Rhino SD3/XD3 Hydraulic Section Pump Outlet Manifolds · 2020. 10. 9. · 2 Rhino SD3/XD3 Hydraulic...

Transcript of Rhino SD3/XD3 Hydraulic Section Pump Outlet Manifolds · 2020. 10. 9. · 2 Rhino SD3/XD3 Hydraulic...

-

Rhino� SD3/XD3Hydraulic Section

Pump Outlet Manifolds

Customer Product ManualPart 1611641-05

Issued 10/20

NORDSON CORPORATION • AMHERST, OHIO • USA

For parts and technical support, call the Industrial CoatingSystems Customer Support Center at (800) 433-9319 or

contact your local Nordson representative.

This document is subject to change without notice.Check http://emanuals.nordson.com for the latest version.

-

Part 1611641-04 � 2020 Nordson Corporation

tents

Table of ContentsSafety 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Qualified Personnel 1. . . . . . . . . . . . . . . . . . . . . . . . .Intended Use 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Regulations and Approvals 1. . . . . . . . . . . . . . . . . .Personal Safety 2. . . . . . . . . . . . . . . . . . . . . . . . . . . .

High-Pressure Fluids 2. . . . . . . . . . . . . . . . . . . . .Fire Safety 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Halogenated Hydrocarbon Solvent Hazards 4.Action in the Event of a Malfunction 4. . . . . . . . . . .Disposal 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Labels 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Description 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Troubleshooting 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Heater Cartridge 7. . . . . . . . . . . . . . . . . . . . . . . . . . .Repair 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replace the Heater Cartridge 8. . . . . . . . . . . . . . . .Remove the Heater Cartridge 8. . . . . . . . . . . . .Install the New Heater Cartridge 9. . . . . . . . . . .

Parts 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Using the Illustrated Parts List 10. . . . . . . . . . . . . . .Pump Outlet Manifold 11. . . . . . . . . . . . . . . . . . . . . . .

Standard Modules 11. . . . . . . . . . . . . . . . . . . . . . . .Stainless Steel Modules 12. . . . . . . . . . . . . . . . . . .

Pump Outlet Manifolds with Ball Check Valve 13. . .Standard Modules 13. . . . . . . . . . . . . . . . . . . . . . . .Stainless Steel Modules 14. . . . . . . . . . . . . . . . . . .

Heated Pump Outlet Manifolds with Ball Check Valve 15. . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-Gallon Standard Modules 16. . . . . . . . . . . . . . . .5-Gallon Stainless Steel Modules 17. . . . . . . . . . .55-Gallon Standard Modules 18. . . . . . . . . . . . .55-Gallon Stainless Steel Modules 19. . . . . . . . .

Heated Pump Outlet Manifolds 20. . . . . . . . . . . . . . .5-Gallon Standard Modules 21. . . . . . . . . . . . . . . .5-Gallon Stainless Steel Modules 22. . . . . . . . . . .55-Gallon Standard Modules 23. . . . . . . . . . . . . . .55-Gallon Stainless Steel Modules 24. . . . . . . . .

Consumables 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contact UsNordson Corporation welcomes requests for information, comments, andinquiries about its products. General information about Nordson can befound on the Internet using the following address:http://www.nordson.com.Address all correspondence to:

Nordson CorporationAttn: Customer Service555 Jackson StreetAmherst, OH 44001

NoticeThis is a Nordson Corporation publication which is protected by copyright.Original copyright date 2017. No part of this document may bephotocopied, reproduced, or translated to another language without theprior written consent of Nordson Corporation. The information containedin this publication is subject to change without notice.

Trademarks

Nordson, the Nordson logo, and Rhino are registered trademarks ofNordson Corporation.

All other trademarks are the property of their respective owners.

-

Change Record i

Part 1611641-04� 2020 Nordson Corporation

Change RecordRevision Date Change

03 6/19 Converted from instruction sheet to manual; added heated check valveand outlet modules.

05 10/20 Added standard pump outlet manifolds

-

Change Recordii

Part 1611641-04 � 2020 Nordson Corporation

-

Rhino� SD3/XD3 Hydraulic Section Pump Outlet Manifolds 1

Part 1611641-04� 2020 Nordson Corporation

Rhino� SD3/XD3 Hydraulic Section PumpOutlet Manifolds

Safety Read and follow these safety instructions. Task- and equipment-specificwarnings, cautions, and instructions are included in equipmentdocumentation where appropriate.

Make sure all equipment documentation, including these instructions, isaccessible to persons operating or servicing equipment.

Qualified Personnel Equipment owners are responsible for making sure that Nordson equipmentis installed, operated, and serviced by qualified personnel. Qualifiedpersonnel are those employees or contractors who are trained to safelyperform their assigned tasks. They are familiar with all relevant safety rulesand regulations and are physically capable of performing their assignedtasks.

Intended Use Use of Nordson equipment in ways other than those described in thedocumentation supplied with the equipment may result in injury to personsor damage to property.

Some examples of unintended use of equipment include

� using incompatible materials

� making unauthorized modifications

� removing or bypassing safety guards or interlocks

� using incompatible or damaged parts

� using unapproved auxiliary equipment

� operating equipment in excess of maximum ratings

Regulations and Approvals Make sure all equipment is rated and approved for the environment in whichit is used. Any approvals obtained for Nordson equipment will be voided ifinstructions for installation, operation, and service are not followed.

-

Rhino� SD3/XD3 Hydraulic Section Pump Outlet Manifolds2

Part 1611641-04 � 2020 Nordson Corporation

Personal Safety To prevent injury follow, these instructions.

� Do not operate or service equipment unless you are qualified.

� Do not operate equipment unless safety guards, doors, or covers areintact and automatic interlocks are operating properly. Do not bypass ordisarm any safety devices.

� Keep clear of moving equipment. Before adjusting or servicing movingequipment, shut off the power supply and wait until the equipmentcomes to a complete stop. Lock out power and secure the equipment toprevent unexpected movement.

� Relieve (bleed off) hydraulic and pneumatic pressure before adjusting orservicing pressurized systems or components. Disconnect, lock out,and tag switches before servicing electrical equipment.

� While operating manual spray guns, make sure you are grounded.Wear electrically conductive gloves or a grounding strap connected tothe gun handle or other true earth ground. Do not wear or carry metallicobjects such as jewelry or tools.

� If you receive even a slight electrical shock, shut down all electrical orelectrostatic equipment immediately. Do not restart the equipment untilthe problem has been identified and corrected.

� Obtain and read Safety Data Sheets (SDS) for all materials used.Follow the manufacturer’s instructions for safe handling and use ofmaterials, and use recommended personal protection devices.

� Make sure the spray area is adequately ventilated.

� To prevent injury, be aware of less-obvious dangers in the workplacethat often cannot be completely eliminated, such as hot surfaces, sharpedges, energized electrical circuits, and moving parts that cannot beenclosed or otherwise guarded for practical reasons.

High-Pressure Fluids High-pressure fluids, unless they are safely contained, are extremelyhazardous. Always relieve fluid pressure before adjusting or servicing highpressure equipment. A jet of high-pressure fluid can cut like a knife andcause serious bodily injury, amputation, or death. Fluids penetrating theskin can also cause toxic poisoning.

If you suffer a fluid injection injury, seek medical care immediately. Ifpossible, provide a copy of the SDS for the injected fluid to the health careprovider.

-

Rhino� SD3/XD3 Hydraulic Section Pump Outlet Manifolds 3

Part 1611641-04� 2020 Nordson Corporation

The National Spray Equipment Manufacturers Association has created awallet card that you should carry when you are operating high-pressurespray equipment. These cards are supplied with your equipment. Thefollowing is the text of this card:

WARNING: Any injury caused by high pressure liquid can be serious. Ifyou are injured or even suspect an injury:

� Go to an emergency room immediately.

� Tell the doctor that you suspect an injection injury.

� Show him this card

� Tell him what kind of material you were spraying

MEDICAL ALERT—AIRLESS SPRAY WOUNDS: NOTE TO PHYSICIAN

Injection in the skin is a serious traumatic injury. It is important to treat theinjury surgically as soon as possible. Do not delay treatment to researchtoxicity. Toxicity is a concern with some exotic coatings injected directly intothe bloodstream.

Consultation with a plastic surgeon or a reconstructive hand surgeon maybe advisable.

The seriousness of the wound depends on where the injury is on the body,whether the substance hit something on its way in and deflected causingmore damage, and many other variables including skin microflora residingin the paint or gun which are blasted into the wound. If the injected paintcontains acrylic latex and titanium dioxide that damage the tissue’sresistance to infection, bacterial growth will flourish. The treatment thatdoctors recommend for an injection injury to the hand includes immediatedecompression of the closed vascular compartments of the hand to releasethe underlying tissue distended by the injected paint, judicious wounddebridement, and immediate antibiotic treatment.

Fire Safety To avoid a fire or explosion, follow these instructions.

� Ground all conductive equipment. Use only grounded air and fluidhoses. Check equipment and workpiece grounding devices regularly.Resistance to ground must not exceed one megohm.

� Shut down all equipment immediately if you notice static sparking orarcing. Do not restart the equipment until the cause has been identifiedand corrected.

� Do not smoke, weld, grind, or use open flames where flammablematerials are being used or stored.

� Do not heat materials to temperatures above those recommended bythe manufacturer. Make sure heat monitoring and limiting devices areworking properly.

-

Rhino� SD3/XD3 Hydraulic Section Pump Outlet Manifolds4

Part 1611641-04 � 2020 Nordson Corporation

Fire Safety (contd)� Provide adequate ventilation to prevent dangerous concentrations of

volatile particles or vapors. Refer to local codes or your material SDSfor guidance.

� Do not disconnect live electrical circuits when working with flammablematerials. Shut off power at a disconnect switch first to preventsparking.

� Know where emergency stop buttons, shutoff valves, and fireextinguishers are located. If a fire starts in a spray booth, immediatelyshut off the spray system and exhaust fans.

� Shut off electrostatic power and ground the charging system beforeadjusting, cleaning, or repairing electrostatic equipment.

� Clean, maintain, test, and repair equipment according to the instructionsin your equipment documentation.

� Use only replacement parts that are designed for use with originalequipment. Contact your Nordson representative for parts informationand advice.

Halogenated Hydrocarbon Solvent Hazards Do not use halogenated hydrocarbon solvents in a pressurized system thatcontains aluminum components. Under pressure, these solvents can reactwith aluminum and explode, causing injury, death, or property damage.Halogenated hydrocarbon solvents contain one or more of the followingelements:

Element Symbol Prefix

Fluorine F “Fluoro-”

Chlorine Cl “Chloro-”

Bromine Br “Bromo-”

Iodine I “Iodo-”

Check your material SDS or contact your material supplier for moreinformation. If you must use halogenated hydrocarbon solvents, contactyour Nordson representative for information about compatible Nordsoncomponents.

Action in the Event of a Malfunction If a system or any equipment in a system malfunctions, shut off the systemimmediately and perform the following steps:

� Disconnect and lock out system electrical power. Close hydraulic andpneumatic shutoff valves and relieve pressures.

� Identify the reason for the malfunction and correct it before restarting thesystem.

Disposal Dispose of equipment and materials used in operation and servicingaccording to local codes.

-

Rhino� SD3/XD3 Hydraulic Section Pump Outlet Manifolds 5

Part 1611641-04� 2020 Nordson Corporation

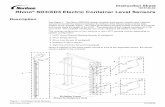

Safety Labels Table 1 lists the safety labels on this equipment. The safety labels areprovided to help you operate and maintain this equipment safely.See Figure 1 for the location of the safety labels.

Table 1 Safety Labels

Item Description

1WARNING: Electrical hazard

2WARNING: Hot surface hazard

12

Figure 1 Safety Labels

-

Rhino� SD3/XD3 Hydraulic Section Pump Outlet Manifolds6

Part 1611641-04 � 2020 Nordson Corporation

Description See Figure 2.

The following Rhino� SD3/XD3 hydraulic section pump outlet manifoldsare available:

� With and without a ball check valve; carbon steel and stainless steel

� Heated and unheated; carbon steel and stainless steel

The pump outlet manifold with the ball check valve is typically used in dualunloader systems where the unloader cannot sense back pressure from theother unloader during operation.

Without the ball check valve, the pump outlet manifold serves as a mountinglocation for the material outlet hose, bleeder valve assembly, and otheroptional functions which are contained in the ball check valve manifold.

NOTE: The pump body is onlyshown for reference and is notincluded with the assembly.

UNHEATED HEATED

10016448/10018196

Figure 2 Typical Hydraulic Section Pump Outlet Manifold Modules

SpecificationsMaximum material pressure 6000 psi (413 bar)

Opening pressure (applicable to check valve only) 20 psi (1.4 bar)

Large frame outlet port size 11/4-in. SAE, size 20 O-ring boss,

15/8-12 UNF-2B thread

Small frame outlet port size3/4-in. SAE, size 12 O-ring boss,11/16-12 UNF-2B thread

Heated Module Wattage Standard Wattage: 240 V, 50 W

High Wattage: 240 V, 100 W

-

Rhino� SD3/XD3 Hydraulic Section Pump Outlet Manifolds 7

Part 1611641-04� 2020 Nordson Corporation

Troubleshooting WARNING: Allow only qualified personnel to perform the following tasks.Follow the safety instructions in this document and all other relateddocumentation.

These troubleshooting procedures cover only the most common problems.If you cannot solve a problem with the information given here, contact yourlocal Nordson representative for help.

Heater Cartridge

Problem Possible Cause Corrective Action

1. Setpoint temperaturenot achieved

Failed heater cartridge 1. See Figure 3. Perform a resistance teston the heater cartridge.

Standard wattageheater cartridge: 443.2−603.3 Ω

High wattageheater cartridge: 221.6−301.6 Ω

2. Replace the heater cartridge if test fails.

HEATER CARTRIDGE

HEATER CARTRIDGE

3−WIRE FLOATING CONNECTORS

CORDSET

1 2

Figure 3 Wiring Diagram

-

Rhino� SD3/XD3 Hydraulic Section Pump Outlet Manifolds8

Part 1611641-04 � 2020 Nordson Corporation

Repair WARNING: Allow only qualified personnel to perform the following tasks.Follow the safety instructions in this document and all other relateddocumentation.

Personnel performing repairs must know how to safely operate the Rhinobulk unloader.

Replace the Heater Cartridge

WARNING: Lockout power to the pump outlet manifoldbefore performing this procedure.

Refer to Table 2 for the items required to perform this procedure.

Table 2 Required Items

Item Use

Metric hex socket set Removing M12 screws

Foot pound torque wrench Tightening the M12 screws.

Inch pound torque wrench Tightening the cover plate screws.

Heatsink compound Apply onto OD of new heatercartridge and ID of heatercartridge bore.

Never-Seez� Apply to threads on M12 Screws

Remove the Heater Cartridge See Figure 4.

1. Relieve system and material pressure before proceeding with thisprocedure.

2. Disconnect the cordset connector (8) from the power source.

NOTE: Check Valve Manifolds Only: When removing a check valvemanifold from the hydraulic section, the ball (11) and spring (10) may fallout. Handle with care to prevent damaging these parts.

3. Remove the screws (2) securing the manifold body (1) to the hydraulicsection (13).

4. Remove the screws (5) securing the cover plate (4) and gasket (3) tothe manifold body (1).

5. Carefully pull out the 3-wire connectors (7) from the manifold body (1).Disconnect the heater cartridge (6) wires as shown in Figure 4.

6. Remove the pipe plug (9) from the rear of the manifold body (1).

7. Use a punch (12) to push out the heater cartridge (6) from the rear ofthe manifold body. Remove the heater cartridge.

-

Rhino� SD3/XD3 Hydraulic Section Pump Outlet Manifolds 9

Part 1611641-04� 2020 Nordson Corporation

Install the New Heater Cartridge See Figure 4.

NOTE: The heater cartridge must be fully inserted into the heater cartridgebore. When the pipe plug is reinstalled, trapped air will force the heatercartridge slightly back.

1. Apply heatsink compound to the OD of the new heater cartridge (6) andto the ID of the bore. Insert the heater cartridge into the manifoldbody (1).

2. Reconnect the heater cartridge (6) wires to the 3-wire connectors (7) asshown in Figure 4. Carefully insert the 3-wire connectors into themanifold body (1).

3. Reinstall the gasket (3) and the cover plate (4) using the screws (5).Tighten the screws to 60−75 in.-lb (6.8−8.5 N•m).

4. Reinstall the manifold body (1) to the hydraulic section (13):

a. Check Valve Manifolds Only: Reinstall the spring (10) and ball (11)if they fell out when the manifold body was removed from thehydraulic section.

b. Apply Never-Seez to the threads of the screws (2). Reinstall themanifold to the hydraulic section using the screws. Tighten thescrews to 50-55 ft-lb (67.8-74.6 N•m).

5. Reconnect the cordset connector (8) to the power source.

1

3

4

5

2

7 6

8

912

10

1113

Figure 4 Typical Heater Cartridge Replacement (check valve manifold shown)

-

Rhino� SD3/XD3 Hydraulic Section Pump Outlet Manifolds10

Part 1611641-04 � 2020 Nordson Corporation

Parts To order parts, call the Nordson Industrial Coating Systems CustomerSupport Center at (800) 433-9319 or contact your local Nordsonrepresentative.

Using the Illustrated Parts List Numbers in the Item column correspond to numbers that identify parts inillustrations following each parts list. The code NS (not shown) indicatesthat a listed part is not illustrated. A dash (—) is used when the part numberapplies to all parts in the illustration.

The number in the Part column is the Nordson Corporation part number. Aseries of dashes in this column (−−−−−−) means the part cannot be orderedseparately.

The Description column gives the part name, as well as its dimensions andother characteristics when appropriate. Indentions show the relationshipsbetween assemblies, subassemblies, and parts.

� If you order the assembly, items 1 and 2 will be included.

� If you order item 1, item 2 will be included.

� If you order item 2, you will receive item 2 only.

The number in the Quantity column is the quantity required per unit,assembly, or subassembly. The code AR (As Required) is used if the partnumber is a bulk item ordered in quantities or if the quantity per assemblydepends on the product version or model.

Letters in the Note column refer to notes at the end of each parts list. Notescontain important information about usage and ordering. Special attentionshould be given to notes.

Item Part Description Quantity Note— 0000000 Assembly 11 000000 � Subassembly 2 A2 000000 � � Part 1

-

Rhino� SD3/XD3 Hydraulic Section Pump Outlet Manifolds 11

Part 1611641-04� 2020 Nordson Corporation

Pump Outlet ManifoldSee Figure 5 and refer to the following parts lists.

10016486

3

5

1

4

2

NOTE: The pump body is onlyshown for reference and is notincluded with the assembly.

Figure 5 Pump Outlet Manifold with Ball Check Valve

Standard Modules

Item Part Part Part Part Description Qty Note

— 1611598 — — —MODULE, pump outlet, 55-gallon,bleeder, carbon steel 1

— — 1611597 — —MODULE, pump outlet, 55-gallon,depressurization, carbon steel 1

— — — 1611596 —MODULE, pump outlet, 5-gallon, bleeder,carbon steel 1

— — — — 1611509MODULE, check valve, 5-gallon,depressurization, carbon steel 1

1 973410 — 973410 — � PLUG, pipe, socket head, standard,¼, zinc 1

2 1041272 1041272 1041272 1041272 � O-RING, −131, Viton�, 1.674 ID,

0.103 W 1 A

3 303706 303706 303706 303706 � O-RING, −920, Viton, 1.475 ID, 0.118W 1 A

4 973477 973477 973477 973477 � PLUG, O-ring, straight thread, 1-¼tube, Zinc 1 A

5 −−−−−− −−−−−− −−−−−− −−−−−− � SCREW, socket, M12 x 130, zinc,Class 12.9, per ISO 4762 4 B

NOTE A: Apply adhesive before installing.

B: Apply Mobil SHC 634 before installing.

-

Rhino� SD3/XD3 Hydraulic Section Pump Outlet Manifolds12

Part 1611641-04 � 2020 Nordson Corporation

Stainless Steel Modules

Item Part Part Part Part Description Qty Note

— 1611602 — — —MODULE, pump outlet, 55-gallon,bleeder, stainless steel 1

— — 1611601 — —MODULE, pump outlet, 55-gallon,depressurization, stainless steel 1

— — — 1611600 —MODULE, pump outlet, 5-gallon, bleeder,stainless steel 1

— — — — 1611509MODULE, pump outlet, 5-gallon,depressurization, stainless steel 1

1 973415 — 973415 — � PLUG, pipe, socket head, standard,¼, stainless steel 1

2 1041272 1041272 1041272 1041272 � O-RING, −131, Viton�, 1.674 ID,

0.103 W 1 A

3 303706 303706 303706 303706 � O-RING, −920, Viton, 1.475 ID, 0.118W 1 A

4 1057808 1057808 1057808 1057808 � PLUG, O-ring, straight thread, 1-¼tube, stainless steel 1 A

5 −−−−−− −−−−−− −−−−−− −−−−−− � SCREW, socket, M12 x 130, zinc,Class 12.9, per ISO 4762 4 B

NOTE A: Apply adhesive before installing.

B: Apply Mobil SHC 634 before installing.

-

Rhino� SD3/XD3 Hydraulic Section Pump Outlet Manifolds 13

Part 1611641-04� 2020 Nordson Corporation

Pump Outlet Manifolds with Ball Check ValveSee Figure 6 and refer to the following parts lists.

10016448

NOTE: The pump body is onlyshown for reference and is notincluded with the assembly.

12

34

5

6

7

9

8

1

Figure 6 Pump Outlet Manifold with Ball Check Valve

Standard Modules

Item Part Part Part Part Description Qty Note— 1611506 — — — MODULE, check valve, large flow, bleed 1

— — 1611507 — —MODULE, check valve, large flow,depressurization 1

— — — 1611508 — MODULE, check valve, small flow, bleed 1

— — — — 1611509MODULE, check valve, small flow,depressurization 1

1 303706 303706 303706 303706 � O-RING, −920, Viton�, 1.475 ID,

0.118 W 2 A

2 1039067 1039067 1039067 1039067 � SEAT, ball, check valve, Rhino SD 1

3 1041272 1041272 1041272 1041272 � O-RING, −131, Viton, 1.674 ID,0.103 W 1 A

4 900006 900006 900006 900006 � BALL, 440 stainless steel, 1.500, 100 15 −−−−−− — −−−−−− — � PLUG, pipe, socket, standard, ¼ NPT 1 B

6 987066 987066 987066 987066 � SPRING, compression, 2.000 x 1.225 OD x 0.125 1

7 1101360 1101360 1101360 1101360 � PLUG, SAE, 1−5/8−12 straight thread,check valve 1 A

8 −−−−−− −−−−−− −−−−−− −−−−−− � SCREW, socket, M12 x 1.75 x 130,zinc, Class 12.9, per ISO 4762 4 C

9 — — 1081041 1081041 � REDUCER, 1 1/16−12 F x 1 ⅝−12 m, steel, Viton 1 A

NOTE A: Apply Mobil SHC 634 before installing.

B: Apply adhesive before installing.

C: Apply Never Seez before installing.

-

Rhino� SD3/XD3 Hydraulic Section Pump Outlet Manifolds14

Part 1611641-04 � 2020 Nordson Corporation

Pump Outlet Manifolds with Ball Check Valve(contd)

Stainless Steel Modules

Item Part Part Part Part Description Qty Note

— 1611510 — — —MODULE, check valve, large flow,stainless steel, bleed 1

— — 1611511 — —MODULE, check valve, large flow,stainless steel, depressurization 1

— — — 1611512 —MODULE, check valve, small flow,stainless steel, bleed 1

— — — — 1611513MODULE, check valve, small flow,stainless steel, depressurization 1

1 303706 303706 303706 303706 � O-RING, −920, Viton, 1.475 ID,0.118 W 2 A

2 1057807 1057807 1057807 1057807 � SEAT, ball, check valve, Rhino SD, stainless steel 1

3 1041272 1041272 1041272 1041272 � O-RING, −131, Viton, 1.674 ID,0.103 W 1 A

4 900006 900006 900006 900006 � BALL, 440 stainless steel, 1.500, 100 1

5 −−−−−− — −−−−−− — � PLUG, pipe, socket, standard,¼ NPT, stainless steel 1 B

6 987066 987066 987066 987066 � SPRING, compression, 2.000 x 1.225 OD x 0.125 1

7 1101346 1101346 1101346 1101346 � PLUG, SAE, 1−5/8−12 straight thread,check valve, stainless steel 1 A

8 −−−−−− −−−−−− −−−−−− −−−−−−� SCREW, socket, M12 x 1.75 x 130,

zinc, Class 12.9, per ISO 4762

4 C

9 — — 1613337 1613337 � REDUCER, 1 1/16−12 F x 1 ⅝−12 m, Viton, stainless steel 1 A

NOTE A: Apply Mobil SHC 634 before installing.

B: Apply adhesive before installing.

C: Apply Never Seez before installing.

-

Rhino� SD3/XD3 Hydraulic Section Pump Outlet Manifolds 15

Part 1611641-04� 2020 Nordson Corporation

Heated Pump Outlet Manifolds with Ball Check ValveNOTE: Manifolds for the 5-gallon Rhino bulk unloader begin on page 16.Manifolds for the 55-gallon Rhino bulk unloader begin on page 18.

See Figure 7 and refer to the following parts lists.

NOTE: The pump body is onlyshown for reference and is notincluded with the assembly.

1

2

34

5

6

10

9

11

12

13

161

15

14

17

78

Figure 7 Heated Pump Outlet Manifold with Ball Check Valve

-

Rhino� SD3/XD3 Hydraulic Section Pump Outlet Manifolds16

Part 1611641-04 � 2020 Nordson Corporation

5-Gallon Standard Modules

Item Part Part Part Part Description Qty Note

— 1614893 — — —MODULE, check valve, 5-gallon, bleed,240 V, standard wattage 1

— — 1614894 — —MODULE, check valve, 5-gallon, bleed,240 V, high wattage 1

— — — 1614901 —MODULE, check valve, 5-gallon,depressurization, 240 V, standard wattage 1

— — — — 1614902MODULE, check valve, 5-gallon,depressurization, 240 V, high wattage 1

1 303706 303706 303706 303706 � O-RING, −920, Viton�, 1.475 ID,

0.118 W 2 A

2 1039067 1039067 1039067 1039067 � SEAT, ball, check valve, Rhino SD, 1

3 1041272 1041272 1041272 1041272 � O-RING, −131, Viton, 1.674 ID 0.103 W 1 A

4 900006 900006 900006 900006 � BALL, 440 stainless steel, 1.500, 100 1

5 −−−−−− − − − − − −−−−−− −−−−−− � PLUG, pipe, socket, standard,¼ NPT, zinc 2/3 B

6 1615315 1615315 1615315 1615315 � CORDSET, check valve, RhinoSD3, heated 1

7 1605675 1605675 1605675 1605675 � CONNECTOR, strain relief,0.260−0.545, ½ NPT 1

8 −−−−−− −−−−−− −−−−−− −−−−−− � NUT, lock, conduit, steel, 0.5 in. 1

9 1615308 1615308 1615308 1615308 � CONNECTOR, plastic, 3-station,12−24 AWG 2

10 1615774 — 1615774 — � HEATER cartridge, 0.38 diameter x3.25 long, 240 V, 50 W 2 C

10 — 1615777 — 1615777 � HEATER cartridge, 0.38 diameter x3.25 long, 240 V, 100 W 2 C

11 1614835 1614835 1614835 1614835 � GASKET, check valve, SD3, heated 1

12 −−−−−− −−−−−− −−−−−− −−−−−− � PLATE, cover, check valve,SD3, heated 1

13 −−−−−− −−−−−− −−−−−− −−−−−− � SCREW, button, socket, M5 x 10,zinc, Class 10.9, per ISO 7380 5

14 −−−−−− −−−−−− −−−−−− −−−−−− � SCREW, socket, M12 x 1.75 x 130,zinc, Class 12.9, per ISO 4762 4 D

15 1101360 1101360 1101360 1101360 � PLUG, SAE, 1−5/8−12 straight thread,check valve 1 A

16 987066 987066 987066 987066 � SPRING, compression, 2.000 x 1.225 OD x 0.125 1

17 1081041 1081041 1081041 1081041 � REDUCER, 1 1/16−12 F x 1 ⅝−12 m, steel, Viton 1 A

NOTE A: Apply Mobil SHC 634 before installing.

B: Depressurization modules use 2. Bleed modules use 3. Apply adhesive before installing.

C: Apply heatsink compound before installing.

D: Apply Never Seez before installing.

-

Rhino� SD3/XD3 Hydraulic Section Pump Outlet Manifolds 17

Part 1611641-04� 2020 Nordson Corporation

5-Gallon Stainless Steel Modules

Item Part Part Part Part Description Qty Note

— 1614897 — — —MODULE, check valve, 5-gallon, bleed,stainless steel, 240 V, standard wattage 1

— — 1614898 — —MODULE, check valve, 5-gallon, bleed,stainless steel, 240 V, high wattage 1

— — — 1614905 —MODULE, check valve, 5-gallon,stainless steel, depressurization,240 V, standard wattage

1

— — — — 1614906MODULE, check valve, 5-gallon,stainless steel, depressurization,240 V, high wattage

1

1 303706 303706 303706 303706 � O-RING, −920, Viton�, 1.475 ID,

0.118 W 2 A

2 1057807 1057807 1057807 1057807 � SEAT, ball, check valve, Rhino SD,stainless steel 1

3 1041272 1041272 1041272 1041272 � O-RING, −131, Viton, 1.674 ID 0.103 W 1 A

4 900006 900006 900006 900006 � BALL, 440 stainless steel, 1.500, 100 1

5 −−−−−− −−−−−− − − − − − − − − − − � PLUG, pipe, socket, standard,¼ NPT, stainless steel 2/3 B

6 1615315 1615315 1615315 1615315 � CORDSET, check valve, RhinoSD3, heated 1

7 1605675 1605675 1605675 1605675 � CONNECTOR, strain relief,0.260−0.545, ½ NPT 1

8 −−−−−− −−−−−− −−−−−− −−−−−− � NUT, lock, conduit, steel, 0.5 in. 1

9 1615308 1615308 1615308 1615308 � CONNECTOR, plastic, 3-station,12−24 AWG 2

10 1615774 — 1615774 — � HEATER cartridge, 0.38 diameter x3.25 long, 240 V, 50 W 2 C

10 — 1615777 — 1615777 � HEATER cartridge, 0.38 diameter x3.25 long, 240 V, 100 W 2 C

11 1614835 1614835 1614835 1614835 � GASKET, check valve, SD3, heated 1

12 −−−−−− −−−−−− −−−−−− −−−−−− � PLATE, cover, check valve,SD3, heated 1

13 −−−−−− −−−−−− −−−−−− −−−−−− � SCREW, button, socket, M5 x 10,zinc, Class 10.9, per ISO 7380 5

14 −−−−−− −−−−−− −−−−−− −−−−−− � SCREW, socket, M12 x 1.75 x 130,zinc, Class 12.9, per ISO 4762 4 D

15 1101346 1101346 1101346 1101346 � PLUG, SAE, 1−5/8−12 straight thread,check valve, stainless steel 1 A

16 987066 987066 987066 987066 � SPRING, compression, 2.000 x 1.225 OD x 0.125 1

17 1613337 1613337 1613337 1613337 � REDUCER, 1 1/16−12 F x 1 ⅝−12 m, stainless steel, Viton 1 A

NOTE A: Apply Mobil SHC 634 before installing.

B: Depressurization modules use 2. Bleed modules use 3. Apply adhesive before installing.

C: Apply heatsink compound before installing.

D: Apply Never Seez before installing.

-

Rhino� SD3/XD3 Hydraulic Section Pump Outlet Manifolds18

Part 1611641-04 � 2020 Nordson Corporation

55-Gallon Standard Modules

Item Part Part Part Part Description Qty Note

— 1614895 — — —MODULE, check valve, 55-gallon, bleed,240 V, standard wattage 1

— — 1614896 — —MODULE, check valve, 55-gallon, bleed,240 V, high wattage 1

— — — 1614903 —MODULE, check valve, 55-gallon,depressurization, 240 V, standard wattage 1

— — — — 1614904MODULE, check valve, 55-gallon,depressurization, 240 V, high wattage 1

1 303706 303706 303706 303706 � O-RING, −920, Viton�, 1.475 ID,

0.118 W 2 A

2 1039067 1039067 1039067 1039067 � SEAT, ball, check valve, Rhino SD 1

3 1041272 1041272 1041272 1041272 � O-RING, −131, Viton, 1.674 ID 0.103 W 1 A

4 900006 900006 900006 900006 � BALL, 440 stainless steel, 1.500, 100 1

5 −−−−−− −−−−−− − − − − − −−−−−− � PLUG, pipe, socket, standard,¼ NPT, zinc 2/3 B

6 1615315 1615315 1615315 1615315 � CORDSET, check valve, RhinoSD3, heated 1

7 1605675 1605675 1605675 1605675 � CONNECTOR, strain relief,0.260−0.545, ½ NPT 1

8 −−−−−− −−−−−− −−−−−− −−−−−− � NUT, lock, conduit, steel, 0.5 in. 1

9 1615308 1615308 1615308 1615308 � CONNECTOR, plastic, 3-station,12−24 AWG 2

10 1615774 — 1615774 — � HEATER cartridge, 0.38 diameter x3.25 long, 240 V, 50 W 2 C

10 — 1615777 — 1615777 � HEATER cartridge, 0.38 diameter x3.25 long, 240 V, 100 W 2 C

11 1614835 1614835 1614835 1614835 � GASKET, check valve, SD3, heated 1

12 −−−−−− −−−−−− −−−−−− −−−−−− � PLATE, cover, check valve,SD3, heated 1

13 −−−−−− −−−−−− −−−−−− −−−−−− � SCREW, button, socket, M5 x 10,zinc, Class 10.9, per ISO 7380 5

14 −−−−−− −−−−−− −−−−−− −−−−−− � SCREW, socket, M12 x 1.75 x 130,zinc, Class 12.9, per ISO 4762 4 D

15 1101360 1101360 1101360 1101360 � PLUG, SAE, 1−5/8−12 straight thread,check valve 1 A

16 987066 987066 987066 987066 � SPRING, compression, 2.000 x 1.225 OD x 0.125 1

17 — — — — � REDUCER, 1 1/16−12 F x 1 ⅝−12 m, steel, Viton 1 E

NOTE A: Apply Mobil SHC 634 before installing.

B: Depressurization modules use 2. Bleed modules use 3. Apply adhesive before installing.

C: Apply heatsink compound before installing.

D: Apply Never Seez before installing.

E: Not used on 55-gallon outlet manifolds.

-

Rhino� SD3/XD3 Hydraulic Section Pump Outlet Manifolds 19

Part 1611641-04� 2020 Nordson Corporation

55-Gallon Stainless Steel Modules

Item Part Part Part Part Description Qty Note

— 1614899 — — —MODULE, check valve, 55-gallon, bleed,stainless steel, 240 V, standard wattage 1

— — 1614900 — —MODULE, check valve, 55-gallon, bleed,stainless steel 240 V, high wattage 1

— — — 1614907 —MODULE, check valve, 55-gallon,stainless steel, depressurization, 240 V,standard wattage

1

— — — — 1614908MODULE, check valve, 5-gallon,stainless steel, depressurization, 240 V,high wattage

1

1 303706 303706 303706 303706 � O-RING, −920, Viton�, 1.475 ID,

0.118 W 2 A

2 1057807 1057807 1057807 1057807 � SEAT, ball, check valve, Rhino SD,stainless steel 1

3 1041272 1041272 1041272 1041272 � O-RING, −131, Viton, 1.674 ID 0.103 W 1 A

4 900006 900006 900006 900006 � BALL, 440 stainless steel, 1.500, 100 1

5 −−−−−− −−−−−− −−−−−− −−−−−− � PLUG, pipe, socket, standard,¼ NPT, stainless steel 2/3 B

6 1615315 1615315 1615315 1615315 � CORDSET, check valve, RhinoSD3, heated 1

7 1605675 1605675 1605675 1605675 � CONNECTOR, strain relief,0.260−0.545, ½ NPT 1

8 −−−−−− −−−−−− −−−−−− −−−−−− � NUT, lock, conduit, steel, 0.5 in. 1

9 1615308 1615308 1615308 1615308 � CONNECTOR, plastic, 3-station,12−24 AWG 2

10 1615774 — 1615774 — � HEATER cartridge, 0.38 diameter x3.25 long, 240 V, 50 W 2 C

10 — 1615777 — 1615777 � HEATER cartridge, 0.38 diameter x3.25 long, 240 V, 100 W 2 C

11 1614835 1614835 1614835 1614835 � GASKET, check valve, SD3, heated 1

12 −−−−−− −−−−−− −−−−−− −−−−−− � PLATE, cover, check valve,SD3, heated 1

13 −−−−−− −−−−−− −−−−−− −−−−−− � SCREW, button, socket, M5 x 10,zinc, Class 10.9, per ISO 7380 5

14 −−−−−− −−−−−− −−−−−− −−−−−− � SCREW, socket, M12 x 1.75 x 130,zinc, Class 12.9, per ISO 4762 4 D

15 1101346 1101346 1101346 1101346 � PLUG, SAE, 1−5/8−12 straight thread,check valve, stainless steel 1 A

16 987066 987066 987066 987066 � SPRING, compression, 2.000 x 1.225 OD x 0.125 1

17 — — — — � REDUCER, 1 1/16−12 F x 1 ⅝−12 m, steel, Viton 1 E

NOTE A: Apply Mobil SHC 634 before installing.

B: Depressurization modules use 2. Bleed modules use 3. Apply adhesive before installing.

C: Apply heatsink compound before installing.

D: Apply Never Seez before installing.

E: Not used on 55-gallon manifolds.

-

Rhino� SD3/XD3 Hydraulic Section Pump Outlet Manifolds20

Part 1611641-04 � 2020 Nordson Corporation

Heated Pump Outlet ManifoldsNOTE: Manifolds for 5-gallon Rhino bulk unloaders begin on page 21.Manifolds for 55-gallon Rhino bulk unloaders begin on page 23.

See Figure 8 and refer to the following parts lists.

1

2

3

5

9

8

10

1112

1

14

13

15

67

4

NOTE: The pump body is onlyshown for reference and is notincluded with the assembly.

Figure 8 Heated Pump Outlet Manifold

-

Rhino� SD3/XD3 Hydraulic Section Pump Outlet Manifolds 21

Part 1611641-04� 2020 Nordson Corporation

5-Gallon Standard Modules

Item Part Part Part Part Description Qty Note

— 1614909 — — —MODULE, pump outlet, 5-gallon, bleed,240 V, standard wattage 1

— — 1614910 — —MODULE, pump outlet, 5-gallon, bleed,240 V, high wattage 1

— — — 1614917 —MODULE, pump outlet, 5-gallon,depressurization, 240 V, standard wattage 1

— — — — 1614918MODULE, pump outlet, 5-gallon,depressurization, 240 V, high wattage 1

1 303706 303706 303706 303706 � O-RING, −920, Viton�, 1.475 ID,

0.118 W 2 A

2 1612115 1612115 1612115 1612115 � ADAPTER, pump outlet 1

3 1041272 1041272 1041272 1041272 � O-RING, −131, Viton, 1.674 ID 0.103 W 1 A

4 −−−−−− −−−−−− −−−−−− −−−−−− � PLUG, pipe, socket, standard,¼ NPT, zinc 2/3 B

5 1615315 1615315 1615315 1615315 � CORDSET, check valve, RhinoSD3, heated 1

6 1605675 1605675 1605675 1605675 � CONNECTOR, strain relief,0.260−0.545, ½ NPT 1

7 −−−−−− −−−−−− −−−−−− −−−−−− � NUT, lock, conduit, steel, 0.5 in. 1

8 1615308 1615308 1615308 1615308 � CONNECTOR, plastic, 3-station,12−24 AWG 2

9 1615774 — 1615774 — � HEATER cartridge, 0.38 diameter x3.25 long, 240 V, 50 W 2 C

9 — 1615777 — 1615777 � HEATER cartridge, 0.38 diameter x3.25 long, 240 V, 100 W 2 C

10 1614835 1614835 1614835 1614835 � GASKET, check valve, SD3, heated 1

11 −−−−−− −−−−−− −−−−−− −−−−−− � PLATE, cover, check valve,SD3, heated 1

12 −−−−−− −−−−−− −−−−−− −−−−−− � SCREW, button, socket, M5 x 10,zinc, Class 10.9, per ISO 7380 5

13 −−−−−− −−−−−− −−−−−− −−−−−− � SCREW, socket, M12 x 1.75 x 130,zinc, Class 12.9, per ISO 4762 4 D

14 973477 973477 973477 973477 � PLUG, O-ring, straight thread,1-1/4 tube 1 A

15 1081041 1081041 1081041 1081041 � REDUCER, 1 1/16−12 F x 1 ⅝−12 m, steel, Viton 1 A

NOTE A: Apply Mobil SHC 634 before installing.

B: Depressurization modules use 2. Bleed modules use 3. Apply adhesive before installing.

C: Apply heatsink compound before installing.

D: Apply Never Seez before installing.

-

Rhino� SD3/XD3 Hydraulic Section Pump Outlet Manifolds22

Part 1611641-04 � 2020 Nordson Corporation

5-Gallon Stainless Steel Modules

Item Part Part Part Part Description Qty Note

— 1614913 — — —MODULE, pump outlet, 5-gallon, bleed,stainless steel, 240 V, standard wattage 1

— — 1614914 — —MODULE, pump outlet, 5-gallon, bleed,stainless steel, 240 V, high wattage 1

— — — 1614921 —MODULE, pump outlet, 5-gallon, stainlesssteel depressurization, 240 V,standard wattage

1

— — — — 1614922MODULE, pump outlet, 5-gallon, stainlesssteel, depressurization, 240 V,high wattage

1

1 303706 303706 303706 303706 � O-RING, −920, Viton�, 1.475 ID,

0.118 W 2 A

2 1612116 1612116 1612116 1612116 � ADAPTER, pump outletstainless steel 1

3 1041272 1041272 1041272 1041272 � O-RING, −131, Viton, 1.674 ID 0.103 W 1 A

4 −−−−−− −−−−−− −−−−−− −−−−−− � PLUG, pipe, socket, standard,¼ NPT stainless steel 2/3 B

5 1615315 1615315 1615315 1615315 � CORDSET, check valve, RhinoSD3, heated 1

6 1605675 1605675 1605675 1605675 � CONNECTOR, strain relief,0.260−0.545, ½ NPT 1

7 −−−−−− −−−−−− −−−−−− −−−−−− � NUT, lock, conduit, steel, 0.5 in. 1

8 1615308 1615308 1615308 1615308 � CONNECTOR, plastic, 3-station,12−24 AWG 2

9 1615774 — 1615774 — � HEATER cartridge, 0.38 diameter x3.25 long, 240 V, 50 W 2 C

9 — 1615777 — 1615777 � HEATER cartridge, 0.38 diameter x3.25 long, 240 V, 100 W 2 C

10 1614835 1614835 1614835 1614835 � GASKET, check valve, SD3, heated 1

11 −−−−−− −−−−−− −−−−−− −−−−−− � PLATE, cover, check valve,SD3, heated 1

12 −−−−−− −−−−−− −−−−−− −−−−−− � SCREW, button, socket, M5 x 10,zinc, Class 10.9, per ISO 7380 5

13 −−−−−− −−−−−− −−−−−− −−−−−− � SCREW, socket, M12 x 1.75 x 130,zinc, Class 12.9, per ISO 4762 4 D

14 1057808 1057808 1057808 1057808 � PLUG, O-ring, 1-1/4 tube, straightthread, stainless steel 1 A

15 1613337 1613337 1613337 1613337 � REDUCER, 1 1/16−12 F x 1 ⅝−12 m, stainless steel, Viton 1 A

NOTE A: Apply Mobil SHC 634 before installing.

B: Depressurization modules use 2. Bleed modules use 3. Apply adhesive before installing.

C: Apply heatsink compound before installing.

D: Apply Never Seez before installing.

-

Rhino� SD3/XD3 Hydraulic Section Pump Outlet Manifolds 23

Part 1611641-04� 2020 Nordson Corporation

55-Gallon Standard Modules

Item Part Part Part Part Description Qty Note

— 1614911 — — —MODULE, pump outlet, 55-gallon, bleed,240 V, standard wattage 1

— — 1614912 — —MODULE, pump outlet, 55-gallon, bleed,240 V, high wattage 1

— — — 1614919 —MODULE, pump outlet, 55-gallon,depressurization, 240 V, standard wattage 1

— — — — 1614920MODULE, pump outlet, 55-gallon,depressurization, 240 V, high wattage 1

1 303706 303706 303706 303706 � O-RING, −920, Viton�, 1.475 ID,

0.118 W 2 A

2 1612115 1612115 1612115 1612115 � ADAPTER, pump outlet 1

3 1041272 1041272 1041272 1041272 � O-RING, −131, Viton, 1.674 ID 0.103 W 1 A

4 −−−−−− −−−−−− −−−−−− −−−−−− � PLUG, pipe, socket, standard,¼ NPT, zinc 2/3 B

5 1615315 1615315 1615315 1615315 � CORDSET, check valve, RhinoSD3, heated 1

6 1605675 1605675 1605675 1605675 � CONNECTOR, strain relief,0.260−0.545, ½ NPT 1

7 −−−−−− −−−−−− −−−−−− −−−−−− � NUT, lock, conduit, steel, 0.5 in. 1

8 1615308 1615308 1615308 1615308 � CONNECTOR, plastic, 3-station,12−24 AWG 2

9 1615774 — 1615774 — � HEATER cartridge, 0.38 diameter x3.25 long, 240 V, 50 W 2 C

9 — 1615777 — 1615777 � HEATER cartridge, 0.38 diameter x3.25 long, 240 V, 100 W 2 C

10 1614835 1614835 1614835 1614835 � GASKET, check valve, SD3, heated 1

11 −−−−−− −−−−−− −−−−−− −−−−−− � PLATE, cover, check valve,SD3, heated 1

12 −−−−−− −−−−−− −−−−−− −−−−−− � SCREW, button, socket, M5 x 10,zinc, Class 10.9, per ISO 7380 5

13 −−−−−− −−−−−− −−−−−− −−−−−− � SCREW, socket, M12 x 1.75 x 130,zinc, Class 12.9, per ISO 4762 4 D

14 973477 973477 973477 973477 � PLUG, O-ring, straight thread,1-1/4 tube 1 A

15 — — — — � REDUCER, 1 1/16−12 F x 1 ⅝−12 m, steel, Viton 1 E

NOTE A: Apply Mobil SHC 634 before installing.

B: Depressurization modules use 2. Bleed modules use 3. Apply adhesive before installing.

C: Apply heatsink compound before installing.

D: Apply Never Seez before installing.

E: Not used on 55-gallon manifolds.

-

Rhino� SD3/XD3 Hydraulic Section Pump Outlet Manifolds24

Part 1611641-04 � 2020 Nordson Corporation

55-Gallon Stainless Steel Modules

Item Part Part Part Part Description Qty Note

— 1614915 — — —MODULE, pump outlet, 55-gallon, bleed,stainless steel, 240 V, standard wattage 1

— — 1614916 — —MODULE, pump outlet, 55-gallon, bleed,stainless steel, 240 V, high wattage 1

— — — 1614923 —MODULE, pump outlet, 55-gallon,stainless steel depressurization, 240 V,standard wattage

1

— — — — 1614924MODULE, pump outlet, 55-gallon,stainless steel, depressurization, 240 V,high wattage

1

1 303706 303706 303706 303706 � O-RING, −920, Viton�, 1.475 ID,

0.118 W 2 A

2 1612116 1612116 1612116 1612116 � ADAPTER, pump outletstainless steel 1

3 1041272 1041272 1041272 1041272 � O-RING, −131, Viton, 1.674 ID 0.103 W 1 A

4 −−−−−− −−−−−− −−−−−− −−−−−− � PLUG, pipe, socket, standard,¼ NPT, stainless steel 2/3 B

5 1615315 1615315 1615315 1615315 � CORDSET, check valve, RhinoSD3, heated 1

6 1605675 1605675 1605675 1605675 � CONNECTOR, strain relief,0.260−0.545, ½ NPT 1

7 −−−−−− −−−−−− −−−−−− −−−−−− � NUT, lock, conduit, steel, 0.5 in. 1

8 1615308 1615308 1615308 1615308 � CONNECTOR, plastic, 3-station,12−24 AWG 2

9 1615774 — 1615774 — � HEATER cartridge, 0.38 diameter x3.25 long, 240 V, 50 W 2 C

9 — 1615777 — 1615777 � HEATER cartridge, 0.38 diameter x3.25 long, 240 V, 100 W 2 C

10 1614835 1614835 1614835 1614835 � GASKET, check valve, SD3, heated 1

11 −−−−−− −−−−−− −−−−−− −−−−−− � PLATE, cover, check valve,SD3, heated 1

12 −−−−−− −−−−−− −−−−−− −−−−−− � SCREW, button, socket, M5 x 10,zinc, Class 10.9, per ISO 7380 5

13 −−−−−− −−−−−− −−−−−− −−−−−− � SCREW, socket, M12 x 1.75 x 130,zinc, Class 12.9, per ISO 4762 4 D

14 1057808 1057808 1057808 1057808 � PLUG, O-ring, 1-1/4 tube, straightthread, stainless steel 1 A

15 — — — — � REDUCER, 1 1/16−12 F x 1 ⅝−12 m, steel, Viton 1 E

NOTE A: Apply Mobil SHC 634 before installing.

B: Depressurization modules use 2. Bleed modules use 3. Apply adhesive before installing.

C: Apply heatsink compound before installing.

D: Apply Never Seez before installing.

E: Not used on 55-gallon manifolds.

-

Rhino� SD3/XD3 Hydraulic Section Pump Outlet Manifolds 25

Part 1611641-04� 2020 Nordson Corporation

Consumables Adhesives and lubricants to use where instructed on the manifolds.

Item Description

156289 LUBRICANT, Mobil SHC� 634

900344 LUBRICANT, Never Seez�, 8 oz

900298 COMPOUND, heatsink, 5 oz, 11281

900481 ADHESIVE, pipe/thread/hydraulic sealant

-

Rhino� SD3/XD3 Hydraulic Section Pump Outlet Manifolds26

Part 1611641-04 � 2020 Nordson Corporation

Your notes

Rhino SD3/XD3 Hydraulic Section Pump Outlet ManifoldsSafetyQualified PersonnelIntended UseRegulations and ApprovalsPersonal SafetyHigh‐Pressure Fluids

Fire SafetyHalogenated Hydrocarbon Solvent Hazards

Action in the Event of a MalfunctionDisposal

Safety LabelsDescriptionSpecifications

TroubleshootingHeater Cartridge

RepairReplace the Heater CartridgeRemove the Heater CartridgeInstall the New Heater Cartridge

PartsUsing the Illustrated Parts ListPump Outlet ManifoldStandard ModulesStainless Steel Modules

Pump Outlet Manifolds with Ball Check ValveStandard ModulesStainless Steel Modules

Heated Pump Outlet Manifolds with Ball Check Valve5‐Gallon Standard Modules5‐Gallon Stainless Steel Modules55‐Gallon Standard Modules55‐Gallon Stainless Steel Modules

Heated Pump Outlet Manifolds5‐Gallon Standard Modules5‐Gallon Stainless Steel Modules55‐Gallon Standard Modules55‐Gallon Stainless Steel Modules

Consumables

WUXI XINJE ELECTRIC CO., ... CPU and expansion devices connection principles, products](https://static.fdocuments.us/doc/165x107/5ab2fcd77f8b9aea528dd685/hardware-xd3xd5xdm-hardware-manualpdfusers-manualhardwarexd3xd5xdm.jpg)