Simulation of Job Shop using Arena - Mini Project Report

-

Upload

kailas-sree-chandran -

Category

Documents

-

view

4.376 -

download

15

description

Transcript of Simulation of Job Shop using Arena - Mini Project Report

SIMULATION OF JOB SHOP USING ARENA

Mini Project Report

Submitted in partial fulfillment of the requirements for

the award of the degree of

Master of Technology

in

Industrial Engineering and Management

by

KAILAS SREE CHANDRAN (Roll No.:M100447ME)

Department of Mechanical Engineering

NATIONAL INSTITUTE OF TECHNOLOGY

CALICUT

April 2011

CERTIFICATE

This is to certify that the report entitled “SIMULATION OF JOB SHOP USING

ARENA” is a bonafide record of the Mini Project done by KAILAS SREE

CHANDRAN (Roll No.: M100447ME), in partial fulfillment of the requirements for the

award of the degree of Master of Technology in Industrial Engineering and

Technology from National Institute of Technology Calicut.

Dr. R. Sridharan

Faculty-in-Charge

(ME6194 – Mini Project)

Dept. of Mechanical Engineering

Place : NIT Calicut

Date : 02/05/2011

ACKNOWLEDGEMENT

I am deeply indebted to my guide Dr. R. Sridharan, Professor, Department

of Mechanical Engineering, for his invaluable guidance, consistent encouragement

and suggestions throughout the course of the work.

I wish to express my sincere thanks to Dr. S. Jayaraj, Professor and Head,

Department of Mechanical Engineering, for providing the necessary facilities to

carry out this work.

Last but not the least, I extend hearty thanks to all our teachers and

classmates whose constant support and encouragement helped me to complete this

mini-project on time.

KAILAS SREE CHANDRAN

ABSTRACT

A Job Shop includes jobs which have different sequence of operations. Here a Gear

manufacturing Job Shop which produces three types of gears was modeled in ARENA

Simulation software to study the Gear flow times (by type), Gear delays at operations

locations, Machine utilizations etc. While modeling the system, the sequence of operations

for different types of gears, plant layout, distance between different facilities, processing time

of each operation, transportation of jobs through the factory, speed of transporter etc. were

considered. The model is run for 1 year with three 8 hour shifts per day. The results were

analyzed and a suggestion was also made to improve the system.

CONTENTS

List of Tables i

1 Introduction 01

1.1 Job Shop Production 01

1.2 Characteristics of Job Shop Production 01

1.3 Importance of Job Shop Production 02

2 Problem Environment 04

2.1 Problem Statement 04

2.2 Assumptions 05

2.3 Objectives of the Project 06

3. ARENA Model 07

3.1 Modeling the System 07

3.1.1 Gear Job Arrivals 08

3.1.2 Gear Transportation 09

3.1.3 Gear Processing 12

3.1.4 Gear Departure 15

3.2 Simulating the Model 18

4. Results 20

5. Improving the System 23

5.1 Suggestion for Improvement 24

5.2 Comparison of Results 24

6. Conclusion 25

Reference 26

LIST OF TABLES

2.1 Distances among Job Shop locations 04

2.2 Operation Plan for gears by type 05

5.1 Comparing Gear Delays at Operation Locations 24

5.2 Comparing Resource Utilization 24

5.3 Comparing Gear Flow Time 24

1

CHAPTER 1

INTRODUCTION

1.1 JOB SHOP PRODUCTION

Job Shop production is characterized by the manufacture of one or few numbers of a single

product designed and manufactured strictly to customer‟s specifications, within, the given

period and wit/tin the price fixed prior to tile contract. Some typical examples of industries

engaged in Job Shop production are: general repair shops; special purpose machine tool

manufacturers; workshops to manufacture jigs and fixtures for other units; building

contractors; tailoring shops manufacturing made-to-measure suite of clothes; manufacturers

of ships, cranes, furnaces, turbo-generators, pressure vessels; and others manufacturing

articles made to customers orders.

1.2 CHARACTERISTICS OF JOB SHOP PRODUCTION

1.2.1 Disproportionate Manufacturing Cycle Time

A considerable amount of pre-planning and organization is necessary in such a venture.

Relatively long delays occur at the assembly as well as at the materials processing stages due

to lack of materials or components, imbalanced work flow, design changes, design errors

detected during manufacture, inaccurate work measurements, etc. which tend to lengthen the

manufacturing cycle time. At times, tile time needed to design the product exceeds its

manufacturing time.

1.2.2 Large Work-In-Progress

The work-in-progress inventory in a Job Shop production is generally very large as detailed

scheduling and progress control in this type of production is economically infeasible. For

various reasons, jobs get delayed causing temporary work shortages. To overcome work

shortages and keep men and machines busy, more work is released to the shop which in turn

increases work-in-progress.

1.2.3 Limited Functions Of Production Planning And Control

The success of Job Shop production mainly depends on the ability of the engineer in-charge

of the contract.

2

1.3 IMPORTANCE OF JOB PRODUCTION

1.3.1 Small Production Runs

Job Shop production is characterized by the manufacture of one or few pieces of a product at

a time under a separate contract; the production is made strictly to customers‟ specifications.

1.3.2 Discontinuous Flow of Materials

The flow of materials and components between different stages of manufacture is highly

discontinuous due to imbalance in operation wise work content.

1.3.3 General Purpose Machines and Process Layout

Plant and equipment is designed or procured and arranged to obtain maximum flexibility.

General purpose machines and handling equipments capable of performing variety of

operations with minimum set-tip times are installed in lie of variety in products. Tile

machines are arranged to give process layout - layout by function. Similar machines, capable

of doing similar type of operations, are grouped together. Presses, for example are kept at one

place; milling machines are placed at another place; drilling machines are kept at third place;

and so on and so forth. Each group of machines is usually designated as a work centre or a

section or a shop.

The grouping of machines gives a lot of flexibility in loading and scheduling. Temporary

machine breakdowns and operator‟s absenteeism can be taken care of by shifting jobs to

another machine or shifting operators from less important jobs to important jobs.

1.3.4 Highly Skilled Labor

The labor force is usually highly skilled-highly qualified trade apprentices who are expected

to work from minimum instructions. Instructions regarding “what to make” are issued in the

form of specifications while instructions as to “how to manufacture” are usually oral. The

workmen being highly skilled are expected to work independently and display a great deal of

initiative and judgment. They are required to set up their own machines and prepare their OW

special tools or production aids in order to further the manufacture of a part or a assembly.

1.3.5 Highly Competent Knowledgeable Supervision

Highly competent general engineers are engaged as foreman in the base workshop and a

group of site engineers, practical men, with thorough training, capable of taking independent

charge of each contract are employed to work at site. Therefore, these engineers (supervisors)

3

in a Job Shop production are the reservoir of job knowledge. The supervisor besides being

able administrator is expected to improvise and determine best work methods, determine tool

requirements, select the best process and provide management with reliable estimates of labor

and materials for specific orders. The span of control - the number of workmen to be

supervised by a supervisor - is kept low because of technical nature of the job.

1.3.6 Simple Mechanism

Tools control function is simple. Standard tools are stocked while special tools are either

made on the shop floor by the operators or purchased on request from supervisor.

1.3.7 Decentralized Process

The scheduling activity is more or less decentralized. A schedule is prepared to show the start

and completion date of each major component of the product. Job tickets giving completion

date of each component are raised and given to the shop. The activity of day to day

scheduling is left to the individual shop supervisor.

4

CHAPTER 2

PROBLEM ENVIRONMENT

2.1 PROBLEM STATEMENT

Consider a Job Shop producing three types of gears, G1, G2, and G3, for a ship. The job shop

is spread out geographically on the factory floor and its layout consists of the following

locations:

An arrival dock

A milling workstations with four milling machines

A drilling workstations with three drilling machines

A paint shop with two spray booths

A polishing area with a single worker

A shop exit

The distances among locations are given in Table 2.1

Table 2.1 Distances among Job Shop locations

Arrival

Dock

Milling

Station

Drilling

Station

Paint

Shop

Polishing

Area Shop Exit

Arrival

Dock 100 100 250 250 550

Milling

Station 100

300 400 150 300

Drilling

Station 100 300

150 400 500

Paint Shop 250 400 150

300 400

Polishing

Area 250 150 400 300

200

Shop Exit 550 300 500 400 200

Gear jobs arrive in batches of 10 units and their inter-arrival times are uniformly distributed

between 400 and 600 minutes. Of arriving batches, 50% are of type G1, 30% are of type G2,

and 20% are of type G3. A gear job arrives at the arrival dock and from there is dispatched to

its specific (type-dependent) sequence of manufacturing operations. A sequence consists of a

subset of milling, drilling, painting, and polishing operations. Table 2.2 displays the

operations plan showing the sequence of operations and the associated processing times for

5

each gear type. The layout of the job shop and operation sequences of gear types are depicted

in Figure 2.1.

Table 2.2 Operation Plan for gears by type

GEAR TYPE OPERATION

SEQUENCES

PROCESSING

TIME(Minutes)

G1

Milling 35

Drilling 20

Painting 55

Polishing 15

G2

Milling 25

Painting 35

Polishing 15

G3

Drilling 18

Painting 35

Polishing 15

Gears are transported among locations by two trucks running at a constant speed of 100

feet/minute. Each truck can carry only one gear at a time. When a job is complete at a

location, the gear is placed into an output buffer, a transport request is made for a truck, and

the gear waits for the truck to arrive. Once a gear is transported to the next location, it is

placed in a FIFO input buffer. Finally, when the polishing operation is completed, the

finished gear departs from the job shop via the shop exit.

To analyze the performance of the job shop, plan to run a simulation over 1 year of operation.

2.2 ASSUMPTIONS

These assumptions were made during modeling the system.

a. Transporter (Truck) speed is same for both loaded and empty.

b. The freed transporter stays at the destination station until requested by another

station.

c. The Job Shop works for 24 hours a day in 3 shifts at 8 hours each.

6

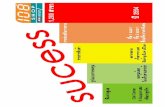

Figure 2.1 Layout of the Job Shop and Operation Sequences by Gear type.

2.3 OBJECTIVE OF THE PROJECT

The following statistics are of interest:

Gear flow times (by type)

Gear delays at operations locations

Machine utilizations

The objective of the project is to model the Gear Manufacturing Job Shop in ARENA

Simulation Software and find;

i. Gear Flow Time (by Type)

ii. Gear Delays at operation locations

iii. Utilization of Resources

iv. Suggest an improvement

Arrival Dock

Milling

Workstation Painting Shop

Shop Exit

Drilling

Workstation

Polishing

Area

G1

G2

G3

7

CHAPTER 3

ARENA MODEL

3.1 MODELING THE SYSTEM

The given system is modeled in ARENA Simulation software. Figure 3.1 depicts the Arena

model for the gear shop, consisting of three main segments:

1. Gear Job Arrivals

2. Gear Transportation

3. Gear Processing

4. Gear Departure

A segment-by-segment walkthrough of the model follows next.

Figure 3.1 Arena Model for the Gear Manufacturing Job Shop

8

3.1.1 Gear Job Arrivals

This part includes the arrival section of Gear Jobs. The segment is shown in Figure 3.2.

Figure 3.2 Gear Job Arrivals Segment

Gear entities are created in the Create module, called Create Jobs, whose dialog box is

displayed in Figure 3.3. The Entities per Arrival field indicates that gear jobs arrive in

batches of 10, and the Time Between Arrivals section specifies batch inter-arrival times to be

uniformly distributed between 400 and 600 minutes. Following arrival, each incoming gear

entity proceeds as a separate entity.

Figure 3.3 Dialog box of the Create module Create Jobs

An arriving gear entity next enters the Assign module, called Assign Job Type and Sequence,

whose dialog box is displayed in Figure 3.4. Here, a gear entity is assigned a type by

sampling it from a discrete distribution, and saving the type code (1, 2, or 3) in its Type

attribute. In addition, the ArrTime attribute is assigned the value of the simulation clock,

Tnow, for later use in computing the gear entity‟s flow time. Finally, the Arena attribute

9

Entity.Sequence is assigned the value of the Type attribute. This attribute acts as an index that

associates a gear type with the corresponding operations sequence.

Figure 3.4 Dialog box of the Assign module Assign Job Type and Sequence.

The operations sequences for gear types are specified in the Sequence module from the

Advanced Transfer template panel, whose dialog spreadsheet is displayed at the bottom of

Figure 3.5. Three sequences (row entries) are defined here, one for each gear type. Each

sequence consists of a sequence name (Name column) and a series of steps (Steps column),

listed in the order of processing.

To specify steps, the modeler clicks the button under the Steps column and pops up the Steps

dialog spreadsheet. The five steps of type G1 gears processing are displayed in the middle

spreadsheet of Figure 3.5. Each step is a row entry specifying the location name and

associated values (under the Assignments column). Clicking the corresponding button pops

up the associated Assignments dialog spreadsheet. The assignment of time for the milling

time operation is exemplified in the top spreadsheet of Figure 3.5.

3.1.2 Gear Transportation

Gear Transportation segment includes jobs arriving to Arrive Dock, Requesting the truck and

transporting the jobs to job shop. The segment is shown in Figure 3.6.

10

Figure 3.5 Dialog spreadsheet of the Sequence module (bottom), the Steps dialog spreadsheet

for specifying operations steps of type G1 gears (middle), and the Steps Assignment

spreadsheet for specifying milling time assignment of type G1 gears (top).

Job shop locations are modeled as Station modules. Accordingly, every gear entity proceeds

to the Station module, called Arrive_Dock, to model its physical arrival at the job shop‟s

arrival dock. From here, gear entities will be transported to the job shop floor to start the first

step in their operations sequence.

Figure 3.6 Gear Transportation Segment

To this end, a gear entity enters the Request module (from the Advanced Transfer template

panel), called Request a Truck, whose dialog box is displayed in Figure 3.7. The Transporter

Name field indicates a request for a Fork Truck transporter. If multiple transporters are

available, the modeler can specify how to select one in the Selection Rule field. Such

selections may be cyclical, random, preferred order (as listed in the Transporter module),

smallest distance, largest distance, or a specific transporter. Here the selection rule requests

the transporter nearest to the arrival dock. Furthermore, the Save Attribute field specifies that

the ID of the selected transporter be saved in the Truck_ID attribute of the requesting gear

11

entity. The saved ID will be used in due time to free that particular truck. Since requesting

transporters from multiple locations is a form of contention for resources, the Priority field

allows the modeler to assign a priority to requests issued at multiple Request modules (here a

high priority is assigned in order to clear the arrival dock as soon as possible). The Entity

Location field indicates the location of the requesting entity, and the Velocity field specifies

the transporter‟s velocity, which is 100 feet/minute in our case. Finally, gear entities

requesting transportation at the same Request module are instructed in the Queue Name field

to wait in the queue, called a Truck.Queue, until a transporter becomes available.

Figure 3.7 Dialog box of the Request module Request a Truck

As soon as a gear entity grabs a truck, it proceeds to the Transport module, called Transport

to Shop Floor, whose dialog box is displayed in Figure 3.8. The Transporter Name and Unit

Number fields specify the type and ID of the selected transporter, which here is the truck

whose ID is kept in the Truck_ID attribute of the requesting gear entity. The transporter/gear

destination is specified in the Entity Destination Type field as the By Sequence option,

indicating that the destination is determined by the gear entity‟s sequence number. This field

may also specify a Station module name, using the Station option. It can also specify an

12

attribute or expression. The gear entity and the transporter move as a grouped entity at a

velocity of 100 feet/minute as specified in the Velocity field. Note that the velocity may

depend on trip type, so that an empty truck and a loaded one can be made to move at different

velocities.

Figure 3.8 Dialog box of the Transport module Transport to Shop Floor

Next, the distances between different facilities are specified. Figure 3.9 displays the dialog

spreadsheet of the Distance module (left), as well as a corresponding Stations dialog

spreadsheet (right), which pops up on clicking a button under the former‟s Stations column.

3.1.3 Gear Processing

This segment includes the actual processing of gears. The gear processing segment

encompasses sets of Station modules, each modeling an operation in the sequence, from

milling to polishing. Since all sets have the same structure (except for names), only the

milling operation logic is explained here. The segment is shown in Figure 3.10.

When a gear entity is transported to the milling operation, it enters the Station module, called

Milling Station. It then proceeds to the Free module, called Free Truck at Mill, whose dialog

box is displayed in Figure 3.11. Here, the Transporter Name and Unit Number fields specify

the truck to be freed for use by other gear entities, using the Truck_ID attribute of the freeing

gear entity.

13

Figure 3.9 Dialog spreadsheet of the Distance module (left) and the Stations dialog

spreadsheet (right).

Figure 3.10 Gear Processing Segment

14

Figure 3.11 Dialog box of the Free module Free Truck at Mill

In this case, it enters the Process module, called Milling, whose dialog box is displayed in

Figure 3.12. The Seize Delay Release option in the Action field is used to model gear delays

at this process. The resource seized is Milling Machine and the processing time is kept in the

Milling Time attribute specified in the Sequence module of Figure 3.5. Furthermore, to model

four milling machines at the milling workstation, resource Milling Machine has to be

declared as having a capacity of four in the spreadsheet view of the Resource module. The

capacity of other machine groups is similarly declared. Figure 3.13 shows it.

Figure 3.13 Dialog spreadsheet of Resource module

On completing the milling operation, the gear entity proceeds to the Request module, called

Request Truck at Milling, whose dialog box is displayed in Figure 3.14. In this module, the

gear entity requests transportation to the next operation, similarly to the first request from the

arrival dock to the job shop floor (Figure 3.7). Here, it may have to wait in the queue, called

Request Truck at Milling.Queue, which serves as the output buffer for the milling process.

The transport operation takes place when a truck arrives and both gear and transporter enter

the Transport module called Transport From Milling.

15

Figure 3.12 Dialog box of the Process module Milling

Gear entities move from one operation to another according to their specified sequences. It

should be pointed out that Arena handles all sequencing details at runtime. The internal

Arena attribute IS keeps track of each gear entity‟s step number in its sequence. Whenever a

sequential transport is requested, Arena increments the IS attribute and indexes into the

appropriate Steps module spreadsheet to determine the destination location and travel time.

The IS attribute may also be modified by the modeler.

3.1.4 Gear Departure

This segment includes the transport of finished gears from job shop to outside. The segment

is shown in Figure 3.15.

Eventually the gear entity arrives at the Station module, called Shop Exit, which is always the

last location in each operations sequence.

16

Figure 3.14 Dialog box of the Request module Request Truck at Milling

Next, the transporting truck is freed in the Free module, called Free Truck at Exit, and the

finished gear entity is ready to record some statistics and then depart from the model at a

Dispose module.

Figure 3.15 Gear Departure Segment

Figure 3.16 displays the dialog box of the Record module, called Tally Flow Time. Here, flow

times are tallied with the aid of the ArrTime attribute of each finished gear entity. Note that

these flow times are tallied by gear type, using the tally set mechanism. The Tally Set Name

field indicates that tallies are to be entered in the Flow Times set. Each gear entity indexes

into this set using its Type attribute, specified in the Set Index field. The Flow Times set is

17

specified in the Set module spreadsheet from the Basic Process template panel. Figure 3.17

displays the Set spreadsheet and the members of the Flow Times set.

Figure 3.16 Dialog box of the Record module Tally Flow Time

Figure 3.17 Dialog spreadsheet of the Set module (bottom) and the Members dialog

spreadsheet of the Flow Times set (top)

Arena computes travel times of transporters among Station modules based on their distances

and transporter speeds. Figure 3.18 introduces Fork Truck transporters into the model and

specifies their parameters in the Transporter module spreadsheet. These include columns for

a Name field to specify the transporter set, a capacity field (Number of Units), a Distance Set

field for specifying the name of a Distance module allowing the user to specify distances

between pairs of Station modules, a Velocity and Units fields that specify the transporter

speed (in our case, in feet per minute), and an Initial Position Status column of buttons,

which pop up the Initial Position Status dialog spreadsheet. The latter is used to specify the

location at which a transporter resides initially (at simulation time 0). Note that the

transporter speed is the default speed. Arena allows the modeler to override this value and to

18

further distinguish between the speed of an empty transporter (specified in a Request module)

and a loaded transporter (specified in a Transport module).

Figure 3.18 Dialog spreadsheet of Transporter module

Finally, the collection of fork truck utilization (a Time-Persistent statistic) and flow-time

statistics (Tally statistics) is specified in the Statistic spreadsheet module, as shown in Figure

3.19. Observe that the Arena variable nt(transporter_name) is used to collect transporter

utilization, in our case, nt(Fork Truck).

Figure 3.19 Dialog spreadsheet of the Statistic module for collecting fork truck utilization and

flow-time tallies.

3.2 SIMULATING THE MODEL

The ARENA job shop model was simulated for 1 year. Parameters like Replication Length

and Hours Per Day etc. are given in Run Setup. The Figure 3.20 shows it. While simulation,

we can see the movement of entities (gears) through different facilities, waiting for

processing, transfer between machines etc.

We are assuming that the plant works for 24 hours. i.e. Three shifts with eight hours each.

After completing the simulation, report will be generated automatically. From the generated

report, we can find Gear flow times (by type), Gear delays at operations locations, Machine

utilizations etc.

19

Figure 3.20 Dialog box of Run Setup

Figure 3.21 Screen Shot of ARENA Model

20

CHAPTER 4

RESULTS

The resulting output report is displayed in Figure 4.1. The Time per Entity section lists the

statistics of gear waiting times for each operation. As expected, the average waiting time at

the paint shop is very large as compared to the other operation locations, since spray times

are quite long. The results are displayed in graphical forms in Figure 4.2, 4.3 and 4.4.

Figure 4.2 Gear Delays at Operation Locations

Figure 4.3 Resource Utilization

0.6656

14.6109

44.8111

3.0743

0

5

10

15

20

25

30

35

40

45

50

Drilling Milling Painting Polishing

Wai

ting

Tim

e(M

inut

es)

Gear Delays At Operation Locations

8.98 12.48

44.8

29.88

37.63

0

5

10

15

20

25

30

35

40

45

50

Drilling M/C Milling M/C Paint Booth Polishing Worker Fork Truck

Utili

zati

on, %

Resource Utilization

21

Figure 4.1 Simulation results for the gear manufacturing job shop model

The Usage section displays resource utilizations at individual operation locations. For

instance, the utilization of a drilling machine is about 0.0898. The User Specified section

displays fork truck utilization statistics and flow-time statistics by gear type. The fact that the

average flow times are much larger than the total processing time bears witness to excessive

delays in resource queues.

22

Figure 4.3 Gear Flow Time

240.46

153.2

105.16

0

50

100

150

200

250

300

G1 G2 G3

Flow

Tim

e, M

inut

es

Gear Flow Time (by Type)

23

CHAPTER 5

IMPROVING THE SYSTEM

5.1 SUGGESTION FOR IMPROVEMENT

In Figure 4.2, its visible that Paint shop is having more waiting time compared to other

stations. To reduce the wait at the paint booth, we modify the job shop model by increasing

the number of paint booth from two to three. The impact of this modification on gear delays

and flow times is indicated in the simulation results of Figure 5.1. Clearly, the addition of a

paint booth has significantly reduced the delay at the paint shop but slightly increased the

delay at the polishing area, because speeding up an operation increases congestion

downstream. The overall effect on gear flow times, however, is a slight reduction.

Figure 5.1 Simulation results for the Modified Gear Manufacturing Job Shop Model

5.2 COMPARISON OF RESULTS

In the Table 5.1, its visible that Painting operation after modification has a delay of just 16

minutes compared to 44 minutes initially. This improvement is not visible in Resource

24

Utilization, see Table 5.2. Initially Resource Utilization of Paint Booth was 44% but after

improvement, it came down to 29% because the number of Paint Booth has increased by one.

But the improvement caused to reduce to Gear Flow time of all types of Gears, Table 5.3.

GEAR DELAYS AT OPERATION LOCATIONS

Initial Suggestion

Drilling 0.6656 0.6556

Milling 14.6109 14.619

Painting 44.8111 16.082

Polishing 3.0743 8.945

Table 5.1 Comparing Gear Delays at Operation Locations

RESOURCE UTILIZATION

Initial Suggestion

Drilling M/C 8.98 8.98

Milling M/C 12.48 12.48

Paint Booth 44.8 29.86

Polishing Worker 29.88 29.86

Fork Truck 37.63 37.42

Table 5.2 Comparing Resource Utilization

GEAR FLOW TIME

Initial Suggestion

G1 240.46 203.02

G2 153.2 141.93

G3 105.16 103.93

Table 5.3 Comparing Gear Flow Time

25

CHAPTER 6

CONCLUSION

The given Job Shop System was modeled in Arena Simulation software and the results were

generated. After analyzing the results, it was noticed that the waiting time in paint shop was

more compared to other stations. So a suggestion was made to increase the number of paint

booth by one. The results before and after improvement were compared. And it was found

that the waiting time in paint shop is increasing but the utilization of that station is

decreasing. The acceptance or rejection of this suggestion depends on the organization

policies. If they are ok with sacrificing the utilization of a machine compared to waiting time,

they can go ahead with this suggestion. They have to consider the cost of machine operation

and loss due to huge waiting time in a station. The trade-off lies there.

Again lot of suggestions can be made in this system, by removing some machines in a station

which has less utilization so that we can increase the utilization and we can save money in

operating the machine. We can also consider changes in the assumptions „a‟ and „b‟.

26

REFERENCE

[1]. David Kelton W., Randall P. Sadowski, Deborah A. Sadowski. 2001. Simulation with

Arena (2nd ed.), McGraw Hill.

[2]. R. Tavakkoli, M., Daneshmand Mehr. 2005. A Computer Simulation Model for Job Shop

Scheduling Problems Minimizing Makespan, Computers & Industrial Engineering, 48,

811–823.

[3]. Rahime Sancar E. & Arslan O. 2009. Simulation Analysis of Lot Streaming in Job Shops

with Transportation Queue Disciplines, Simulation Modelling Practice and Theory,

17,442–453.

[4]. Tayfur Altiok & Benjamin Melamed. 2007. Simulation Modeling and Analysis with

Arena (2nd ed.), Elsevier Inc.