Sampling of Coal Dr kalyan sen Director, Central Fuel Research Institute, Dhanbad, 2003.

-

Upload

felipe-charity -

Category

Documents

-

view

217 -

download

1

Transcript of Sampling of Coal Dr kalyan sen Director, Central Fuel Research Institute, Dhanbad, 2003.

Sampling of CoalSampling of Coal

Dr kalyan sen

Director, Central Fuel Research Institute,

Dhanbad, 2003

04/18/23 2

Quality Monitoring (QM) of Coal is an essential requirement for process

control, plant performance or for any

commercial transaction between Consumer

and Producer

QM requires proper implementation QM requires proper implementation of standard sampling, preparation of standard sampling, preparation and test proceduresand test procedures

04/18/23 3

Objective

To collect a representative portion

of fuel (coal)

for determination

of quality parameters.

04/18/23 4

Purpose

Commercial Transaction Location Normally at Loading point

Parameters Ash, TM, 60% RH moisture,GCV

Quality Parameters for Power Generation

Location Normally at unloading point

Parameters Ash, TM, GCV, VM

S, N, Maceral composition

04/18/23 5

Steps for quality assessment

Sampling

Sample preparation

Analysis

04/18/23 6

Coal is heterogeneous material Very difficult to achieve highest level of

Sampling precision In terms of variance

80 % is from Sampling 20 % is from preparation & analysis

Overall precision is influenced primarily due to Sampling

Utmost importance need to be given for Sampling

04/18/23 7

Sampling methods depend onSampling methods depend on

mechanical or manual samplingmechanical or manual sampling

sampling from moving belt sampling from moving belt

sampling from stationary lot sampling from stationary lot

(wagon, stockpile, etc.)(wagon, stockpile, etc.)

04/18/23 8

Sampling types

Moving Stream

Auto-mechanical

sampling system

Manual

Stationary lot, Wagon, Stockpiles, etc.

Auto-mechanical Auger

Manual

04/18/23 9

Sampling variance is a function of product variability

i.e. different results can be obtained from

same increments for different coal

different increments for same coal

04/18/23 10

The objective is to reduce the The objective is to reduce the

sampling variance as far as sampling variance as far as

practicable practicable

04/18/23 11

Any Sampling scheme normally Any Sampling scheme normally conforms with the national or conforms with the national or international standards international standards (BIS/ISO/ASTM, etc.)(BIS/ISO/ASTM, etc.)

Constraint - technical, cost and Constraint - technical, cost and timetime

Thus modifications in sampling Thus modifications in sampling

procedures are necessary with mutual procedures are necessary with mutual

agreement between partiesagreement between parties

04/18/23 12

Precision

measures the closeness of data in given condition indicates the reproducibility of the results measures the chance error as expressed by

variance

SMALLER THE RANDOM ERROR, PRECISE IS THE METHOD

A commonly accepted index of precision is twice the population standard deviation

04/18/23 13

Precision depends onPrecision depends on

Variability of coal

number of samples from a lot

number of increments comprising each sample

mass of sample related to the nominal top size

04/18/23 14

Precision

PL = 2 * Sqrt [VI/m*n + VPT/m]

n = no. of increments m = no. of sub lots VI = Primary increment variance VPT = Preparation & testing variance PL = Overall precision

at 95% confidence level

04/18/23 15

Bias

Systematic error which leads to the

average value of a series of results being

persistently higher or lower than those

which are obtained using a reference

sampling method which is intrinsically

unbiased

04/18/23 16

Reference method of sampling Reference method of sampling

is ‘Stop Belt Method’is ‘Stop Belt Method’ (free of Bias)(free of Bias)

04/18/23 17

Design of Sampling Scheme

Basic Principles

Both for Mechanical & Manual systems

04/18/23 18

General scheme for sampling . . .General scheme for sampling . . . Decide purpose of sampling e.g. plant

performance, process control, commercial transaction

Identify the quality parameters, viz., general analysis, TM, size, washability, etc.

Define the lot Define the precision required Decide whether continuous or intermittent

sampling is required

04/18/23 19

Determine the number of sub-lots, increments to

achieve the required precision.

Determine the nominal top size of the coal

Determine the min. mass/ increment and the

min. mass of the total sample

Decide on the method of combining the different

increments for gross sample

Decide on drawing common or separate

samples, for analysis

General scheme for samplingGeneral scheme for sampling . . . . contd.contd...

04/18/23 20

General principle of SamplingGeneral principle of Sampling

Primary increments should account for the Variability

Equal probability to all particles to be selected and included in the sample

Largest particle of the lot should pass freely through the sample device

Sufficient mass of the sample to enable particles to be present in the same ratio as in the lot

04/18/23 21

SAMPLING SAMPLING FOR FOR COMMERCIAL COMMERCIAL TRANSACTIONTRANSACTION

Joint SamplingJoint Sampling• Washed coking coalWashed coking coal

• Power coalPower coal

04/18/23 22

Joint samplingJoint sampling at loading point - by customer and

producer on mutually agreed methods

at both ends - mean value

bonus/penalty to producer for values beyond agreed tolerance limits

requires periodic testing . . . Unfortunately rarely

practiced in India

04/18/23 23

Reasons for discrepancies in resultsReasons for discrepancies in results

level of precision not defined Non-identical procedures for sampling

at both ends manual sampling results in large human

error

deviation in procedures from agreed one

04/18/23 24

Primary requirements for development Primary requirements for development of a methodologyof a methodology

testing for estimation of the variances, Vi and Vpt decision on level of precision of the ash value calculation for no. of sub-lot and increment /sublot

at desired precision from known values of variances estimation of precision for the existing procedure estimation of min. mass/ sub-lot form the std. Table estimation of min. mass/ increment

04/18/23 25

SAMPLING SCHEME is designed SAMPLING SCHEME is designed based on the above testbased on the above test

The procedure can significantly The procedure can significantly

reduce the discrepancies in the reduce the discrepancies in the

results at both endsresults at both ends

04/18/23 26

Sampling of washed coking coalSampling of washed coking coal

Samples are drawn from the Automatic mechanical Sampler (AMS) Conveyor Belt

For day to day quality monitoring, samples For day to day quality monitoring, samples are reduced by offline and/or manual means are reduced by offline and/or manual means to analyze to analyze ASH & TOTAL MOISTUREASH & TOTAL MOISTURE

04/18/23 27

Sampling of Power CoalSampling of Power Coal

Best option: AMS at loading/ unloading pointBest option: AMS at loading/ unloading point

AMS for coal x200mm or above is not a AMS for coal x200mm or above is not a

proper choice to ascertain quality parameterproper choice to ascertain quality parameter

Suggestion: Suggestion: sampling on crushed coal sampling on crushed coal

below 50mm or preferably at 20mmbelow 50mm or preferably at 20mm

04/18/23 28

Where AMS is non-existing/ non-functioning , Where AMS is non-existing/ non-functioning ,

sampling may be done for the time being, at loading sampling may be done for the time being, at loading

point from the wagon by manual meanspoint from the wagon by manual means

Wagon top sampling is difficult, becauseWagon top sampling is difficult, because

• segregation occurs because of large sizesegregation occurs because of large size

• impractical to collect sample from the full depthimpractical to collect sample from the full depth

• introduces bias due to manual operationintroduces bias due to manual operation

Suggestion: smaller size (< 50mm) of the sampleSuggestion: smaller size (< 50mm) of the sample

04/18/23 29

Periodic tests

Estimate of overall precision

Estimation of increment variance

Estimation of preparation & testing variance

If the overall precision is different fromthe desired one then, number of increment

& sub lot to be modified accordingly.

04/18/23 30

Alternative

Long Term

Auto mechanical sampling system at

Sampling points

Auto mechanical Augers from the

wagons

04/18/23 31

Alternative

Short Term

Estimation of variance of sampling,

sample preparation & testing

Design a practical procedure for

routine implementation

Perform periodic test for checking

04/18/23 32

Conclusion:Conclusion:• Choice of Sampling methodology Choice of Sampling methodology depending on the purposedepending on the purpose

• Efforts to reduce the sampling Efforts to reduce the sampling variance to a min. possible limit variance to a min. possible limit

• Sampling on mechanically crushed Sampling on mechanically crushed coal below 50mm coal below 50mm

• Preferable size is 20mm ( feed to most Preferable size is 20mm ( feed to most power plants) power plants)

04/18/23 33

•Replacement of manual sampling Replacement of manual sampling method by AMSmethod by AMS

•In absence of AMS, manual wagon top In absence of AMS, manual wagon top

sampling of this size would give better sampling of this size would give better

resultsresults

• In absence of AMS, manual sampling In absence of AMS, manual sampling

from wagon top can be done as an from wagon top can be done as an

temporary option, following the temporary option, following the

prescribed methodologyprescribed methodology

Conclusion…………contd.Conclusion…………contd.

04/18/23 34

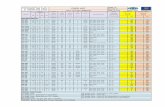

Ash Sample PreparationAsh Sample Preparation Gross Sample

Air dry & Crush to 12.5 mm

Air dry (if required oven dry at 35 deg but not more than 2 h at a time)

Reduce the sample to 2 kg

Divide into 4 parts

2 parts (Reserve); 1 part (212 micron) & 1 part (212 micron)

1 part preserve as check sample

1 part divide using laboratory divider (2 samples)

Sample A1 Sample A2

04/18/23 35

Total Moisture Sample PreparationTotal Moisture Sample PreparationGross Sample

Air dry Record wt.

Crush to 12.5mm

Reduce 2.5kgCrush to 2.8mm

Divide into 4 parts

Sample A Sample B RESERVE

Size12.5 mmabove ?

Record Initial wt.

Stage 1 loss%

Stage 2 loss%Oven dry 35deg

not exceed 2hRecord wt.

Stage 3 Moist.10g, 108deg, 2h

Y

N

04/18/23 36

Common Sample PreparationCommon Sample PreparationCommon Bottle Sample

Air dryRecord wt.

Crush to 2.8mm

Divide into 2 parts

Sample A Sample B

RESERVE

Record Initial wt.

Stage 1 loss%

Stage 2 loss%Oven dry 35degnot exceed 2hRecord wt.

Stage 3 Moist.10g, 108deg, 2h

Divide

Crush to 2.8mmCrush to 2.8mm

Sample C

Ash

Divide into 2 parts

04/18/23 37

THANKSTHANKS