrication and delivery schedule.

d. Vendor’s standard guarantee and warranty of the complete unit.

e. Valve GA drawings.

f. Any other information not specifically listed here, which are considered necessary by the vendor.

g. Documents / drawings as per VDRL (Refer Appendix-3).

9.2 Documentation to be supplied after award of contract

a. General arrangement drawing with detailed Bill of Materials.

b. Cross sectional drawing with parts list and MOC.

c. Quality plan covering the complete design, fabrication welding and inspection procedures.

d. Documents / drawings as per VDRL (Refer Appendix-3).

10. Vendor Responsibility

The VENDOR shall be responsible for all activities including transportation, intermediate

storage, payment of all customs duty, port clearance charges etc., until safe delivery of the material to the Company’s store in Oman. Any damage incurred before hand-over to the

Company shall be to VENDOR’s account. VENDOR or his agent must obtain a Goods Inward

and Damage Report from the Company upon delivery identifying the status of the materials. The Goods Inwards and Damage Report must accompany Invoice Submission.

This specification shall in no way release the Vendor from final guarantee as to materials,

apparatus, workmanship and performance of the Ball valves.

All correspondences shall be in English. Vendor shall submit all documents / drawings as per VDRL.

Specification and Requisition for Ball Valves

DOC NO : XXX-3-XXXX-XXX-XX-X-0 REV - 0 Page 11 of 23

11. Appendices

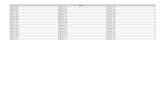

11.1 Appendix-1, Table of Compliance

The SUPPLIER shall confirm that he has accepted all the clauses contained in the specification or otherwise made clarifications / exceptions to be noted below:

Ref. Section SUPPLIER

Confirm: Y/N Alternative: Y/N Noted: Y/N Clarifications

1.1

1.2

1.3

1.4

2.1

2.2

2.3

2.4

2.5

3

4.1

4.2

4.3

4.4

4.5

4.6

5

5.1

6

7

8

9

9.1

9.2

10

Appendix-2

Appendix-3

Specification and Requisition for Ball Valves

DOC NO : XXX-3-XXXX-XXX-XX-X-0 REV - 0 Page 12 of 23

11.2 Appendix-2, Data Sheet for Ball Valves

11.2.1 DN 150 (NPS 6), Ball VALVE Description Specified Vendor response Nominal size DN 150 (NPS 6) Design spec, pressure rating ASME CL 300 Design spec API SPEC 6D Design spec, f to f (e to e) API SPEC 6D Length, f to f (e to e) 403 mm (15.88 in) Type of end connection FLANGED Type of face RAISED FACE Type of pattern STANDARD Type of closure member TRUNNION MOUNTED BALL Type of bore REDUCED Type of construction TWO/THREE PIECE Type of bonnet/cover BOLTED (NON-EXTENDED) Type of seat SOFT SINGLE Uni/bi-directional BI-DIRECTIONAL Service(s) SOUR Mat requirement, sour service NACE MR-01-75 (VERSION 2002) / ISO 15156

+ DEP 39.01.10.12-Gen + SP-2041

Temperature, min MINUS 29 deg C MINUS 20 deg F Temperature, max PLUS 150 deg C PLUS 300 deg F Emission class B Mat, body CARBON STEEL Mat, trim AISI 316/FILLED PTFE Mat, seals THERMOPLASTIC GRAPHITE Mat spec, body ASTM A350 GRADE LF2, CLASS 1 ASTM A105 NORMALISED ASTM A216 GRADE WCB ASTM A216 GRADE WCC Mat spec, bonnet ASTM A105 NORMALISED ASTM A216 GRADE WCB ASTM A216 GRADE WCC ASTM A350 GRADE LF2, CLASS 1 Mat spec, cover ASTM A105 NORMALISED ASTM A216 GRADE WCB ASTM A216 GRADE WCC Mat spec, gland flange ASTM A105 NORMALISED ASTM A216 GRADE WCB ASTM A216 GRADE WCC ASTM A350 GRADE LF2, CLASS 1 Mat spec, gland ring ASTM A182 GRADE F 316 ASTM A182 GRADE F 316L ASTM A276 TYPE 316 ASTM A276 TYPE 316L ASTM A479 -321 Mat spec, closure member ASTM A182 GRADE F 316 ASTM A182 GRADE F 316L ASTM A351 –CF3M

Specification and Requisition for Ball Valves

DOC NO : XXX-3-XXXX-XXX-XX-X-0 REV - 0 Page 13 of 23

ASTM A351 –CF8M Mat spec, stem ASTM A182 GRADE F 51 ASTM A479 UNS S31803 ASTM A182 GRADE F 316 ASTM A182 GRADE F 316L ASTM A276 TYPE 316 ASTM A276 TYPE 316L ASTM B637 UNS N07718 Mat spec, trunnion ASTM A182 GRADE F 316 ASTM A182 GRADE F 316L ASTM A276 TYPE 316 ASTM A276 TYPE 316L ASTM A182 GRADE F 51 ASTM A479 UNS S31803 Mat spec, seat ASTM A182 GRADE F 316 ASTM A182 GRADE F 316L ASTM A351 –CF3M ASTM A351 –CF8M Mat spec, seat insert FILLED PTFE PEEK Mat spec, spring(s) ASTM B637 UNS N07718 Mat spec, static primary seal VIRGIN PTFE FILLED PTFE MODIFIED PTFE Mat spec, static sec seal GRAPHITE Mat spec, dynamic primary seal VIRGIN PTFE FILLED PTFE MODIFIED PTFE Mat spec, dynamic sec seal(s) BRAIDED GRAPHITE + PTFE LUB BRAIDED GRAPHITE DIE FORMED GRAPHITE + PTFE LUB DIE FORMED GRAPHITE Mat spec, bolts/studs ASTM A320 GRADE L7M ASTM A193 GRADE B7M Mat spec, nuts ASTM A194 GRADE 7M ASTM A194 GRADE 2HM Mandatory requirements MESC SPE 77/130 2017 MESC SPE 77/300A 2017 MESC SPE 77/302 2017 MESC SPE 77/312 2017 MESC SPE 85/203 2017 MESC SPE 85/204 2017 SP-2154 Ver-2 (Dec. 2015) Inspection category IC-I Tec classification code BA-TR-ST-BD-SB-BB-XX-API 6D-ST Quantity required 1 Number NOTES:

1. Ball valve shall comply SP-2154 requirements. 2. Ball valve shall be provided with sealant injection & cavity vent and drain as per GME-ENG-L2-203. 3. Vendor need to submit the general arrangement (GA) drawing of valve along with technical offer.

Specification and Requisition for Ball Valves

DOC NO : XXX-3-XXXX-XXX-XX-X-0 REV - 0 Page 14 of 23

11.3 Appendix-3, Vendor Document Requirement Listing (VDRL)

Document Type Code Key: A Master Data Schedule B Commercial Data C Drawings D System Diagrams/Schematics E Data Sheets/Specifications F Schedules/Listings G Calculations H Performance Data J Welding & Materials Engineering Data K Certification Data L Quality Assurance M HSE Data N Installation/Spares & Maintenance Data P Post Manufacturing Procedures

Minimal document attributes: Vendor Document Number Project Document Number Vendor Revision Code Project Revision Issue Code Status Discipline and Doc type Code Document Title Issue Date ID/signature of originator, checker and approver Purchase order number Official name of Vendor and/or sub-vendor

company The item/tag number or equipment number

General Instructions to Vendors:

All documents shall be supplied in English and free of copyrights prohibiting use within PROJECT. All units of measure shall be in SI. All documents that have been marked in this VDRL have to be submitted electronically.

If “In Data Book” is marked for any document, the Vendor shall include all documents marked as “In Data Book”. “Date 1st Review” is noted as weeks after or before one of the following milestones The Contractors or Vendor submittal requirements will be denoted on the VDRL as follows with regard to documentation listed on the VDRL. Usage of such symbols can clearly be seen on the VDRL.

A = Date receiving Approval of Drawings (e.g. A+1 = 1 week after Approval) P = Date of purchase order P + X =X weeks after purchase order or Loi T = Date of Test T + -X =X weeks after or prior test D = Date of Dispatch D + - X =X weeks after or prior to dispatch Q = Date of process Q – X =X weeks prior to manuf./job process U = Use of procedure U – X =X weeks prior to use of procedure E = Final inspection E + X =X weeks after final inspection C = Date of Call Off C + X =X weeks after Call Off S = Date of Shipment (e.g. S-1 = 1 week before Shipment)

REVIEW CLASS O = Review at Purchasers Office S = Review by Inspector at Vendors Works I = Submit to Purchasers Office for Information Only A = Review by Audit at Vendors Works

Specification and Requisition for Ball Valves

DOC NO : XXX-3-XXXX-XXX-XX-X-0 REV - 0 Page 15 of 23

R = Review by Engineering at Vendors Works F = Certified Document to be sent to site with Materials J = Incorporate Certified Issue in J01 K = Incorporate Certified Issue in K01 H = Document shall be retained in safe custody by Vendors.

Required documentation submission points will be indicated on the VDRL by a period in weeks or days from a specific point of time, e.g. P. + 4 = four weeks after receipt of Purchase Order; D – 2 = two weeks prior to shipment; T - 1 = one week prior to test date, etc., for submissions during design/manufacture. Documents marked “With Bid” or “For Review” shall be submitted electronically in .pdf (Adobe Acrobat) format. Documents marked “As-Built” or “In Data Book” shall be submitted electronically in .pdf and as native file format, preferably MS Office, AutoCAD and PDMS (if used). Documents marked “In Data Book” shall also be submitted in paper format.

Equipment No

-- Requisition No XXX-3-XXXX-XXX-XX-X-0

Declaration by Vendor: In the event of a Purchase Order being awarded, we confirm that the VDRL documentation shall beprovided by the dates indicated.

Vendor Signature

Name Date

WITHBID

FIRSTISSUE

DATEREQD

FINAL ISSUE

AS-

BUILT

REVIEW

CLASS

IN DATA BOOK

CODE DOCUMENT DESCRIPTION

NO OF COPIES REQUIRED

No of Hard Copies

Electronic Copy

A00

11.3.1.1 MASTER DATA SCHEDULE

11.3.1.2 A00

Manufacturer Record Book / Vendor Data Book

D-1 11.3.1.3 5 11.3.1.4 5 11.3.1.5 11.3.1.6 O/S 11.3.1.7 YES

11.3.1.8 A01 Vendor Master Data Schedule (VMDS)

1 1 P+2 11.3.1.9 1 11.3.1.10 1 11.3.1.11 11.3.1.12 O 11.3.1.13

11.3.1.14 COMMERCIAL DATA

B01 Fabrication/Production Schedule

1 P+2 11.3.1.15 1 11.3.1.16 1 11.3.1.17 11.3.1.18 I

B02 Sub-Order Schedule

B03 Weekly Progress/Monthly Progress Reports

B04 Company Profile

B05 Customer List

B06 Certificate of Origin S F YES

B07 Certificate of Compliance E-2 1 1 I YES

B08 Exceptions to Codes & Specifications

1 O

B09 Original Invoices

B10 Certificates of Ownership

Specification and Requisition for Ball Valves

DOC NO : XXX-3-XXXX-XXX-XX-X-0 REV - 0 Page 16 of 23

B11 Waivers and Release Notes

B12 Independent Verification Body Release Notes

11.3.1.19 DRAWINGSC01 General Arrangements 1 1 P+2 1 1 O YES

C02 Foundation Loading Diagrams & Support Details

C03 Detail Drawings

C04 Exploded View/Cross Sectional Drawings

C05 Mechanical Seal Detail Drawings

C06 Panel Cabinet Layouts

C07 Electrical/Instrument Layouts

C08 Instrument Outline Drawings

C09 Insulation/Lining Details

C10 Isometric Drawings

11.3.1.20 SYSTEM DIAGRAMS/SCHEMATICS

D01 Process/Utility Flow Schemes (PFS/UFS) & Heat Mass Balance

D02 Process/Utility Engineering Flow Schemes (PEFS/UEFS)

D03 Electrical Single Line Diagrams (SLD’s)

D04 Instrument/Electrical Logic Diagrams

D05 Control Philosophy & Block Diagrams

D06 Electrical Schematic Diagrams

D07 Internal Wiring Diagrams (Connection Diagrams)

D08 Interconnection Diagrams

D09 Instrument Termination & Hook-Up Details

D10 Terminal Block Diagrams

D11 Electrical Termination & Hook-Up Details

D12 Loop Diagrams

D13 Hydraulic & Pneumatic Schematics

Specification and Requisition for Ball Valves

DOC NO : XXX-3-XXXX-XXX-XX-X-0 REV - 0 Page 17 of 23

D14 Interface Drawings Input/Output Power Supplies

D15 Cause & Effect Diagrams

D16 Visual Display Unit (VDU) Graphics

11.3.1.21 DATA SHEETS/SPECIFICATIONSE01 Weight Data Sheets

E02 Equipment Data Sheets

E03 Instrument Data Sheets

E04 Noise Level Data Sheets

E05 Mechanical Alignment Data Sheets

E06 Valve Data Sheets 1 1 P+2 1 1 O YES

E07 Electrical Data Sheets

E08 Functional design Specification

11.3.1.22SCHEDULES/LISTINGSF01 Instrument Schedule

F02 Cable Schedule

F03 Load/Motor Schedule

F04 Distribution Board Schedule

F05 Input/Output Schedule/ Bit Maps

F06 Bolt Schedule

F07 Lubrication Schedule

F08 Terminal Point Schedule

F09 Transit Schedule

F10 Utilities Schedule

F11 Erection Fastener Schedule

F12 Bill of Materials/Equipment List

F13 Piping Line List

F14 Trace Heating Schedule

F15 Schedule of Pressure Safety Valves (PSV’s)

F16 Schedule of Pressure Vessels

F17 Schedule of Runway Beams & Lifting Appliances

F18 Schedule of Electrical Equipment in Hazardous

Specification and Requisition for Ball Valves

DOC NO : XXX-3-XXXX-XXX-XX-X-0 REV - 0 Page 18 of 23

Areas

F19 Schedule of Ingress Protection (IP) Rated Equipment

11.3.1.23CALCULATIONS

G01

Pressure Vessel/Tank Mechanical Strength Calculations (incl. Pulsation Dampers, Filters etc.)

G02 Process/Utility Calculations

G03 Structural Steel Calculations

G04 Foundation Support Calculations

G05 System Head Loss Calculations

G06 Lateral Critical Speed Calculations

G07 Torsional Critical Speed Calculations

G08 Bearing Life Calculations

G09 Thrust Bearing Size Calculations

G10 Heat Emission Calculations

G11 Reliability, Availability & Safety Integrity Level (SIL) Calculations

G12 Hydraulic Calculations

G13 Exchanger Thermal Rating Calculations

G14 Instrument Calculations

G15 Acoustic Enclosure Ventilation System Calculations

G16 Exhaust Duct Calculations

G17 Coupling Selection Calculations

G18 Lube & Seal Oil System Calculations

G19 Anti-Surge Valve Sizing

G20 Rotor/Shaft System Imbalance Response Analysis

G21 Piping Stress Analysis

G22 Failure Mode & Effects

Specification and Requisition for Ball Valves

DOC NO : XXX-3-XXXX-XXX-XX-X-0 REV - 0 Page 19 of 23

Analysis (FMEA)

G23 Finite Element Analysis

G24 Nozzle Loads & Movements

G25 Externally Applied Loadings Calculations (incl. Seismic)

G26

Gaseous (Inergen)/Water Mist Fire Extinguishant flow, pressure & time design Calculations

G27 Electrical Calculations

H01 Electrical Protection Curves & Relay Characteristics

H02 Current, Potential & Power Transformer Curves

H03 Motor Performance Curves

H04 Lighting Performance Data

H05 Battery Charge/ Discharge Curves

H06 Power System Analysis Data

H07 Electrical Generator Performance Curves

H08 Combustion Gas Turbine Performance Curves

H09 Compressor Performance Curves

H10 Centrifugal Pump Performance Curves

H11 Rotary Pump Curves

H12 Reciprocating Pump Performance Curves

H13 Fan Performance Curves

H14 Engine Performance Curves

H15 Speed/Torque Starting Curves

H16 Crane Load/Radius Curves

H17 Computer System Manuals

H18 Catalogue Data 1 1 1 I YES

Specification and Requisition for Ball Valves

DOC NO : XXX-3-XXXX-XXX-XX-X-0 REV - 0 Page 20 of 23

11.3.1.24 WELDING & MATERIALS ENGINEERING DATA

J01 Weld Location & NDE Plans (including weld repairs & casting defects)

1 P+2 1 1 O YES

J02

Welding Procedure Specifications (WPS) & Qualification Records (WPQR)

1 P+2 1 1 O YES

J03 Non Destructive Examination (NDE) Procedures

1 P+2 1 1 O YES

J04 Surface Preparation & Coating Specification

J05 Forming & Heat Treatment Procedures

J06 Hydrostatic/Pneumatic Test Procedures

1 P+2 1 1 O YES

J07 Corrosion Testing Procedures

11.3.1.25CERTIFICATION DATAK00 Quality Dossier

K01 Type Approval Certificates

1 P+2 1 1 I YES

K02 Hazardous Area Certificates

K03 Performance Test Results (all disciplines)

D-2 1 1 O/ S YES

K04 Factory Acceptance Test Reports

D-2 1 1 O/ S YES

K05 Vibration Reports

K06 Noise Reports

K07 Weight Reports/Certificates

K08 Dimensional Control Reports

D-2 1 1 O/ S YES

K09 Material Test Certificates D-2 1 1 S, F YES

K10 NACE Requirements D-2 1 1 S, F YES

K11 Welder Qualification Certificates

T 1 1 S YES

K12 NDE Operator Qualification Certificates

T S

K13 Pre-Production Qualification & Production Test Results

K14 Heat Treatment Records

K15 NDE Records (Visual, T 1 1 S, F YES

Specification and Requisition for Ball Valves

DOC NO : XXX-3-XXXX-XXX-XX-X-0 REV - 0 Page 21 of 23

Radiography, DPI, MPI, Eddy Current etc.)

K16 Material Traceability Records

T 1 1 S, F YES

K17 Calibration Certificates

K18 Pressure Test Certificates D-2 1 1 S/O YES

K19 Leak Test Certificates

K20 Proof Load Test Certificates

K21 Coating/Insulation Reports & Compliance Certificates

D-2 1 1 S, F YES

K22 Cable Record Cards

K23 Nameplate Rubbing/Photo

K24 Approved Concessions & Concessions Register

K25 Inspection Release Certificates (Principal/Purchaser)

D-1 1 1 O YES

K26

Inspection/Survey Reports (Certifying Authority, Regulatory Authority, etc.)

D-1 1 1 O

K27 Non Conformance Reports (Principal/Purchaser)

D-1 1 1 O

K28 Non Acceptance Reports (Certifying Authority, Regulatory Authority, etc.)

K29 Technical Passport Contents List

K30 Technical Passport

K31 Certificate of Conformity

K32 Permit to use foreign made hazardous equipment

K33

Electromagnetic Compatability (EMC) Declaration of Conformity

11.3.1.26 QUALITY ASSURANCE AND CONTROL L01 Quality Manual

L02 Quality Plan

L03 Quality Control Plan (Inspection & Test Plan)

1 P+2 1 1 1 O YES

L04 Quality Management Accreditation (including any

1 1 1 I

Specification and Requisition for Ball Valves

DOC NO : XXX-3-XXXX-XXX-XX-X-0 REV - 0 Page 22 of 23

manufacturing licenses held by Vendor, e.g. API, ASME etc.)

L05 Audit Schedule

L06 Audit Reports (incl. Quality Assessments)

L07 Corrective Action Reports

11.3.1.27HSE DATA

M01 Material Safety Data Sheets (MSDS)

M02 Emissions to Atmosphere Data

M03 Safety & Environmental Evaluation

M04 Safety Standards

M05 HAZOP Reports

M06 Project Safety Plan

M07 Safety Management System

M08 Environmental Management System

11.3.1.28 INSTALLATION AND OPERATING MANUAL (IOM)

N01 Installation, Commissioning, Operating & Maintenance Manuals Contents List

N02 Installation, Commissioning, Operating & Maintenance Manuals

D 1 1 1 I YES

N03 Special Tools List (If applicable)*

D 1 1 1 I YES

N04 Spare Parts & Interchangeability Record (SPIR) Schedule

S-1 1 1 1 I YES

N05 Training Data

N06 Document to Tag Relationship; Equipment Register & Tag Register

11.3.1.29 POST MANUFACTURING PROCEDURES

P01 Functional & Performance Test Procedures

P02 Flushing Procedures

P03 Weight Control/Weighing Procedures

P04 Lifting Procedures

P05 Pre-commissioning/Commissioning Procedures

Specification and Requisition for Ball Valves

DOC NO : XXX-3-XXXX-XXX-XX-X-0 REV - 0 Page 23 of 23

P06

Preparation for Shipping with Recommended Handling, Storage & Preservation Procedures

D-2 1 1 I YES

P07 Leak Test Procedures

P08 Erection & Installation Procedures

P09 Shutdown and Start-up procedure