SET 1 Dis Aggregation MPS

-

Upload

abhayprakashranjan -

Category

Documents

-

view

218 -

download

0

Transcript of SET 1 Dis Aggregation MPS

8/9/2019 SET 1 Dis Aggregation MPS

http://slidepdf.com/reader/full/set-1-dis-aggregation-mps 1/29

DisaggregationDisaggregation

(Master Production Scheduling)(Master Production Scheduling)

Set Set--11

1

8/9/2019 SET 1 Dis Aggregation MPS

http://slidepdf.com/reader/full/set-1-dis-aggregation-mps 3/29

Hierarchy of Plans

3

8/9/2019 SET 1 Dis Aggregation MPS

http://slidepdf.com/reader/full/set-1-dis-aggregation-mps 4/29

Master scheduling

Material requirements planning

Order scheduling

Weekly workforce and

customer scheduling

Daily workforce and customer scheduling

Process planning

Strategic capacity planning

Sales and operations (aggregate) planning

Long

range

Intermediate

range

Short

range

ManufacturingServices

Exhibit 14.1

Sales plan Aggregate operations plan

Forecasting

& demand

management

4

8/9/2019 SET 1 Dis Aggregation MPS

http://slidepdf.com/reader/full/set-1-dis-aggregation-mps 5/29

Hierarchical Planning Process

ItemsItems

Product lines orProduct lines orfamiliesfamilies

IndividualIndividualproductsproducts

ComponentsComponents

ManufacturingManufacturingoperationsoperations

ResourceResourceLevelLevel

PlantsPlants

IndividualIndividualmachinesmachines

CriticalCriticalwork work

centerscenters

ProductionProductionPlanningPlanning

CapacityCapacityPlanningPlanning

Resourcerequirements

plan

Rough-cut capacity

plan

Capacityrequirements plan

Input/ output control

Aggregateproduction

plan

Masterproduction

schedule

Materialrequirements

plan

Shop floorschedule

All work All work centerscenters

Figure 9.5Figure 9.5 5

8/9/2019 SET 1 Dis Aggregation MPS

http://slidepdf.com/reader/full/set-1-dis-aggregation-mps 7/29

Master Schedule:

The overall objective is to devise a detailed time table for individual products which allows the aggregate plan to

be achieved as efficiently as possible.

The master schedule disaggregates the aggregate plan and

specifies the number of individual products to be madein, typically, each week.

Inputs that may affect the planning process:

± Promised delivery times

± Resources

± Shortages

± Costs

± Available raw material etc.

7

8/9/2019 SET 1 Dis Aggregation MPS

http://slidepdf.com/reader/full/set-1-dis-aggregation-mps 8/29

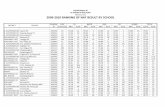

Master Schedule: (An Example)

A Bicycle manufacturer: Ladies¶ and Men¶s The aggregate plan:

± Next month 8000bikes & 6400 bikes the month after

Current stocks: 500 men¶s and 300 ladies¶

Factory capacity: 2200 bicycles a week Men¶s bicycles usually account for 60% of sales.

Actual orders received for following deliveries:

Week 1 2 3 4 5 6

M 1400 1200 1000 700 300 -

L 2000 800 400 100 - -

8

8/9/2019 SET 1 Dis Aggregation MPS

http://slidepdf.com/reader/full/set-1-dis-aggregation-mps 9/29

1 2 3 4 5 6 7 8

M Actual order 1400 1200 1000 700 300 - - -

Opening stock 500 -400 0 100 480 1140 2100 3060

Production 500 1600 1100 1080 960 960 960 960

L

Actual orders 2000 800 400 100 - - - -

Opening stock 300 0 -200 100 720 1360 2000 2640

Production 1700 600 700 720 640 640 640 640Total Prodn 2200 2200 1800 1800 1600 1600 1600 1600

Aggregate Plan <--------------8000--------------> <--------------6400-------------->

9

8/9/2019 SET 1 Dis Aggregation MPS

http://slidepdf.com/reader/full/set-1-dis-aggregation-mps 10/29

Hierarchy of Planning Decisions:

Capacity planning is a strategic function with

implications in the long term.

Strategic decisions:

± Building more facilities/Closing facilities

± Recruiting more staff/Laying off

± Changing process to use higher technology ± Increase capital investment

± selling equipment and so on

10

8/9/2019 SET 1 Dis Aggregation MPS

http://slidepdf.com/reader/full/set-1-dis-aggregation-mps 11/29

Hierarchy of Planning Decisions (contd):

Capacity plans followed by a hierarchy of decisions abouthow this capacity can be best used and what short-term

adjustments are needed:

Aggregate plans: overall production for families of

products (typically by month)

Master Schedules: a detailed time table of production for

individual products (typically by week)

Short term schedules: which show detailed allocation of

jobs to equipment (typically by day)

11

8/9/2019 SET 1 Dis Aggregation MPS

http://slidepdf.com/reader/full/set-1-dis-aggregation-mps 12/29

An ILLUSTRATIVE EXAMPLE:

A company which makes bicycles in three plants.The series of decisions are:

1. ST

RAT

EGIC PLANS: Make fundamental decisions ± Make bikes for next few years

± Product and process design decisions

± Continue operations in 3 factories A, B and C

12

8/9/2019 SET 1 Dis Aggregation MPS

http://slidepdf.com/reader/full/set-1-dis-aggregation-mps 13/29

2. CAPACITY PLANS: examine long-term forecasts

and make adjustments to match capacity to these

Long term forecasts suggest sale of 5000 bikes a year.

There is a shortage of capacity of 2000 bikes a year.

Decisions made: ± Factory A to make 1000 bikes a year (AS USUAL)

± Factory B to make 2000 bikes a year (ALLOW 2

SHIFTS)

± Factory C to make 2000 bikes a year (INCREASESTAFF)

13

8/9/2019 SET 1 Dis Aggregation MPS

http://slidepdf.com/reader/full/set-1-dis-aggregation-mps 14/29

3. AGGREGATE PLANS: breaks down capacity plans

into monthly plans for individual facilities.

Typical Decisions:

± Factory A to make 100 bikes in January. This needs a

staff of 100 and achieves9

0% utilization of equipment

± Factory B to make 250 bikes in January. This needs

200 staff and achieves 85% utilization of equipment.

± And so on«.

14

8/9/2019 SET 1 Dis Aggregation MPS

http://slidepdf.com/reader/full/set-1-dis-aggregation-mps 15/29

4. MASTER SCHEDULE: breaks down aggregate

plans into weekly plans for individual product

s.

Typical Decisions (in FACTOR Y A):

± Week 1 of January (10 alpha bikes; 5 beta bikes; 10

super bikes) ± Week 2 of January (5 alpha and 25 super bikes)

± Week 3 of January (10 alpha bikes and 10 super

bikes)

± And so on«.

15

8/9/2019 SET 1 Dis Aggregation MPS

http://slidepdf.com/reader/full/set-1-dis-aggregation-mps 16/29

5. SHOR T TERM SCHEDULES: breaks down

master schedule into daily timetable for individualbatches of bikes and equipments.

Typical Decisions (in FACTOR Y A; WEEK 1 of JAN):

± MONDAY

MORNING SH

IFT

1 alpha bike on machines 1 to 4

1 super bike on machines 5 to 8 then

1 beta bike on machines 1 to 8

± MONDAY AFTERNOON SHIFT

2 BETA BIKES ON MACHINES 1 TO 8

± TUESDAY MORNING SHIFT

± And so on«.

16

8/9/2019 SET 1 Dis Aggregation MPS

http://slidepdf.com/reader/full/set-1-dis-aggregation-mps 17/29

QUIZ:

Broadening the planning horizon from a single-stage

to a multi-stage model can improve the effectiveness

of the aggregate planning system.

[TRUE OR FALSE]

WHY?

17

8/9/2019 SET 1 Dis Aggregation MPS

http://slidepdf.com/reader/full/set-1-dis-aggregation-mps 18/29

Iterative Planning Process

18

8/9/2019 SET 1 Dis Aggregation MPS

http://slidepdf.com/reader/full/set-1-dis-aggregation-mps 19/29

Type of Production Planning & Control Systems

19

8/9/2019 SET 1 Dis Aggregation MPS

http://slidepdf.com/reader/full/set-1-dis-aggregation-mps 20/29

Type of Production Planning & Control Systems (contd)

20

8/9/2019 SET 1 Dis Aggregation MPS

http://slidepdf.com/reader/full/set-1-dis-aggregation-mps 21/29

Type of Production Planning & Control Systems (contd)

21

8/9/2019 SET 1 Dis Aggregation MPS

http://slidepdf.com/reader/full/set-1-dis-aggregation-mps 22/29

Type of Production Planning & Control Systems (contd)

22

8/9/2019 SET 1 Dis Aggregation MPS

http://slidepdf.com/reader/full/set-1-dis-aggregation-mps 23/29

Key Points Covered Importance of hierarchical planning

Importance of robust plans (aiming for

DFX)

Types of Production Planning and Control

Systems

23

8/9/2019 SET 1 Dis Aggregation MPS

http://slidepdf.com/reader/full/set-1-dis-aggregation-mps 24/29

References:

Buffa,E.S., and R.K.Sarin, Modern Production/OperationsManagement, 8th Ed. or latest John Wiley & Sons, 1987.

Hax, A. C. and D. Candea, Production and Inventory Management,

Prentice-Hall Inc., New Jersey, 1984

Waters, C.D.J., Operations Management, Publisher ?? & Year ??

Operations Management by N. Gaither and G. Frazier

Operations Management by Roberta S. Russell & Bernard W.

Taylor; Pearson Education

Operations Management for Competitive Advantage by Richard

B. Chase, F. Robert Jacobs, Nicholas J. Aquilano, and Nitin K

Agarwal; Tata McGraw-Hill (Eleventh Edition; Sixth Reprint 2008)

2

4

8/9/2019 SET 1 Dis Aggregation MPS

http://slidepdf.com/reader/full/set-1-dis-aggregation-mps 25/29

Appendix-1

25

8/9/2019 SET 1 Dis Aggregation MPS

http://slidepdf.com/reader/full/set-1-dis-aggregation-mps 26/29

FG Inv

Customers

RMInv

Produce parts & subassemblies

WIP InvAssemble Finished Products

Pond Draining Approach to PPC

(Source: Gaither & Frazier)

Suppliers

26

8/9/2019 SET 1 Dis Aggregation MPS

http://slidepdf.com/reader/full/set-1-dis-aggregation-mps 27/29

Challenges to MPS: Capacity and resource constraints

Deriving a detailed operational plan from a

general aggregate plan

± Meeting customers by Due Date

± Meeting finance by min. inventory

± Meeting mgt. by max. productivity; customer service; and min. resource consumption

± Meeting Mfr. by lead-time; and set-up time

27

8/9/2019 SET 1 Dis Aggregation MPS

http://slidepdf.com/reader/full/set-1-dis-aggregation-mps 28/29

AP ± MPS - MRP

Engg.

Design

Inventory

MRP

Aggregate Plan

MPS

Primary Prodn.

Reports

Secondary Prodn.

Reports28

8/9/2019 SET 1 Dis Aggregation MPS

http://slidepdf.com/reader/full/set-1-dis-aggregation-mps 29/29

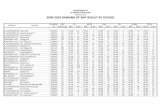

Ampere, Inc.(Example of Developing an MPS)

from 3 months¶ Agg. Plan

MonthMeter A Meter B Sub-assembly D

Known Random Known Random Known Random

3 1,000 250 410 60 200 70

4 600 250 300 60 180 70

5 300 250 500 60 250 70

MPS

Week

9 10 11 12 13 14 15 16 17

Meter A 1250 850 550

Meter B 470 360 560

Sub-assembly D 270 250 320

Delivery on 1st week of every month

Known Customer Order Forecast Random Deman

29