Reume format Hardik Rathod

-

Upload

hardik-rathod -

Category

Documents

-

view

248 -

download

6

Transcript of Reume format Hardik Rathod

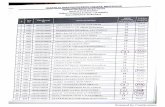

CURRICULUM VITAEHardik Rathod K.62, Ashadeep Nagar Nr. Ekta Apartment, Lal bunglow C.T.M Road Hatkeshwar Ahmedabad-380026.Email id:- [email protected]

VisionAim is to be associated with progressive organization that gives scope to apply my knowledge and skills in the work entrusted to me, and to be part of the team that dynamically works towards the growth of the organization.

Profession Summary Having 1+ Yrs experience in Design and Manufacturing of Plastic components design for Automobile Industry.

Currently associated with SHAILY ENGINEERING PLASTIC LTD as, TOOL ROOM Engineer. Abilities in design of components using tools like Catia V5.Career Profile

Company

Shaily Engineering plastic ltd. Baroda.This company is a supplier for every plastic product. Like LAKEME lipstick box, some interior electrical accessories for L&T. Medical equipments for G.E.ACustomers: FAG, SIEMENS, IKEA, G.E.A, HINDUSTAN UNILEVER LIMITED, ABB, L&T, COPELAND, CALMAR, ROSEMOUNT Etc.Designation

Tool Room EngineerDuration

September 2014 Till Date

Software

Solid works 5Responsibilities

Responsibility to solve any problem in mould during trial or during breakdown. Provide easy solution for manufacturing of any damaged part.

Maintaining ISO documents

Maintenance of Moulds.

Company

Texspin Bearings ltd.Based in Ranpur region 130 kms away from Ahmedabad, Gujarat, India, the company includes Tata Motors, Mahindra & Mahindra, Daimler, Eicher, sml, TAFE and BMW amongst its customers. Manufacturing complex medium size moulds for cages in different bearing. Manufacturing of concentric slave cylinder mould, Manufacturing of hub mould for clutch release bearing Designation

Design & Development EngineerDuration

July 2013- September 2014Software

Pro E- CreoResponsibilities

Verify cage design & made easy tool

Product modification as per tooling requirement.

Concept designing for customers. Designing & Development of Injection Moulds. Prepare and verify Drawings for Manufacturing.

Decide Process Plan for every part under tooling from raw material to finished goods. Solving problem during Manufacturing of parts.Projects Handled Leader for Special Purpose Mould Manufacturing.

Manufacturing for cage for steering bearing.

Manufacturing of one way clutch cage for 2 wheelers.

Manufacturing of child parts of Concentric slave cylinder.

Leader for first trial moulds. (Defining process criteria for particular plastic product.)Educational Qualification SSC completed in 2009 with 77.85 %. Diploma in Tool and Die Making from IGTR Ahmadabad with 74% in 2013. Specialized Course:1. AutoCAD2. Pro E3. Catia4. UniGraphics5. Mater cam. I have completed 1year practical training in production department of IGTR Ahmedabad. Some work of excellence given below :1. Basic knowledge of CNC machining with programming code.2. Knowledge of every measuring instrument used in every tool room based company3. Knowledge of operating of CMM machine.4. Knowledge of operating of Calibration machine.5. Knowledge of profile projector, Tool Makers microscope, Roughness Tester machine.6. Knowledge of working principle of Rapid Prototype. Personal Profile

Name

: Hardik RathodFathers Name

: Kamlesh bhai RathodDate of Birth

: 23/3/1994Sex

: MaleMarital Status

: UnmarriedNationality

: IndianLanguages Known

: English, Hindi & Gujarati.Other activities

: Playing Games, listening of musicEmail ID

: [email protected] No.

: +91-8141065808I here by declare that the above-mentioned information is correct up to my knowledge and I bear the responsibility for the correctness of the above-mentioned particulars.

Place: Ahmedabad. Signature

Date: 26/9/2014

[ ]