RONCO | Intro to Safety and Personal Protective Equipment (PPE)

-

Upload

ronco-canada -

Category

Business

-

view

690 -

download

2

description

Transcript of RONCO | Intro to Safety and Personal Protective Equipment (PPE)

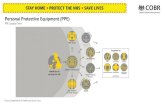

Personal Protective

Equipment

Ronco - Industrial Safety Products

An informative gathering of general knowledge on PPE.

PPE - StatisticsAccording to the Bureau of Labor Statistics (BLS), there

were more than 4 million recordable nonfatal

injuries and illnesses in private industry workplaces in

2007. And while the BLS, the Occupational Safety

& Health Administration (OSHA) and other organizations

regularly track and evaluate many details about

workplace injury and illness statistics, a key question

remains: How many of those injuries and illnesses were

the result of non-compliance or improper use of personal

protective equipment (PPE)?

PPE is more than just a good idea. In fact, OSHA requires

the use of PPE to reduce employee exposure

to hazards when engineering and administrative controls

are not feasible or effective in reducing these

exposures to acceptable levels.

Yet, 85 percent of safety professionals surveyed at the

2007 National Safety Council (NSC) Congress said they

had observed people in their organization failing to wear

PPE when they should have been. Moreover, 47 percent

said this had happened on numerous occasions.

Sixty-six percent of the safety professionals polled went

on to say that PPE compliance was an issue within

their organization – with 40 percent describing it as a

“major concern” that they were attempting to correct.

The main reasons for noncompliance, according to

these safety professionals, are a feeling of

Invulnerability among workers, lack of awareness of

workplace hazards, lack of training on proper PPE use

protocols, and ill-fitting, uncomfortable garments.

Proper Compliance Starts with Proper

Selection

First, when PPE is “connected to” the wearer,

compliance becomes more automatic.

For example, integrating earplugs with safety

glasses via a lanyard makes complying with

hearing protection protocols much easier, because

the PPE is in easy reach and is not an

afterthought.

Second, PPE that allows workers to express their

individuality leads to greater compliance. Providing

a range of options in terms of color, and other style

aspects gives workers some control over how they

look.

When people are content with their appearance in

the PPE, it follows that they will be more likely to

wear the PPE appropriately.

Third, PPE that is perceived as “cool” is more

likely to be worn. That is why many PPE

Manufacturers are looking toward the consumer

fashion and sports apparel industries for cues

on the latest styles, which can be adapted for

the PPE market.

In addition to these three themes, consider the

issue of overall PPE comfort and “wearability.”

If coveralls don’t provide adequate breathability, if

safety glasses fog up during use, or if protective

gloves don’t allow for hand dexterity, there is the

chance that users will avoid wearing the PPE, or

that they will modify the PPE in some way, thus

compromising its protective features.

PPE Training

Safety professionals typically undertake an extensive

review and analysis of the hazards in their workplaces and

the potential risks those hazards pose to their workers,

because basic hazards analyses and risk assessments are

key to the PPE selection process.

But how often are those risks and hazards clearly

communicated to workers who wear the PPE?

A key part of promoting proper compliance with

PPE protocols is making sure users are trained to

understand the consequences of non compliance.

For example, they need to understand that there is

a big difference in the PPE required -- and the

risks to a worker’s health and safety if PPE is not

properly worn -- between a worker exposed to a

quart of acetone in a well-ventilated room and a

worker exposed to a large vat of acetone in an

enclosed space.

Workers also need to understand that, even when

they may not be in imminent danger of being hurt,

some wearing protocols are designed to avoid

problems linked to long-term exposure.

Just because the danger isn’t obvious and imminent,

doesn’t mean the use protocols are less important.

Wearers should have a “commonsense“ understanding,

of why they are required to use PPE properly.

PPE training is part of OSHA’s requirements under

29 CFR 1910, which states that PPE training

programs should address:

• When PPE is necessary.

• What PPE is necessary

• How to properly don, doff, adjust and wear PPE.

• The limitations of the PPE.

• The proper care, maintenance, useful life and disposal of the PPE.

The standard goes on to state that “each affected

employee shall demonstrate an understanding of

the training specified … and the ability to use PPE

properly, before being allowed to perform work

requiring the use of PPE.”

In addition, “when the employer has reason to believe

that any affected employee who has already been trained

does not have the understanding and skill required…the

employer shall retrain each such employee.”

OSHA notes that circumstances where retraining

is required include, but are not limited to, situations

where:

• Changes in the workplace render previous training

obsolete.

• Changes in the types of PPE to be used render previous

training obsolete.

• Inadequacies in an affected employee’s knowledge or use

of assigned PPE indicate that the employee has not

retained the requisite understanding or skill.

Moreover, OSHA requires employers to verify that

each affected employee has received and

understood the required training through a

written certification that contains the name of each

employee trained, the date(s) of training, and that

identifies the subject of the certification.

PPE – Do We Know?

Improper re-use of PPE may become an even bigger issue if

we are ever faced with a pandemic, especially since PPE

may be required by people who may not normally use PPE

as part of their jobs and therefore are not trained in proper

protocols.

For example, will the general population know the difference

between a basic procedure mask and an N95 respirator?

Will they know when a mask becomes unhygienic and

“clogged” enough to warrant a new one?

Noise pollution is another commonly overlooked

protection issue that may be linked to improper

training.

The need to change the level of protection

afforded by PPE when moving from one area of a

worksite to another is not visually evident and can

be easily missed.

For example, installing and teaching workers to recognize

clear visual signage showing the exact locations in a plant

where different levels of hearing protection are needed

would be an important focus area for PPE training.

Benefits of PPE Training

While training employees in the proper use of all PPE is

important, it is especially important to educate users on the

nature of workplace hazards and the consequences of not

using PPE as well as what to do in the event of protective

clothing or equipment failure.

One essential aspect of training is to make the user aware

of the need for protective wear and to instill motivation for

its proper use and maintenance.

OSHA suggests several benefits of proper

training in the use of PPE.

• Allows the user to become familiar with the equipment

in a non-hazardous, non-emergency condition.

• Instills confidence of the user in his/her equipment.

• Makes the user aware of the limitations and

capabilities of the equipment.

• Increases worker efficiency in performing various

tasks.

• Reduces the likelihood of accidents.

And don’t forget about what happens when

the employee leaves the workplace.

Training in off-the-job safety concerns shows

an employer’s commitment to a worker’s

safety 24 hours a day.

Now for the Test!