R2E relocation & shielding activities

description

Transcript of R2E relocation & shielding activities

R2E relocation & shielding activities

Anne Laure Perrot EN/MEF- LE

R2E project meeting, 23rd October 2012

Outline

1. R2E mitigation activities - status

2. R2E LS1 planning

3. Documentation

4. Organisational aspects

R2E project meeting, 23rd October 2012 A. L. Perrot, EN-MEF/LE 2

Areas of the R2E mitigation activitiesMain critical areas today considered

UJ76

UJ14/16RR13/17

UJ56RR53/57

US85

R2E project meeting, 23rd October 2012 A. L. Perrot, EN-MEF/LE 3

Status of the mitigation activitiesActions already performed – shielding (2009-2012)

Point 1: RBs/UJs Points 2 & 8: UJ22/23/88/87 Point 7: UJ76 wall Point 6: ducts between RAs/UAs 63/67

Xmas break 2011

RBs and UJs in LSS1, Xmas break 2011

R2E project meeting, 23rd October 2012 A. L. Perrot, EN-MEF/LE 4

Shielding activities - 2011 Christmas breakPoint 1: RBs/UJs

5

Point 1: RBs/UJs

Shielding activities - 2011 Christmas break

R2E project meeting, 23rd October 2012 A. L. Perrot, EN-MEF/LE 6

2008: UX85 cryogenics cold compressor system, PLCs QURCA & QUICC

2008 - 2009: UPS removed from UJ76

2009: UX85 cryogenics valves positionners (QURCA, QUICC)

2009: US85 fire & ODH detector control racks and associated detectors units

2010 - 2011 Christmas break: UJ56/76 EN/EL RTUs UJ56/76 fire & ODH detection control racks

2011- TS4: UJ14/16 PIC TS5: cryogenics US85 CPU (QURCb)

Actions already performed – relocation (2008-2011)

Status of the mitigation activities

R2E project meeting, 23rd October 2012 A. L. Perrot, EN-MEF/LE 7

Actions already performed – relocation (2011-2012)

2011 Xmas breakPoint 1: Fire detectors (from RR13/17 to US15)Points 4/6: cryogenics CPUs (from UX to UL)Point 5:UPS (from UJ56 to UL557) UL557: Civil engineering activities (ducts, vault along 20 m) Point 8: Ethernet racks (startpoint) (from US85 to UL86) WIC & timing racks (from US85 to UA83) QURCb & rack EYQ (from US85 level 2 to lUS85 level 0)

2012 Technical Stops (TS1-3)Point 1: cable trays, survey references, empty racks installed in ULsPoint 5: cable trays, GGPSO preparatory work for installation, UL557 new lightning, pipes survey of the UL557 by CE Point 7: cables trays, survey references, empty racks moved to nominal location EL preparatory work before wall dismantling Point 8: cable trays

Status of the mitigation activities

R2E project meeting, 23rd October 2012 A. L. Perrot, EN-MEF/LE 8

Actions to be performed during Xmas break 2012

Relocation Point 1: cable trays, if time start cables installation, Point 5: UL557: GGPSO installation, cable trays modification, new lightning

UJ56: survey activity to link UJ56 to LHC tunnel framework Point 7: power sockets replacement Point 8: start installing the UPS cables between US85 and UA83,

Shielding Point 8: CE activities (rail installation) for US85 mobile shielding

Status of the mitigation activities

R2E project meeting, 23rd October 2012 A. L. Perrot, EN-MEF/LE 9

Relocation

Point 8

Point 5

Point 1

Point 7

ShieldingPoints 1, 5, 7 & 8

Integration studies

R2E activities in

Point 8

Point 5

Point 1

Point 7

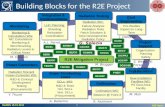

Planning – LS1

Finished and approvedSequences finished

Merged into LHC LS1 planning

Status of the mitigation activities

R2E project meeting, 23rd October 2012 A. L. Perrot, EN-MEF/LE 10

R2E LS1 planning work by M. Barberan

https://espace.cern.ch/MEFactivitiesforR2E/R2E_home/Home.aspx

R2E project meeting, 23rd October 2012 A. L. Perrot, EN-MEF/LE 11

RE

18

RE

22

RE

28

UJ3

2

RE

38

RE

42

RE4

8

RE

52

RE5

8

RE

62

RE

68

RE

72

RE

78

RE

82

RE8

8

RE1

2

Pt 5LSSArc 23 LSS Pt 3 LSS Arc 34 LSS

Pt 1LSS Arc 12 LSS Pt 2 LSS

MAY MAY

Arc 81 LSSR2E R2E R2E

Pt 7LSS Arc 78 LSS Pt 8 LSSArc 56 LSS Pt 6 LSS Arc 67 LSSPt 4 LSS Arc 45 LSS

APR

8 8

1 1

FEB FEB

2013

2013

2 2

3 3

MAR MAR

4 4

5 5

6 6

7 7

12

APR9 9

10 10

11 11

16 16

13 13

14 14

15 15

12

JUNE

17 17

JUNE18 18

19 19

AUG AUG

26 26

27 27

20 20

JULY

21 21

JULY22 22

23 23

28 28

29 29

30 30

24 24

25 25

SEPT SEPT31 31

32 32

33 33

34 34

42 42

OCT OCT35 35

36 36

37 37

38 38

47 47

JAN JAN

48 48

43 43

DEC DEC44 44

45 45

46 46

NOV

39 39

NOV40 40

41 41

2014

2014

49 49

50 50

51 51

52 52

FEB FEB53 53

54 54

55 55

56 56

MAR MAR57 57

58 58

59 59

60 60

APR APR61 61

62 62

63 63

64 64

69 69

JUNE JUNE70 70

71 71

72 72

MAY MAY

65 65

66 66

67 67

68 68

73 73

JULY JULY74 74

75 75

76 76

77 77

AUG

78 78

AUG79 79

80 80

81 81

82 82

SEPT SEPT83 83

84 84

85 85

86 86

OCT OCT

87 87

88 88

NOV NOV92 92

93 93

94 94

89 89

90 90

91 91

DEC

95 95

DEC96 96

97 97

98 98

99 99

Cabl

ing

Cam

paig

n

CRYO

DFBA

CRYO

CRYO

CRYO

EPC 60A

EPC 60A

VSC IV

EPC 60A

EPC 60A

MPE

EE

MPE

EE

MPE EE

DYPBDYPB

DYPB

DYPB

Cool-Down

Cool-Down

Cool-Down

Cool-Down

IC train

ELQA

Powering tests

ELQA

UPS

ELQA

Leak tests

Powering tests

ELQA

WarmUp

IC train

Cool-Down

UPS

Preparation

Flushing

IC train

Powering tests

Powering tests

IC train

IC train

Powering tests

ELQA

Preparation

Flushing

Powering tests

ELQA

Wat

er C

oole

d ca

bles

MKI

gene

rato

rs m

aint

enan

ce

Wat

er C

oole

d ca

bles

WARM UP

ELQA

POWERING TESTS

UPS

POWERING TESTS

ELECTRICAL Maint. (No access)

ELECTRICAL Maint. (No access)

PREPARATION

FLUSHING

COOL DOWN

FLUSHING

PREPARATION

C15R1

A22R1

C30R1

C33R1

C33L2

A29L2

B25R2

A23R2 C

15L3

Q7R3

Q23R3

Q26R3

Q27R3

B32R3

C17R4

B31R4

Colli

mat

or c

ontro

l

Colli

mat

or c

ontro

lM

KI g

ener

ator

s

MKQ

ARF

ACS

Wat

er C

oole

d ca

bles

Colli

mat

or c

ontro

l

Wat

er C

oole

d ca

bles

MKD

mai

nten

ance

& a

dd. t

ank

MKD

mai

nten

ance

& a

dd. t

ank

MKD

& M

KB g

ener

ator

s mai

nten

ance

Colli

mat

or c

ontro

l

Colli

mat

or c

ontro

l

Colli

mat

or c

ontro

l

Wat

er C

oole

d ca

bles

Cabl

ing

Cam

paig

n

CV ac

tiviti

esUP

S re

loca

tion

R2E

cabl

ing

for c

ryo

Shie

ldin

g

C15R

1

Powering tests

ELQA

Warm Up

ELQA

Leak tests

A22R

1

C30R

1

C33R

1

C23L

2

A29L

2

UPS

Preparation

Flushing

Warm Up

ELQA

ELQA

Leak tests

A23R

2B2

5R2

IC train

Warm up

ELQA

CSCM

ELQA

Leak tests

Q7R

3

Q23

R3

Q26

R3

Q27

R3

B32R

3

Preparation

Flushing

Powering tests

ELQA

C17R

4

B31R

4

UPS

UPS

Preparation

Cool-Down

Flushing

Powering tests

ELQA

ELQA

Warm Up

ELQA

Leak tests

Powering tests

ELQA

Warm Up

ELQA

Leak tests

UPS

UPS

ELQA

Powering tests

ELQA

Preparation

ELQA

Leak tests

UPS

Powering tests

ELQA

Powering tests

ELQA

Warm Up

IC train

PreparationFlushing

Flushing

UPS

Cool-Down

Powering tests

Preparation

Flushing

IC train

ELQA

Leak tests

Powering tests

ELQA

Warm Up

Electrical maintenance - No access

Cabl

ing

Cam

paig

n

Cabl

ing

Cam

paig

n

Cabl

ing

Cam

paig

n

Christmas

Com

mis

ioni

ng o

f eq

uipm

ent

Shie

lddi

ng R

R &

U

Jplu

g

Relo c.

shie

ldi

ng

Access

Prep

. w.

Dis

man

tling

Pipi

ng

Cabl

e Cam

paig

nCr

yo.

Pre p.

w.

Dis

man

tling

Pipi

ng

Opt. Fib.

PC

Ethernet

Pipe

s &

UTA

Wat

er C

oole

d ca

bles

Com

mis

ioni

ng o

f eq

uipm

ent

Shie

lddi

ng R

R &

U

Jplu

g

Relo c.

shie

ldi

ng

Access

Cabl

e Cam

paig

nCr

yo.

Opt. Fib.

PC

Ethernet

CV :

UTA

& p

ipes

Cryo

geni

csCa

blin

g Ca

mpa

ign

Dismantling & dicsonnection

Pipi

ng &

Venti

latio

n W

ater

Co

oled

ca

bles

O.F

. (II

& II

I)

PC

Mov

e ra

cks

Acce

ss

Dismantling & dicsonnection

Cabling campaign

Civi

l eng

inee

ring

(incl

. pro

tecti

on)

Dis

man

tl

OF

Cryo

geni

cs

Acce

ss

Alar

ms

Cabl

eTr

ayM

ove

rack

s

UTA

Ethe

rnet

Chic

ane

Vacu

um

Electrical maintenance - No access

CE

Cool-Down

Pipe

s & U

TAW

ater

Coo

led

cabl

es

UPS

UPS

UPS

UPS

UPS

UPS

UPS

UPS

UPS

UPS

UPS

UPS

UPS

UPS

UPS

Q5L

8

C15L

3

B30R

7

B21L

8

Cablin g Sart

Cabling Start

Cabling Sart

Civi

l eng

inee

ring(

incl

. pro

tecti

on) M

ur ty

mpa

nSh

ield

ding

RR

53Sh

ield

ding

RR

57Sa

fe R

oom

(I)

Cabl

eTr

ay

Pipi

ngO

.F. (

I))

Dive

rse

Wor

ks

Ethe

rnet

Mov

e ra

cks

Com

mis

ioni

ng

0 0

DYPB

DYPB

DYPB

DYPB + MPE EPDYPB + MPE EP

VSC IV

VSC IV

VSC IV

EPC 60A

EPC 60A

EPC 60A

EPC 60A

EPC 60A

EPC 60A

EPC 60A

EPC 60A

ELQA

Powering tests

MPE EP

MPE EP

MPE EP

MPE EP

MPE EP

DYPB

DYPB

UTA

Cabl

ing

Cam

paig

n

Cabl

ing

Cam

paig

n

Cabl

ing

Cam

paig

n

Electrical maintenance - No access

Cabl

ing

Cam

paig

n

Cabl

ing

Cam

paig

n

DFBX

Cab

ling

Ca

Cabl

ing

Cam

paig

n

AUG Tests AUG Tests

AUG Tests

AUG Tests

DSO Tests

REPAIR LEAKS IN QRL 4-5

AUG Tests

UPS

UPS

UPS

Electrical maintenance -No access

CRYO

CRYO

CRYO

CRYO

DFBA

DFBA

DFBA

DFBA

DFBA

DFBA

DFBA

DFBA

DFBA

DFBA

DFBA

DFBA

DFBA

DFBA

DFBX

DFBX

DFBX

DFBX

DFBX

DFBX

DFBX

QRL service Modules

QRL service Modules

QRL service Modules

QRL service Modules

QRL service Modules

QRL service Modules

QRL service Modules

QRL service Modules

QRL service Modules

QRL service Modules

QRL service Modules

QRL service Modules

QRL service Modules

QRL service Modules

QRL service Modules

MPEEE

Electrical maintenance - No access

Electrical maintenance - No access

Voies EvacuationVoies Evacuation

Voies EvacuationVoies Evacuation

Voies EvacuationVoies Evacuation

Voies EvacuationVoies Evacuation

Voies Evacuation

SF-

M

SF-

W

UW-M

SF-

M1

SF-W

UW-M

UW-

W

UW-M

UW-

W

UW-

M

SF-

M

SF-

W

UW-

W

SF-M

SF-M

UW

SF-M

UW

SF-

M

UW

SF-M

UW

SF-M

UW-

W

DYPB

DYPB

DYPB

DYPB

DYPB

DFBA

MKI

Beam

Vac

uum

A7L1

A4L1A6L1

A1L1

Beam

Vac

uum

A1R1

A4R1

A6R1

A7R1

Beam

Vac

uum

MKI

TDI

A6L2

A1L2A4L2

B1L2

A7L2

I5L2

A5L2

C4L2

Beam

Vac

uum

A1R2

A4R2

A5R2

A7R2

Beam

Vac

uum

A7L3

B5L3

A5L3

A4L3

IP3

A5R3

B5R3

A7R3

Beam

Vac

uum

A7L4E5L4D5L4B5L4D5R

4

IP4A6R

4

A7R4

Beam

Vac

uum

A7L5

A6L5B4L5

A1L5A5L5A4L2

Beam

Vac

uum

A1RA4RA5R

B4R5

A6RA7R

Beam

Vac

uum

E5L6

A5L6

A4L6

IP6

IP6

A4R6

C5R6

A5R6

Beam

Vac

uum

A7L7

A7R7

A67B57A57IP7A4RA5RB5RA6R

Beam

Vac

uum

A7L8

A6L8A5L8A1L8

A4L8

Beam

Vac

uum

A4RA1RI5RA6R

B4R8

C4R 8

A5R8

MKI

A7R8

Christmas

Cabl

ing

Cam

paig

n

Cabl

ing

Cam

paig

n

Cabl

ing

Cam

paig

n

Cabl

ing

Cam

paig

n

Cabl

ing

Cam

pai

gn

Cabl

ing

Cam

paig

n

Test AUG (R2E)- No access

Safe

Roo

m

(II)

Test Fire Detection (R2E) - No access

Test Fire Detection (R2E) - No access

Start Cabling

Test AUG (R2E) - No accessAUG TestsAUG Tests

Modification ODH (R2E) - No Access

Detection Incendie_ANNUAL

Detection Incendie_ANNUAL

Detection Incendie_ANNUAL

Detection Incendie_ANNUAL

Detection Incendie_ANNUALDetection Incendie_ANNUAL

Detection Incendie_ANNUAL

Detection Incendie_ANNUAL

Detection Incendie_ANNUAL GAZ_ANNUAL

GAZ_ANNUAL

GAZ_ANNUAL

GAZ_ANNUAL

GAZ_ANNUALGAZ_ANNUAL

GAZ_ANNUAL

GAZ_ANNUAL

GAZ_ANNUAL

Detection Incendie/GAZ_QUARTERLY

Detection Incendie/GAZ_QUARTERLY

Detection Incendie/GAZ_QUARTERLYDetection Incendie/GAZ_QUARTERLY

Detection Incendie/GAZ_QUARTERLY

Detection Incendie/GAZ_QUARTERLY

Detection Incendie/GAZ_QUARTERLYDetection Incendie/GAZ_QUARTERLY

Detection Incendie/GAZ_QUARTERLY

Detection Incendie/GAZ_QUARTERLY

Detection Incendie/GAZ_QUARTERLY

Detection Incendie/GAZ_QUARTERLYDetection Incendie/GAZ_QUARTERLY

Detection Incendie/GAZ_QUARTERLY

Detection Incendie/GAZ_QUARTERLY

Detection Incendie/GAZ_QUARTERLYDetection Incendie/GAZ_QUARTERLY

Detection Incendie/GAZ_QUARTERLY

Detection Incendie/GAZ_QUARTERLY

Detection Incendie/GAZ_QUARTERLY

Detection Incendie/GAZ_QUARTERLYDetection Incendie/GAZ_QUARTERLY

Detection Incendie/GAZ_QUARTERLY

Detection Incendie/GAZ_QUARTERLY

Detection Incendie/GAZ_QUARTERLYDetection Incendie/GAZ_QUARTERLY

Detection Incendie/GAZ_QUARTERLY

Detection Incendie_ANNUAL

Detection Incendie_ANNUAL

Detection Incendie_ANNUAL

Detection Incendie_ANNUAL

Detection Incendie_ANNUALDetection Incendie_ANNUAL

Detection Incendie_ANNUAL

Detection Incendie_ANNUAL

Detection Incendie_ANNUAL

ODH_ANNUAL

ODH_ANNUAL

ODH_ANNUAL

ODH_ANNUAL

ODH_ANNUALODH_ANNUAL

ODH_ANNUAL

ODH_ANNUAL

ODH_ANNUAL

AUG Tests

Point 1 - 62 weeksStart = End of April 2013

End = mid July 2014

Point 5 – 68,5 weeksStart = mid April 2013

End = Aug. 2014

Point 7 – 54 weeksStart = May 2013End = June 2014

Point 8 - 31 weeksStart = mid May 2013End = mid Dec. 2014

R2E LS1 planning work by M. Barberan & K. Foraz

R2E project meeting, 23rd October 2012 A. L. Perrot, EN-MEF/LE 12

13

Criticality

Point 1: EL 45 weeks, CV 33 weeks

Point 5: EL 59 weeks (2 shifts), CV 32 weeks (2 teams), CE 9 weeks

No margin!

Anticipationin implementation

(2012 Technical stops)

20 days in total

Profit of each day & each available ressource

Minimise the criticality level

Point 7: EL 58 # weeks, CV 16 weeks, CE 9 weeks

&

Very close supervision of work in-situ

Material procurement Installation procedures

Key points to avoid delays

Storage areas management

R2E LS1 planning

Constraints by LHC activities

Exception: Point 1- preparatory work start during ELQA sectors 12 &81; but equipment unplug only after ELQA

R2E after ELQA tests in adjacent sectors

Constraints on LHC activities Point 1: Cool down starts when R2E commissioning activities are finished

Point 7: Cryo and 3 VAC control racks (insulation vacuum control for QRL and cold magnets) relocated and commisionned before the cool down can start in adjacent sectors .

Point 5: - Cool down depends of the R2E cryo activities - Shielding transport via Pt4/6 and/or via PM54 => co-activities with LHC and/or CMS to be optimisedPt5 planning may

slightly change

R2E LS1 planning

R2E project meeting, 23rd October 2012 A. L. Perrot, EN-MEF/LE 14

Integration studies

Documentation (1/2)

Title= %integration R2E%(exact)

in EDMS: 32 documents

R2E project meeting, 23rd October 2012 A. L. Perrot, EN-MEF/LE 15

- ‘Protection of equipment located in UJ76 ‘ (Phase I, edms: 977085)

- ‘Mobile shielding for RR73/77’ (edms: 985313)

- ‘Protection of equipment located in US85’: Phase I (edms: 1053225) & Phase II (edms 1146827)

- ‘Strategy against SEE for Fire and Oxygen deficiency detection systems’ (edms: 1126688 )

- ‘Protection of equipment located in UJ56’ ( edms: 1215705)

- ‘R2E shielding for LHC Points 1, 5, and 8’ (edms: 1182068)

- ‘Protection of equipment located in UJ14 and UJ16’ (edms: 1218906)

- ‘Protection of equipment located in UJ76 (phase II)’ : under preparation

Documentation (2/2)ECRs

All in EDMS:/projects/LHC machine/LHC R2E Project/related documents/Integration and Installation

R2E project meeting, 23rd October 2012 A. L. Perrot, EN-MEF/LE 16

Organisation towards LS1

- R2E relocation & shielding meetings are now weekly from mid November focus on installation & material issues

- Work-package analysisPoint 1 : 28/09/2012Point 5: 19 & 26/10/2012Point 7: 9 & 16/11/2012Point 8: 10/09/2012

Documents by Maria(soon in edms for approval)

- Installation drawings checksStart in December by EN/MEF-int if drawings available

Drawings provided by EN/EL and EN/CV (firm)

- Installation procedures Request by EN/MEF-OSS at the end of the WPA Follow-up in R2E meetings

(start mid-November)

ICL

LS1 & R2E

meetings

R2E project meeting, 23rd October 2012 A. L. Perrot, EN-MEF/LE 17

Critical points during LS1 implementation

Integration

Material

Intermediate survey scans BE/ABP

Follow-up Eqpt owners & services- procurement

- storage before installation

- Installation non conformities

Cross-checks with models EN/MEF

Delays vs planning

Installation

Follow–up & adaptation EN/MEF

Required action TeamCritical points

Day-to-day in-situ supervision EN/MEF, BE/OP

Management of storage areas EN/MEF

R2E project meeting, 23rd October 2012 A. L. Perrot, EN-MEF/LE 18

19

1. Day-to-day in-situ management & supervision (rapidly react/solve problems of all nature as they occurred, direct contact with the groups supervisors,

cleaning/ waste management)

5. Planning: follow – up and adaptation (detailed installation planning & critical path weekly updated, impact on/of the non R2E works)

3. Material delivery & contracts: weekly follow – up

6. Communicating (periodical reviews of the activities, non conformities & planning)

2. Safety supervision (sites managers to enforce safety and environment protection rules, ‘VIC’, follow the implementation of safety measures/procedures)

4. Integration: non conformities follow-up (weekly reports, intermediate survey scans )

Organisation during the LS1 installation

R2E implementation & worksite organisation

R2E Point coordinator

in charge

R2E point coordinator

involved

Main concerns – Review 2011 Integration

Technical solution proposed by EN DSO and M. Brugger to DGS/SEE: Fire proof racks in TZ76 (see Markus presentation)

- Relocation of EN/EL equipment located in the UJ56 safe room

- TZ76 separating wall dismantling

Worksite supervision – R2E point coordinatorsPoint 1: M. Jeckel Point 5: B. LefortPoint 7: O. AndujarPoint 8: B. Mikulec

Storage requests (surface- tunnel)- Space already reserved in surface for shielding blocks - Material storage under the equipment owners responsibility

(discussed during work-package analysis)

R2E project meeting, 23rd October 2012 A. L. Perrot, EN-MEF/LE 20

Main concerns towards LS1

Integration - Installation drawingsChecks by LHC integration team (ICL) Should start in Dec. 2012 with EN/EL – EN/CV

- Cables trays in USC55 Discussion with CMS and EN/EL

Material procurement

Manpower

Regular follow-up by R2E will start mid November

Equipment owners should finalise their requests

R2E project meeting, 23rd October 2012 A. L. Perrot, EN-MEF/LE 21

Summary

Integration & planning studies = finished R2E activities will start Mid April 2013

ECR documentation almost finished (Pt7 ECR missing)

WPA : in progress

Main concerns raised during R2E 2011 review= solved

Main concerns towards LS1: Installation drawings & procedures, material requirement, storage areas, manpower Follow-up start Mid November in the R2E relocation & shielding meetings

R2E project meeting, 23rd October 2012 A. L. Perrot, EN-MEF/LE 22

Addendum

R2E LS1 planningEvolution Point 5

7/06/2012 54 weeks

12/06/2012 64,5 weeks (10 weeks )CV No work in // with ELCV 2 TeamsEL 2 Shifts

13/07/2012 66,5 weeksNo works during Christmas (2 Weeks)

10/08/2012 67, 5 weeksTransport UTAs (1 Week)

23/10/2012 68,5 WeeksERD & Power Converters Board (1 Week)

LS1 R2E civil engineering activities

Point 5: UL557-UL558: 2 ducts Ø350mm

R2E work package analysis, 10th September 2012 A. L. Perrot, EN-MEF/LE 25

UL557: mini ‘safe room’ implementationUL557-UJ56: 4 ducts 16 m long Ø400mmUJ56 – LHC tunnel: 5 ducts Ø350mm

Point 7 TZ76 wall dismantling

access

EL

UPS: already relocated in TZ76

Point 7 – RelocationEquipment to be relocated outside UJ76- level 0

inside blue thick borders equipment to be relocated .

48 V dc system

CO

AUG

CO

Anti-panic ligthning

R2E work package analysis, 10th September 2012 A. L. Perrot, EN-MEF/LE 26

Point 7 – RelocationTZ76 equipment layout after relocation

Today: extremity of the separating wall

R2E work package analysis, 10th September 2012 A. L. Perrot, EN-MEF/LE 27