Product Catalog - HydrafluxGodwin’s HL series Dri-Prime pumps offer higher discharge head...

Transcript of Product Catalog - HydrafluxGodwin’s HL series Dri-Prime pumps offer higher discharge head...

Product CatalogOUR GREAT PEOPLE... DESIGN, MANUFACTURE, SPECIFY, SERVICE, SELL AND RENT ...OUR GREAT PUMPS

TABLE OF CONTENTSWith more than 30 years as the industry leader in pump manufacturing, Godwin is an immediately recognizable name in the international portable pump industry by way of its innovative approach to pump manufacturing, rental, sales, and service. Godwin sets the pace for the range and versatility of pumping solutions available worldwide because it designs, manufactures, services, sells and rents products that are economical, reliable and targeted to the specific needs of its clients.

4 ........ Manufacturing

5 ........ Engineering

6 ........ 24/7 Parts & Service

7 ........ Maintenance & Support

8 ........ Godwin Dri-Prime® Pumps - What is Dri-Prime?

9 ........ Environmentally Sensible

10 ...... Godwin Diesel Dri-Prime Pumps – CD Series ............ High Volume, Medium Head, Large Solids-Handling Capabilities

12 ...... Godwin Diesel Dri-Prime Pumps – HL Series ........... High Head and Jetting Pumps with Solids-Handling Capabilities

14 ...... Godwin Diesel Dri-Prime Pumps – NC Series ........... Stringy Material and General Dewatering Applications

15 ...... Godwin Electric Drive Dri-Prime Pumps

16 ...... Godwin Electric Dri-Prime Pumps – CD Series ............ High Volume, Medium Head, Large Solids-Handling Capabilities

18 ...... Godwin Electric Dri-Prime Pumps – HL Series ............ High Head and Jetting Pumps with Solids-Handling Capabilities

20 ...... Godwin Electric Dri-Prime Pumps – NC Series ............ Stringy Material and General Dewatering Applications

21 ...... Dri-Prime Backup System (DBSTM)

22 ...... Godwin Sub-Prime® Electric Submersible Pumps ............ Small Dewatering Pumps

23 ...... Control Panels

24 ...... Godwin Heidra® Pumps - Hydraulic Submersible Pumpend

26 ...... Godwin Wellpoint Pumps

27 ...... Godwin Rotary Lobe Pumps

28 ...... Godwin Wet-Prime Pumps ............ Dewatering, Trash, Pressure and Plastic

30 ...... Accessories

31 ...... Hose

32 ...... Godwin Power Generators

34 ...... Godwin Light Towers

MANUFACTURING

Our engineering teams in the U.S. and U.K. have worked to refine our manufacturing process. While all pumps are designed and manufactured in the U.K., they are assembled for use in the Americas at our headquarters in Bridgeport, New Jersey.

Our pumpends have an interchangeable footprint that allows for a streamlined assembly process. The planned precision of each of our pump components enables us to have the world’s most readily available range of pumps for rental and sale.

ENGINEERINGOur product design engineers utilize the most up-to-date computer- aided drafting (CAD) and computational fluid dynamics (CFD) tools to help design and engineer everything from a new model of pump, to a large-scale or highly-complex pumping system.

Our U.S.-based engineering department employs full-time engineers with varied backgrounds: civil, mechanical, electrical and chemical. Depending on the job, we utilize the most suitable experience to design the best solution for you. Working in cooperation with our UK-based engineering department in our Quenington facility, and the staff of ITT Corporation, you have engineering support with you regardless of your location.

Our Application Engineering team designs pumping systems specific to your applications. You need to be sure that the system will fit the job site before a single pump is shipped. Our product design and application engineers are backed by more than 100 years of experience, with expertise to help you choose the right pump for your application. Whether the job is big or small, our people work hard to provide the extra attention and support needed to make your job run smoothly.

Technical ProposalsOur expert engineers enable us to develop and present tailored system designs and curves to show our customers how and why our solution will be the right fit to their job. Using a combination of the physical environment and conditions of a job, system requirements, and our pump capabilities, our engineers create technical proposals that precisely and effectively illustrate a solution that is tailored to your specific needs.

Contact Godwin’s engineering department to develop a customized technical proposal for your needs.

Godwin Product Catalog • 5

MAINTENANCE & SUPPORT

We stand by our products and pride ourselves on reliability and responsiveness. Our in-house and field technicians service and maintain our extensive fleet of rental equipment. We extend these same services to you.

Godwin is available to serve you around the clock. Our service and sales staff is on call 24/7 to meet your emergency pumping needs whenever and wherever they occur. Our service and support includes:

■ Application specialists—Our Sales Engineers ensure that you rent the right equipment for your job, from routine dewatering to large, complex sewer bypasses, industrial plant water systems and late night emergency rentals.

■ Engineering and design services—Our Product Engineers use application data and field experience to design the very best specialized equipment in the market. In addition, Godwin is supported by a staff of Application Engineers who analyze system requirements and specify efficient and effective solutions.

■ Custom pump fabrication—Our expanded fabrication department has access to state-of-the art lifting and fabrication equipment for fast turnaround of customized equipment that is built to specification.

24/7 PARTS & SERVICE

Emergencies don’t work a 9–5 schedule, and neither do we. Our Great Pumps and Great People are available to you whenever you call. Godwin maintains the industry's largest inventory. This inventory includes spare parts for current and discontinued production models. In addition to servicing our own fleet, our parts inventory supports our fleet of service trucks. Each truck carries an array of parts inventory, so we are able to immediately deploy and service pumps wherever and whenever service is needed.

When you call any one of our branches after business hours, you will get access to one of our field technicians—24 hours a day, 7 days a week.

Field Services

When you need assistance in the field, Godwin has the support you need to keep everything moving.

Godwin field services include:

■ Maintenance and repair

■ HDPE pipe fusion

■ Application setup and tear down

■ Pump watch

We also provide on-site fusion technicians who use our machines to fuse HDPE pipe up to 36" in diameter. And because your local dealer is always ready to help, you’re just a call or click away from assistance with any other issues you may encounter on site.

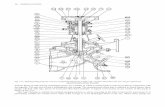

DRI-PRIME® PUMPS

What is Dri-Prime?

How it works...

Compressed air (1) travels through the Godwin venturi (2) creating a vacuum and evacuating air from the pump body and suction hose (3) while the non-return valve ball (4) seals out air from the discharge, allowing product to enter the impeller (5) and begin pumping—automatically!

ENVIRONMENTALLY SENSIBLECritically Silenced

The Critically Silenced enclosure houses the versatile Dri-Prime CD, HL and NC range pumps in a specially designed, acoustically-silenced enclosure. The Critically Silenced unit is intended for use in any application where pumping is required and engine and other noise must be kept to a minimum. Sound levels are approximately 68 dBA at 30'.

The Critically Silenced unit is engineered from start to finish for quiet operation. The enclosure consists of 12 or 14 gauge sheet metal lined with 1" and 2" layers of polydamp acoustical sound deadening material. We’ve designed the engine with a critical grade silenced muffler, silenced the priming exhaust, and isolated engine vibration to further reduce operating noise. Hinged, lockable doors provide convenient access to operating controls and service locations. For added versatility, the entire skid mounted unit can be unbolted and removed from the DOT highway trailer.

2

3

5

41

8 • Godwin Product Catalog

Elevated Head, Solids Handling

CD75MA5 CD80D CD80M CD100M CD103M CD150M CD200M CD225M CD250M DPC300 CD300M CD400M CD500M CD140M CD160M CD180M

Branch Size (in) 2x2/3x3 3x3 3x3 4x4 4x4 6x6 8x8 8x8 10x10 12x12 12x12 18x18 24x18 4x4 6x6 8x6

Flow Range (gpm) 0-300 0-350 0-350 100-750 300-1,000 700-1,700 800-1,900 1,000-3,100 1,500-3,600 2,000-5,000 3,000-6,000 4,000-10,000 8,000-16,500 300-1,000 700-1,700 1,000-3,100

Max Total Dynamic Head (ft) 74 71 93 115 170 167 170 180 183 115 200 147 200 280 255 260

HP@RPM 11.5@2,400 14@2,200 14@2,200 24.6@2,200 41@2,200 68@2,200 68@2,200 99@2,200 147@2,200 151@2,400 228@1,800 275@1,800 600@1,800 100@2,000 97@1,800 142@2,000

Solids Handling (in) 1 5/8 1 5/8 1 5/8 1 3/4 3 3 3 3 1/8 3 1/8 3 1/2 3 3/4 5 4 3 3 3

Impeller Diameter (in) 6 3/4 6 5/8 7 1/2 9 10 11 11 11 7/16 11 7/16 17 14 1/4 19 11/16 21 5/8 13 1/2 14 14

Standard MountSite trolley/GP10 Hwy Trailer

GP30 Hwy Trailer

GP30 Hwy Trailer

GP30 Hwy Trailer

GP60 Hwy Trailer

GP60 Hwy Trailer

GP3052 Hwy Trailer Skid Base Skid Base Skid Base Skid Base Skid Base Skid Base Skid Base Skid Base Skid Base

Height (in)Trolly GDP

40 49

71

71

67

75

75

90

72

72

72

72

72

93

99

99

116

Length (in) 62 80 98 98 98 117 117 150 121 138 145 160 180 204 51 51 51

Width (in) 34 49 54 54 52 66 66 76 53 60 58 71 86 95 75 75 75

Wet Weight (lb) 700/950 1,430 1,620 1,825 2,850 3,250 4,400 Skid – 4,950 Trailer – 5,350 6,313 7,260 11,288 13,575 23,000 4,532 5,340 5,621

Curve Number 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

GODWIN DIESEL DRI-PRIME PUMPS – CD SERIES High Volume, Medium Head, Large Solids-Handling Capabilities

Features

Godwin CD series Dri-Prime pumps will handle raw sewage, sludges and liquids with solids up to 4" in diameter. The pumps offer automatic priming to 28', utilizing the Dri-Prime automatic priming system with no moving parts and simple maintenance. Available with a variety of diesel or gas engines or electric motors, and a cast chromium steel impeller for longer life, CD series Dri-Prime pumps are ideal for construction sites and general dewatering. Possible builds include:

► 316 or CD4MCu stainless steel pumpend construction for high and low pH applications

► Highway trailer or skid mount, both incorporating integral overnight running fuel tanks

► Sound attenuated enclosures for any model

CD SeriesCurve Number

1. CD75MA52. CD80D3. CD80M4. CD100M5. CD103M6. CD150M7. CD200M8. CD225M9. CD250M10. DPC30011. CD300M12. CD400M13. CD500M14. CD140M15. CD160M16. CD180M

0

50

100

150

200

250

300

0 280 1,120 4,480 17,920

Tota

l Dyn

amic

Hea

d (f

t)Flow Rate (GPM)

12

34

5

67

8 910

11

12

13

14

1516

10 • Godwin Product Catalog Godwin Product Catalog • 11

GODWIN DIESEL DRI-PRIME PUMPS – HL SERIES High Head and Jetting Pumps with Solids-Handling Capabilities

Features

Godwin’s HL series Dri-Prime pumps offer higher discharge head capabilities to 600' or 260 psi with a single stage impeller design. The pumps will handle raw sewage, sludges and liquids with solids up to 3" in diameter, and offer automatic priming to 28'. Like the CD series Dri-Prime pumps, HL series pumps are available with:

► A variety of diesel or gas engines or electric motors

► Dry-running oil bath seal arrangements with abrasion resistant silicon carbide interfaces

► Cast chromium steel impeller for longer life

► 316 or CD4Mcu stainless steel pumpend construction for high and low pH applications

► Highway trailer or skid mount, both incorporating integral overnight running fuel tanks

► Sound attenuated enclosures for any model

Extreme High Head

HL80M HL100M HL125M HL150M HL200M HL225M HL250M HL110M HL130M HL160M HL260M

Branch Size (in) 4 x 3 4 x 4 6 x 4 6 x 6 8 x 6 10 x 8 12 x 10 4 x 3 6 x 4 8 x 6 10 x 10

Flow Range (gpm) 0-450 300-800 300-1,000 500-1,450 800-2,300 1,500-3,600 2,500-5,200 200-600 400-1,300 400-2,000 1,500-3,600

Max Total Dynamic Head (ft) 325 455 455 500 320 380 380 600 640 600 500

HP@RPM 71@2,400 102@2,400 151@2,400 220@2,400 214@2,000 300@2,000 440@2,200 147@2,200 300@2,100 440@2,000 600@1,800

Solids Handling (in) 1 1 3/8 1 3/8 1 3/8 1 1/2 3 3 ¾ 1 3/8 1 3/8 2

Impeller Diameter (in) 12 13/16 14 9/16 14 9/16 15 1/8 15 3/4 17 5/16 17 5/16 18 5/16 20 ¼ 20 22

Standard Mount Skid Base Skid Base Skid Base Skid Base Skid Base Skid Base Skid Base Skid Base Skid Base Skid Base Skid Base

Height (in) 75 88 71 71 78 76 98 137 150 162 168

Length (in) 117 149 137 137 137 150 162 53 68 70 79 1/16

Width (in) 66 76 53 53 53 65 70 78 76 98 98

Wet Weight (lb) 3,050 4,800 5,370 7,312 7,512 10,505 14,425 7,712 11,255 14,675 18,800

Curve Number 1 2 3 4 5 6 7 8 9 10 11

HL SeriesCurve Number

1. HL80M2. HL100M3. HL125M4. HL150M5. HL200M6. HL225M7. HL250M8. HL110M9. HL130M10. HL160M11. HL260M

Tota

l Dyn

amic

Hea

d (f

t)

Flow Rate (GPM)

0

100

200

300

400

500

600

700

0 800 3,200 6,000

1 23

45

6

7

8

9 10

11

12 • Godwin Product Catalog Godwin Product Catalog • 13

GODWIN DIESEL DRI-PRIME PUMPS – NC SERIES Stringy Material and General Dewatering Applications

NC80 NC100 NC150

Branch Size (in) 3x3 4x4 6x6

Flow Range (gpm) 0-350 100-750 700-1,700

Max Total Dynamic Head (ft) 115 165 205

HP@RPM 14@2,200 24.6@2,200 68@2,200

Solids Handling (in) 1 1/4 1 1/2 1 5/8

Impeller Diameter (in) 7 3/4 10 11 1/4

Standard Mount GP30 Hwy Trailer GP60 Hwy Trailer GP60 Hwy Trailer

Height (in) 70 73 75

Length (in) 97 114 117

Width (in) 54 66 66

Wet Weight (lb) 1,840 3,100 3,250

Curve Number 1 2 3

GODWIN ELECTRIC DRIVE DRI-PRIME PUMPS

For maximum performance, Godwin automatic self-priming Dri-Prime pump models are available with electric motors. Designed for long lasting durability, the electric drive Dri-Prime pump is ideally suited for both temporary pumping and permanent installations. Perfect for industrial and municipal applications, a permanently installed electric drive Dri-Prime pump will provide reliable, continuous pumping and reduced operating and maintenance costs. Or for temporary jobs where refueling is difficult, an electric Dri-Prime pump is the ideal solution. Plus, electric drive Dri-Prime pumps can be customized using a wide range of speeds and impeller trims in the CD (solids-handling, medium head) or HL (high head) ranges of the Dri-Prime pump series. All horsepowers are available with soft starts and VFDs.

Eight 18” CD400M electric drive pumps are benched four feet down from the originally intended location, and positioned to pull product out of the influent chamber.

Two permanently installed 12” DPC300 electric drive pumps replaced two Archimedes screw pumps moving effluent from a secondary trickling filter to a chlorination chamber and then discharge.

NC SeriesCurve Number

1. NC802. NC1003. NC150

Tota

l Dyn

amic

Hea

d (f

t)

Flow Rate (GPM)

0

20

40

60

80

100

120

140

160

180

200

0 500 1,000 1,500 2,000

1

3

2

Features

Godwin's NC Series Dri-Prime pumps are extremely powerful yet compact pumps designed to handle the toughest stringy material and general dewatering applications. They feature Flygt's unique patented N-technology with an innovative self-cleaning impeller. Godwin NC pumps deliver the highest total system efficiency, lowering your fuel bill and reducing unplanned maintenance costs.

► Fully automatic priming from dry to 28' suction lift

► Extensive application flexibility. It will handle sewage, slurries and liquids with solids up to 1 5/8" in diameter

► Dry-running high pressure oil bath mechanical seal, with high abrasion resistant silicon carbide faces

► A close-coupled centrifugal pump with Godwin Dri-Prime system mounted to a diesel engine or electric drive

► Incorporates high efficiency Flygt N-technology

14 • Godwin Product Catalog

Elevated Head, Solids Handling

CD75MA5 CD80D CD80M CD100M CD103M CD150M CD200M CD225M CD250M DPC300 CD300M CD400M CD500M CD140M CD160M CD180M

Branch Size (in) 2x2/3x3 3x3 3x3 4x4 4x4 6x6 8x8 8x8 10x10 12x12 12x12 18x18 24x18 4x4 6x6 8x6

Flow Range (gpm) 0-300 0-350 0-350 100-750 300-1,000 700-1,700 800-1,900 1,000-3,100 1,500-3,600 2,000-5,000 3,000-6,000 4,000-10,000 13,500 1,122 190 190

Max Total Dynamic Head (ft) 74 71 93 115 170 167 170 180 183 115 200 147 200 280 255 260

HP@RPM 10@1,800 10@1800 10@1800 20@1,800 30@1,800 50@1,800 50@1,800 75@1,800 100@1,800 125@1,200 200@1,800 250@1,200 800@1,200 75@1,800 150@1,800 150@1,800

Voltage/Phase 230/460 230/460 230/460 230/460 230/460 230/460 230/460 230/460 460 460 460 460 4160 230/460 460 460

Amps 26/13 26/13 26/13 50/25 72/36 120/60 120/60 184/92 115 145 232 300 99 184/92 170 170

Solids Handling (in) 1 5/8 1 5/8 1 5/8 1 3/4 3 3 3 3 1/8 3 1/8 3 1/2 3 3/4 5 4 3 3 3

Impeller Diameter (in) 6 3/4 6 5/8 7 1/2 9 10 11 11 11 7/16 11 7/16 17 14 1/4 19 11/16 21 5/8 13 1/2 14 14

Standard Mount Skid Base Skid Base Skid Base Skid Base Skid Base Skid Base Skid Base Skid Base Skid Base Skid Base Skid Base Skid Base Skid Base Skid Base Skid Base Skid Base

Height (in) 42 42 42 43 47 47 51 55 55 56 54 70 66 57 50 72

Length (in) 27 54 54 60 70 68 70 80 84 108 120 140 204 80 92 98

Width (in) 54 27 27 30 32 31 30 46 54 57 63 87 101 42 48 49

Wet Weight (lb) 850 875 1,000 1,250 1,600 2,050 2,040 3,416 4,000 5,400 7,450 10,000 25,880 2,380 5,120 5,120

GODWIN ELECTRIC DRI-PRIME PUMPS – CD SERIES High Volume, Medium Head, Large Solids-Handling Capabilities

Features

Godwin’s CD series Dri-Prime pumps will handle raw sewage, sludges and liquids with solids up to 4" in diameter. The pumps offer automatic priming to 28', utilizing the Dri-Prime automatic priming system with no moving parts and simple maintenance. Available with a variety of diesel or gas engines or electric motors, and a cast chromium steel impeller for longer life, CD series Dri-Prime pumps are ideal for construction sites and general dewatering. Possible builds include:

► 316 or CD4MCu stainless steel pumpend construction for high and low pH applications

► Highway trailer or skid mount, both incorporating integral overnight running fuel tanks

► Sound attenuated enclosures for any model

CD SeriesCurve Number

1. CD75MA52. CD80D3. CD80M4. CD100M5. CD103M6. CD150M7. CD200M8. CD225M9. CD250M10. DPC30011. CD300M12. CD400M13. CD500M14. CD140M15. CD160M16. CD180M

0

50

100

150

200

250

300

0 280 1,120 4,480 17,920

Tota

l Dyn

amic

Hea

d (f

t)

Flow Rate (GPM)

12

34

5

67

8 910

11

12

13

14

1516

16 • Godwin Product Catalog Godwin Product Catalog • 17

GODWIN ELECTRIC DRI-PRIME PUMPS – HL SERIES High Head and Jetting Pumps with Solids-Handling Capabilities

Features

Godwin’s HL series Dri-Prime pumps offer higher discharge head capabilities, to 600' or 260 psi with single stage impeller design. The pumps will handle raw sewage, sludges and liquids with solids up to 3" in diameter, and offer automatic priming to 28'. Like CD series Dri-Prime pumps, HL series pumps are available with:

► A variety of diesel or gas engines or electric motors

► Dry-running oil bath seal arrangements with abrasion resistant silicon carbide interfaces

► Cast chromium steel impeller for longer life

► 316 or CD4Mcu stainless steel pumpend construction for high and low pH applications

► Highway trailer or skid mount, both incorporating integral overnight running fuel tanks

► Sound attenuated enclosures for any model

Extreme High Head

HL80M HL100M HL125M HL150M HL200M HL225M HL250M HL110M HL130M HL160M HL260M

Branch Size (in) 4 x 3 4 x 4 6 x 4 6 x 6 8 x 6 10 x 8 12 x 10 4 x 3 6 x 4 8 x 6 10 x 10

Flow Range (gpm) 0-450 300-800 300-1,000 500-1,450 800-2,300 1,500-3,600 2,500-5,200 200-600 400-1,300 400-2,000 4,760

Max Total Dynamic Head (ft) 325 455 455 500 320 380 380 600 640 600 500

HP@RPM 50@1,800 75@1,800 75@1,800 125@1,800 150@1,800 300@1,800 400@1,800 200@1,800 300@1,800 400@1,800 600@1,800

Voltage/Phase 230/460 230/460 230/460 460 460 460 460 460 460 460 460/4160

Amps 120/60 184/92 184/92 145 170 360 445 232 360 445 720/75

Solids Handling (in) 1 1 3/8 1 3/8 1 3/8 1 1/2 3 3 ¾ 1 3/8 1 3/8 2

Impeller Diameter (in) 12 13/16 14 9/16 14 9/16 15 1/8 15 3/4 17 5/16 17 5/16 18 5/16 20 1/4 20 22

Standard Mount Skid Base Skid Base Skid Base Skid Base Skid Base Skid Base Skid Base Skid Base Skid Base Skid Base Skid Base

Height (in) 47 58 64 61 50 65 63 50 54 63 73

Length (in) 68 80 78 84 100 114 144 86 114 126 156

Width (in) 40 40 41 47 53 62 72 49 61 66 71

Wet Weight (lb) 2,050 3,000 3,100 4,056 5,375 9,272 10,190 6,083 7,450 10,150 14,591

Curve Number 1 2 3 4 5 6 7 8 9 10 11

HL SeriesCurve Number

1. HL80M2. HL100M3. HL125M4. HL150M5. HL200M6. HL225M7. HL250M8. HL110M9. HL130M10. HL160M11. HL260M

Tota

l Dyn

amic

Hea

d (f

t)

Flow Rate (GPM)

0

100

200

300

400

500

600

700

0 800 3,200 6,000

1 23

45

6

7

8

9 10

11

18 • Godwin Product Catalog Godwin Product Catalog • 19

NC80 NC100 NC150

Branch Size (in) 3x3 4x4 6x6

Flow Range (gpm) 0-350 100-750 700-1,700

Max Total Dynamic Head (ft) 115 165 205

HP@RPM 10@1,800 20@1,800 50@1,800

Voltage/Phase 230/460 230/460 230/460

Amps 26/13 50/25 120/60

Solids Handling (in) 1 1/4 1 1/2 1 5/8

Impeller Diameter (in) 7 3/4 10 11 1/4

Standard Mount Skid Base Skid Base Skid Base

Height (in) 43 45 47

Length (in) 54 68 68

Width (in) 24 31 31

Wet Weight (lb) 1,000 1,600 2,050

Curve Number 1 2 3 DRI-PRIME BACKUP SYSTEMEngineers are now using Godwin Critically Silenced Dri-Prime pumps in what is being called the next generation of pump station design. The Godwin DBSTM concept you to replace your traditional pump station emergency backup system—a generator and permanently installed electric sewage pumps—with a Critically Silenced diesel Dri-Prime pump and automatic control panel. This alternative solution avoids common pump station problems including primary power, switch gear and sewage pump failures. In addition, the Dri-Prime Backup System can act as a primary system during routine maintenance and emergency repairs. Thus, the Godwin solution ensures that pumping continues.

■ Sound levels as low as 68 dBA at 30'.

■ Hinged, lockable doors provide access to operating controls and service locations.

■ Pumping can continue despite power, switch gear or sewage pump failures.

■ Dri-Prime backup acts as the primary pumping system during routine maintenance and emergency repairs.

■ Available in sizes 3" through 18" with flows to 13,500 gpm, heads to 600' and solids handling to 5".

The Godwin Dri-Prime Backup System offers the peace-of-mind you can only find when you have a reliable contingency plan for your lift station. The Godwin DBS provides independently-powered pumping in one dependable package for a variety of emergency situations. Because it is rated to meet the power and pumping demands of your system, the Godwin Dri-Prime Backup System is ready, willing and waiting to meet your needs—whenever you need it.

When maintaining system integrity is important, there’s no better choice than the Godwin Dri-Prime Backup System.

GODWIN ELECTRIC DRI-PRIME PUMPS – NC SERIES

NC SeriesCurve Number

1. NC802. NC1003. NC150

Tota

l Dyn

amic

Hea

d (f

t)

Flow Rate (GPM)

0

20

40

60

80

100

120

140

160

180

200

0 500 1,000 1,500 2,000

1

3

2

Features

Godwin's NC Series Dri-Prime pumps are extremely powerful yet compact pumps designed to handle the toughest stringy material and general dewatering applications. They feature Flygt's unique patented N-technology with an innovative self-cleaning impeller. Godwin NC pumps deliver the highest total system efficiency, lowering your fuel bill and reducing unplanned maintenance costs.

► Fully automatic priming from dry to 28' suction lift

► Extensive application flexibility. It will handle sewage, slurries and liquids with solids up to 1 5/8" in diameter

► Dry-running high pressure oil bath mechanical seal, with high abrasion resistant silicon carbide faces

► A close-coupled centrifugal pump with Godwin Dri-Prime system mounted to a diesel engine or electric drive

► Incorporates high efficiency Flygt N-technology

20 • Godwin Product Catalog

GODWIN ELECTRIC SUBMERSIBLE PUMPS Small Dewatering Pumps

Features

► Compact, slim-line, top discharge design to fit into confined spaces

► Durable silicon carbide upper and lower mechanical seals and external lip seal—protects against leaks and runs dry without damage

► Reliable high-torque, capacitor-start motor with thermal overload protection

► Non-wicking power cable

► Standard length and maximum submergence: GSP05 – 30', GSP10 – 50'

Rated HP

Speed RPM

Operating Voltage

Rated Current Amps

Discharge Connection (in)

Weight (lbs)

Maxiumum Height (in)

Maximum Width (in)

Maximum Solids (in)

GSP Small Dewatering Pumps - Single Phase

GSP05 0.5 3,600 115/230 5.8/3.2 2 20 12 4/5 7 1/5 1/3

GSP10 1.0 3,600 115/230 10.3/5.11 2 29 14 1/10 7 1/5 1/3

GSP20 2.0 3,600 115/230 25.9/13.0 3 61 24 1/2 9 1/4 1/3

GSP Small Trash Pumps - Single Phase

GST05 0.5 3,600 115/230 5.8/2.9 2 22 14 7/10 9 9/10 1

GST10 1.0 HP 3,600 115/230 10.3/5.1 2 29 16 2/5 9 9/10 1

Automated Controls

Godwin is at the forefront of pump control and monitoring in response to factors such as emissions and noise regulations, pump efficiency and longevity, and power/fuel efficiency.

PrimeGuardTM Controller

The Godwin PrimeGuard Controller is a fully programmable microprocessor engine control system allowing for inputs from level, flow, pressure transducers or standard floats. Using any of these systems, a Godwin Dri-Prime pump can start and stop automatically with no operator intervention required.

Electric Pump Controls

Manual Control Panel

► The manual control panel is the most basic way to manually control an electric pump with no remote capability, allowing it to be available at a much lower cost than other starters.

Automatic Control Panel

► The automatic control panel can be automatically controlled by any pair of normally open contacts (floats, relays, pressure switch and remote switch).

Soft Start Controller

► The Soft Start Controller has all of the features of the automatic control panel, and can allow an electric pump to be slowly brought up to speed, reducing inrush amps and mechanical stresses.

VFD

► The variable frequency drive (VFD) is the ultimate electric pump controller. It has all of the features of the other controllers while also allowing the speed of the pump to vary to achieve a specific duty point.

CONTROL PANELS

Manual CP Auto CP Soft Start VFD

Contact Circuit breaker only

Circuit breaker and contactor

Circuit breaker, contactor and soft starter

Circuit breaker and VFD

Remote Capability NO YES YES YES

Recommended HP Range

up to 60HP up to 200HP up to 400HP 20-400

Enclosure NEMA 3R NEMA 3R NEMA 3R NEMA 3R

Motor Speed 60hz 60hz 60hz 0hz to 60hz to 120hz

Rate and Type of Speed

Instant, Fixed

Instant, Fixed

Ramped, Fixed Ramped, Variable

Auto Speed Adjustment

NO NO NO YES

80

70

60

50

40

30

20

10

00 10 20 30 40 50 60 70 80 90 100 110 120

Tota

l Dyn

amic

Hea

d (f

t)

Flow Rate (GPM)

GSP DewateringCurve Number

1. GSP052. GSP103. GSP20

13

2

22 • Godwin Product Catalog Godwin Product Catalog • 23

High Head

Heidra 80 Heidra 100TD

Heidra 100SG Heidra 103 Heidra

150MRHeidra 150V

Heidra 150SG

Heidra 150VSG Heidra 200 Heidra

200SG Heidra 250 Heidra 300 Heidra 80HH

Heidra 110HH

Heidra 150HH

Image Not Available

Branch Size (in) 3" FNPT 4" FNPT 4" ASA 150 4" FNPT 6" FNPT 6" FNPT 6" ASA 150 6" ASA 150 8" ASA 150 8" ASA 150 10" ASA 150 12" ASA 150 3" ASA 150 3" ASA 300 6" ASA 150

Flow Range (gpm) 0-350 100-750 100-750 300-1,000 700-1,900 700-1,900 700-1,900 700-1,900 1,000-3,100 1,000-3,100 1,500-3,600 3,000-6,000 0-450 200-600 500-1,450

Max Total Dynamic Head (ft) 85 115 115 170 170 75 170 75 180 180 185 205 325 600 500

Solids Handling (in) 1 9/16 2 2 3 3 5 3 3 3.25 3 3 1/4 3 3/4 1 3/4 1 3/8

Impeller Diameter (in) 7 1/2 9 1/8 9 1/8 10 11 11 11 11 11 7/16 11 7/16 11 7/16 14 1/4 12 13/16 18 5/16 15 1/8

Pumpend Hydraulic Motor Gear type Gear type Gear type Gear type Gear type Gear type Gear type Gear type Piston type Piston type Piston type Piston type Gear type Piston type Piston type

Drive Pressures (psi) 2,800 3,500 3,500 2,500 3,500 3,500 3,500 3,500 4,000 4,000 4,000 5,000 3,500 4,000 4,000

Height (in) 20 23 33 25 27 32 34 37 49 51 49 72 20 50 50

Length (in) 14 19 29 20 20 20 19 17 23 28 28 55 20 26 26

Width (in) 14 19 17 20 23 23 32 32 23 40 28 41 18 24 24

Weight (lbs) 100 141 255 325 355 403 370 429 777 931 800 2080 374 800 800

Power Pack GHPU10 (Heidra 80) GHPU10 GHPU10SG GHPU30

(Heidra 103) GHPU30 GHPU30 GHPU30SG GHPU30SG GHPU50 GHPU50SG GHPU50 GHPU90 GHPU30 GHPU90 GHPU50/GHPU90

GODWIN HEIDRA® PUMPS Hydraulic Submersible Pumpend

POWER PACKS GHPU10 (Heidra 80) GHPU10 GHPU10SG GHPU30

(Heidra 103) GHPU30 GHPU30SG GHPU50/GHPU50SG GHPU90

HP@RPM 18@2,600 34@2,600 34@2,600 41@2,200 71@2,400 71@2,400 147@2,200 225@2,100

Hydraulic Reservoir Capacity (gal) 10 10 10 40 40 40 75 75

Hydraulic Oil Flow Rate (gpm) 4-9 4-9 4-9 17-35 17-35 18-36 30-55 50-90

Powerpack Hydraulic Pump Gear type Gear type Gear type Gear type Gear type Piston type Piston type Piston type

Drive Pressures (psi) 2,500 3,500 3,500 2,500 3,500 3,500 4,000 4,000

Standard Mount GP30 Trailer GP30 Trailer GP30 Trailer GP60 Trailer GP60

TrailerGP100MV Trailer SKID SKID

Height (in) 71 71 73 73 78 133 72 72

Length (in) 96 96 109 109 119 70 138 135

Width (in) 55 40 65 65 66 72.5 53 53

Weight (lbs) 1,230 1,450 2,400 2,400 2,996 3,000 6,500 8,900

Features

Godwin’s Heidra line features hydraulic-drive pumpends, which include rugged cast chromium steel impellers for general pumping of slurries and sludges. Features include:

► Available semi-recessed impeller for sewage and solids handling up to 5"

► Pump bearings independent of hydraulic motor, which means that loads will not affect motor reliability

► Double mechanical seal design, which incorporates carbon upper surfaces and silicon carbide lower surfaces

24 • Godwin Product Catalog Godwin Product Catalog • 25

CD100MV CD150MV CD225MV

Branch Size (in) 4x4 6x6 8x8

Flow Range (gpm) 100-750 700-1,700 1,000-3,100

Max Total Dynamic Head (ft) 77 110 220

HP@RPM 17@1,800 60@1,800 75@1,800

Voltage/Phase 230/460 230/460 230/460

Amps 50/25 120/60 184/92

Solids Handling (in) 1 3/4 3 3 1/8

Impeller Diameter (in) 9 11 11 7/16

Standard Mount GP60 Trailer GP100MV Trailer Skid Base

Height (in) 43 73 78

Length (in) 60 129 120

Width (in) 30 70 53

Wet Weight (lb) 1,250 4,500 6,000

Curve Number 1 2 3

GODWIN WELLPOINT PUMPS Dewatering Systems

GODWIN ROTARY LOBE PUMPS

Features

Godwin Rotary Lobe pumps service a range of on-site dewatering applications, including wellpointing and sock operations. The positive displacement-style rotary lobe pumps are available in an 8" GRL200 model and a 12" GRL300 model. Both pumps offer the best longevity and performance in less abrasive pumping environments.

► Capable of achieving higher flow rates using less horsepower, thereby reducing fuel and overall operational costs

► Removable front cover for inline maintenance access without disturbing piping connections

► Reduced vibration from rotational speed, increasing operating speed capabilities and decreasing vibrational wear on downstream equipment

► Formed steel pump casing for extended wear

► Available in diesel or electric

GRL200 GRL300

Pipe Connections 8x8 12x12

Max Capacity (gpm) 1,560 3,175

Displacement/Revolution (gal) 2.6 2.6

Max Working Pressure 30 psi 30 psi

Max Normal Op. Speed - Pump (rpm) 500 500

Max Normal Op. Speed - Engine (rpm) 2,000 1,500

Suction Lift (ft) 29 29

Max Air Handling (cfm) 208 425

Height (in) 71 1/2 71 1/2

Length (in) 120 138

Width (in) 55 55

Wet Weight (lb) 5,000 7,000

Curve Number 1 2

* Curves reflect pump speed. GRL200 engine speed is 3.75x pump speed. GRL300 engine speed is 3.66x pump speed.

200 250 300 350 400 450 500 550 600 650

GEAR REDUCTION RATIO 3.66:1

GEAR REDUCTION RATIO 3.75:1

3,000

3,400

2,600

2,200

1,800

1,400

1,000

600

200

Rotery LobesCurve Number

1. GRL200*2. GRL300*

Flow

Rat

e (G

PM)

Pump Speed (RPM)

1

2

Flow Rate (GPM)

WellpointCurve Number

1. CD100MV2. CD150MV3. CD225MV

Tota

l Dyn

amic

Hea

d (f

t)

0

20

40

60

80

100

120

140

0 500 1,000 1,500 2,000 2,500 3,000 3,500

1

32

Features

Godwin Wellpoint pumps are a complete line of wellpoint pumps available for rental or sale. Godwin Wellpoint pumps are capable of maximum flow rates from 750 to 3,100 gpm, total heads from 115' to 180', solids handling up to 3 1/8" in diameter and air handling capabilities to 200 cfm. Each pumpset includes a centrifugal, single stage end suction pump and single stage end suction pump with high volume, belt driven vacuum pump and single action float air/water separation tank. Additional features include hardened wearparts and a dry-running oil bath mechanical seal.

Self-jetting Godwin wellpoints and header pipe complete a system that is easy to transport and construct. With up to 20° deflection at header coupling joints, the pipes adapt easily to site and ground conditions without loss of suction and pressure integrity.

26 • Godwin Product Catalog Godwin Product Catalog • 27

Trash

The right pump for construction and industrial, trash-laden water, stream/pond dewatering, septic tanks and manholes, pumping water with light abrasives and solids.

Pressure

The right pump for marine construction, remote firefighting, landscaping, irrigation, tank cleaning and jetting.

Plastic

The right pump for agricultural chemicals, general dewatering, landscaping, irrigation, saltwater dewatering, and swimming pools.

GODWIN WET-PRIME PUMPS

Dewatering

The right pump for pumping water with light abrasives and small solids, semi-trash construction and industrial dewatering, landscaping and irrigation, utilities, manholes & vault draining.

Dewatering Trash Pressure Plastic

GWP-25HX GWP-50HX GWP-80HX GWP-100HX GTP-50HX GTP-100HX GPP-50HX GPL-50HX

Suct./Disch. Dia. (in) 1 2 3 4 2 4 2 2

Solids Handling Dia. (in) 1/5 3/4 3/4 3/4 1 2 1/8 1/8

Max Total Dynamic Head (ft) 106 95 85 92 98 82 187 85

Flow (gpm) 30 158 238 383 185 425 116 148

Power (HP) 1.1 4.0 5.5 8.0 5.5 11.0 5.5 4.0

Fuel Tank Cap. (gal) 0.15 0.66 0.95 1.58 0.95 1.72 0.95 0.45

Dimensions (in) 9x14x13 18x14x15 20x15x17 26x20x26 24x18x19 30x28x28 20x15x17 20x15x16

Weight (lbs) 12.1 51 64 123 104 172 71 46

28 • Godwin Product Catalog Godwin Product Catalog • 29

Temporary Road RampsFor use with 4", 6", 8", 12", 18" and 24" pipelines, Godwin road ramps provide a temporary crossing for low-traffic industrial, mining, commercial and residential areas where vehicular access over a pipeline is required.

High Density Polyethylene Pipe (HDPE) – 4"-36"Thousands of feet available for immediate rental or sale. Fittings and adapters available for complete system installation.

Fusion MachinesSelf-contained for on-site polyethylene pipe fusion and installation. Capable of fusing in sizes to 36".

ACCESSORIES

Bauer PipeGodwin carries the unique Bauer pipe and adapter quick disconnect (QD) coupling system on discharge hose and pipe. Strong and durable yet lightweight, Godwin Bauer pipe is produced from high tensile strength abrasion-resistant steel that is hot-dipped galvanized, offers deflection at each joint up to 30°, and is available in 3', 6', 10' and 20' lengths.

Lansas Pipe and Sewer PlugsTough inflatable plugs for total stoppage in sewer bypass applications in sizes from 5"-60".

Rugged, multi-purpose rubber pipeline plugs with metal end caps available in sizes from 4"-30" with no-flow and flow-thru designs.

Fill kits available for all sizes. Tough rubber plugs resistant to tears and punctures, yet easy to install and inflate.

Sediment Filter BagsGodwin is pleased to offer sediment filter bags. Ideal for dewatering conditions involving sand, silt and fines, Godwin’s sediment filter bags are equipped with heavy-duty ties that can be attached to the pump discharge.

Suction Hose – 1"-12", Black Rubber. For Water, Oil and Chemical Applications Godwin features heavy duty suction hoses, fully vacuum rated 1"–12" diameters. Available with easy-to-use Bauer connectors, Camlock fittings or flanges.

GODWIN HOSE A Complete Range to Fit Any Application

Discharge Hose – 2"-12" Godwin Orange Hose Available In Collapsible Layflat or Flanged High Pressure High pressure layflat discharge hose is rugged, oil resistant hose built for the rental industry. Available with Godwin Quick Disconnect or Camlock fittings, with double bolt clamps for open discharge and medium pressure applications.

Composite OS&D Hose When high pressure and flexible are a prerequisite, 150 lb flanged high pressure hose is the hose of choice. Capable of full vacuum rating and pressure to 200 psi, for use in water and petroleum applications.

PVC Layflat Hose Heavy-duty discharge hose available in 2"-8" diameters and 50' lengths with premium quality PVC tube and cover suitable for agriculture, quarry, irrigation, mining, construction and industrial applications.

Bull Air Hose (with high pressure ground joint fittings) Heavy-duty, steel wire air hose 2"-4" in diameter, 50' lengths with SBR cover for use in mines, quarries, construction and industrial.

Cargo OS&D Hose Rugged, high pressure psi rated hose with 150 lb or 300 lb flanges is used for water, oil, petroleum, sewage and sludge applications.

Cross Link Chemical SLD Hose Cross Link Polyethylene hose with stainless steel Camlock fittings is suitable for chemical applications in low or high pH conditions.

Kanaline SR Hose Extremely lightweight and rated for full vacuum as well as pressure. Available with Godwin Quick Disconnect or Camlock fittings. Perfect for applications where flexibility and light weight are required.

Stainless Steel Braided Hose High temperature, high pressure stainless steel braided hose available in 2"-6" diameters provides flexibility and durability fit for most metal hose applications.

Air Hose 200 psi-rated synthetic rubber air hose with spiraled reinforced cord for a wide range of industrial and construction applications.

Standard hose lengths are 10' and 20'. Custom lengths are available on request.

30 • Godwin Product Catalog Godwin Product Catalog • 31

GODWIN POWER GENERATORSGODWIN POWER GENERATORS

G20kW-S GHP26kW-R GHP35kW-R GHP45kW-R GHP60kW-R GHP65kW-R GHP80kW-R GHP100kW-R GHP115kW-R GHP140kW-R GHP150kW-R GHP185kW-R GHP250kW-R GHP255kW-R GHP325kW-R

POWER OUTPUT

Three Phase - Prime (kW) 18 27 34 46 59 67 80 97 119 144 152 190 233 256 327

Amps 480V Prime Rating 28 41 52 69 89 101 120 146 179 217 229 285 350 385 492

Amps 480V Standby Rating 30 45 57 77 99 112 132 161 197 238 251 315 386 425 539

Single Phase - Prime kW 15 26 33 45 56 62 72 95 117 142 150 - - - -

Amps 240V 63 108 138 188 233 258 300 396 488 592 625 - - - -

AC DISTRIBUTION

Main Breaker Amps 90 125 200 225 300 300 400 450 600 700 700 800 1,200 1,200 1,600

Voltage Selection3 Position Padlockable Switch

3 Position Padlockable Switch

3 Position Padlockable Switch

3 Position Padlockable Switch

3 Position Padlockable Switch

3 Position Padlockable Switch

3 Position Padlockable Switch

3 Position Padlockable Switch

3 Position Padlockable Switch

3 Position Padlockable Switch

3 Position Padlockable Switch

Link / Reconnect Board

Link / Reconnect Board

Link / Reconnect Board

Link / Reconnect Board

ENGINE

HP @ Prime @1800 (rpm) 31.5 43 53 72 91 102 122 150 180 216 228 286 353 422 489

Fuel Tank Volume gal 56 66 106 113 147 147 147 342 342 342 342 360 480 480 616

Fuel Consumed Prime (gal/hr) 1.8 2.6 3.0 4.0 5.6 5.6 6.2 7.7 9.8 10.9 11.0 15.2 16.9 17.9 21.1

Approximate Run Time hrs @ Prime 31.00 25.00 32.00 25.00 24.00 24.00 22.00 40.00 32.00 29.00 28.00 21.00 26.00 24.00 27.00

SIZE & WEIGHT

Skid Mounted L x W x H (in) N/A 83X35X52 95X35X56 95x35x56 96x38x62 96x38x62 96x38x62 132x50x73 132x50x77 132x50x77 132x50x77 132x50x77 156x60x90 156x60x90 175x60x96

Dry Weight (lbs) N/A 2,074 2,537 2,415 3,438 3,563 3,549 6,206 6,409 6,765 6,765 7,330 8,860 8,860 1,275

OPTIONAL TRAILER

Trailer Mounted L x W x H (in) 105x68x56 150x57x67 143x57x72 143x57x72 158x60x84 158x60x84 158x60x84 210x86x90 210x86x93 210x86x93 210x86x93 210x86x93 231x102x110 231x102x126 250x102x116

Dry Weight (lbs) 1,640 2,594 3,057 2,930 4,173 4,298 4,248 7,602 7,805 8,705 8,705 9,270 10,860 11,763 16,000

32 • Godwin Product Catalog Godwin Product Catalog • 33

LIGHT TOWERS NOTES

Features

Godwin light towers are easy to use and engineered for one person set-up and breakdown.

► Full tubular steel frame

► 30' tall all steel mast

► 1000 W metal halide lights

► Four point outrigger stance withstands 65+ MPH winds

► Low oil/high temperature automatic shutdowns

Model GLT416

Generator 4-pole, brushless, self-regulated 6,000 W

Fuel Tank 30 gal

Mast & Card 30' maximum extension, coiled

Lights Four 1000 W metal halide

Ballast Type Coil and core

Lumens 440,000

Coverage 5-7 acres

34 • Godwin Product Catalog Godwin Product Catalog • 35

Xylem1. The tissue in plants that brings water upward from the roots2. A leading global water technology company We’re 12,000 people unified in a common purpose: creating innovative solutions to meet our world’s water needs. Developing new technologies that will improve the way water is used, conserved, and re-used in the future is central to our work. We move, treat, analyze, and return water to the environment, and we help people use water efficiently, in their homes, buildings, factories and farms. In more than 150 countries, we have strong, long-standing relationships with customers who know us for our powerful combination of leading product brands and applications expertise, backed by a legacy of innovation.

For more information on how Xylem can help you, go to xyleminc.com

|’zīl m| e

Dewatering Solutions Bridgeport, NJ • Telephone +1 (856) 467-3636

Godwin is a brand of Xylem. For the latest version of this document, more information about Godwin products and the nearest office location or distributor near you visit www.godwinpumps.com

Godwin Product Catalog. Master 11.2011