REV DESCRIPTION DATE BY 02 DRAFT, ADDED … · UPDATED TO SHOW DRILL POINT FEATURE ON FLUSH DRILL...

Transcript of REV DESCRIPTION DATE BY 02 DRAFT, ADDED … · UPDATED TO SHOW DRILL POINT FEATURE ON FLUSH DRILL...

DPROPRIETARY STATEMENT: THIS DOCUMENT CONTAINS INFOCHIP SYSTEMS PROPRIETARY INFORMATION AND SHALL NOT BE REPRODUCED OR DISCLOSED TO THIRD PARTIES WITHOUT PRIOR WRITTEN CONSENT OF INFOCHIP SYSTEMS.

A B C D E F G H

8

7

6

5

4

3

2

1

1. ALL DIMENSIONS ARE:UNLESS OTHERWISE SPECIFIED

PR

OJE

CTI

ON

DRAWN

CHECKED

APPROVED

DATE

DATE

DATE SCALE

TITLE

DWG. SIZE COMPONENT PART NUMBER

SHT

REV

MATERIALRoHS

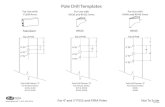

"NEAR FLUSH" INSTALLATION EXAMPLE

EXAMPLE "NEAR-FLUSH" ASSET

DURAPLUG 6

"RECESSED" INSTALLATION EXAMPLE

EXAMPLE "RECESSED" ASSET

DURAPLUG 6

NOTES:

THIS DOCUMENT CONTROLS INSTALLATION OF INFOCHIP DURAPLUG 6 RFID TAG PRODUCTS IN THE FOLLOWING 1.INSTALLATION TYPES: "NEAR-FLUSH" AND "RECESSED".

IT IS THE CUSTOMER RESPONSIBILITY TO ENSURE THAT THE TARGET ASSET MAINTAINS SUFFICIENT STRUCTURAL INTEGRITY 2.AFTER DRILLING AND INSTALLATION OF THE DURAPLUG 6 DEVICE. ASSETS SHOWN IN THIS DRAWING ARE ARBITRARY AND ARE SHOWN FOR EXAMPLE REFERENCE ONLY. FLAT ASSET TOP SURFACES ARE SHOWN FOR SIMPLICITY

IT IS THE CUSTOMER RESPONSIBILITY TO ENSURE THAT THE INSTALLED LOCATION OF THE DURAPLUG DEVICE ON THE ASSET 3.WILL PERMIT THE TAG TO BE SCANNED BY ANY RFID READERS DESIRED FOR USE BY THE CUSTOMER.

INFOCHIP REQUIRES THE USE OF CUSTOM INFOCHIP-SUPPLIED DRILL BITS TO ENSURE THE DRILLED HOLES EXHIBIT THE 4.CRITICAL FEATURES AND ACCURACY NEEDED FOR A RELIABLE PRESS-FITTED INSTALLATION. DRILL BITS FOR DURAPLUG 6 ARE CURRENTLY OFFERED IN 4 VERSIONS BASED ON THE INSTALLATION TYPE. IT IS CRITICAL THAT THE CORRECT VERSION OF BIT IS USED BASED ON THE FINAL INSTALLATION TYPE. DRILL PART NUMBERS ARE CLEARLY MARKED ON EACH DRILL

INFOCHIP REQUIRES THE USE OF A CUSTOM INFOCHIP-SUPPLIED TOOL (HOLETOOL-6) FOR ANY INSTALLATIONS TO BE USED 5.IN SEVERE ENVIRONEMNTS WHICH WILL NEED INCREASED PRESS-FIT RETENTION. THE HOLETOOLE-6 IS A BASIC HAND-OPERATED TOOL USED TO ADD AN UNDERCUT TO THE DRILLED HOLE BEFORE PRESS-FITTING.

INFOCHIP RECOMMENDS THE USE OF MILLING/DRILLING EQUIPMENT WITH A COLLET-TYPE CHUCK TO ENSURE HIGH 6.RIGIDITY OF THE DRILLING SETUP WITH MINIMAL RUNOUT. A "DRILL-CHUCK" SHOULD NOT BE USED. A COLLET CHUCK TO BE USED SHOULD BE VERIFIED BY DIAL INDICATOR WITH A TOTAL INCLUDED RUNOUT OF LESS THAN 0.013MM (0.0005"). HAND DRILLS CANNOT BE USED FOR PRESS-FITTED INSTALLATIONS. UNLESS PRE-AUTHORIZED BY INFOCHIP, ANY DRILLING AND INSTALLATION METHODS OTHER THAN THOSE SPECIFIED ON THIS DRAWING WILL VOID ANY WARRANTIES.

INFOCHIP RECOMMENDS THAT THE DRILLING SHOULD FOLLOW EFFECTIVE MACHINING PRACTICES (SPEEDS/FEEDS, 7.COOLANT) FOR THE SPECIFC ASSET METAL AND HARDNESS TO ENSURE MAXIMUM LIFE OF THE DRILLING TOOLS AND ACCURACY OF THE DRILLED HOLE.

PRESS-FITTING OF THE DURAPLUG 6 SHOULD BE CARRIED OUT AS PER SHEET 5 OF THIS DRAWING TO ENSURE IT IS FULLY 8.INSTALLED AND NOT DAMAGED DURING THE INSERTION.

THIS DRAWING IS TO BE PRINTED IN FULL COLOR AS SOME VIEWS ARE COLORED FOR VISUAL CLARITY. ASSET SURFACES 9.SHOWN IN GREY COLOR ARE FORMED BY THE DRILLING PROCESS.

INSTALLATION PROCEDURE FOR "NEAR-FLUSH" INSTALL IS SHOWN ON SHEET 5. INSTALLATION PROCEDURE FOR "RECESSED" 10.INSTALL IS SIMILAR AND IS NOT SHOWN ON THIS DRAWING.

REVISIONSREV DESCRIPTION DATE BY02 DRAFT, ADDED REFERENCE DIMENSIONS 2015-05-16 KP03 DRAFT, UPDATED FOR DP6 BODY CHANGES. CHANGED HOLE PROFILES AND DRILLS 2014-07-23 KP

05A UPDATED FOR INSTALLATION PROCESS CHANGES. DRAFT FOR INTERNAL REVIEW 2014-08-18 KP06 REMOVED DRAFT STATUS 2014-10-23 KP

06B UPDATED PART NUMBERS AND DESCRIPTIONS FOR DRILL BITS AND SEVERE SERVICE HOLE TREATMENT TOOL. UPDATED TO SHOW DRILL POINT FEATURE ON FLUSH DRILL BITS AT REV 05 2015-06-03 KP

Installation Reference - DuraPlug 6Near-Flush and Recessed

06B mm [INCH]

KP 2015-06-03

NONE 1 of 5

Installation Reference - DP6

SEE ABOVE

DPROPRIETARY STATEMENT: THIS DOCUMENT CONTAINS INFOCHIP SYSTEMS PROPRIETARY INFORMATION AND SHALL NOT BE REPRODUCED OR DISCLOSED TO THIRD PARTIES WITHOUT PRIOR WRITTEN CONSENT OF INFOCHIP SYSTEMS.

A B C D E F G H

8

7

6

5

4

3

2

1

1. ALL DIMENSIONS ARE:UNLESS OTHERWISE SPECIFIED

PR

OJE

CTI

ON

DRAWN

CHECKED

APPROVED

DATE

DATE

DATE SCALE

TITLE

DWG. SIZE COMPONENT PART NUMBER

SHT

REV

MATERIALRoHS

12.00.472

12.00.472

BB

3.75.148

CSECTION B-B SCALE 8 : 1

B PRIMARY BORE

0.05+-0.100.05

.002+-.004.002

SPOT FACE

6.090±0.01.2398±.0004

COUNTERBORE

2.30±0.05.091±.002EFFECTIVE

HOLE DEPTH

8.96.353

SPOT FACE

2.35.093

OVERALL DEPTH

R0.20.008

3.00.118

DRILL POINT

H

DETAIL C SCALE 32 : 1

SPOT FACE

REFERENCE NEAR-FLUSH ASSET76.203.000

OVERALL LENGTH

R0.50.020

9.53.375

118.00°

EXAMPLE OF "BIT-6-F-TOOLREQD" CONFIGURATION

R0.18.007

CRITICAL FEATUREFOR PRESS-FITAND SEALING

R0.30.012

CRITICAL FEATUREFOR PRESS-FIT

0.51.020

30.0°

DETAIL H SCALE 128 : 1

NOTES:

NEAR-FLUSH DRILL BITS FOR DURAPLUG 6 ARE OFFERED IN TWO CONFIGURATIONS:1.BIT-6-F-TOOLREQD THIS BIT MUST ONLY BE USED WITH HOLES WHICH WILL BE TREATED WITH THE 6mm SEVERE SERVICE HOLE TOOL.BIT-6-F-NO-TOOL THIS BIT MUST NOT BE USED WITH HOLES WHICH WILL BE MODIFIED WITH THE 6mm SEVERE SERVICE HOLE TOOL.

A MODEL OF BIT-6-F-TOOLREQD IS SHOWN ON THE LEFT OF THIS PAGE FOR REFERENCE (DRILL FLUTES ARE NOT SHOWN).2.

BITS ARE DESIGNED TO BE USED IN A SINGLE PLUNGE OPERATION.3.

BITS ARE 2-FLUTE HELICAL TYPE, GROUND TO INFOCHIP SPECIFICATION FROM SOLID MICRO-GRAIN CARBIDE. BITS ARE COATED WITH TITANIUM 4.NITRIDE.

BITSS ARE TO HAVE PERMANENT MARKINGS AS SHOWN IN THE TABLE ON THIS SHEET, INCLUDING THE DESIGN REVISION AS SHOWN.5.

BITS ARE TO BE INDIVIDUALLY PACKAGED AND CUTTING END SHOULD BE PROTECTED.6.

INFOCHIP RECOMMENDS TO USE A MINIMAL DEPTH FOR THE "SPOT-FACE" FEATURE TO ENSURE THAT ALL INFOCHIP HIGH-FREQUENCY RFID 7.READERS WILL BE ABLE TO RELIABLY SCAN THE INSTALLED DURAPLUG RFID TAG. IF DRILLING WITHOUT PRODUCING A SPOT FACE FEATURE, ENSURE THAT SUFFICIENT HOLE DEPTH IS ACHIEVED TO ENSURE THE INSTALLED DURAPLUG IS NOT PROTRUDING FROM THE ASSET.

EFFECTIVE HOLE DEPTH TOLERANCE IS ENSURED BY THE USE OF INFOCHIP "NEAR-FLUSH" DRILL PROVIDED THAT THE DRILLING DEPTH IS 8.SUFFICIENT TO PRODUCE THE "SPOT-FACE" FEATURE.

THE "NEAR-FLUSH" BITS ARE TYPICALLY USED FOR INSTALLATION ON FLAT ASSET SURFACES. IT IS ALSO ACCEPTABLE FOR INSTALLATION TO 9.ASSETS WITH CONVEX CURVATURE WHERE THE RADIUS OF CURVATURE IS A MINIMUM OF APPROXIMATELY 0.75 INCHES. AS AN EXAMPLE, THE NEAR-FLUSH DRILL CAN BE USED FOR INSTALLATIONS ON A PIPE MEASURING 2 INCHES IN OUTER DIAMETER.

INFOCHIP RECOMMENDS THAT THE PRIMARY BORE (LOWER) BE MEASURED AFTER DRILLING TO ENSURE A PROPER PRESS-FIT. SUGGESTED 10.MAXIMUM ALLOWABLE MEASURED BORES ARE SHOWN IN THE TABLE ON THIS SHEET. THE LOWER BORE DIAMETER CAN BE MEASURED USING A HALF-BALL TYPE HOLE GAUGE ALONG WITH A MICROMETER.

DETAILING "NEAR-FLUSH" DRILLED ASSETS

NEAR-FLUSH DRILL BIT CONFIGURATION CHART FOR DURAPLUG 6

PART NUMBER LASER MARKINGS BASIC PRIMARY BORE (B) MAXIMUM ALLOWABLE DRILLED PRIMARY BORE

BIT-6-F-TOOLREQD BIT-6-F-TOOLREQD REV04MUST USE WITH IC-HOLETOOL-6 6.000mm 6.020mm

BIT-6-F-NO-TOOL BIT-6-F-NO-TOOL REV 05 DO NOT USE WITH IC-HOLETOOL-6 5.940mm 5.960mm

Installation Reference - DuraPlug 6Near-Flush and Recessed

06B mm [INCH]

KP 2015-06-03

NONE 2 of 5

Installation Reference - DP6

SEE ABOVE

DPROPRIETARY STATEMENT: THIS DOCUMENT CONTAINS INFOCHIP SYSTEMS PROPRIETARY INFORMATION AND SHALL NOT BE REPRODUCED OR DISCLOSED TO THIRD PARTIES WITHOUT PRIOR WRITTEN CONSENT OF INFOCHIP SYSTEMS.

A B C D E F G H

8

7

6

5

4

3

2

1

1. ALL DIMENSIONS ARE:UNLESS OTHERWISE SPECIFIED

PR

OJE

CTI

ON

DRAWN

CHECKED

APPROVED

DATE

DATE

DATE SCALE

TITLE

DWG. SIZE COMPONENT PART NUMBER

SHT

REV

MATERIALRoHS

REFERENCE RECESSED ASSET

CONICAL RECESS

76.203.000

OVERALL LENGTH

R0.50.020

7.88.310

MAXIMUMTHEORETICAL

RECESS 23.0°

15.88.625

EXAMPLE OF "BIT-6-R-TOOLREQD" CONFIGURATION

20.00.787

FF

20.00.787

G

SECTION F-F SCALE 6 : 1

7.50 MAX.295 MAXEXAMPLE

RECESS DEPTH

10.55.415

15.55

.612 EXAMPLE TOP COUNTERSINK

2.30.091

DRILL SHOULDERTO HOLE BOTTOM

6.090±0.010.2398±.0004

COUNTERBORE

B PRIMARY BORE

R0.20.008

9.19.362

VIRTUAL SHARPS

K

DETAIL G SCALE 12 : 1

R0.50.020

R0.18.007

23.0°

R0.30.012

0.51.020

2.30.091

DETAIL K SCALE 48 : 1

DETAILING "RECESSED" DRILLED ASSETS

NOTES:

RECESSED DRILLS BITS FOR DURAPLUG 6 ARE OFFERED IN TWO CONFIGURATIONS:1.BIT-6-R-TOOLREQD THIS BIT MUST ONLY BE USED WITH HOLES WHICH WILL BE TREATED WITH THE 6mm SEVERE SERVICE HOLE TOOL.BIT-6-R-NO-TOOL THIS BIT MUST NOT BE USED WITH HOLES WHICH WILL BE MODIFIED WITH THE 6mm SEVERE SERVICE HOLE TOOL.

A MODEL OF BIT-6-R-TOOLREQD IS SHOWN ON THE LEFT OF THIS PAGE FOR REFERENCE (DRILL FLUTES ARE NOT SHOWN).2.

BITS ARE DESIGNED TO BE USED TO CREATE A VARIABLE-DEPTH COUNTERSUNK RECESS, IN A SINGLE PLUNGE OPERATION3.

BITS ARE 2-FLUTE HELICAL TYPE, GROUND TO INFOCHIP SPECIFICATION FROM SOLID MICRO-GRAIN CARBIDE. BITS ARE COATED 4.WITH TITANIUM NITRIDE.

BITS ARE TO HAVE PERMANENT MARKINGS AS SHOWN IN THE TABLE ON THIS SHEET INCLUDING THE DESIGN REVISION AS SHOWN.5.

BITS ARE TO BE INDIVIDUALLY PACKAGED AND CUTTING END SHOULD BE PROTECTED6.

THIS DRAWING INCLUDES VIEWS OF A REFERENCE ASSET, DRILLED TO AN ARBITRARY RECESS DEPTH SHOWN FOR EXAMPLE. THE BIT 7.SHOULD BE ABLE TO ACCOMMODATE A MAXIMUM RECESS DEPTH AS SHOWN ABOVE (MAXIMUM THEORETICAL RECESS).

ALL FEATURES ON THE CUTTING END OF THE BIT ARE CUTTING FEATURES INCLUDING RADII. THERE ARE NO NON-CUTTING FEATURES.8.

INFOCHIP RECOMMENDS THAT THE PRIMARY BORE (LOWER) BE MEASURED AFTER DRILLING TO ENSURE A PROPER PRESS-FIT. 9.SUGGESTED MAXIMUM ALLOWABLE MEASURED BORES ARE SHOWN IN THE TABLE ON THIS SHEET. THE LOWER BORE DIAMETER CAN BE MEASURED USING A HALF-BALL TYPE HOLE GAUGE ALONG WITH A MICROMETER.

RECESSED DRILL BIT CONFIGURATION CHART FOR DURAPLUG 6

PART NUMBER LASER MARKINGS BASIC PRIMARY BORE (B) MAXIMUM ALLOWABLE DRILLED PRIMARY BORE

BIT-6-R-TOOLREQD BIT-6-R-TOOLREQD REV 04MUST USE WITH IC-HOLETOOL-6 6.000mm 6.020mm

BIT-6-R-NO-TOOL BIT-6-R-NO-TOOL REV 04 DO NOT USE WITH IC-HOLETOOL-6 5.940mm 5.960mm

Installation Reference - DuraPlug 6Near-Flush and Recessed

06B mm [inch]

KP 2015-06-03

NONE 3 of 5

Installation Reference - DP6

SEE ABOVE

DPROPRIETARY STATEMENT: THIS DOCUMENT CONTAINS INFOCHIP SYSTEMS PROPRIETARY INFORMATION AND SHALL NOT BE REPRODUCED OR DISCLOSED TO THIRD PARTIES WITHOUT PRIOR WRITTEN CONSENT OF INFOCHIP SYSTEMS.

A B C D E F G H

8

7

6

5

4

3

2

1

1. ALL DIMENSIONS ARE:UNLESS OTHERWISE SPECIFIED

PR

OJE

CTI

ON

DRAWN

CHECKED

APPROVED

DATE

DATE

DATE SCALE

TITLE

DWG. SIZE COMPONENT PART NUMBER

SHT

REV

MATERIALRoHS

BASE

KNOB

TAP, THREAD-FOMING

SEVERE SERVICE HOLE TREATMENT TOOL FOR DURAPLUG 6(IC-HOLETOOL-6)

DETAILING USE OF HOLETOOL-6

PROCEDURE FOR USING SEVERE SERVICE HOLE TREATMENT TOOL FOR DURAPLUG 6:

CHECK THAT THE LOWER BORE IS WITHIN SPECIFICATION FOR "TOOL REQUIRED" TYPE HOLE BEFORE PROCEEDING.1.

REMOVE ANY DEBRIS FROM THE DRILLED HOLE.2.

LOCATE THE HOLETOOL-6 OVER THE HOLE AND ENSURE THE TIP OF THE TAP IS ENGAGED IN THE HOLE.3.

HOLD THE BASE FIRMLY AGAINST THE ASSET WITH ONE HAND TO PREVENT THE HOLETOOL-6 FROM TILTING OR MOVING DURING USE. 4.GRASP THE FLATS NEAR THE BOTTOM OF THE BASE BETWEEN THUMB AND INDEX FINGER.

APPLY ROUGHLY 3 POUNDS OF DOWNWARD FORCE TO THE KNOB AND TURN THE KNOB CLOCKWISE BY HAND.5.

CONTINUE PRESSING DOWN WHILE TURNING UNTIL THE TAP CONTACTS THE BOTTOM OF THE HOLE. AT THIS POINT, A SHARP RISE IN 6.DRIVING TORQUE WILL BE FELT AND TAPPING SHOULD BE STOPPED AT THIS POINT. (ABOUT 2.5 TURNS).

KEEP HOLDING THE BASE FIRMLY AND ROTATE THE KNOB COUNTERCLOCKWISE TO EXTRACT THE TAP. ONCE THE TAP IS DISENGAGED 7.WITH THE THREADS (ABOUT 2.5 TURNS) THE JIG CAN BE LIFTED AWAY AND HOLE TREATMENT IS COMPLETED.

ADDITIONAL NOTES:

THE HOLETOOL-6 IS USED TO CREATE A CONTROLLED UNDERCUT IN THE LOWER BORE OF DRILLED HOLES FOR DURAPLUG 6. PRESS-•FITTING INTO A TREATED (UNDERCUT) HOLE PERMITS MAXIMUM PRESS-OUT FORCE AND MAXIMUM RETENTION OF THE INSTALLED DURAPLUG.

THE RESULTING CONTROLLED UNDERCUT IS A THREAD-FORM WITH PARTIAL DEPTH AND IT IS VISIBLE TO THE NAKED EYE. AN EXAMPLE •PHOTOGRAPH OF SIDE-BY-SIDE TREATED AND UNTREATED DRILLED HOLES IS SHOWN BELOW.

THE HOLETOOL-6 CAN BE USED TO TREAT BOTH "FLUSH" AND "RECESSED" HOLES.•

THE HOLETOOL-6 IS DESIGNED TO BE USED BY HAND WHERE HOLES ARE DRILLED INTO ASSETS ON FLAT SURFACES. THE TOOL BASE •CAN BE MODIFIED BY MACHINING OR REDESIGN SO THAT IT WILL WORK WITH OTHER ASSET SURFACES (SUCH AS CYLINDRICAL SURFACES).

PHOTOGRAPHIC EXAMPLE OF TREATED AND UNTREATED DRILLED HOLES

Installation Reference - DuraPlug 6Near-Flush and Recessed

06B mm

KP 2015-06-03

NONE 4 of 5

Installation Reference - DP6

SEE ABOVE

2. TOLERANCES ON LINEAR DIMENSIONS ARE 0.10mm UNLESS OTHERWISE SPECIFIED

DPROPRIETARY STATEMENT: THIS DOCUMENT CONTAINS INFOCHIP SYSTEMS PROPRIETARY INFORMATION AND SHALL NOT BE REPRODUCED OR DISCLOSED TO THIRD PARTIES WITHOUT PRIOR WRITTEN CONSENT OF INFOCHIP SYSTEMS.

A B C D E F G H

8

7

6

5

4

3

2

1

1. ALL DIMENSIONS ARE:UNLESS OTHERWISE SPECIFIED

PR

OJE

CTI

ON

DRAWN

CHECKED

APPROVED

DATE

DATE

DATE SCALE

TITLE

DWG. SIZE COMPONENT PART NUMBER

SHT

REV

MATERIALRoHS

STEP 2

STEP 1

DURAPLUG 6LOGO SIDE FACING UP

REFERENCE ASSET(NEAR-FLUSH TYPE)

SEALING LIP

CRUSH RIB - 8 PLACESFOR PERMANENT PRESS-FIT

A

DURAPLUGDRIVER TOOL

STEP 4:DETAIL A

SCALE 8 : 1

STEP 5 - COMPLETED INSTALLATION

9.00.354

114.304.500

12.70.500

EXAMPLE DURAPLUG 6DRIVER TOOL

DRIVER TOOL

DD

INSTALLED

SECTION D-D SCALE 8 : 1

DETAIL INSTALLED SCALE 32 : 1

DURAPLUG SHOULD BE FULLY INSERTED TO BOTTOM OF HOLE

DURAPLUG MAY BE FLUSH TO SLIGHTLY DEPRESSED AFTER INSTALLATION

SEALING LIP ON DURAPLUG PRESS-FITS AND SEALS INTO COUNTERBORE

INSTALLATION STEPS (NEAR-FLUSH TYPE):

STEP 1: ENSURE THAT THE ASSET IS DRILLED AND THAT THE HOLE IS TREATED, AS APPLICABLE, TO SPECIFICATIONS AND THE INSTALL HOLE IS CLEANED OF ANY CUTTINGFLUID OR DEBRIS.

STEP 2: PLACE THE DURAPLUG WITH LOGO SIDE UP ONTO THE ASSET NEAR THE HOLE. USE FINGER ON THE TAG TO SLIDE IT INTO POSITION. WHEN NESTED N POSITION, THE TAG WILL DROP DOWN SLIGHTLY. AT THIS POINT IT IS NESTED, READY TO BE PRESS-FITTED.

STEP 3: USE A PRESS SUCH AS AN ARBOR PRESS OR DRILL-PRESS AND CHUCK THE DRIVER TOOL IN THE PRESS (NOT SHOWN).

STEP 4: VISUALLY ALIGN THE ASSET AND NESTED DURAPLUG WITH THE DRIVER TOOL.

STEP 5: USE THE PRESS TO INSTALL THE DURAPLUG UNTIL IT IS FLUSH WITH THE DRILLED COUNTERBORE. TRY TO USE ONLY ENOUGH FORCE NEEDED TO SEAT THE PLUG FLUSH IWTH THE SPOTFACE SURFACE.

STEP 6: VISUALLY INSPECT THE INSTALLATION FOR FULL INSERTION AND CARRY OUT READING TEST.

ADDITIONAL NOTES:

AN EXAMPLE OF A DRIVER TOOL IS SHOWN WHICH WILL FIT TO A DRILL CHUCK OF A DRILL-PRESS. THE DRIVER TOOL GEOMETRY CAN BE CHANGED AS NEEDED BASED ON THE TYPE OF PRESS THAT WILL BE USED . ENSURE THAT THE DRIVING FACE OF THE •TOOL IS FLAT, SMOOTH AND SQUARE. ACETAL MATERIAL(DELRIN, ACETRON, ETC) IS RECOMMENDED FOR THE MATERIAL.

IF THE INSTALLATION WILL NOT BE USING A TREATED HOLE, AND IF THE USE OF A PRESS IS NOT PRACTICAL, THE DURAPLUG MAY BE INSTALLED MANUALLY. IN THIS CASE, IT IS RECOMMENDED TO USE THE DRIVER TOOL, AND ALIGN IT BY EYE TO THE NESTED •DURAPLUG KEEPING IT PARALLEL TO THE DRILLED HOLE. COMPLETE THE INSTALLATION BY TAPPING THE TOOL WITH A 1 LB TO 1.5 LB DEAD-BLOW HAMMER UNTIL THE DURAPLUG IS FLUSH.

FOR TREATED HOLES, INFOCHIP STRONGLY RECOMMENDS TO USE A PRESS FOR THE INSTALLATION.•

EXTRACTION: AN INSTALLED DURAPLUG 6 CAN BE REMOVED WITHOUT DAMAGING THE INSTALLATION HOLE. THE FOLLOWING PROCEDURE CAN BE USED WITH FLUSH AND RECESSED INSTALLATIONS AND WITH TREATED AND UNTREATED HOLES:•DRILL A 9/64" HOLE THROUGH THE TAG USING A TWIST-DRILL, TRY TO DRILL CLOSE TO CENTER. DRILL TO APPROXIMATELY 2mm DEEP.1.TAP IN A T25 (TORX) SCREWDRIVER UNTIL IT BOTTOMS OUT.2.FOR A TREATED HOLE, SIMPLY TWIST THE SCREWDRIVER COUNTER-CLOCKWISE AND THE PLUG WILL SCREW OUT IN APPROXIMATELY 2.5 TURNS.3.FOR AN UNTREATED HOLE, TWIST AND LIFT/TILT SLIGHTLY AND THE PLUG WILL MOVE OUT OF THE HOLE REMAINING FIXED TO THE SCREWDRIVER TIP.4.

DETAILING "NEAR-FLUSH" INSTALLATION PROCEDURE

Installation Reference - DuraPlug 6Near-Flush and Recessed

06B mm

KP 2015-06-03

NONE 5 of 5

Installation Reference - DP6

SEE ABOVE