QPQ (Salt Bath Ferritic Nitrocarburizing 5898_BNA Melonite Rev 1_0

-

Upload

mark-johnson -

Category

Documents

-

view

115 -

download

3

Transcript of QPQ (Salt Bath Ferritic Nitrocarburizing 5898_BNA Melonite Rev 1_0

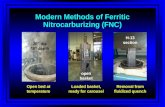

MELONITE / QPQ®

WHAT IS MELONITE®?MELONITE is a surface treatment designed to improve wearresistance and provide corrosion resistance to ferrousmaterials. The process is generically known as salt bath ferr iticnitrocarburizing. During the Melonite process, high concentrationsof nitrogen, carbon and oxygen are diffused into the surface of awork piece. The diffusion of these three elements produce a solid,primarily, single phase epsilion nitride layer commonly referred toas the “compound zone” or “white layer”. Below this layer, nitrogenis at lower concentrations and can be found in solid solution. Thisregion is referred to as the “diffusion zone.” A thin oxide layer isalso formed at the surface of the compound zone which providesimproved c orrosion resistance on iron, plain carbon, and alloysteels. The oxide layer also yields an aesthetically pleasing darkblack surface color.

FEATURES: BENEFITS

Epsilon Nitride Compound Zone High Hardness / Wear ResistanceUniform Depth of LayerAnti seize (Galling Properties)Good Ductility of Compound ZoneCompound layer diffused in surfacewill not spall or flake off parts

Solution Hardened Diffusion Zone Improved Fatigue PropertiesTensile and Yield StrengthIncrease in Modulus of elasticityElongation MaintainedResidual Compressive Stress

Surfaces Finishes Uniform Black FinishPolished Finish (with QPQ)

Dimensional Control Uniform Growth ~30% ofCompound Zone Layer DepthNo Transformation on CoolingLow Temperature ProcessLow DistortionProcessing is often performedon finish machined parts

Versatile Steel, tool steel, cast iron, andstainless steel applicationsRetention of core propertiesCompound layer properties maybe customized for optimalperformance

Low Total Cost Short Treatment TimesHigh Volume ProductionReduced Overall Cost

WHAT IS QPQ®?QPQ (Quench – Polish – Quench) is an optional process that maybe performed after Melonite is complete. The QPQ p rocessconsists of m echanically polishing Melonite processed parts toenhance their surface finish. The polishing is then followed byreheating and requenching the p arts in oxidizing s alts. Thisprocess producess the best corrosion resistance possible alongwith a smo oth s hiny surface fin ish t hat impr oves th e ov erallappearance. An additional benefit is increased lubricity of partsdue to a reduction in the coefficient of friction.

PROPERTIESThe compound z one is c omprised alm ost e ntirely of si nglephase epsilon iron nitride. Compound zone hardness rangesfrom 55 to 65 HRC depending on the alloy composition of thesteel. This high hardness, thin layer produces improved wearresistance and anti-seizing properties. Compound zone depthscan be specified from .0002” up to .0015”. A typical processrange is .0004” to .0010”.

Compound Zone at surface of Melonite processed part

Since Melonite is a diffusion process, the compound zone formsin the su rface of the work pie ce. The result is a high integritymetallurgical bond not subject to flaking or peeling.

The diffusion zone l ies beneath the compound zone andconsists of nitrogen in solid solution. Depth of the diffusion zonecan reach up to .020”. The hardness of the diffusion zone isdependant on the base alloy selected. Alloys with nitride formingelements such as C r, Al , Mo , V, W, and Ti are capable offorming diffusion zones with near surface hardness in excess of50 HRC. Nitrogen in solid solution imparts compressive stressinto the surfac e o f a work pi ece resulting in improv ed fatigueproperties.

For more information contact:Bodycote 16167 W Rogers Drive • New Berlin, WI 53151Phone: (262) 782-5553 • Fax: (262) 782-5660www.bodycote.com

MELONITE / QPQ®

MATERIAL SELECTIONMELONITE can be a pplied to m ost ferro us alloy s includ ingcarbon, alloy, tool, and stainless steels. Many grades of castiron can be successfully processed. In many applications, lowcarbon steel can replace expensive alloy steels as a resultof the improved properties imparted by the Melonite process.

APPLICATIONSMELONITE has be en s uccessfully a pplied to a wide ran ge o fparts from a single plast ic inject ion mo l d ing tool, to dentalprobes, sliding gate valve components, and hand tools, throughhigh-volume automotive engine valves, t ransmission clutchplates, windshield wiper components, ball-valve stems, waterpump shafts, and shock absorber rods.

In ma ny c ases, M ELONITE is selected as a cost-effectiveengineering alternative with superior dimensional control toconventional heat t reat processes that c reate unacce ptabledistortion or growth. While growth and distortion are notentirely eliminated, they are reduced by an order ofmagnitude. Dimensional changes are typically controlled toless than .0005” per surface. In some applications, postgrinding and plating operations have been eliminated.

MELONITE/QPQ has a lso been successfully applied t o p artsthat require corrosion resistance pro perties along with hig hsurface hardness and wear resistance. MELONITE/QPQ hasproven t o be very s uccessful in me eting corrosion r esistancerequirements for parts that require it.

MELONITE/QPQ has also been used as a decorative finishfor some applications where physical and metallurgicalproperties are not even considered.

A few of our MELONITEsuccesses are listed below.

Automotive Engine Valves: Require high surface wearresistance to prevent failure in the engine. These parts are alsosubject t o h igh heat a nd corr osive environments. Meloniteprovides the optimum combination of wear resistance andcorrosion protection for this application.

Plastic Injection Mold / Diecast Tooling: Melonite provideswear properties to dies used in molding and diecasting. Meloniteimproves the life of this tooling that is exposed to highly abrasiveliquid metal and plastics flowing over the tooling under pressure.

Clutch Plates: Melonite provides wear resistance to these partsthat are exposed to friction in service. These thin stampingscould not be carburized without warping the parts beyond use.Melonite yields dimensional stability that allows these distortion-prone parts to be processed and maintain critical dimensionaltolerances.

Automotive engine valves after Melonite processing

For more information contact:Bodycote 16167 W Rogers Drive • New Berlin, WI 53151Phone: (262) 782-5553 • Fax: (262) 782-5660www.bodycote.com