Raschig Ring

-

Upload

aissaoui25 -

Category

Documents

-

view

15 -

download

10

description

Transcript of Raschig Ring

-

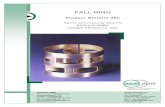

Raschig Ring Tower Packing Product Specification Typical Carbon Raschig Ring Data

Size Nominal OD Bulk Weight Surface Area

Free Space

Wall Thickness

Ash Level No. of Rings

Raschig Rings

(in.) (mm) (lb/ft3) (Kg/m3) (Ft2/Ft3) (m2/m3) ( %) (in.) (mm) (wt.%) pcs/cuft (approximate)

CRR 3/8 X 1/2 1/2 13 30 474 117 384 71 1/16 1.75 10567 CRR 1/2 x 3/4 3/4 19 38 602 67 219 61 5/32 4.24 2100 CRR 3/4 x 1 1 25 35 563 50 163 62 7/32 5.46 900 CRR 1 x 1 1/12 1 1/2 38 35 558 35 114 60 11/32 8.43 325 CRR 1 1/2 x 2 2 51 27 438 29 94 71 9/32 7.14 180 CRR 2 3/8 x 3 3 76 21 333 17 56 78 11/32 8.63

< 0.5%

40

F220-00000-002 Rev. A

Metaullics Systems Co. L.P. Specialty Graphite Plant 2040 Cory Road Sanborn, New York 14132-9388 Telephone 716 731-3221 Facsimile 716 731-4943

The information, recommendations, and opinions set forth herein are offered solely for your consideration, inquiry and verification and are not, in part or total, to be construed as constituting a warranty or representation for which we assume legal responsibility. Nothing contained herein is to be interpreted as authourization to practice a patented invention without a license.

Corrosion resistance, thermal shock resistance, and high temperature stability are benefits derived from the use of Metaullics Systems Co LP.s Carbon Raschig Ring tower packing. Features: 1. Low coefficient of thermal expansion, resists damage caused by severe shocks 2. May be used in most acids, alkalies and solvents. (Not recommended in highly

oxidizing conditions.) 3. Light weight and high mechanical strength with no soluble bond. 4. Long life packing with high temperature operating capabilities. Used in

chlorine-hydrochloric mixtures and phosphoric acid. 5. Fully carbonized to eliminate extractable impurities.

Stocked in six sizes to meet all packed tower requirements.